Casting device for cylinder sleeve formation

A cylinder liner and rotary cylinder technology, applied in the field of cylinder liner molding equipment, can solve the problems of poor molding quality, achieve the effect of improving molding quality, improving efficiency, and realizing automatic work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

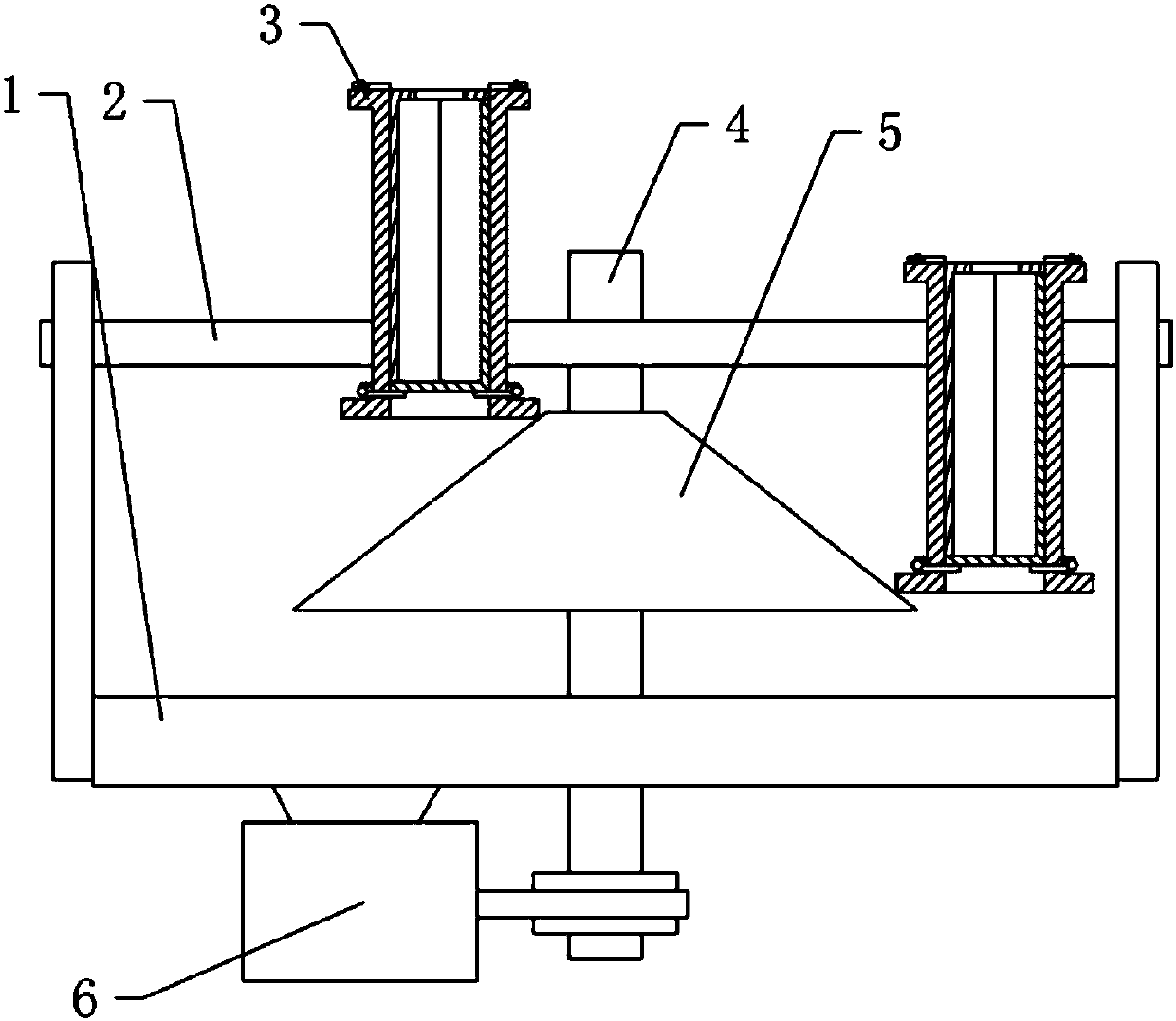

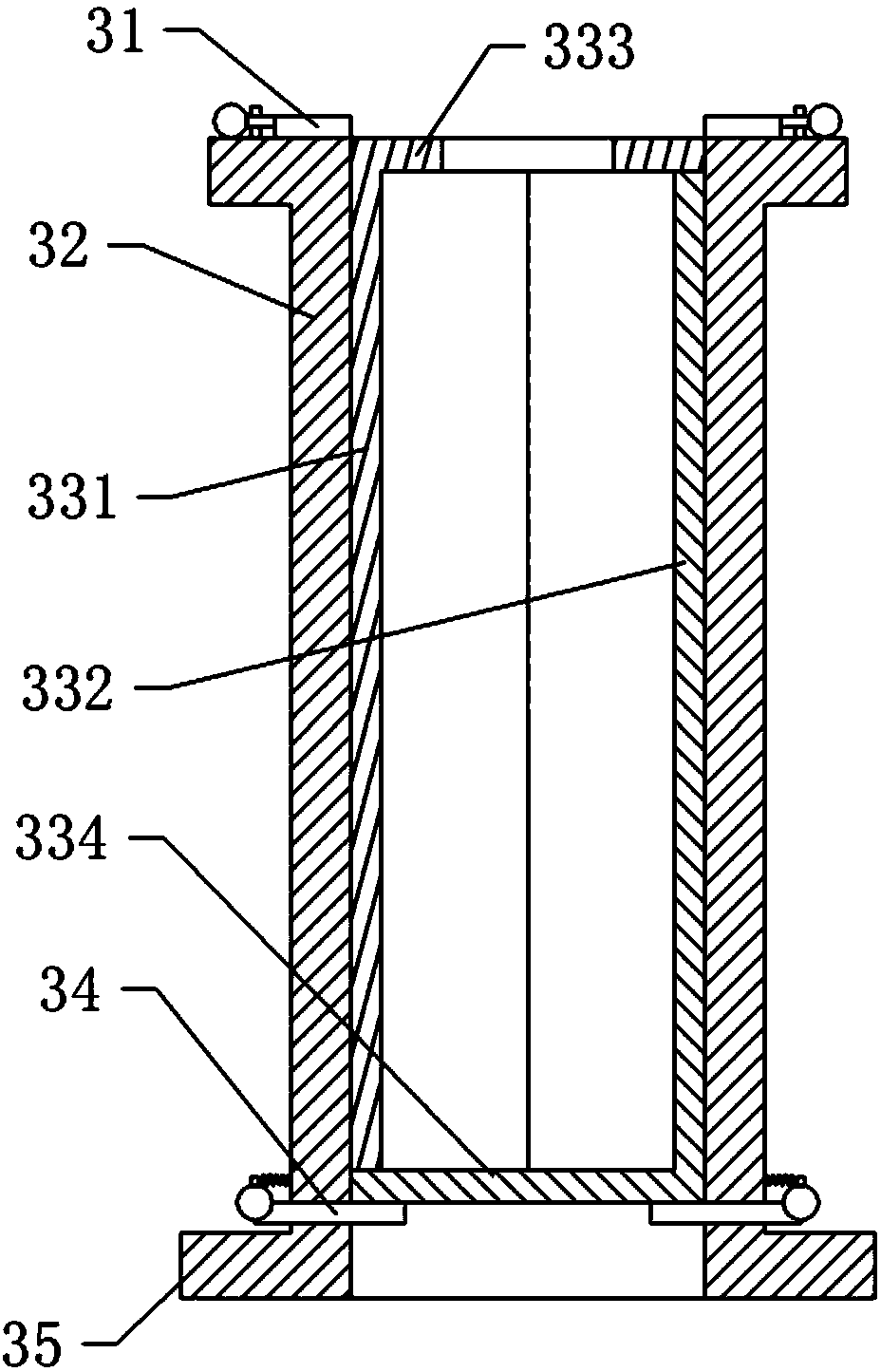

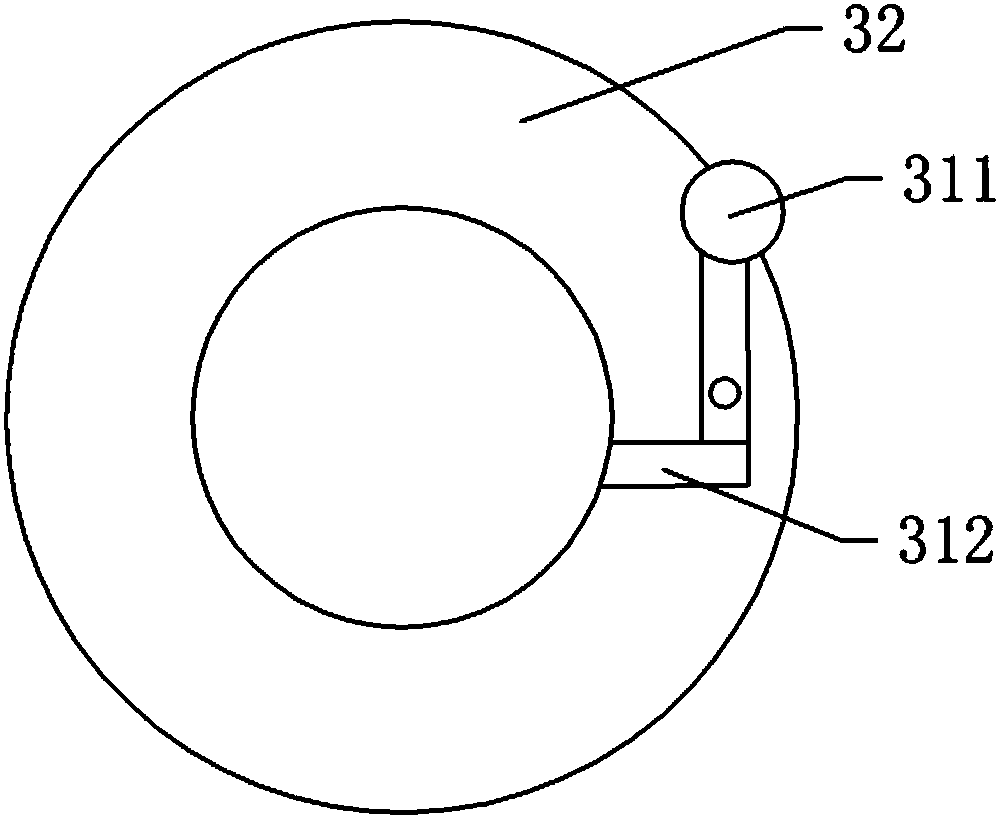

[0017] Example: such as figure 1 , figure 2 and image 3 Shown: a casting device for cylinder liner molding, including a frame 1, a vertical shaft 4 is rotatably connected to the frame 1, a motor 6 is fixedly installed on the frame 1, and the output shaft of the motor 6 is connected to the shaft 4 A worm gear mechanism is provided, the worm gear flat key is connected on the rotating shaft 4, and the output shaft of the worm gear and the motor 6 is welded coaxially. The rotating shaft 4 is coaxially fixedly connected with a frustum-shaped driving wheel 5, and the small-diameter end of the driving wheel 5 faces upwards; the frame 1 is horizontally slidably connected with a support frame 2, and the support frame 2 is provided with two pouring units 3, two Each pouring unit 3 is relatively arranged on the left and right sides of the rotating shaft 4 . The pouring unit 3 includes a drum 32, a forming mold, an upper limit mechanism 31 and a lower limit mechanism 34. The drum 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com