Self-cooling system of air compressor rotor borne by air foil bearing

A technology of foil bearings and air compressors, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low cooling efficiency, uneven cooling and heat dissipation of air compressor rotors, and lack of intelligence, etc., to achieve extended Effective life, avoiding uneven cooling and heat dissipation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

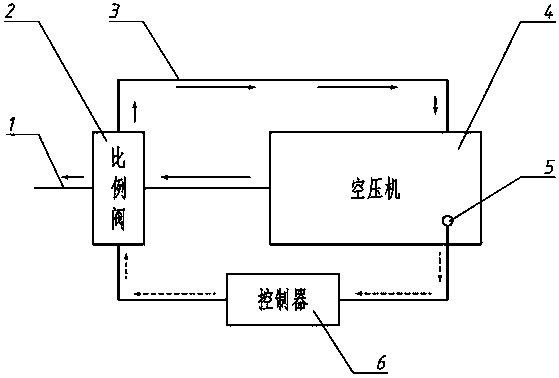

[0032] like figure 1 As shown, a self-cooling cooling system for an air compressor supported by an air foil bearing specifically includes a high-pressure gas delivery pipeline 1, a reinjection gas flow control valve 2, a high-pressure gas reinjection pipeline 3, an air compressor 4, Temperature sensor 5, PID controller 6. The reinjection gas flow control valve 2 is connected to the high pressure gas reinjection pipeline 3 in the high pressure gas delivery pipeline 1, and the other end of the high pressure gas reinjection pipeline 3 is connected to the air compressor 4; the temperature sensor 5 is set The surface temperature parameters of the rotor system of the air compressor are measured in the body of the air compressor 1; the PID controller 6 is connected to the temperature sensor 5 and the reinjection gas flow control valve 2 respectively.

[0033] The high-pressure gas generated by the operation of the air compressor 4 is delivered to the gas-consuming equipment by the h...

Embodiment 2

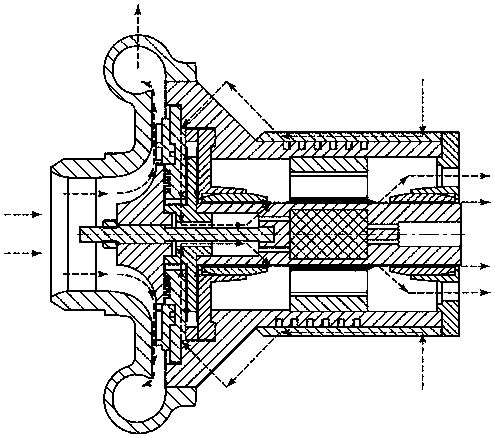

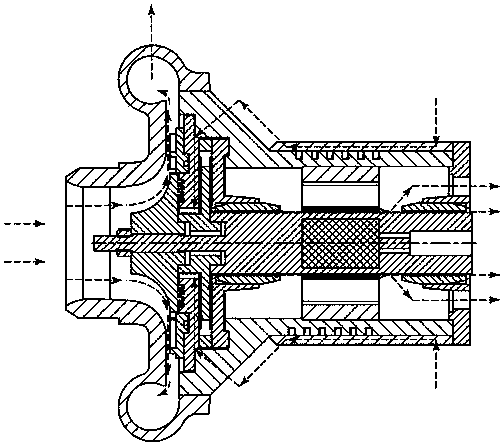

[0039] like Figure 4 , Figure 5 As shown, the execution scheme in this embodiment is generally the same as that in Embodiment 1, and the external cooling channels and control schemes are the same, but the difference lies in the composition of the internal cooling channels. In this embodiment, the air compressor 4 adopts the solid rotor 271 of the air compressor, so that the internal cooling channel is slightly changed. The high-pressure cooling gas no longer flows through the middle part of the thrust disc 25, but flows through the inside of the air compressor rotor, and only flows along the outer surface of the thrust disc 25 and the air compressor training rotor 271. Above, only this change is made to the internal cooling channel, and the rest of the channels are consistent with the first embodiment.

Embodiment 3

[0041] like Figure 6 , Figure 7 As shown, the execution scheme in this embodiment is generally the same as that in Embodiment 1, and the external cooling channels and control schemes are the same, but the difference lies in the composition of the internal cooling channels. In this embodiment, the air compressor 4 adopts the arrangement scheme of placing the thrust plate 252 behind, so that the internal cooling flow channel is changed. The high-pressure cooling gas passes through the uniformly distributed holes in the radial direction of the front end cover 22 and then reaches the outer circumferential surface of the front section of the compressor rotor 272, where the high-pressure cooling gas is divided into two parts. A part flows along the outer surface of the air compressor rotor 272 and passes through the radial air foil bearing 26 at the front end; a part enters the hollow part of the air compressor rotor 272 from the uniformly distributed radial channels at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com