Cam-driven-type dual-station stamping device

A punching device and driving technology, applied in the field of punching device and cam-driven punching device, can solve the problems of high manufacturing precision requirements of hydraulic components, high operation and maintenance costs, complex hydraulic system design, etc. The effect of low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

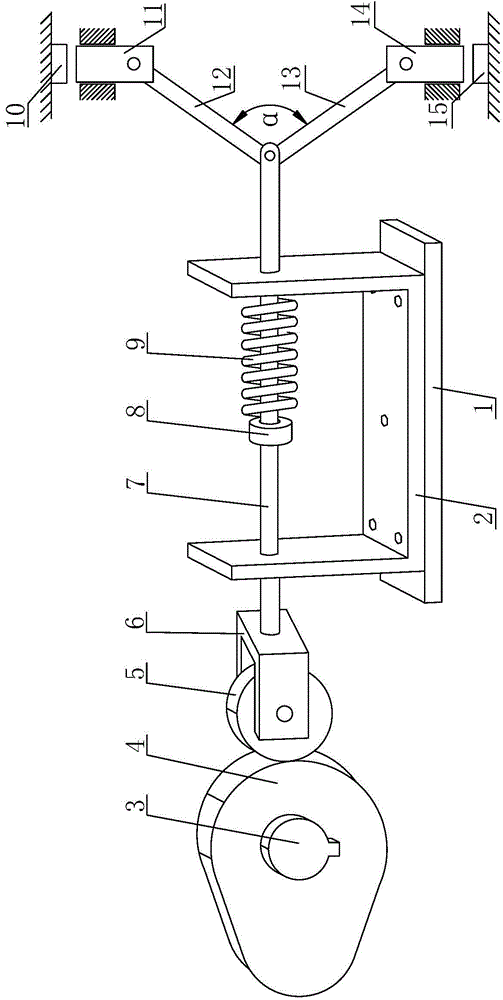

[0021] Such as figure 1 A cam-driven double-station stamping device shown includes a U-shaped bracket 2 for supporting the push rod 7, a base 1 for supporting the U-shaped bracket 2, and a base 1 for driving the push rod 7 forward The sliding disc cam 4 also includes a back-moving spring 9 for driving the reset of the push rod 7, a stamping head one 11 for stamping the workpiece one 10 and a stamping head two 14 for stamping the workpiece two 15; The rod 7 is slidably installed on the U-shaped bracket 2, the middle part of the push rod 7 is fixedly provided with a spring stop 8, and the return spring 9 is arranged between the spring stop 8 and the U-shaped bracket 2, One end of the push rod 7 is rotated with a roller 5 through the roller frame 6, and the disc cam 4 is installed on the end of the power shaft 3, and the other end of the push rod 7 is respectively connected to an end of the transmission rod 12 and the end of the drive rod 12. One end of the transmission rod two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com