Interlocking assembly and cooking utensil

A technology for cooking utensils and interlocking, which is applied in the field of cooking utensils with the above-mentioned interlocking components, and can solve problems such as violent impact on the door body, paint peeling off on the door body, acceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

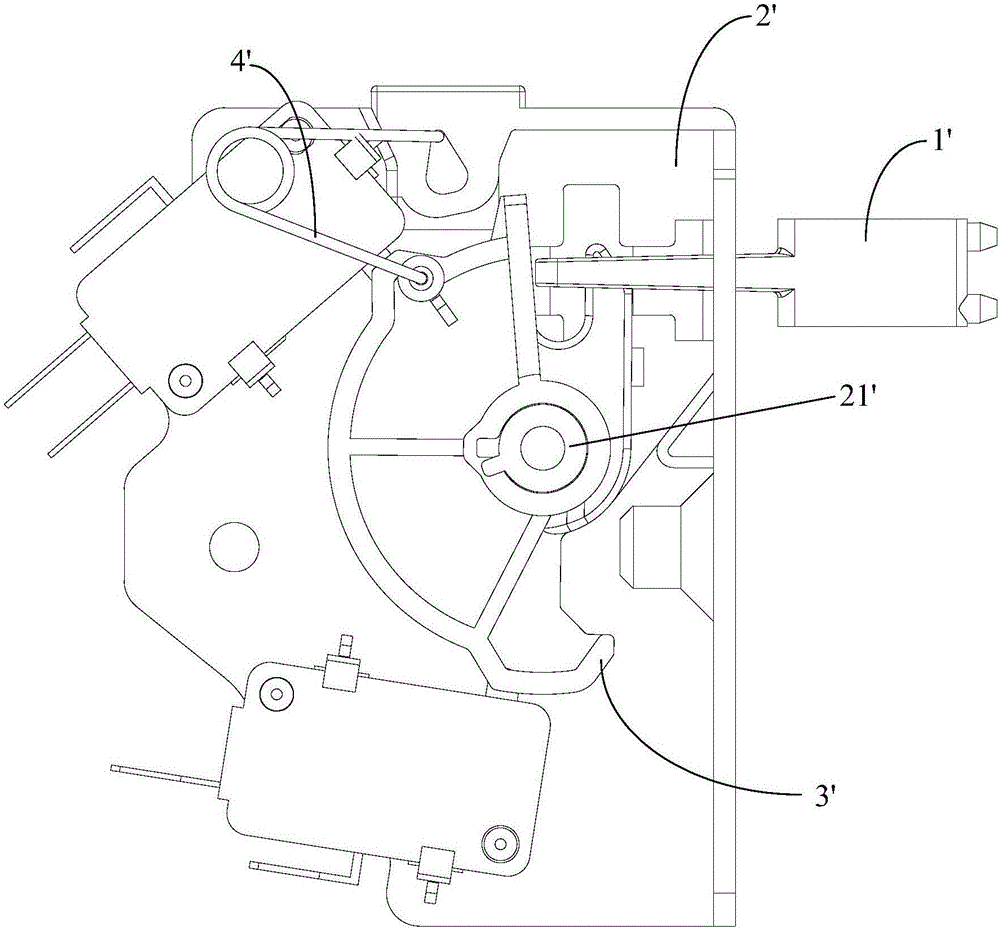

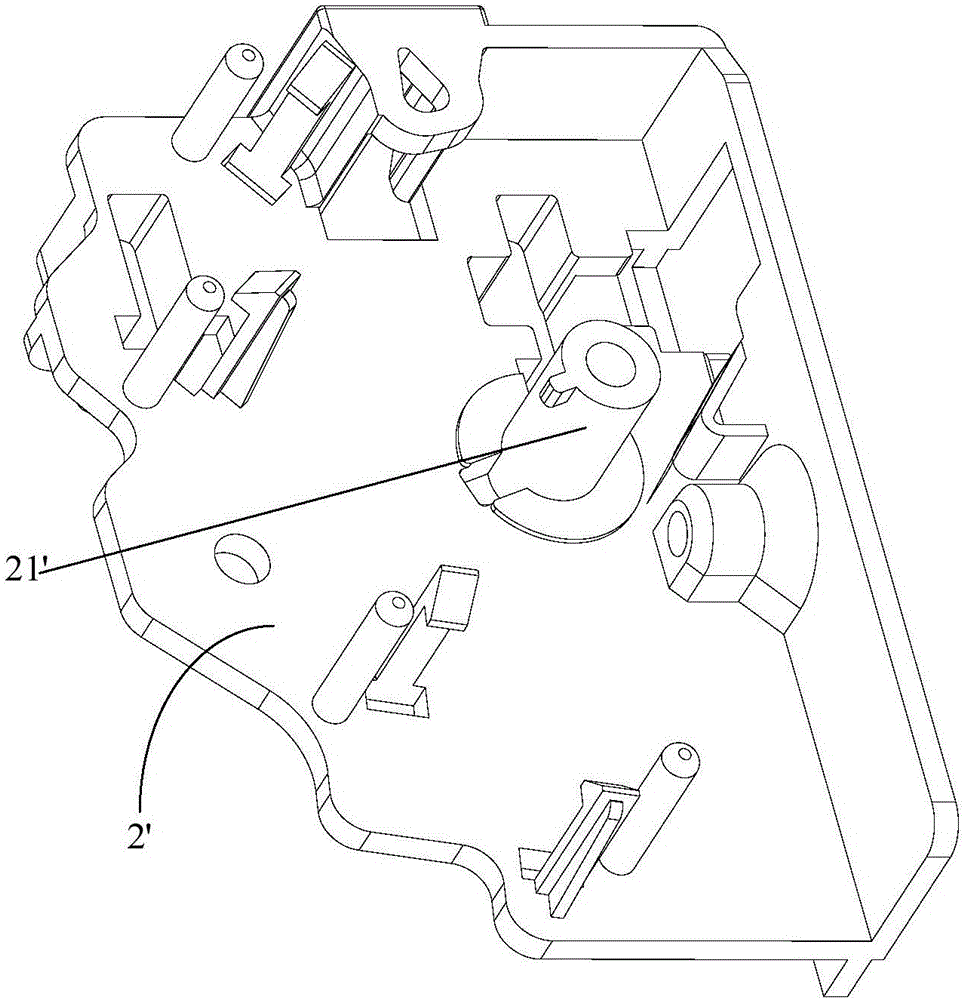

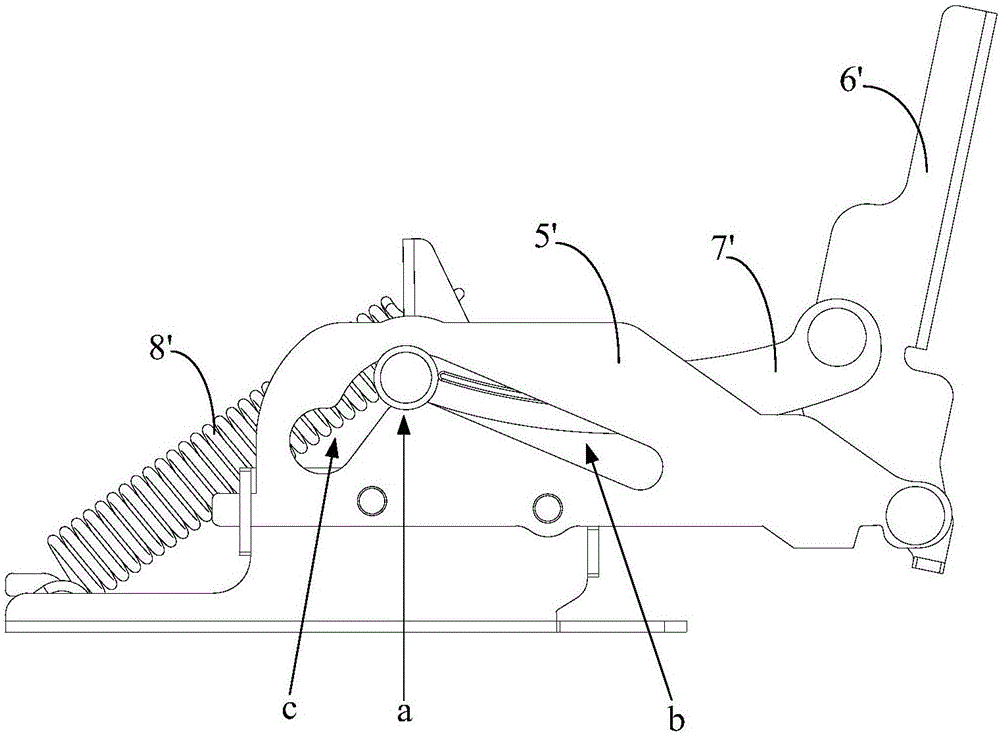

[0045] like Figure 4 to Figure 7 As shown, the interlocking assembly provided by this solution includes a door hook 1, an interlocking bracket 2, an interlocking rotary block 3, a positioning torsion spring 4 and a buffer torsion spring 5. The door hook 1 is arranged on the surface of the door body facing the box. And the door hook 1 is provided with a limit hole 11; the interlocking bracket 2 is fixedly installed on the box body, and the interlocking bracket 2 is provided with a mounting column 21; 21 rotation, the interlocking rotary block 3 is provided with a limit protrusion 31 for cooperating with the limit hole 11; one end of the positioning torsion spring 4 is rotationally connected with the interlocking bracket 2, and the other end is rotationally connected with the interlocking rotary block 3; One end of the torsion spring 5 interferes with the interlock bracket 2 , and the other end is used for interference with the interlock rotary block 3 .

[0046] The working p...

Embodiment 2

[0055] The interlocking components provided by this solution include door hooks, interlocking brackets, interlocking rotary blocks, positioning torsion springs and buffer springs. The lock bracket is fixedly installed on the box body, and the interlock bracket is provided with a mounting column; the interlock rotating block is set on the mounting column and can rotate relative to the mounting column, and the interlock rotating block is provided with a limit hole for matching with the limit hole. One end of the positioning torsion spring is rotatably connected with the interlock bracket, and the other end is rotatably connected with the interlock rotary block; the buffer device includes a buffer spring, one end of the buffer spring is matched with the interlock bracket, and the other end is used for interlock with the interlock rotary block Cooperate.

[0056] In this solution, the buffering torsion spring in the first embodiment is replaced by a buffering spring, and the linka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com