Bidirectional automatic variable-speed motor transmission device

A technology of motor transmission and automatic transmission, applied in the field of machinery, can solve problems such as affecting the life safety of car owners, affecting safety, etc., and achieve the effect of reducing precision requirements and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

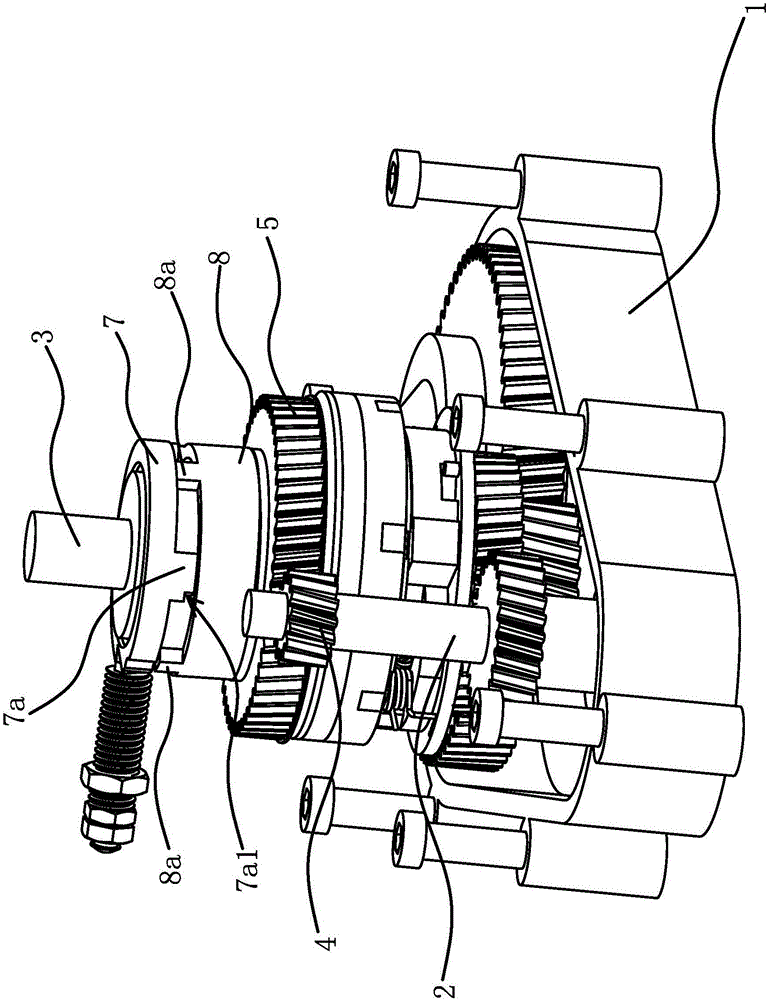

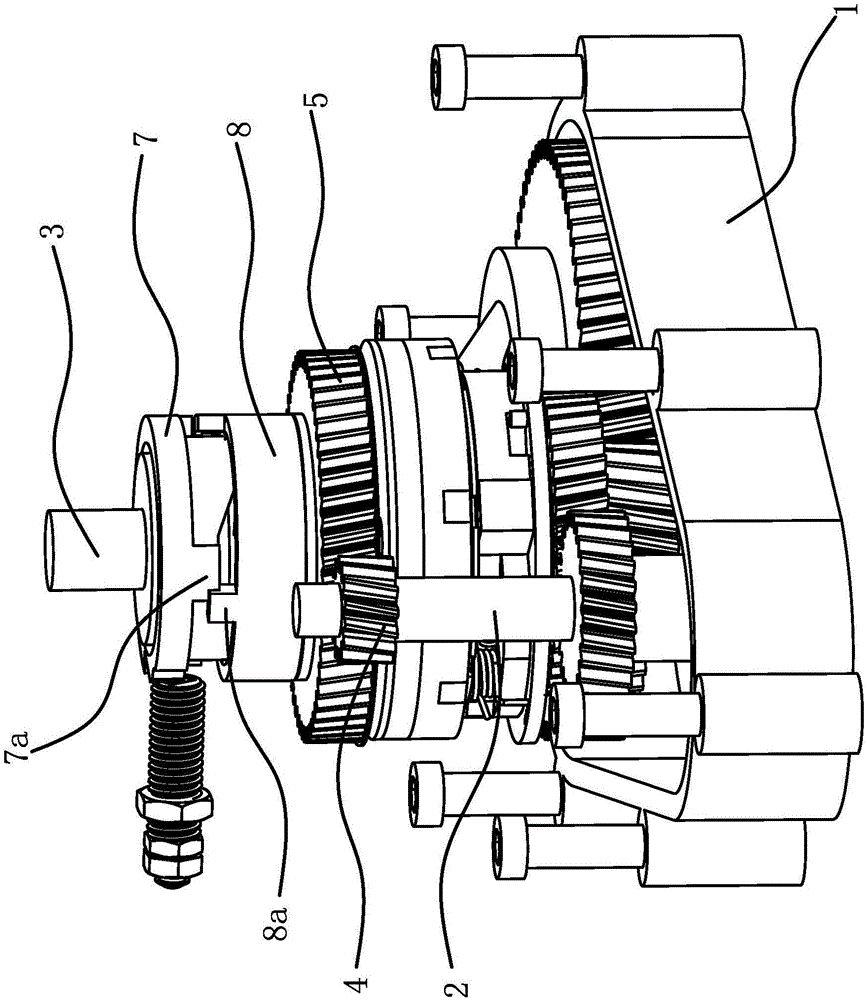

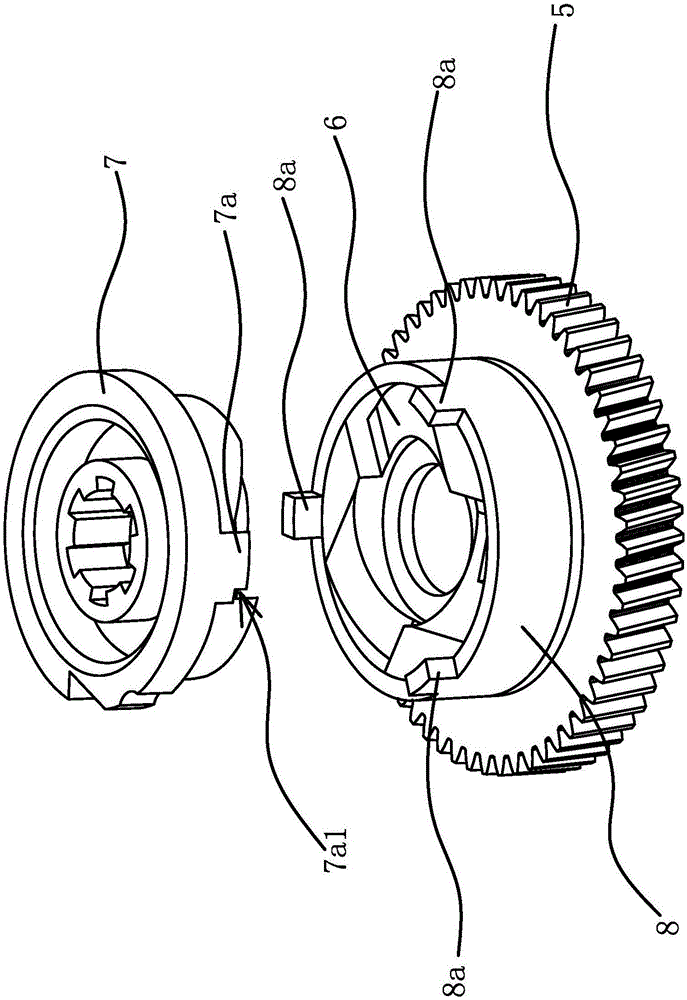

[0031] Such as Figure 1-Figure 4 As shown, the two-way automatic variable speed motor transmission device includes a housing 1 and an input shaft 2 and a transmission shaft 3 arranged in the housing 1. The input shaft 2 and the transmission shaft 3 are arranged in parallel, and the input shaft 2 is fixed with a drive tooth 4. The transmission shaft 3 is provided with a transmission tooth 5 on its outer casing, and the transmission tooth 5 is meshed with the driving tooth 4 . A connecting sleeve 6 is fixed on the transmission gear 5, and a one-way ring 8 is arranged outside the connecting sleeve 6. A connection sleeve 6 and a one-way ring 8 are arranged between the connecting sleeve 6 and the one-way ring 8 so that when the input shaft 2 rotates counterclockwise, the connecting sleeve 6 and the one-way ring 8 one-way mechanisms combined with synchronous rotation.

[0032] The transmission shaft 3 is connected with a transmission sleeve 7 through a spline, and the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com