Vacuum melting and rapid hardening equipment with collecting tank and manufacturing methods of permanent magnetic alloy and permanent magnet

A technology of vacuum smelting and manufacturing method, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems such as the inability to refine grains, and the inability to reduce the amount of heavy rare earths, and achieves low product cost. Save heavy rare earth resources, good grain consistency

Active Publication Date: 2014-12-24

沈阳中北真空技术有限公司

View PDF17 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Chinese patent CN97,217,372.2 discloses a double-roll cooling vacuum quick-setting equipment, as shown in Figure 2, the alloy liquid of the equipment is cast into the gap between the cooling roll 7 and the cooling roll 8 through the funnel 6 to form an alloy sheet 9; this technology belongs to Due to the short contact time between the alloy liquid and the cooling roll, the temperature of the alloy sheet after twin-roll rolling is higher than 800°C. Although twin-roll rolling solves the problem of double-sided cooling, it cannot reach Refine the grains, improve the consistency of the grains, and thus increase the coercive force requirements; in order to improve the shortcomings of the aforementioned patents, Chinese patent CN01,241,237.6 discloses that on the basis of double-rolled rolling, an additional The cooling roll technology, although the invention improves the performance of the aforementioned patents and increases the thickness of the produced alloy sheet, it is still twin-roll rolling, which cannot solve the problem that the temperature of the alloy sheet leaving the cooling roll is lower than 700°C, and cannot achieve the reduction of heavy rare earths. purpose of dosage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

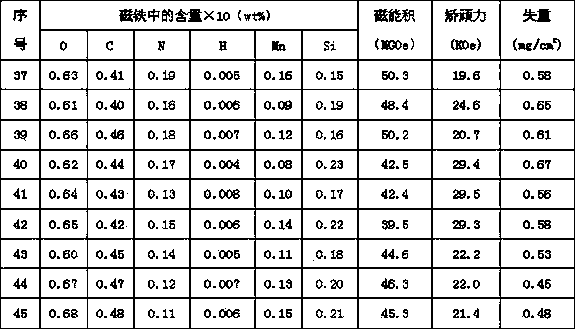

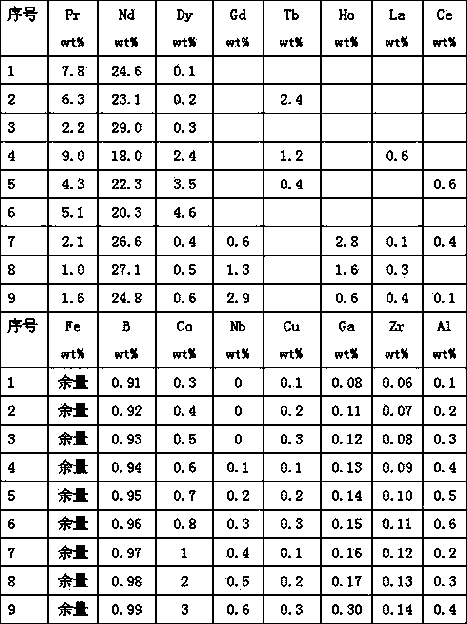

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses vacuum melting and rapid hardening equipment with a collecting tank. The vacuum melting and rapid hardening equipment comprises a melting crucible, a tundish, a first rotary roller, a crushing device and the collecting tank, wherein the melting crucible, the tundish and the first rotary roller are arranged in a vacuum shell; a rotary mechanical crushing device is arranged below the first rotary roller; a valve is arranged below the mechanical crushing device; one end of the valve is connected with the vacuum shell, and the other end of the valve is connected with the collecting tank; the collecting tank is provided with a cooling device; one of water, a cold medium, argon gas and nitrogen gas is taken as a cooling medium. The invention further discloses methods for producing a neodymium-iron-boron rare-earth permanent magnetic alloy and a rare-earth permanent magnet by adopting the equipment.

Description

technical field The invention belongs to the field of rare earth permanent magnets, and in particular relates to a vacuum smelting quick-setting equipment with a material tank, a method for manufacturing rare earth permanent magnet quick-setting alloys, and a method for manufacturing rare earth permanent magnets; the equipment of the invention can also be used for rare earth storage Production of hydrogen alloys and vacuum quick-setting alloys. Background technique NdFeB rare earth permanent magnet materials, with their excellent magnetic properties, have been used more and more, and are widely used in medical nuclear magnetic resonance imaging, computer hard drives, audio, mobile phones, etc.; with the requirements of energy saving and low-carbon economy , NdFeB rare earth permanent magnet materials have begun to be used in auto parts, household appliances, energy saving and control motors, hybrid vehicles, wind power generation and other fields. In 1983, Japanese patents...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D11/06H01F41/02

Inventor 孙宝玉陈晓东

Owner 沈阳中北真空技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com