Rotary double focus laser-MIG electric arc composite welding head

A hybrid welding and laser welding technology, applied in laser welding equipment, arc welding equipment, welding equipment, etc., can solve the problems of unfavorable welding process stability, poor weld bridging ability, low laser utilization rate, etc., to improve thermal influence The occurrence of area defects, the reduction of assembly precision requirements, and the effect of improving process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

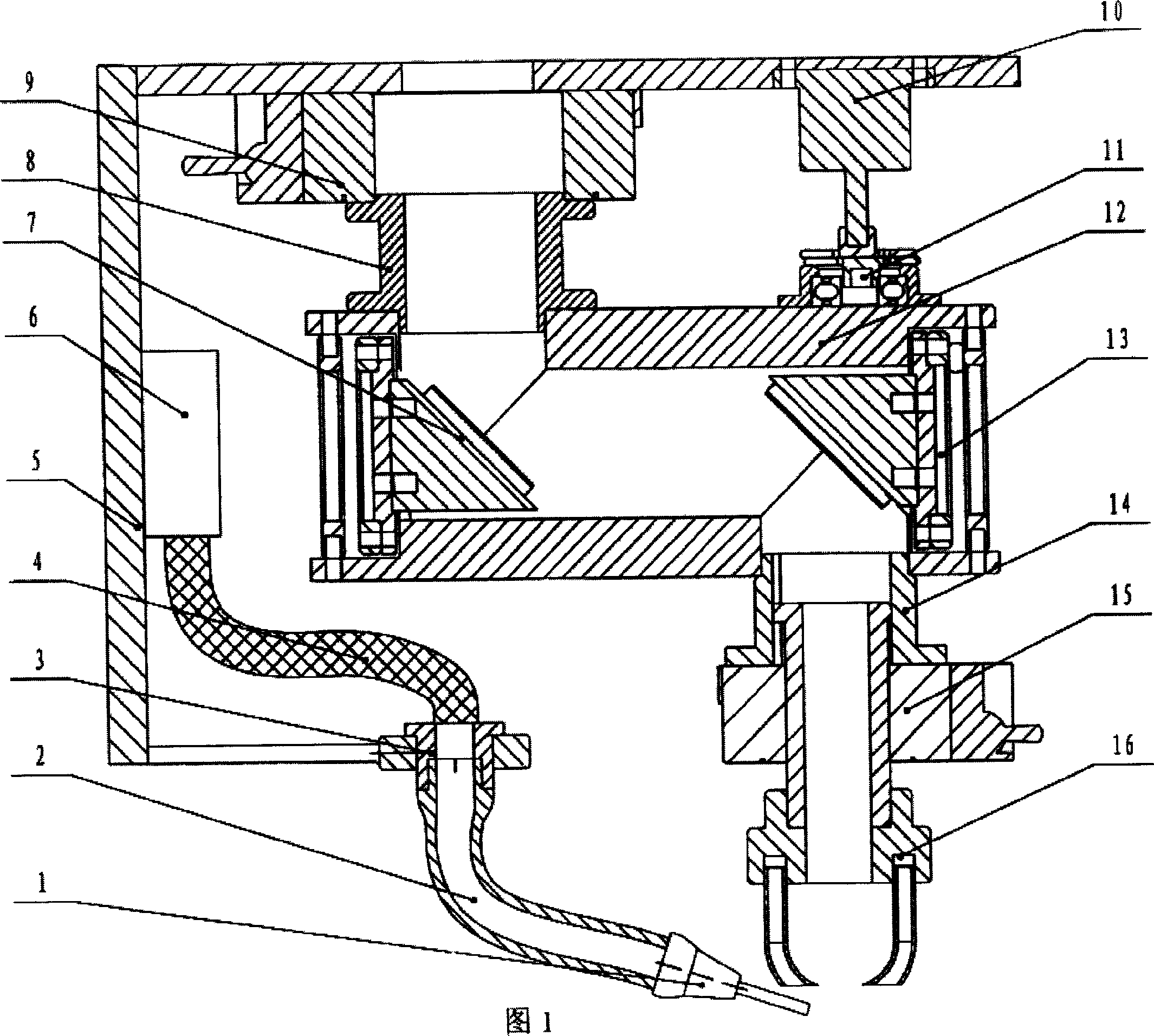

[0020] The invention mainly includes two parts, one is the dual-focus rotation realization part of laser welding, and the other part is the MIG arc welding part.

[0021] As shown in Fig. 1, the connecting plate 5 of the rotating bifocal laser-MIG arc hybrid welding head of the present invention is used to connect the welding laser head with the welding torch of MIG arc welding. The wire feeder 6 is fixed on the connecting plate 5 and transports welding wire for MIG arc welding. Connected below the wire feeder 6 is a wire feeding hose 4 , which is connected to the soft gooseneck 2 , and the welding wire enters the gooseneck 2 through the wire feeding hose 4 and the conductive tip 3 . A protective nozzle 1 is connected to the end of the gooseneck 2 by threads, and the welding wire comes out from the protective nozzle 1 to form a certain angle with the welding seam. The lower part of the connecting plate 5 is connected with the rotary table 9, and the rotation of the rotary tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com