Gear reversing locking device of automobile transmission

A technology for locking devices and transmissions, which is applied in transmission control, components with teeth, belts/chains/gears, etc., and can solve problems that affect the life of parts that affect shifting force, inconsistent selection force, large selection force, etc. , to achieve the requirements of lower manufacturing and assembly precision, the same reciprocating gear selection force, and the effect of improving shift quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

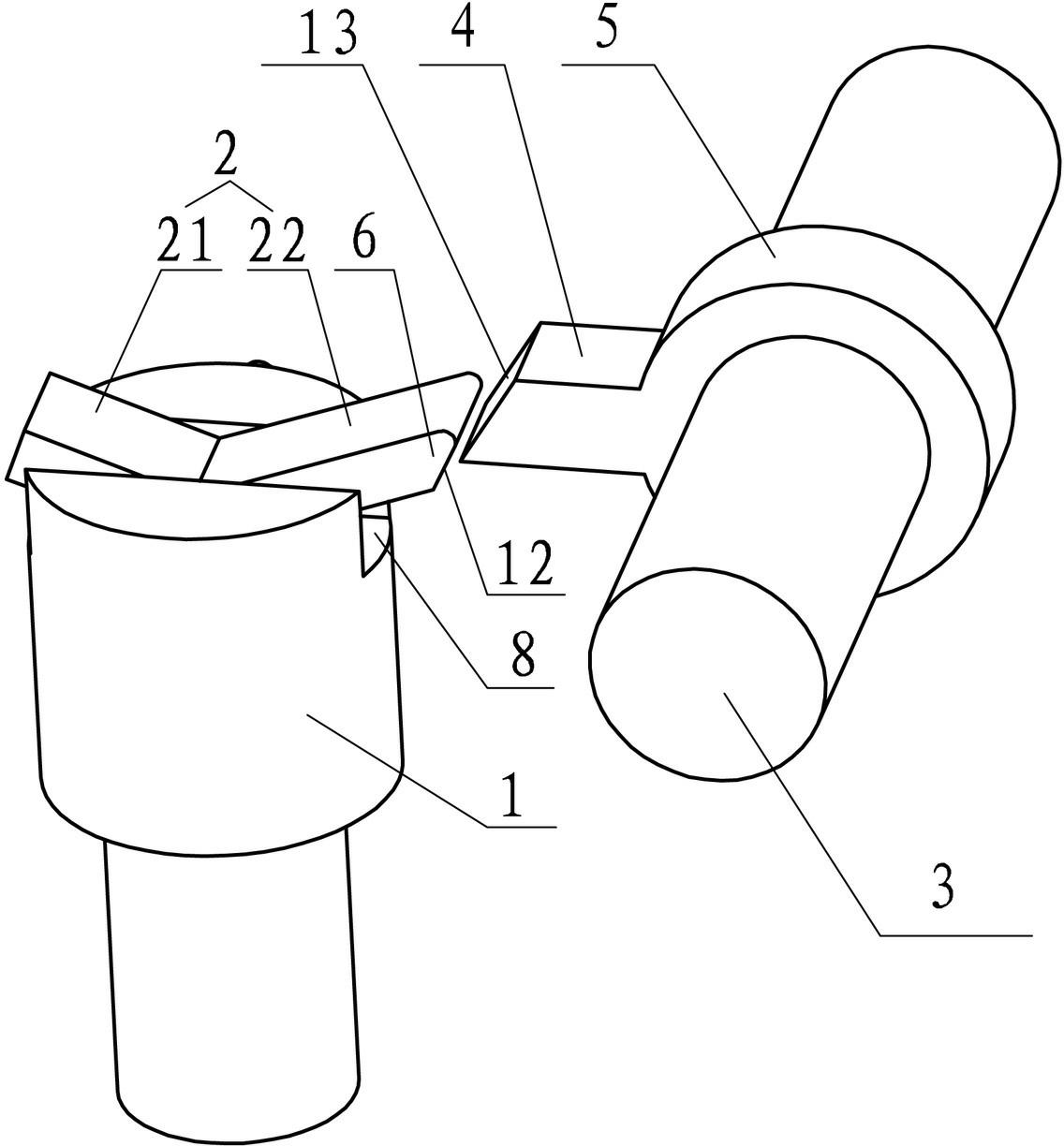

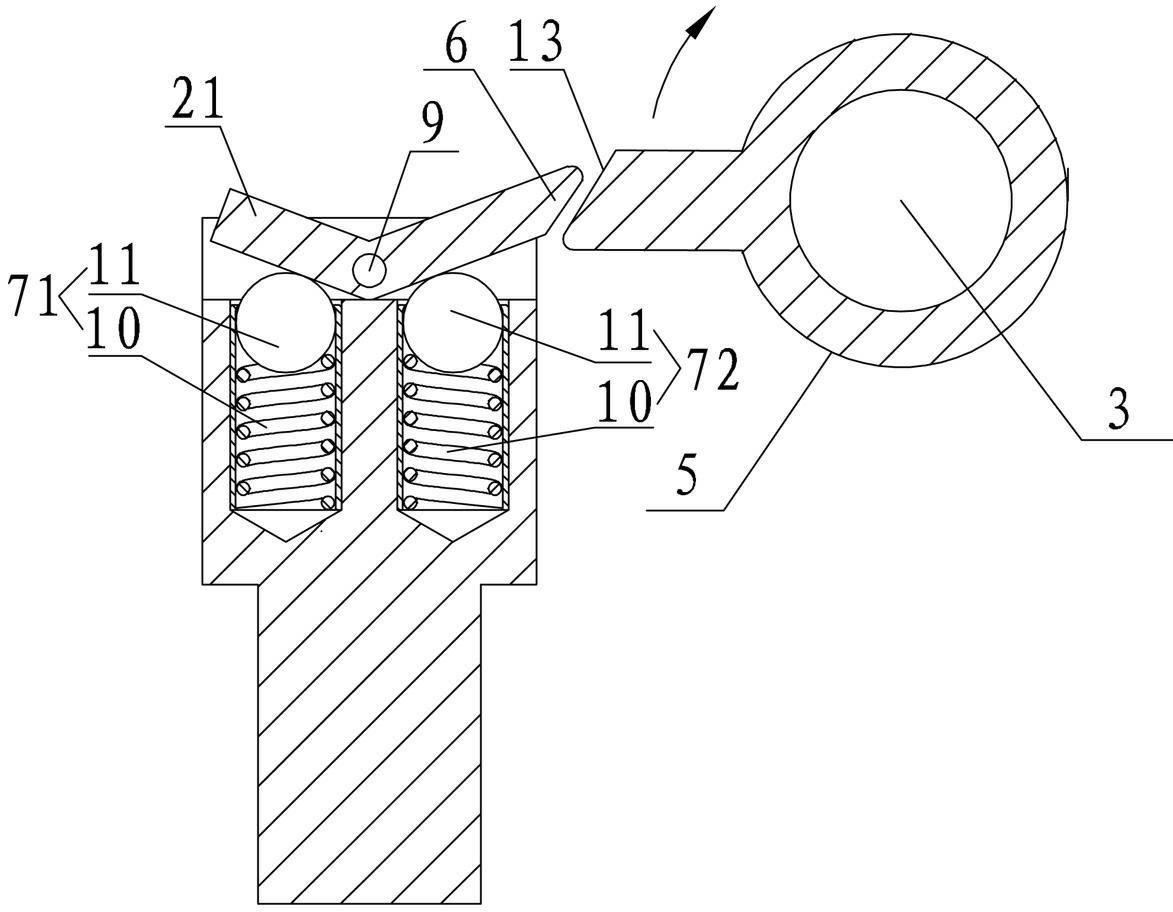

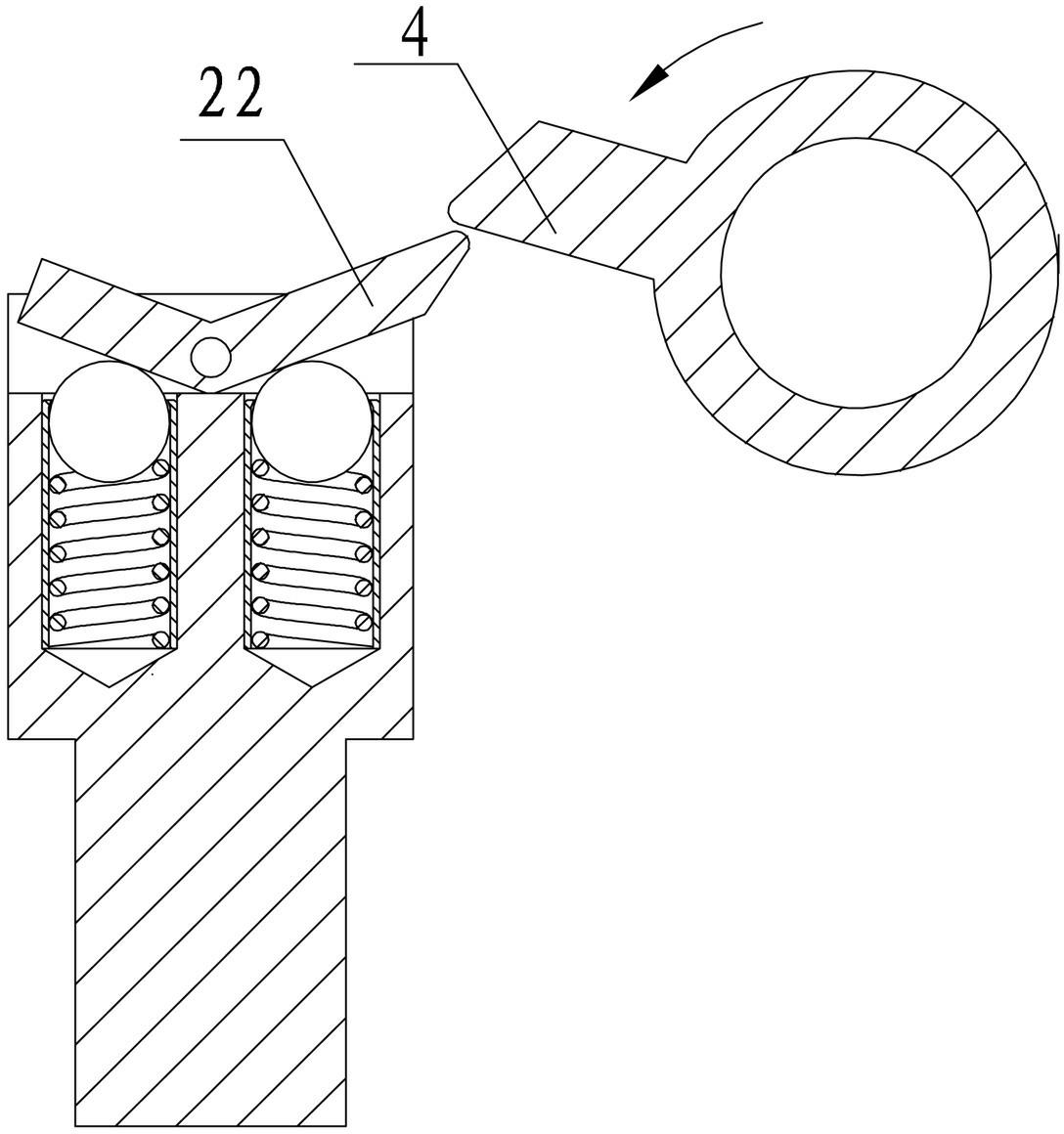

[0018] The vehicle transmission reverse gear locking device of the present invention, in the structure of this embodiment, consists of figure 1 , figure 2 As shown, it includes a fixed block 1 that is fixed relative to the transmission case, a reverse lock block 2 that is rotated on the fixed block 1, and is arranged on the fixed block 1 to cooperate with the reverse block 2 so that the reverse block 2 The resetting device that resets to the natural state and the interlocking shift block 5 with the shift head 4 fixed on the shift shaft 3 . Wherein, the fixed block 1 adopts a T-shaped shaft structure, and its top is provided with a groove 8, and the width of the groove 8 should be enough to accommodate the reverse gear lock block 2.

[0019] The reverse gear lock block 2 is a V-shaped structure composed of the first lock arm 21 and the second lock arm 22. The two side walls of the groove 8 are rotationally fitted. In order to make the rotation connection between the reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com