Patents

Literature

48results about How to "To achieve the purpose of assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

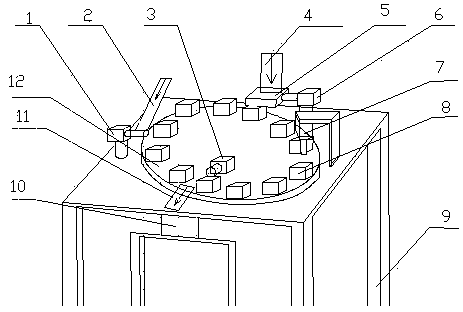

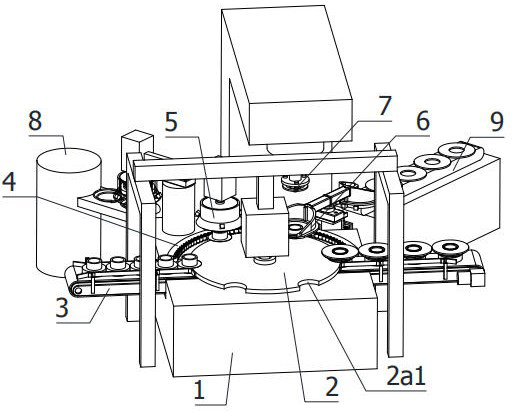

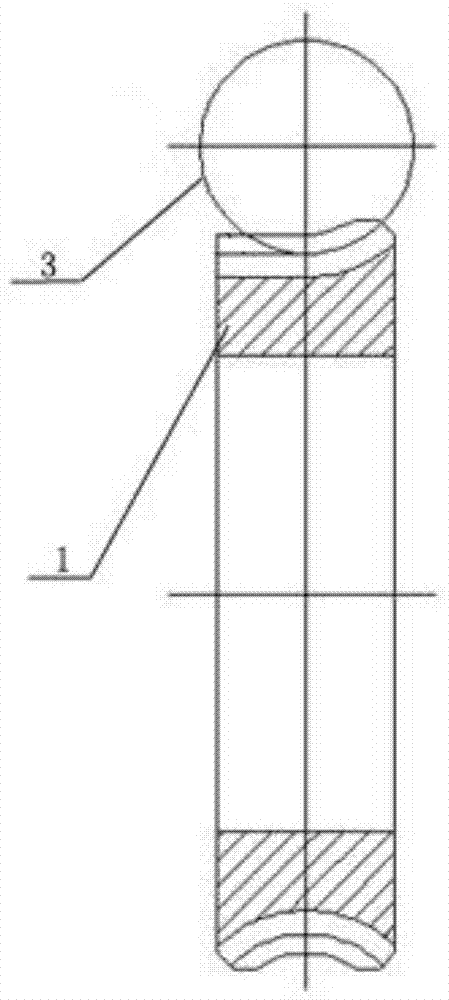

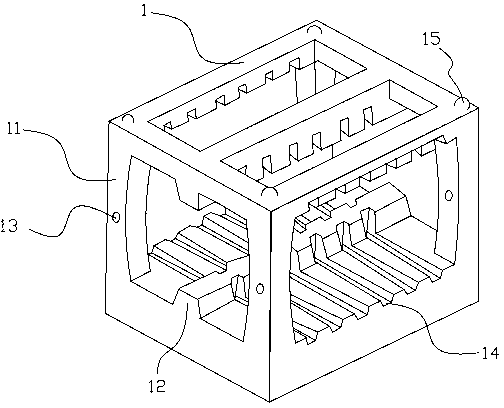

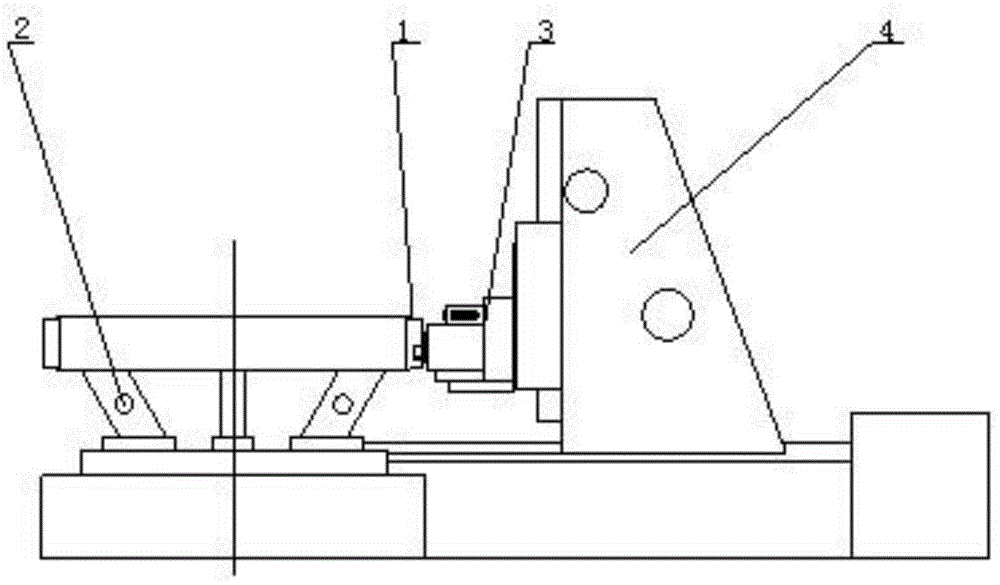

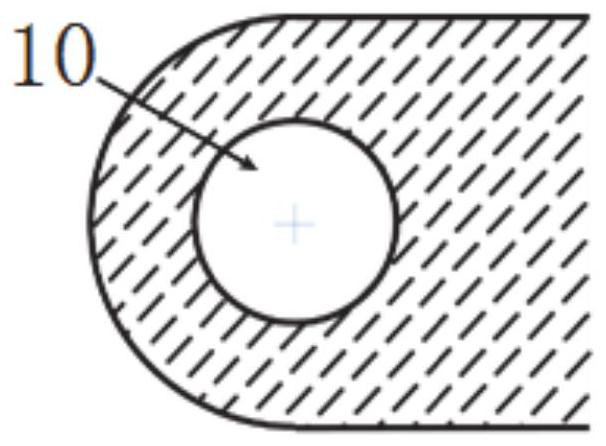

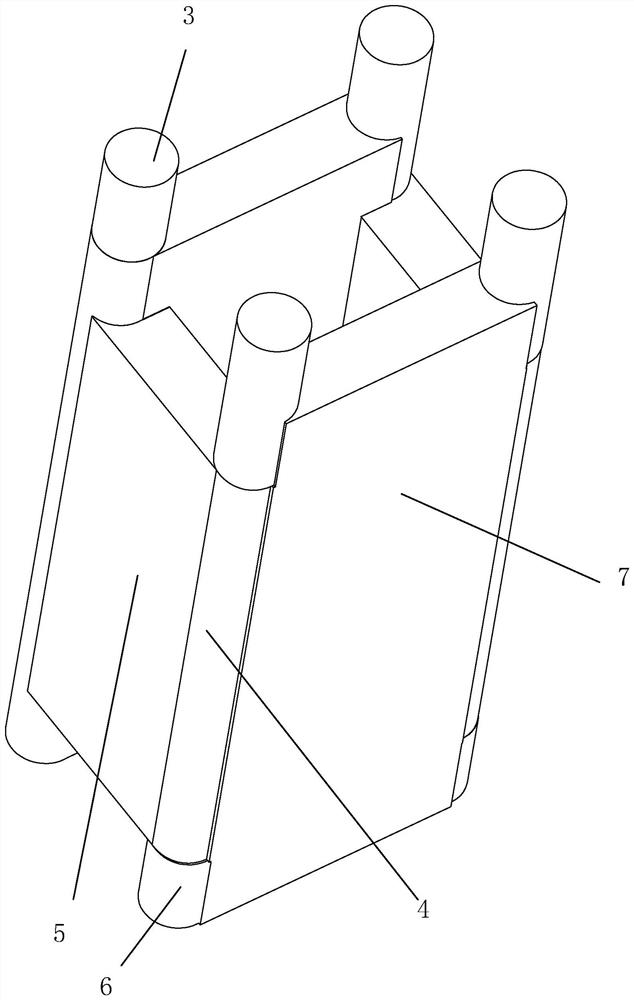

Ball assembling device

ActiveCN104191191ATo achieve the purpose of assemblySimple structureMetal working apparatusElectric machineryEngineering

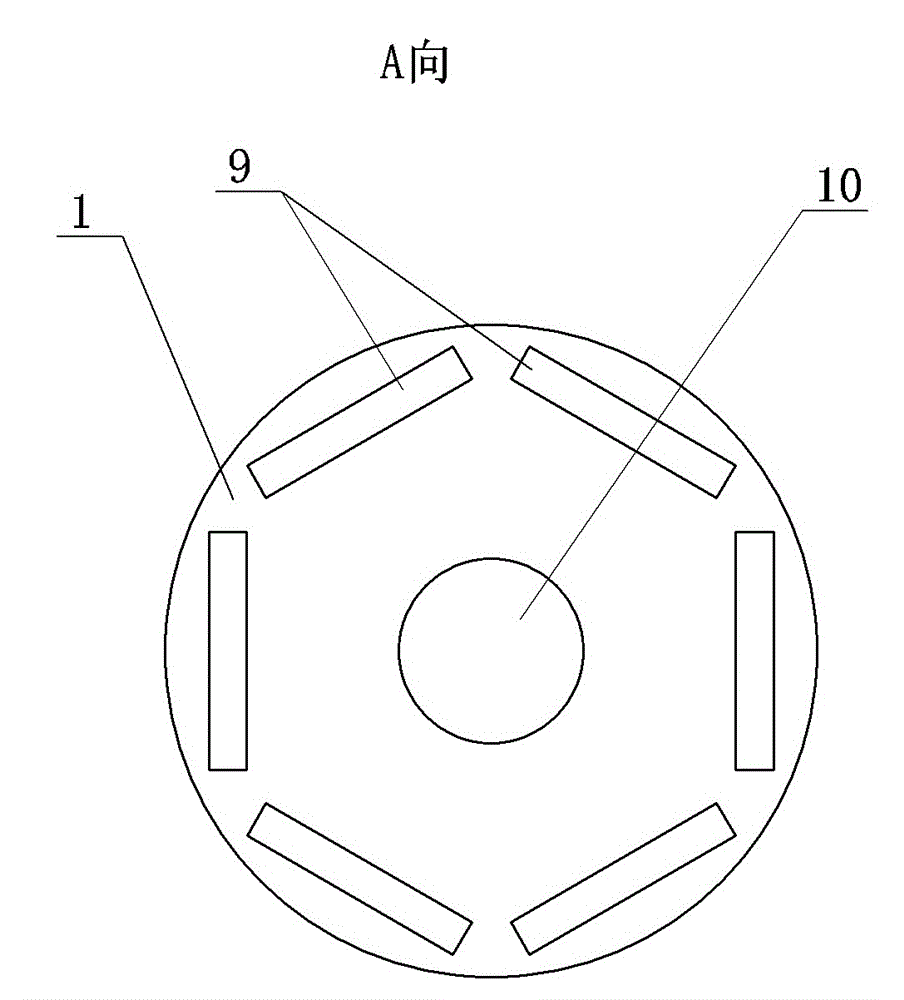

The invention relates to a ball assembling device which comprises an operation table, a workpiece feeding rail, a ball feeding rail, clamps, a motor, an assembly output rail and a rotating workbench. The motor intermittently drives the rotating workbench to rotate, and the assembling task of workpieces and balls is completed through the motion of air cylinder push rods at four work positions. According to the ball assembling device, the aim of ball assembling is achieved through the simple movement cooperation of air cylinders and the rotating workbench, the structure is simple, operation is convenient, the needed labor cost is greatly lowered, the assembling efficiency is improved, and the rejection rate is reduced. Meanwhile, the assembling flexibility and stability are improved.

Owner:HOHAI UNIV CHANGZHOU

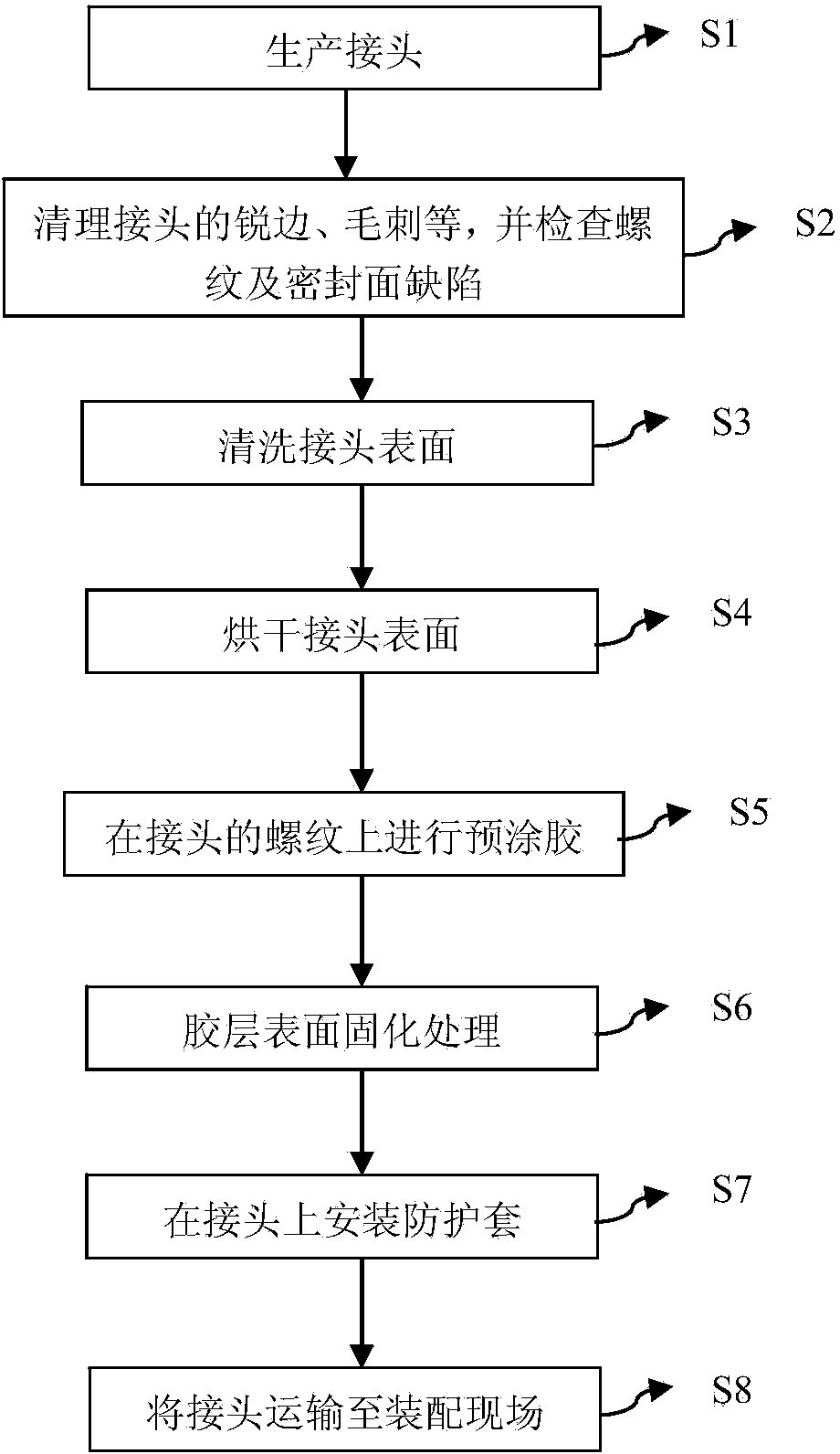

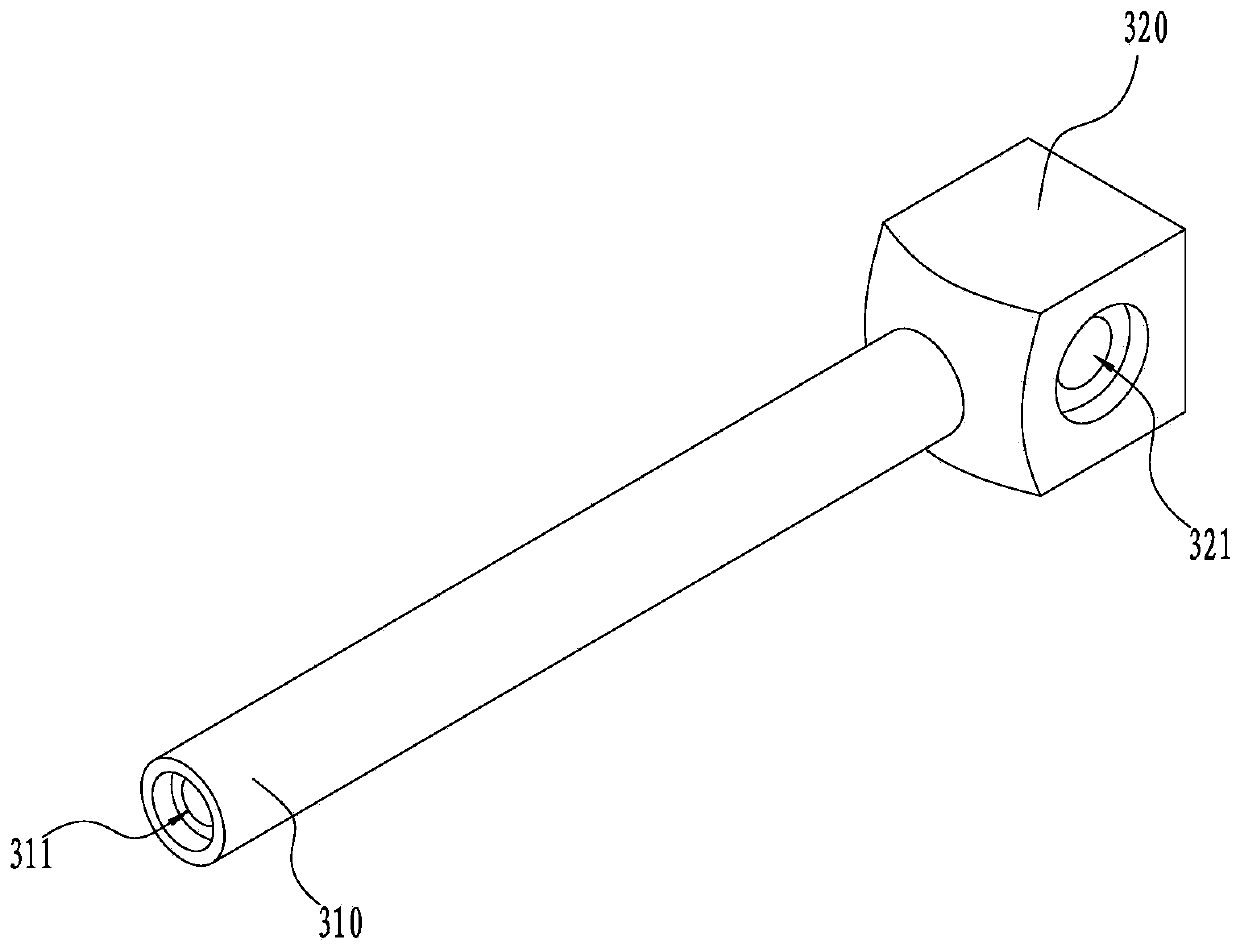

Pre-gluing method for pipeline joint

InactiveCN103953803AAssembly efficiency impactAvoid pollutionNon-disconnectible pipe-jointsFastening meansEmulsionMechanical engineering

The invention discloses a pre-gluing method for a pipeline joint. The method comprises the following steps: after finishing processing the joint, clearing away sharp edges and burrs of the joint, examining whether the defects of scratches and collisions exist on a thread and a sealing surface of the joint; cleaning the surface of the joint if no defects of scratches and collisions exist on the thread and the sealing surface of the joint; drying the surface of the joint; pre-gluing glue on other threads except a first thread of the joint; solidifying the surface of the glue, solidifying and drying the outer layer of the glue, and enabling the inner layer of the glue to be in an emulsion state; transporting the joint coated with the glue to an assembly field and assembling, extruding the emulsion glue in the inner layer of the glue, and filling the extruded emulsion glue in a gap of the sealing surface to form an elastic sealing tape. The operation of applying the glue on the thread of the joint is arranged after the processing of the joint, and is separated from the assembly of an engine, so that the gluing procedure does not affect the assembly efficiency of the engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

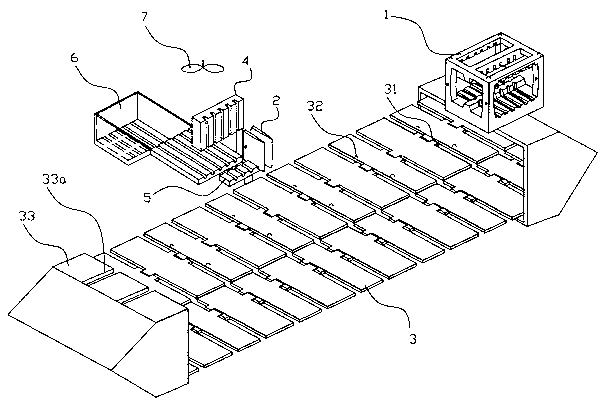

Modularized algae multiplication method

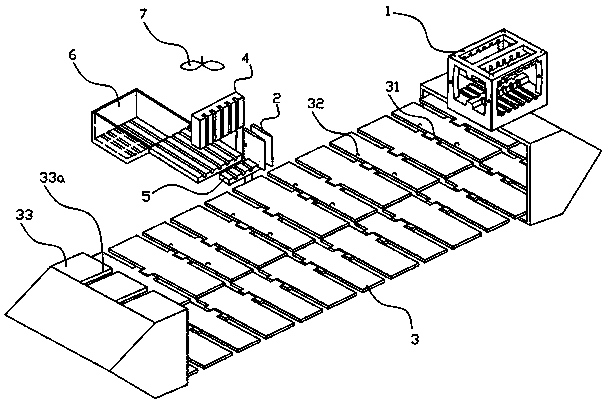

InactiveCN103270989AQuickly reach the purpose of assemblyTo achieve the purpose of assemblyClimate change adaptationPisciculture and aquariaEngineeringAssembly line

The invention discloses a modularized algae multiplication method including the steps such as egg attaching, transplanting and species alternating. A dragging protruded ball is arranged on a conveyor belt integrated with a specified assembly line. Tail end covers are arranged at two ends of the chained conveyor belt. Reserved grooves are formed in the tail end covers to accommodate the dragging protruded ball. A lifting table is arranged near a lateral face of the chained conveyor belt. A reciprocating pushing plate is arranged near the top of the lifting table. Parallel sliding grooves are reserved on the upper surface of the lifting table. A soaking sliding-groove container is arranged near the lifting table and on one side of the lower portion of the reciprocating pushing plate. The soaking sliding-groove container is provided with a water tank capable of containing liquid; and one side edge opening of the water tank extends outside near the lifting table. Thereby, the modularized algae multiplication method has the advantages that splicing and assembling are quick, egg attachment can be controlled, requirements on splicing accuracy are low, mass fishing reef arrangement application is suitable, operation is facilitated extremely, and labor is saved.

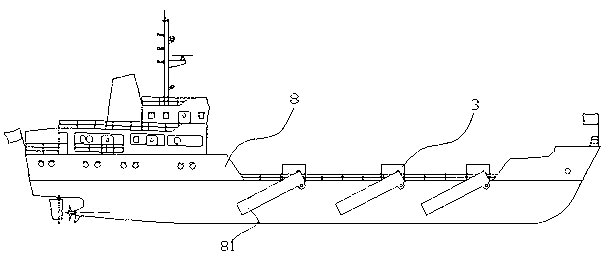

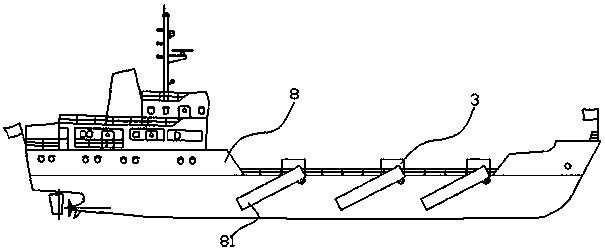

Alga multiplication device assembling ship

ActiveCN103270988APrevent water flowNovel structureClimate change adaptationPisciculture and aquariaAssembly lineMarine engineering

The invention discloses an alga multiplication device assembling ship which comprises a ship body. An assembly line device is mounted on the ship body. Guide grooves are arranged on the lateral sides of the ship body. Chained conveying belts are arranged on the assembly line device and protruding traction protruding balls are processed on the conveying belts. Tail end covers are arranged at two ends of the chained conveying belts, and reserved grooves for allowing the traction protruding balls to pass are processed on the tail end covers. Lifting platforms are arranged near to the lateral sides of the chained conveying belts, and reciprocate pushing plates are arranged near to the upward sides of the lifting platforms. Parallel sliding chutes are processed on the upper surfaces of the lifting platforms. Soaking sliding chute containers are arranged on one sides, below the reciprocate pushing plates, near to the lifting platforms. Each soaking sliding chute container is provided with a water tank capable of storing liquid and an edge opening on one side of each water tank extends outwards to be near to each lifting platform. Parallel sliding chutes are processed on the surfaces of the outward-extending edge openings, and extend to the bottoms of the water tanks along the side walls of the water tanks. The alga multiplication device assembling ship has the advantages of novel structure, rapidness in slicing and assembling, low requirement on slicing and assembling accuracy, and applicability to fish-shelter application distribution on a large scale.

Owner:ZHEJIANG OCEAN UNIV

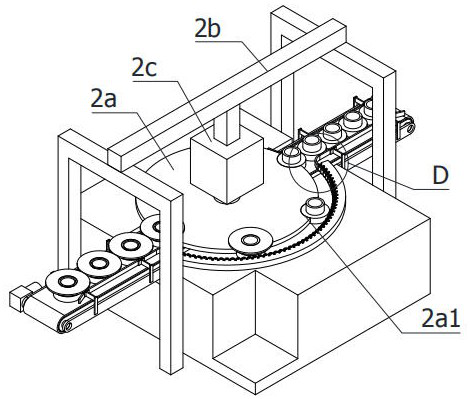

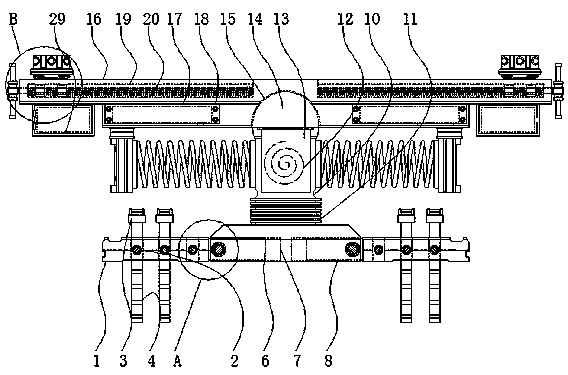

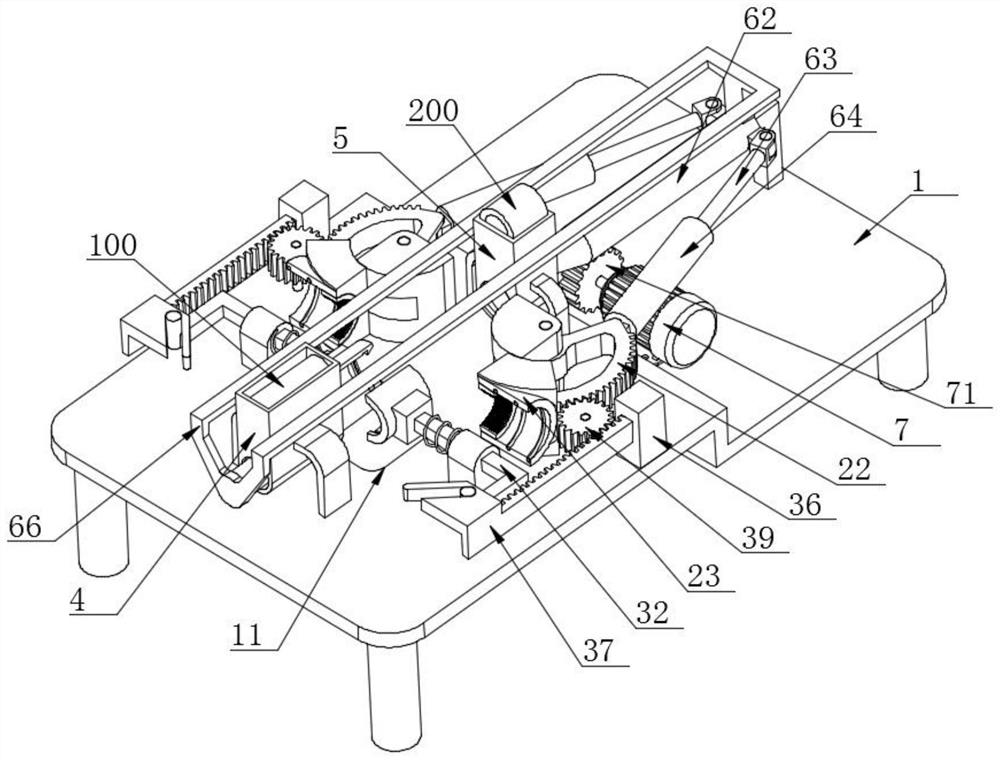

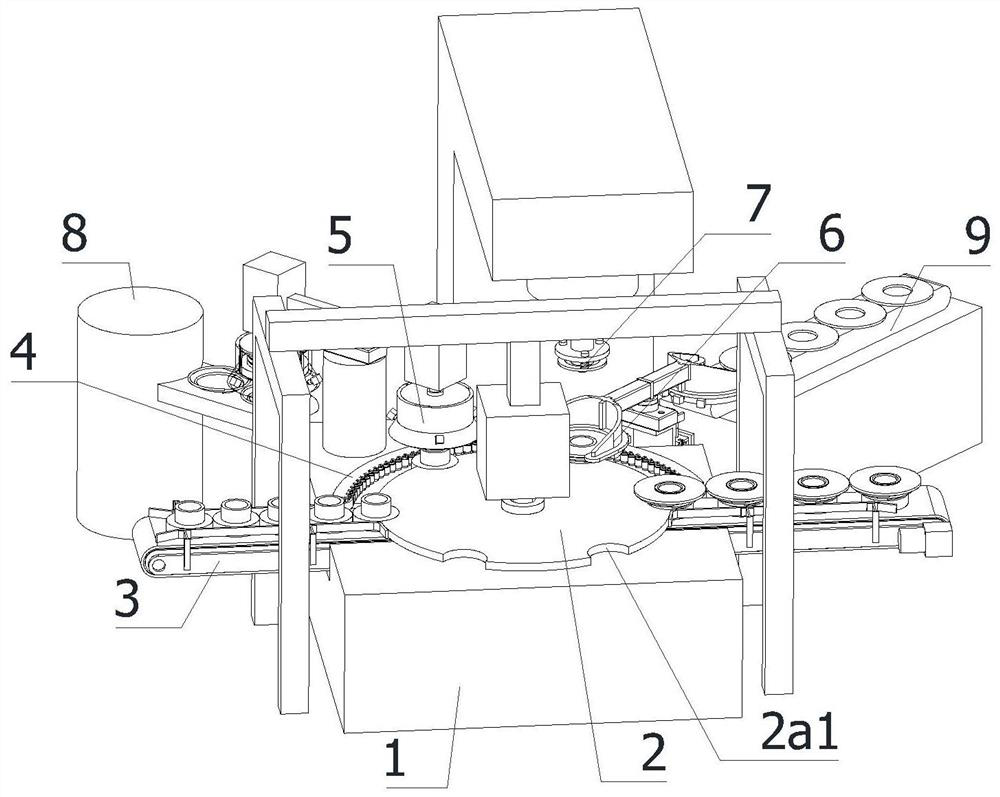

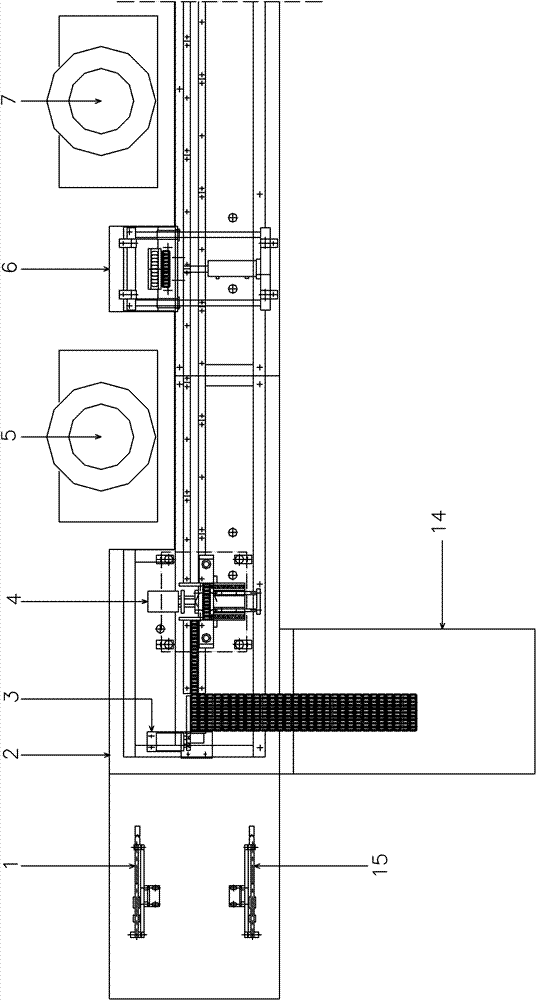

Automobile shock absorber circulation part machining equipment

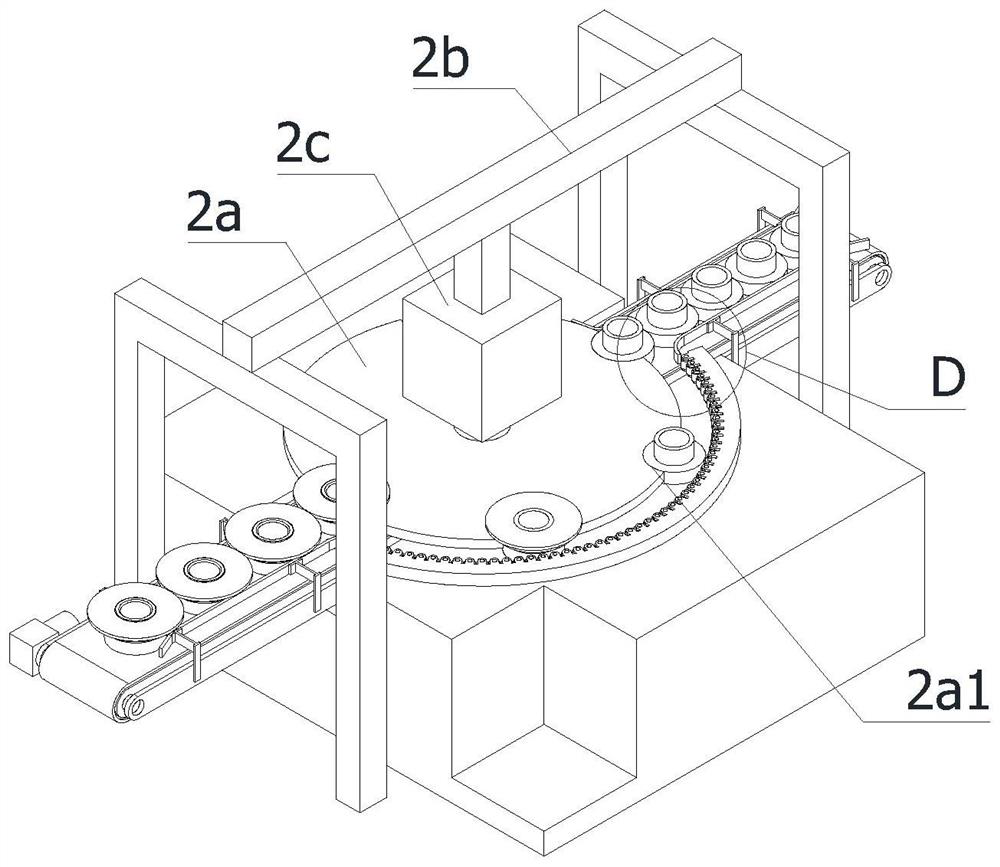

ActiveCN112059610AImprove assembly work efficiencyTo achieve the purpose of assemblyAssembly machinesMetal working apparatusEngineeringMachining

The invention relates to the technical field of automatic assembly of automobile parts, in particular to automobile shock absorber circulation part machining equipment. The automobile shock absorber circulation part machining equipment comprises a workbench; a stepping rotary conveying assembly, wherein the stepping rotary conveying assembly comprises a rotary disc, the axis of the rotary disc isvertically and rotationally arranged on the workbench, and flanges and half-moon grooves used for clamping are evenly distributed in the circumferential surface of the rotary disc along the axis; a synchronous belt conveyor horizontally arranged at the bottom end of the stepping rotary conveying assembly in the radial direction of the stepping rotary conveying assembly; a semicircular limiting ring coaxially arranged on the outer edge of the stepping rotary conveying assembly; a first rotary loading mechanism and a second rotary loading mechanism, wherein the loading mechanisms are sequentially arranged on the outer edge of the semicircular limiting ring in the conveying direction of the stepping rotary conveying assembly; a riveting and pressing mechanism, wherein the working end of the riveting and pressing mechanism vertically faces the feeding end of a spring feeding mechanism and is arranged on the outer side of the workbench; and the spring feeding mechanism and a valve plate feeding mechanism, wherein the feeding mechanisms are arranged on the first rotary loading mechanism and the second rotary loading mechanism correspondingly, and the device is high in working efficiencyand precision.

Owner:宁波云帆新能源科技有限公司

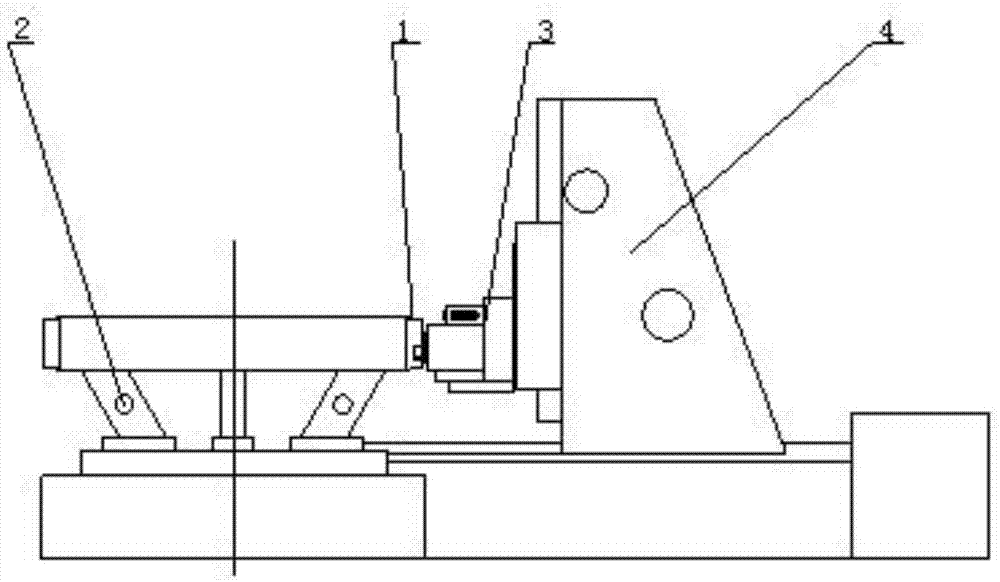

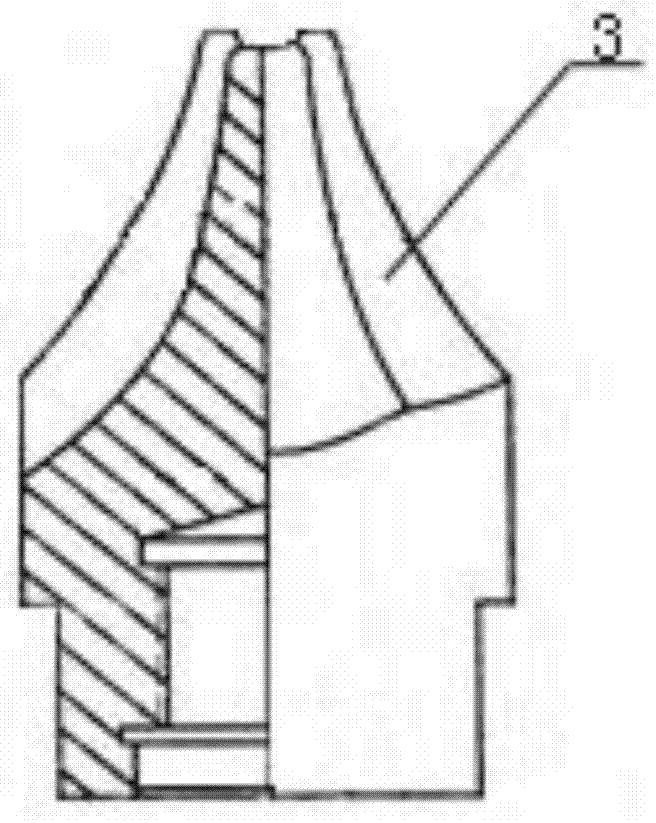

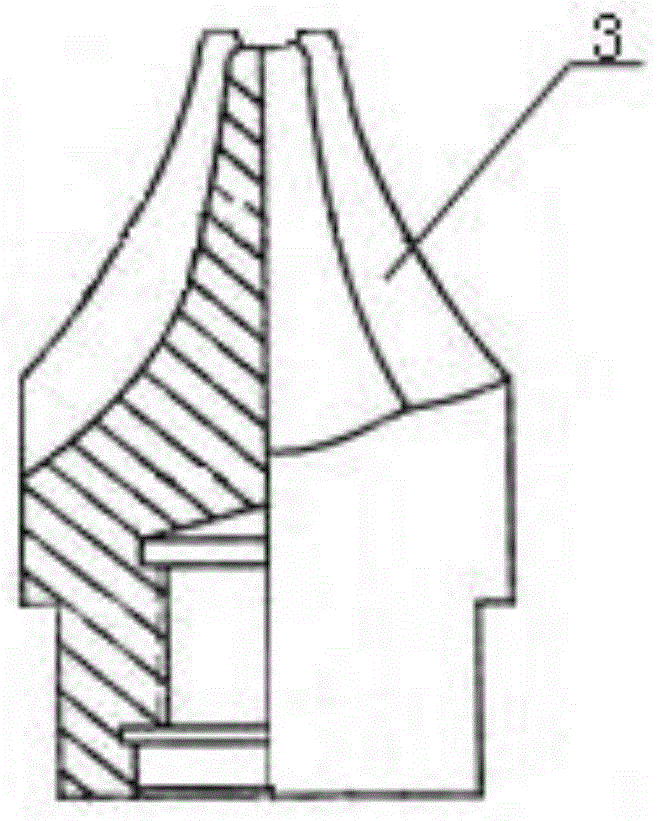

Plain-surface modifying machining Method for tooth surfaces of worm gears

ActiveCN104259581ASolve the requirements of face-to-face modificationTo achieve the purpose of assemblyWorm wheelsEngineeringMilling cutter

The invention relates to a plain-surface modifying machining method for tooth surfaces of worm gears. The plain-surface modifying machining method is used for milling the tooth surfaces in the height directions according to reference circles, and the widths of the tooth surfaces are equal to 1 / 2 of the tooth widths of the worm gear. The plain-surface modifying machining method includes steps of 1), machining finger-shaped milling cutters according to tooth profiles of the reference circles of the worm gears with milled teeth; 2), laying worm gear workpieces with the milled teeth on worktables of gear bobbing machines and aligning the worm gear workpieces; 3), adjusting the cutters according to the tooth surfaces at the reference circles, and machining the tooth surfaces according to lead angle adjusting differential mechanisms of worms until certain positions of the tooth surfaces are machined; 4), indexing and machining a next tooth surface after each tooth surface is completely machined; 5), machining a plurality of tooth surfaces according to assembly requirements, completely machining the tooth surfaces, coating oil on the tooth surfaces after the tooth surfaces pass inspection, and storing the tooth surfaces. The widths of the certain positions of the reference surfaces are equal to 1 / 2 of the tooth widths of the worm gears. Compared with the prior art, the plain-surface modifying machining method has the advantages that plain-surface modifying requirements on the tooth surfaces of the worm gears can be met, and the purposes of simultaneously placing the worm gears and the worms into boxes assembling the worm gears and the worms in the boxes can be achieved; machining procedures are simple, production procedures are easy to control, and requirements on the quality of products can be met; indexing functions of the gear bobbing machines can be sufficiently utilized, and accordingly the plain-surface modifying machining method is high in machining precision.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

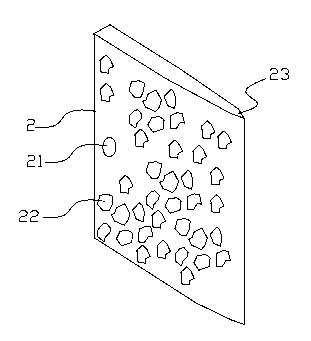

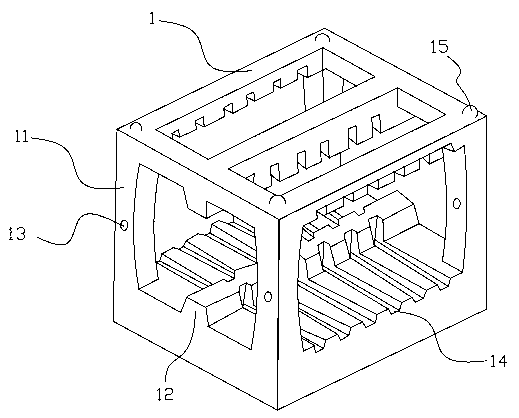

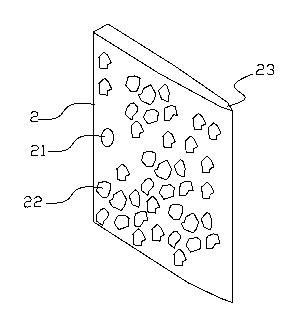

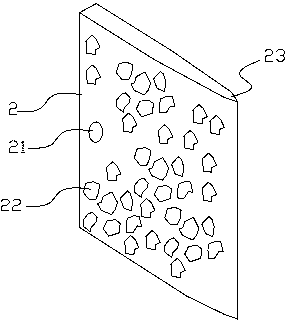

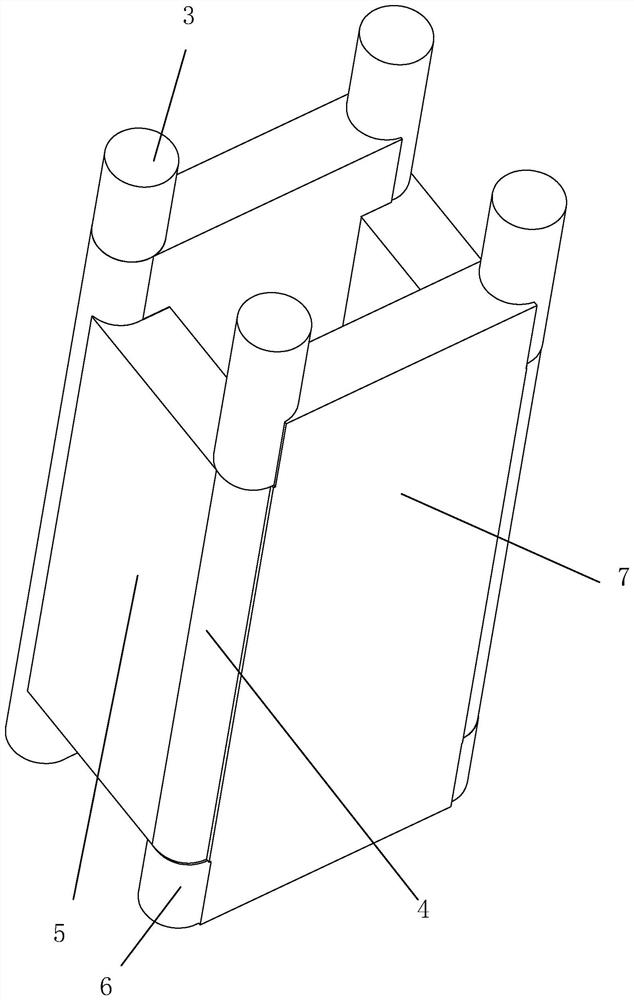

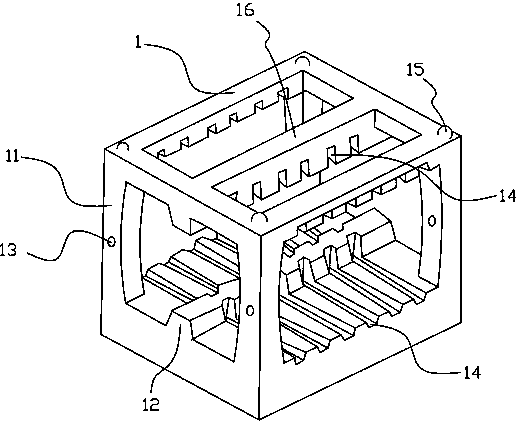

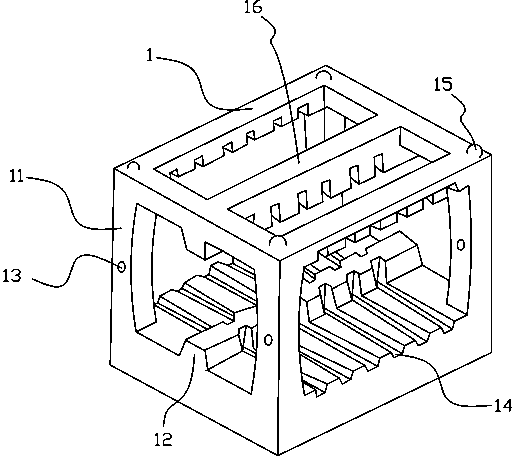

Modular algae multiplication device

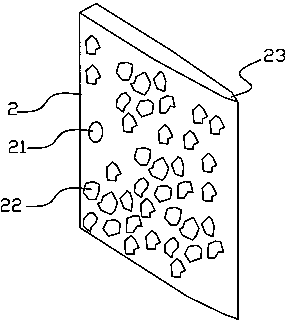

InactiveCN103299930AQuickly reach the purpose of assemblyTo achieve the purpose of assemblyClimate change adaptationPisciculture and aquariaModularityEngineering

The invention discloses a modular algae multiplication device which comprises a sinking frame and an attaching sheet which can be installed in the sinking frame, wherein the sinking frame adopts a prismatic structure; an upright on the lateral surface of the sinking frame is provided with a positioning hole in a run-through manner; the bottom of the sinking frame is provided with a platform and the platform is provided with a fixed groove; the top of the sinking frame is provided with a limiting beam and the limiting beam is provided with a fixed groove; the fixed grooves take the shape of a horn mouth and the openings of the horn mouths face to the outside of the sinking frame; the top of the sinking frame is provided with a limiting convex ball and the bottom surface of the sinking frame is provided with a limiting blind hole which can be matched with the limiting convex ball; the surface of the attaching sheet is provided with a concave pit; one side of the attaching sheet is provided with a wedge-shaped front edge; and the edge of the attaching sheet is provided with a connecting hole. The modular algae multiplication device has the advantages of stability for arrangement, good algae species attaching effect, high multiplication efficiency, capability of regulating density of multiplication population and species density as required, high splicing and assembling speed and difficulty in oxygen deficiency.

Owner:ZHEJIANG OCEAN UNIV

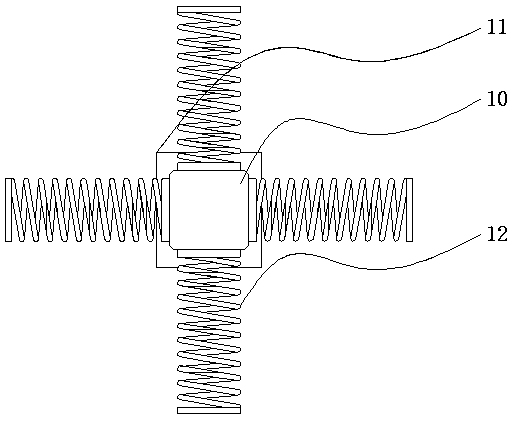

Convenient-to-calibrate balance mechanism with regulating and locating functions for robot

InactiveCN109397336AExtended connection piercing columnImprove thermal performanceManipulatorHeat sinkEngineering

The invention relates to a convenient-to-calibrate balance mechanism with regulating and locating functions for a robot. The balance mechanism comprises a side foot edge seat and a screw via hole, wherein a side joint locating screw penetrates through the front wall of the side foot edge seat, and side joint fixing pins are connected above the side foot edge seat; pre-buried bolt holes are arranged in the bottom ends of the side joint fixing pins in a penetrating manner; and pin connecting holes are arranged in the side foot edge seat in a penetrating manner. The convenient-to-calibrate balance mechanism with regulating and locating functions for the robot has the beneficial effects that through the arrangement of a cooling fin and a buffering spring and the joint action of the cooling fin, the cooling performance of a central support coiled column can be improved, the cooling performance of the device is accordingly improved, and the cooling performance of the robot used with the device is also improved; through the connection of the buffering spring, better buffering can be realized between the central support coiled column and a footstock; and at the same time, the footstock hasrestoring performance, so that the balance keeping of the footstock is facilitated.

Owner:DONGGUAN UNIV OF TECH

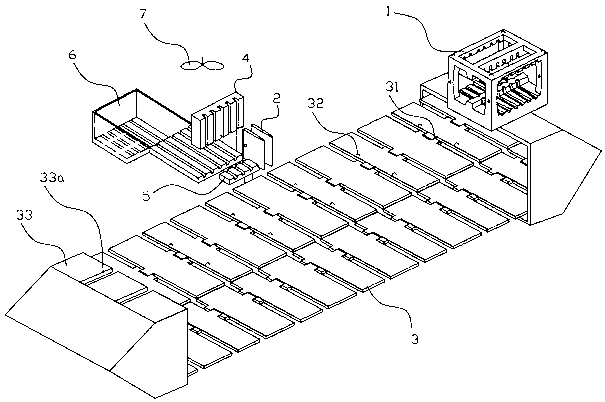

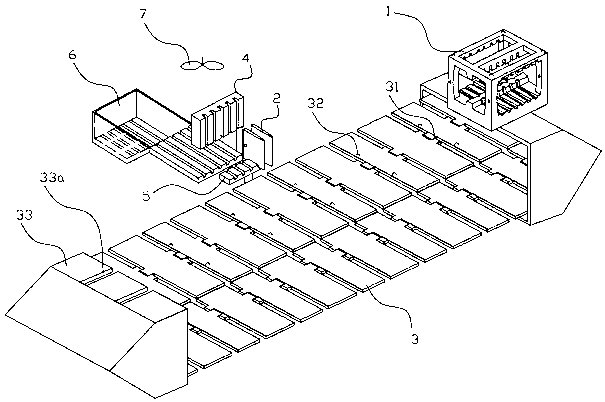

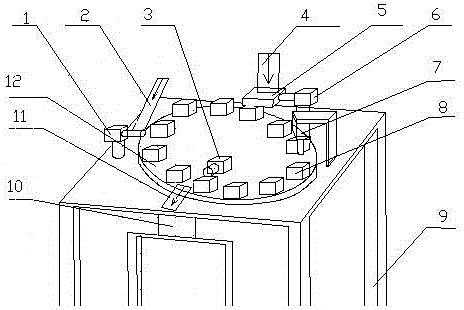

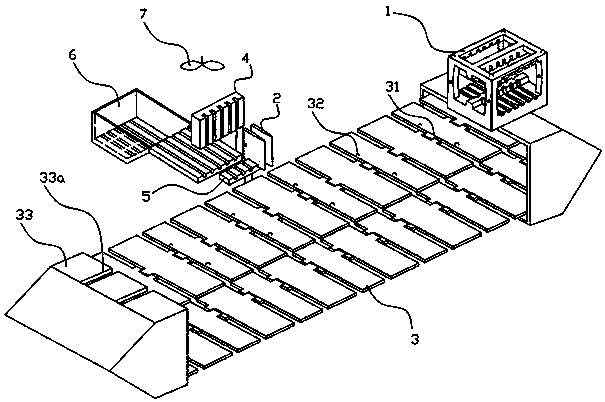

Modular algae multiplication device assembly line

ActiveCN103299932APrevent water flowNovel structureClimate change adaptationPisciculture and aquariaAlgaeChain type

The invention discloses a modular algae multiplication device assembly line which comprises a chain-type conveying belt, wherein the conveying belt is provided with a raised traction convex ball; both ends of the chain-type conveying belt are provided with tail end covers; the tail end covers are provided with preserved grooves capable of allowing the traction convex ball to pass through; a lifting platform is arranged near the lateral surface of the chain-type conveying belt; a reciprocating push plate is arranged near the upper part of the lifting platform; the upper surface of the lifting platform is provided with parallel chutes; a soaking chute container is arranged near the lifting platform and on one side below the reciprocating push plate; the soaking chute container is provided with a water tank capable of accommodating liquid and an edge opening on one side of the water tank extends outwards to the position near the lifting platform; the extending edge opening surface of the lifting platform is provided with parallel chutes and the chutes extend to the bottom of the water tank along the side wall of the water tank; and a fan is arranged near the upper part of the reciprocating push plate. Therefore, the modular algae multiplication device assembly line has the advantages of novel structure, high splicing and assembling speed, low requirement on splicing accuracy and suitability for application to fishing rock arrangement in a large scale.

Owner:ZHEJIANG OCEAN UNIV

A ball assembly device

ActiveCN104191191BTo achieve the purpose of assemblySimple structureMetal working apparatusElectric machineryEngineering

The invention relates to a ball assembling device which comprises an operation table, a workpiece feeding rail, a ball feeding rail, clamps, a motor, an assembly output rail and a rotating workbench. The motor intermittently drives the rotating workbench to rotate, and the assembling task of workpieces and balls is completed through the motion of air cylinder push rods at four work positions. According to the ball assembling device, the aim of ball assembling is achieved through the simple movement cooperation of air cylinders and the rotating workbench, the structure is simple, operation is convenient, the needed labor cost is greatly lowered, the assembling efficiency is improved, and the rejection rate is reduced. Meanwhile, the assembling flexibility and stability are improved.

Owner:HOHAI UNIV CHANGZHOU

New energy automobile part assembling facility

InactiveCN112846749AAchieve clampingAchieve positioningHollow article cleaningMetal working apparatusNew energySurface cleaning

The invention discloses a new energy automobile part assembling facility, and particularly relates to the technical field of automobile parts. The facility comprises a machine frame, wherein a discharging opening is formed in one side of the middle of the machine frame, cleaning and heating mechanisms are arranged on the two sides of the middle of the top of the machine frame, clamping mechanisms are arranged on the same sides of the two cleaning and heating mechanisms, and a first material barrel is arranged on the sides, far away from the cleaning and heating mechanisms, of the two clamping mechanisms. According to the facility, two semi-cylindrical cleaning brushes and two semi-high-frequency induction heating coils can be combined through rotation of two arc-shaped racks towards the middle, so that the purposes of cleaning the surface of a hole piece and increasing the hole diameter through high-frequency induction heating are achieved; the purpose of clamping and positioning the hole piece is achieved through the combination of two semi-cylindrical clamping blocks, and the purpose that a rear push column pushes a shaft piece to enter an inner hole of the hole piece to achieve assembly is achieved; and the two semi-cylindrical clamping blocks can be automatically separated, and therefore the purpose of automatic discharging is achieved.

Owner:李为

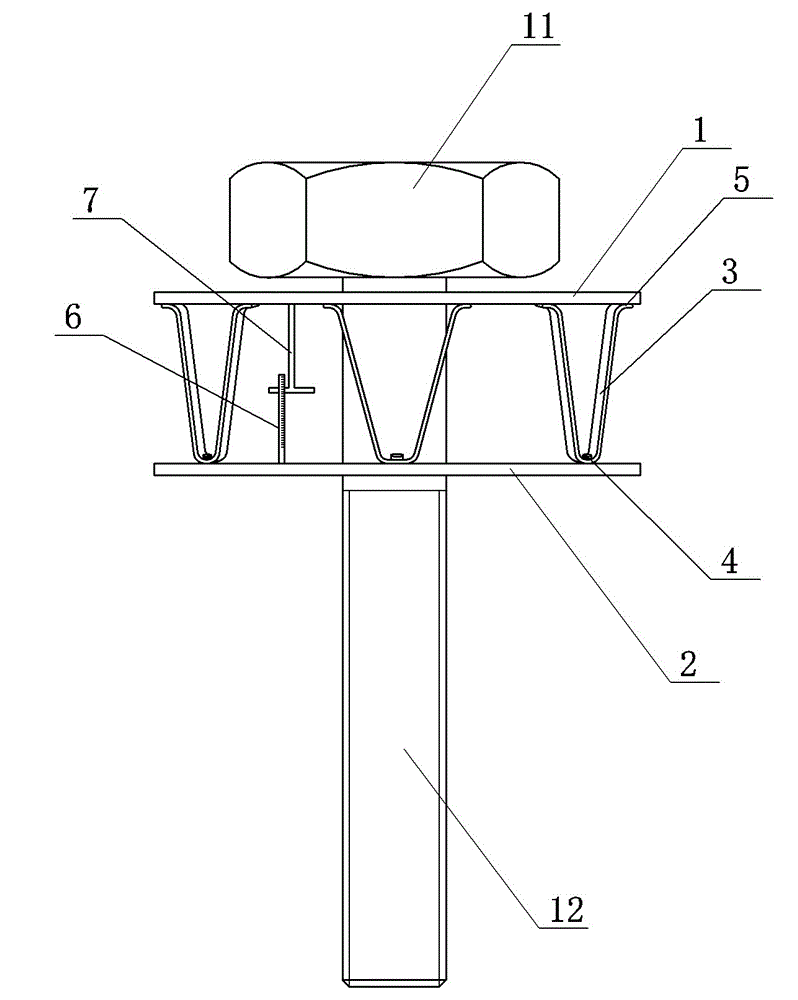

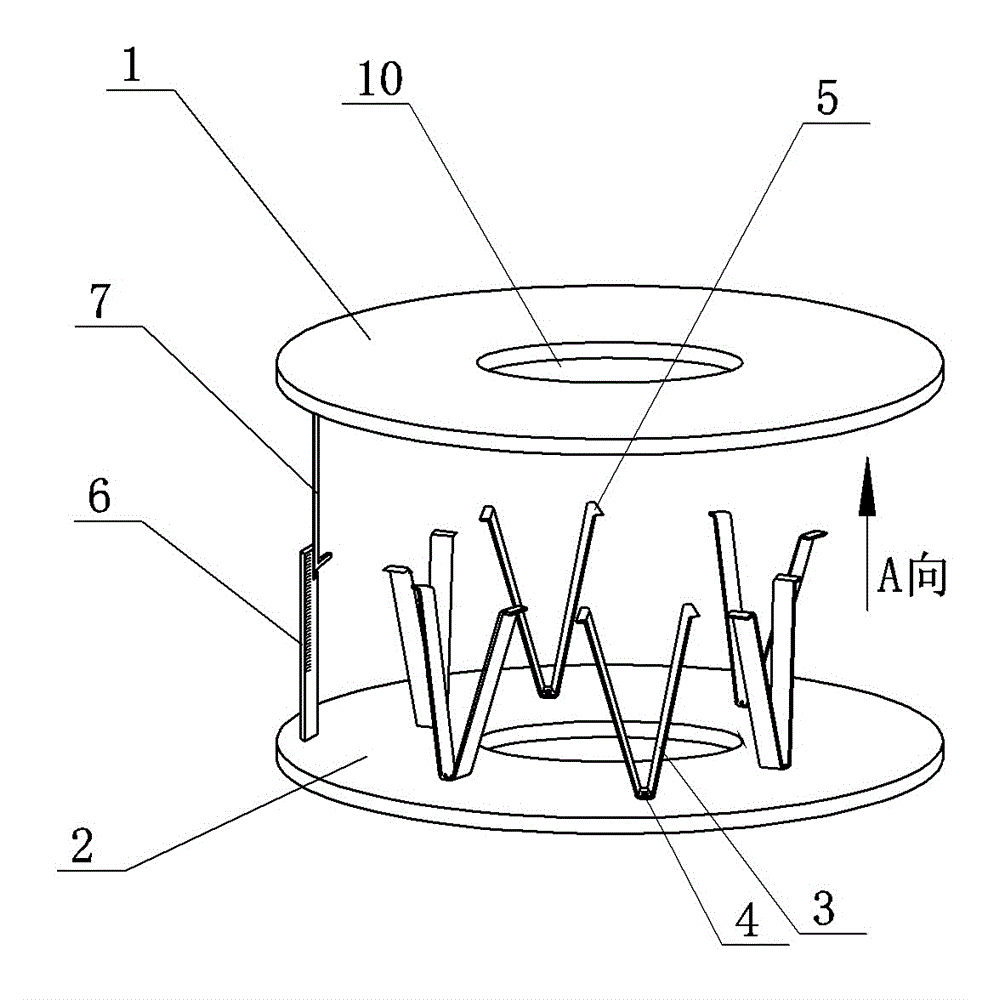

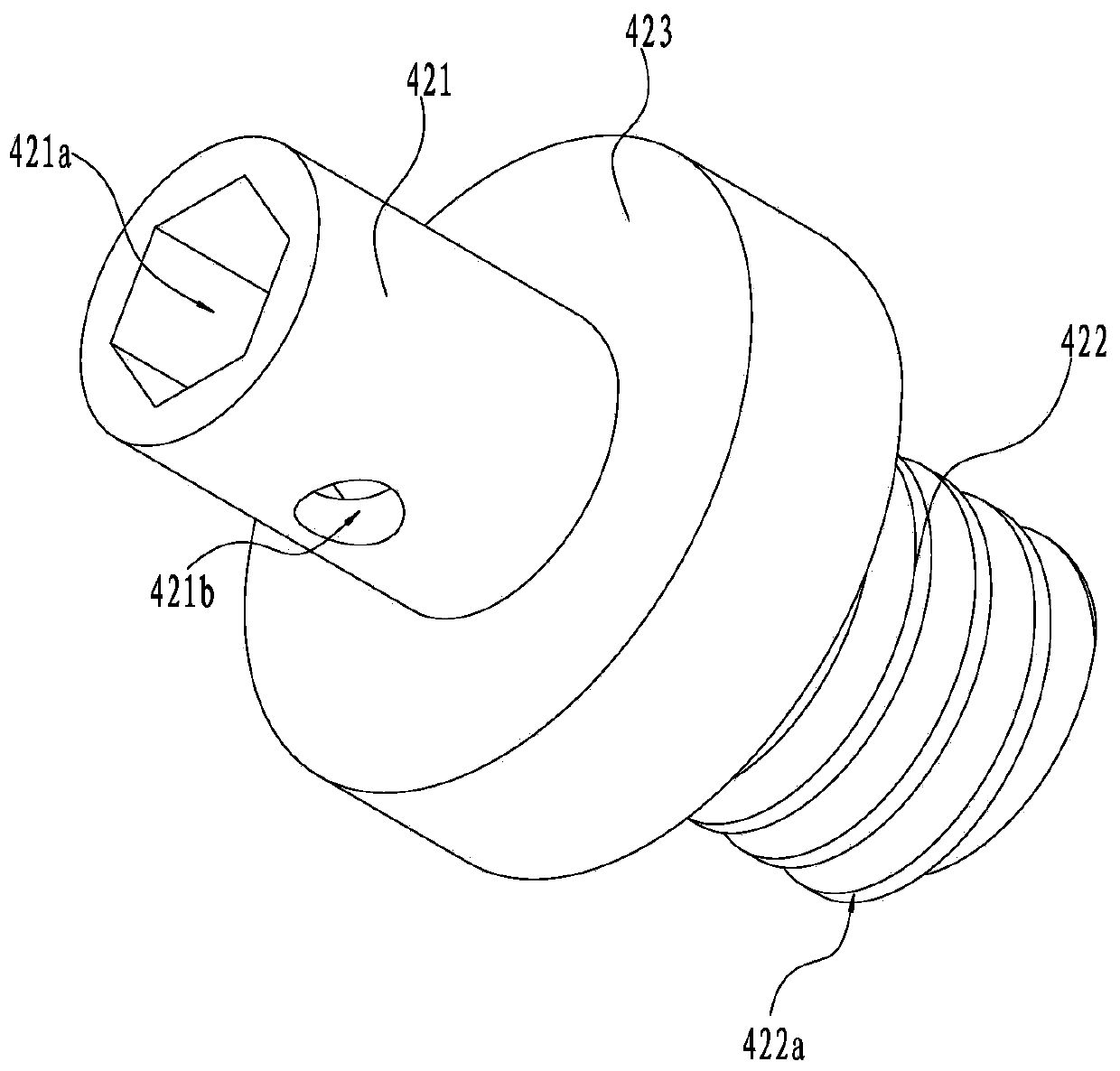

Fixed-torque gasket

The invention discloses a fixed-torque gasket. The fixed-torque gasket comprises an upper gasket and a lower gasket, wherein a plurality of symmetrical elastic bodies are fixedly distributed around the center hole of the lower gasket; the upper end of each symmetrical elastic body is in sliding fit with the inner surface of the upper gasket; a positioning mechanism for determining the distance between the two gaskets is arranged between the upper gasket and the lower gasket. The distance between the upper gasket and the lower gasket can be determined through the positioning mechanism, and the elastic compression amount between the upper gasket and the lower gasket can be determined after the determination of the distance, so that the aim of assembling under a specific torque condition is fulfilled. The fixed-torque gasket is reasonable in structural design, is easy to implement, is particularly suitable for fixed-torque bolt installation in narrow regions with a very good effect, and is suitable for popularization and application. The current compulsory fixed-torque tool can be replaced after the fixed-torque gasket is put into use, and the working cost is reduced; the additional workload is relieved, and the working efficiency is increased.

Owner:HENAN POLYTECHNIC UNIV

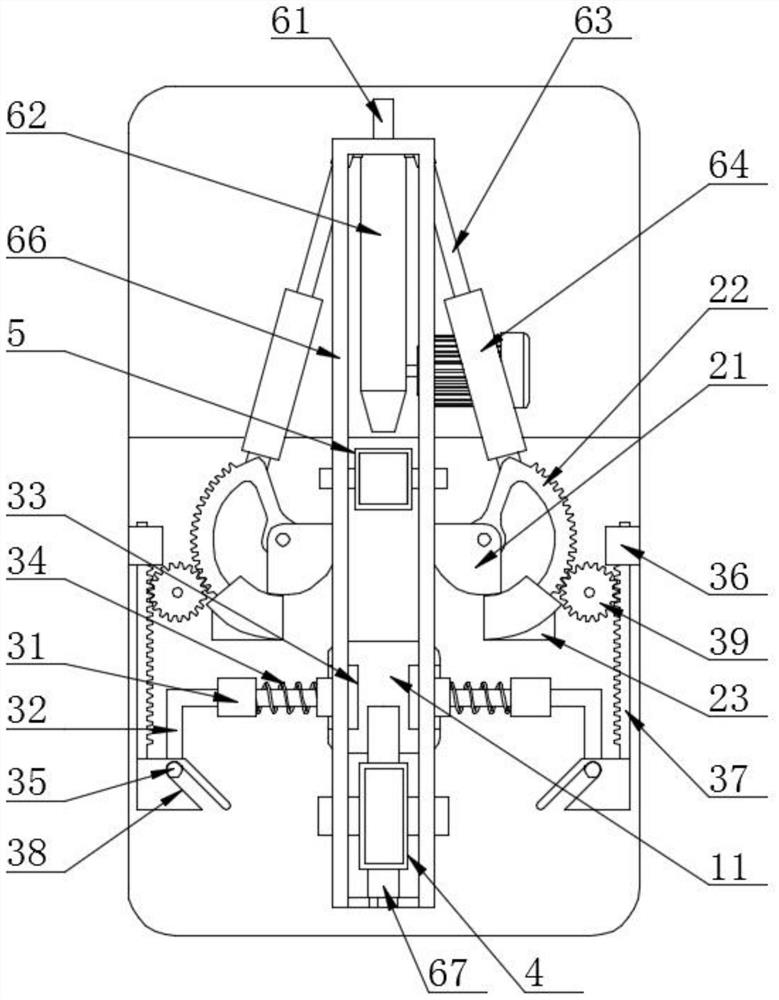

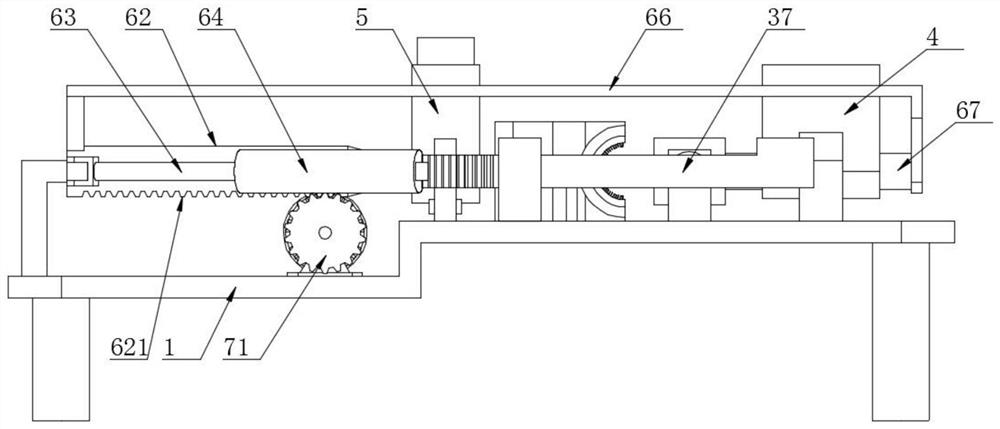

Ball valve assembly device in manufacturing industry

PendingCN112372271ATo achieve the purpose of assemblyImprove efficiencyMetal working apparatusElectric machineryManufacturing sector

The invention relates to an assembly device, in particular to a ball valve assembly device in manufacturing industry. The ball valve assembly device in the manufacturing industry has the advantages that the efficiency is improved, the assembly quality is uniform, and the assembly speed is increased. The ball valve assembly device in the manufacturing industry comprises a base below which a collecting frame is arranged, a first bracket connected with one side of the top of the base, a knocking mechanism connected between the tops of the first bracket and the base, and a moving mechanism connected between the base and the knocking mechanism. Through cooperation of a motor, a rotating shaft, missing teeth and a knocking rod, the purpose of assembling a ball valve is achieved, and the efficiency is improved; through cooperation of a transmission assembly, a roller, a mounting plate and a rotating block, the purpose of automatic operation is achieved; and the assembly speed is increased.

Owner:邹福明

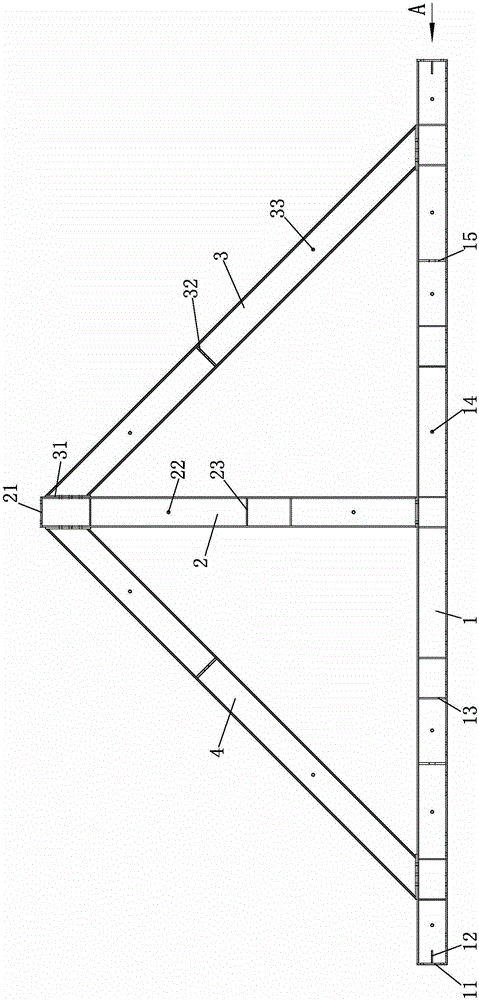

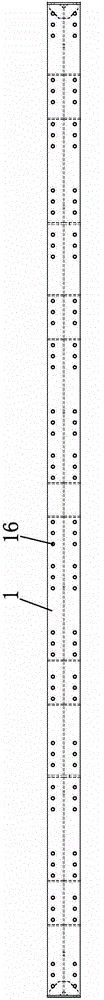

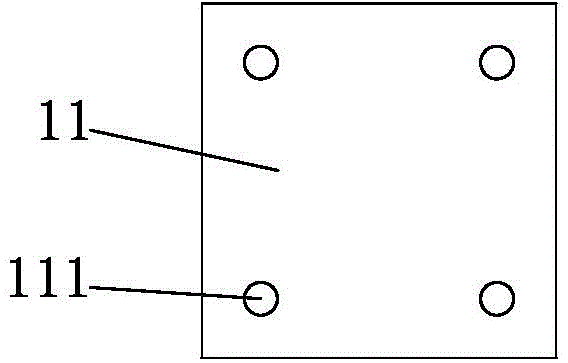

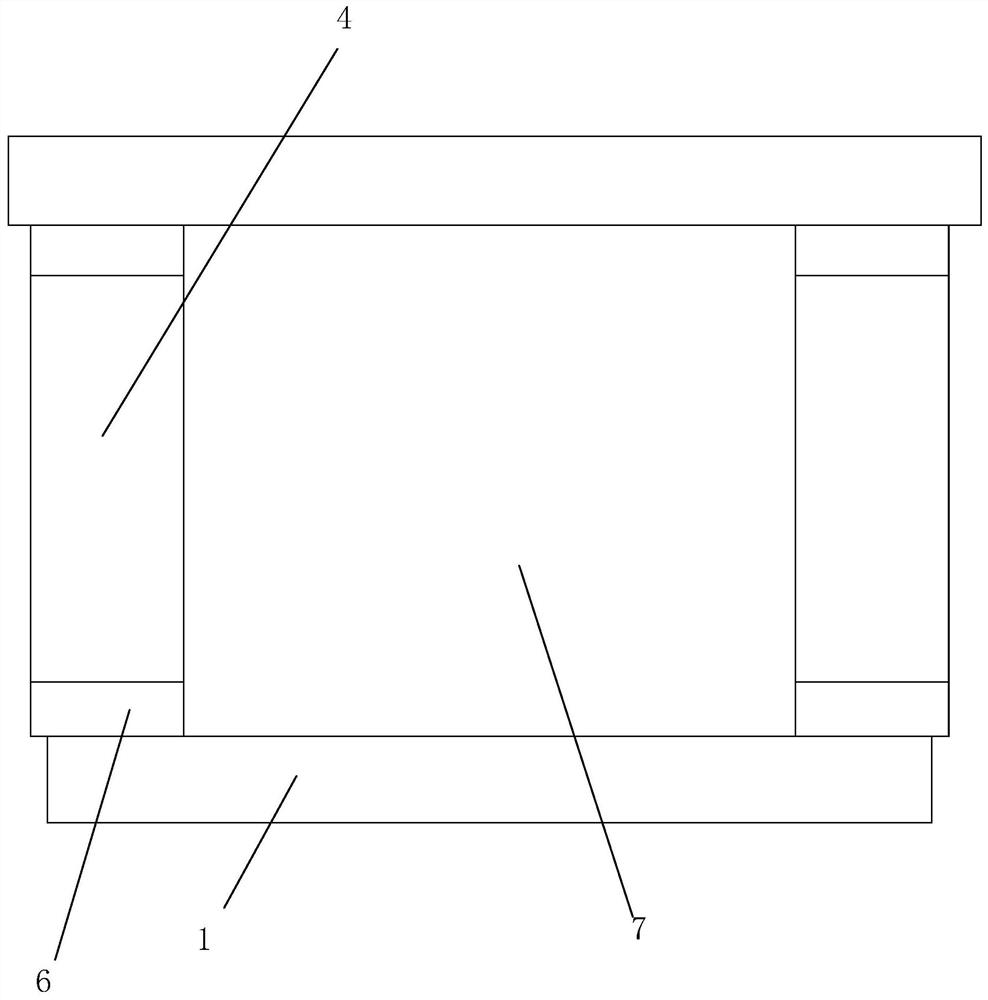

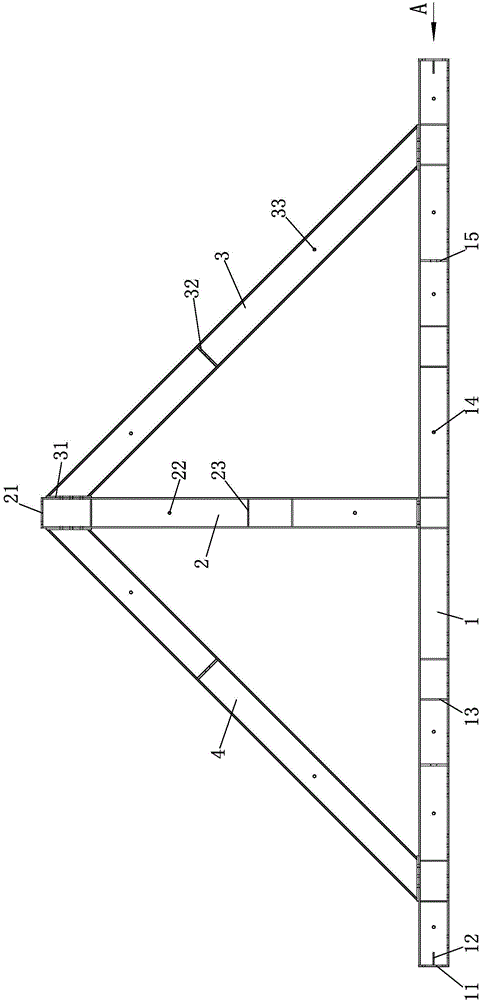

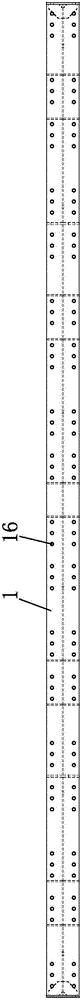

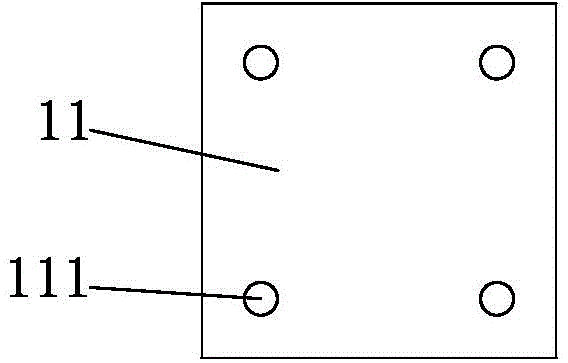

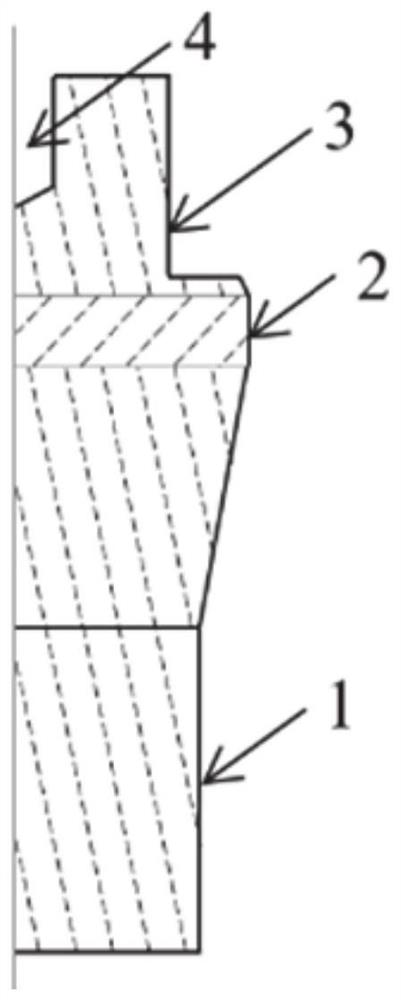

Fish-belly beam components of the inner support system of foundation pit support

ActiveCN103437362BTo achieve the purpose of assemblyFulfilling Assembly RequirementsExcavationsSupporting systemBolt connection

The invention discloses a fish belly sill part of a foundation pit support inner supporting system. The fish belly sill part comprises a lower chord beam part made of H-type steel, a belly rod part and inclined supporting parts. The two ends of the lower chord beam part are fixedly and respectively provided with a square flange plate, reinforcing plates, lug plates and drainage holes are formed in grooves in the two sides of the lower chord beam part, and a plurality of connecting holes are formed in an outer wing plate. The two ends of the belly rod part are respectively provided with a square flange plate in a welded mode, one end of the belly rod part is connected with an inner wing plate of the lower chord beam part through a bolt, and reinforcing plates and drainage holes are formed in grooves in the two sides of the belly rod part. Two end faces of each inclined supporting part are 45-degree inclined faces and are connected with rectangular flange plates in a welded mode, one end of each inclined supporting part is connected with the belly rod part through a bolt, the other end of each inclined supporting part is connected with the lower chord beam part through a bolt, lug plates and drainage holes are formed in grooves in the two sides of each inclined supporting part, and the two inclined supporting parts are symmetrically arranged on the two sides of the belly rod part respectively. The lower chord beam part, the belly rod part and the belly plates made of H-type steel of the inclined supporting parts are located in the same plane. According to the technical scheme, the fish belly sill part is convenient to assemble and disassemble and can be used repeatedly, and the aims of saving construction cost and facilitating construction are achieved.

Owner:杭州爱默乐实验设备有限公司

Assembled building structural system and construction method

ActiveCN111779139AEasy to transportTo achieve the purpose of assemblyBuilding constructionsArchitectural engineeringMechanical engineering

The invention relates to an assembled building structural system and a construction method. The system comprises a base plate. A plurality of clamping blocks are arranged on the upper side of the baseplate, the clamping blocks are located on the circumference of the base plate, the base plate is in clamping connection to column bodies through the clamping blocks, first connecting rings are connected in the middle parts of the column bodies in a sleeving manner, a first coaming is connected integrally between adjacent first connecting rings, the column bodies are connected to second connectingrings located on the upper and lower sides of the first coaming in a sleeving manner, a second coaming is connected among the second connecting plates, two cantboards are integrally connected to twosides of the upper ends of the column bodies, the cantboards are obliquely arranged relative to the column bodies, and a top cover in clamping connection to the cantboards is arranged above the columnbodies.

Owner:浙江正立高科建设有限公司

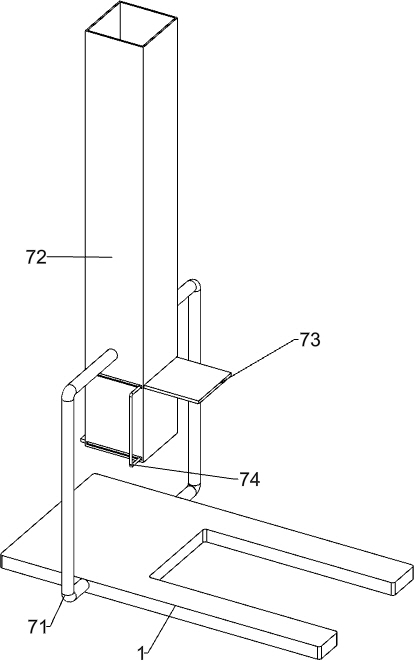

A processing equipment for circulation parts of automobile shock absorber

ActiveCN112059610BImprove assembly work efficiencyTo achieve the purpose of assemblyAssembly machinesMetal working apparatusEngineeringWorkbench

The invention relates to the technical field of automatic assembly of auto parts, in particular to a processing equipment for circulation parts of automobile shock absorbers, including: a workbench; Set on the workbench, the circumferential surface of the rotating disk is evenly distributed along the axis for clamping ribs and half-moon grooves; the synchronous belt conveyor is horizontally arranged at the bottom of the stepping and rotating conveying assembly along the radial direction of the stepping and rotating conveying assembly; The semicircle limit ring is coaxially arranged on the outer edge of the stepping rotary conveying assembly; the first rotary charging mechanism and the second rotary charging mechanism, the charging mechanisms are sequentially arranged at the semicircular limit along the conveying direction of the stepping rotary conveying assembly The outer edge of the ring; the riveting mechanism, the working end is vertically facing the feeding end of the spring feeding mechanism and is arranged outside the workbench; the spring feeding mechanism and the valve plate feeding mechanism are respectively arranged on the first rotary charging mechanism and the second Two rotary charging mechanism, the device has high working efficiency and precision.

Owner:宁波云帆新能源科技有限公司

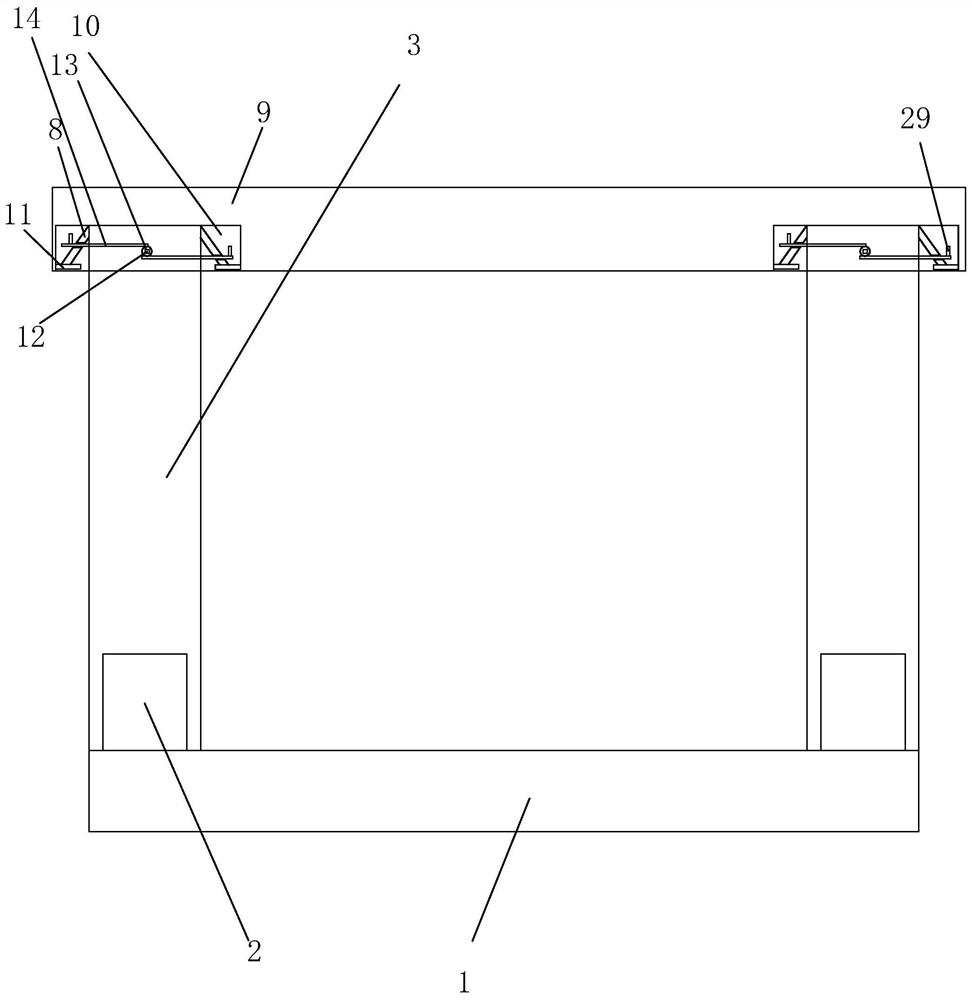

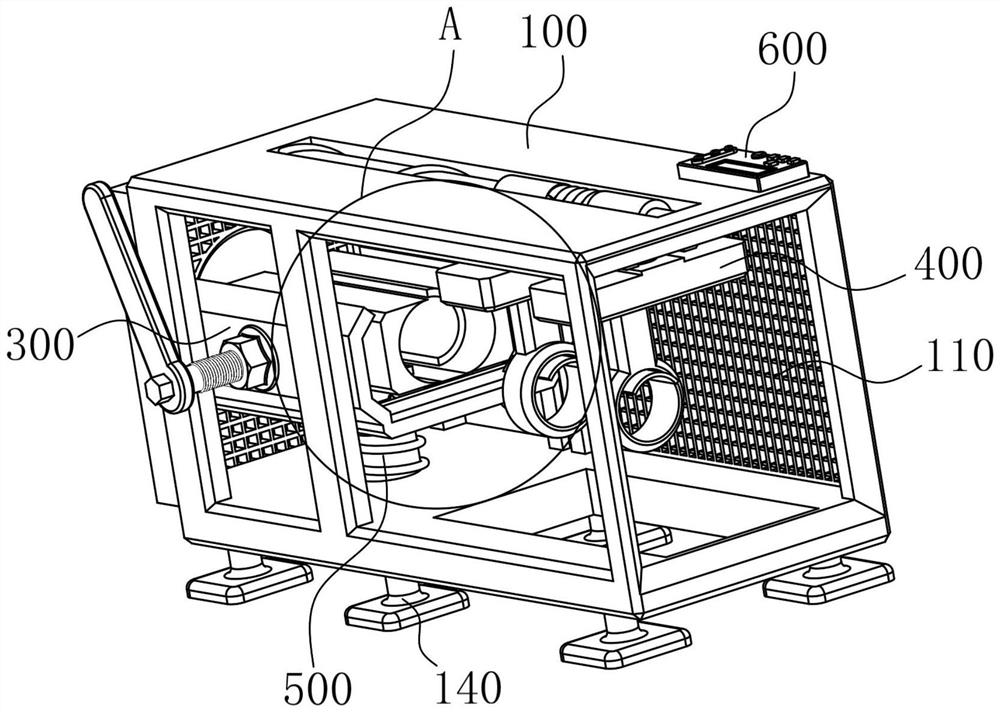

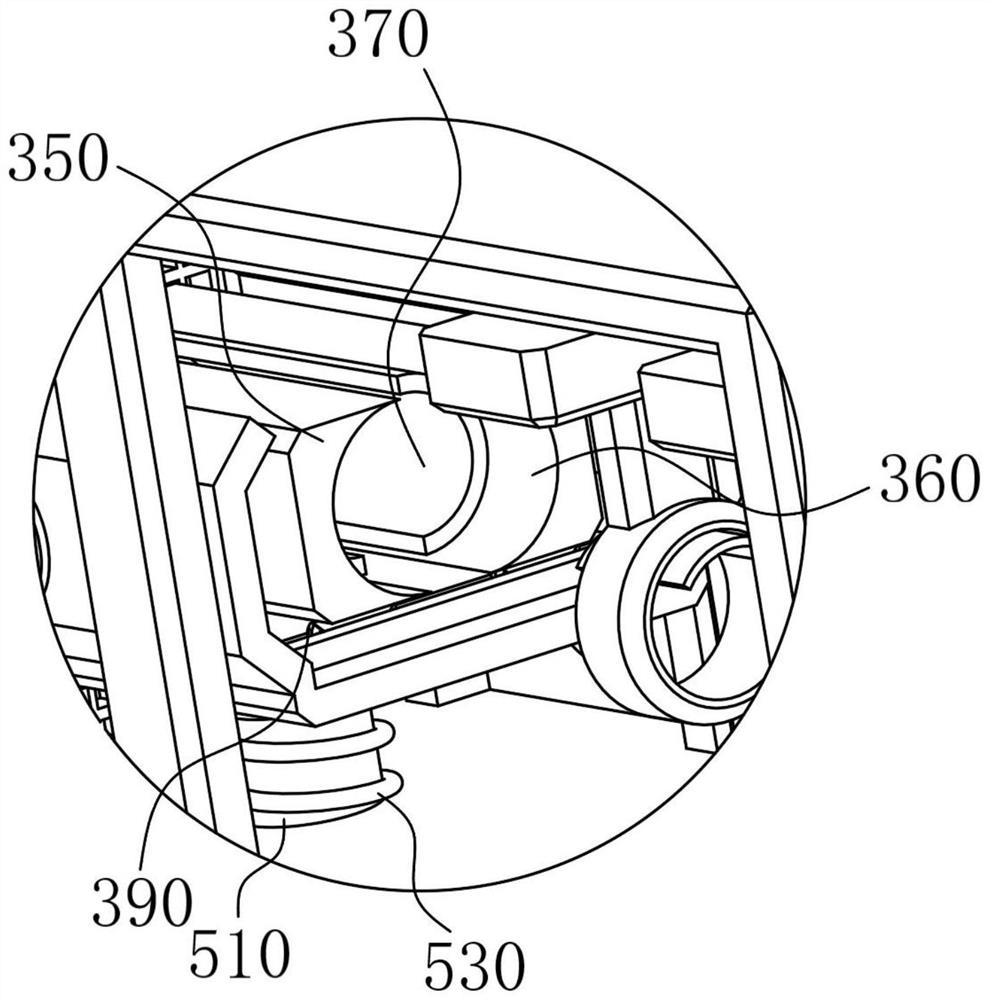

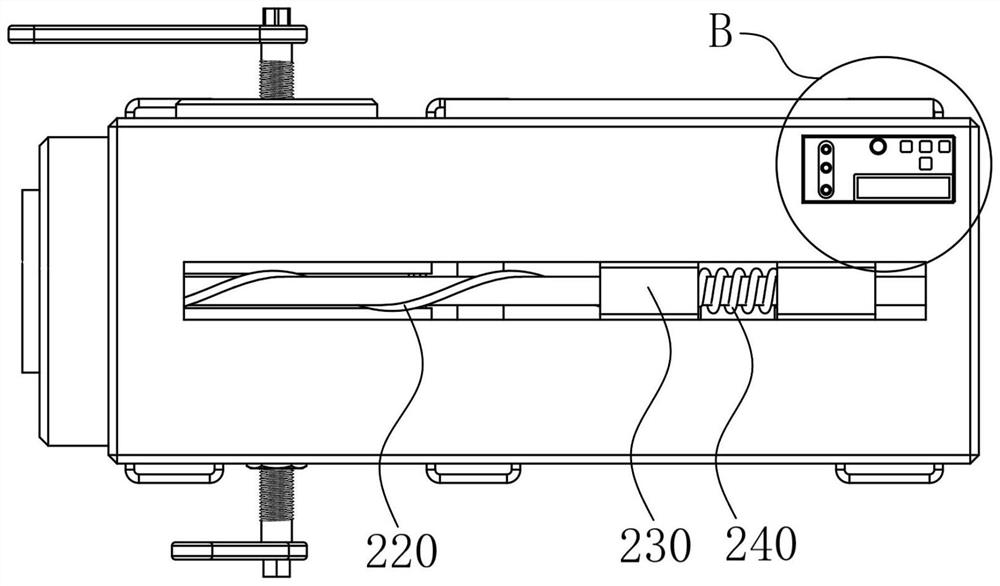

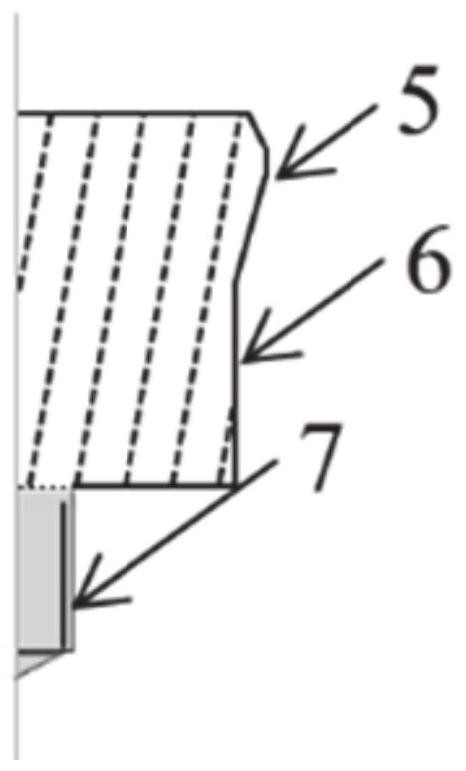

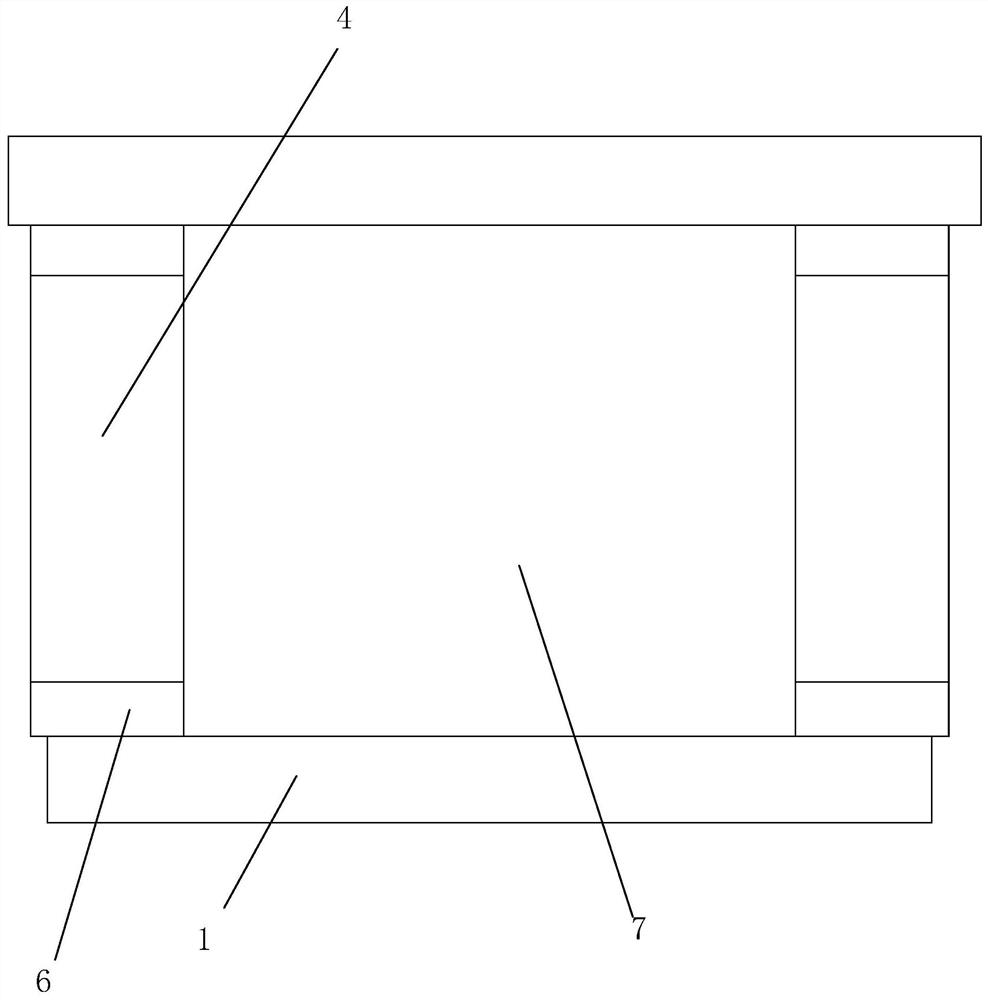

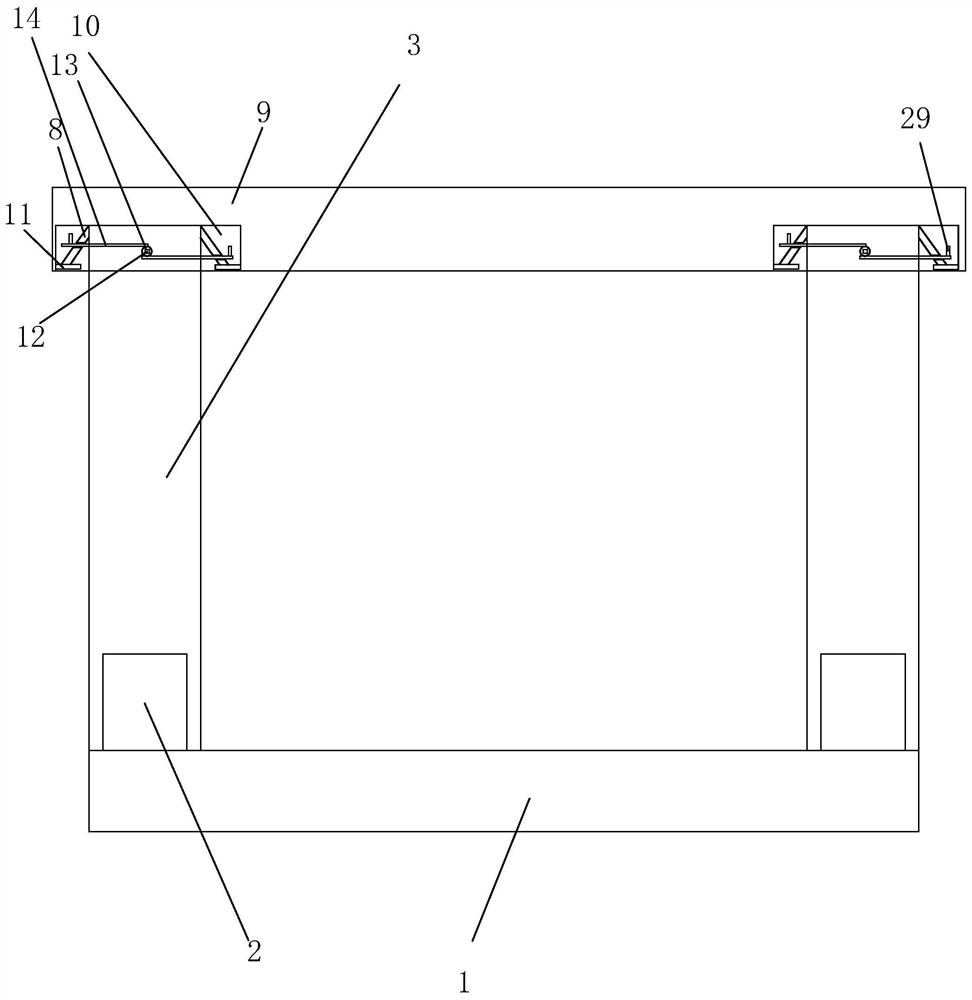

Hydraulic oil cylinder barrel and piston rod assembling device

InactiveCN112658632APrecise positioningSave human effortMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of cylinder barrel and piston rod assembling, in particular to a hydraulic oil cylinder barrel and piston rod assembling device. The hydraulic oil cylinder barrel and piston rod assembling device comprises a main framework, a transmission device, a fastening device, a guiding and positioning device, a lifting device and a control console. The main framework comprise a main framework body. The guiding and positioning device comprises guiders, guiding shafts, guiding rods, rod body fixing sleeves and connecting columns, the connecting columns mainly play a role in connection, one end of each guider is connected with the lower surface of the corresponding connecting column respectively, the guiders play a role in connecting the guiding shafts, and a rectangular mounting groove is formed in one surface of each guider. The guiding shafts are connected with the rectangular mounting grooves respectively and mainly connected with the guiders, the guiding rods are in sliding fit with the guiding shafts respectively, and one end of each rod body fixing sleeve is welded to the lower surface of the corresponding guiding rod respectively. The positions of an oil cylinder barrel and a piston rod are controlled through the fastening device and the guiding and positioning device, and the purpose of accurate positioning during assembling is achieved.

Owner:娄底鼎力液压科技有限公司

A processing method for face-to-face modification of worm gear tooth surface

ActiveCN104259581BSolve the requirements of face-to-face modificationTo achieve the purpose of assemblyWorm wheelsMachine indexingMilling cutter

Owner:ANSTEEL HEAVY MACHINERY CO LTD

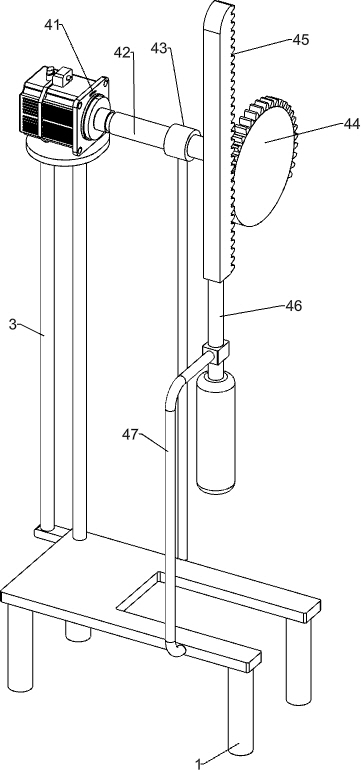

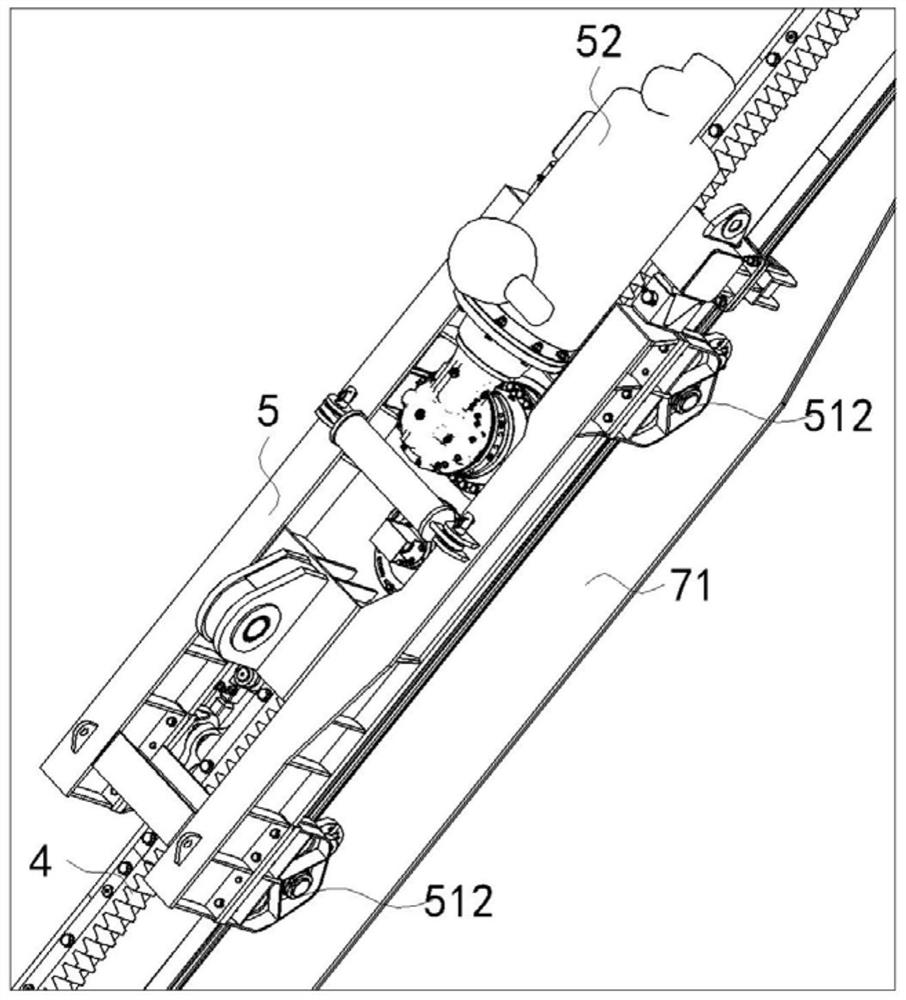

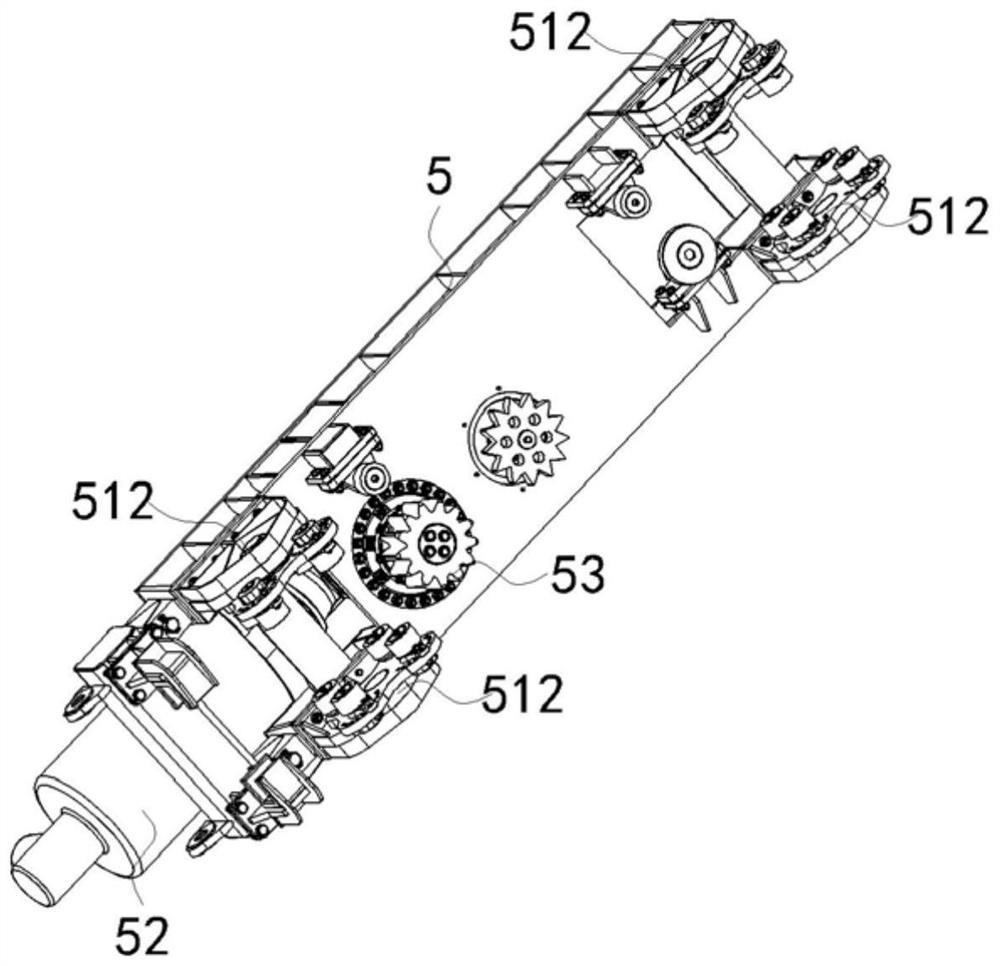

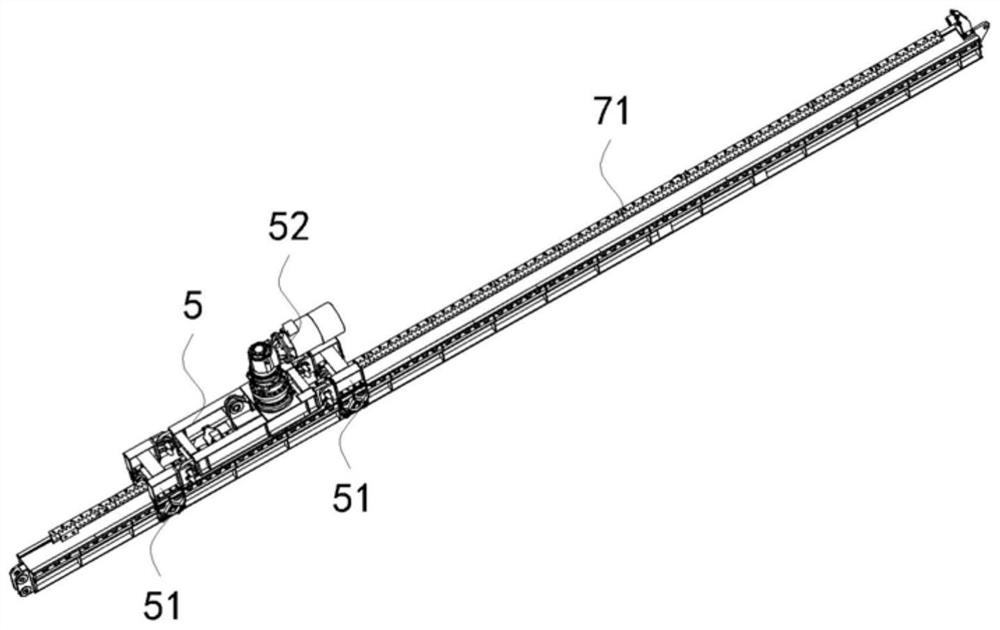

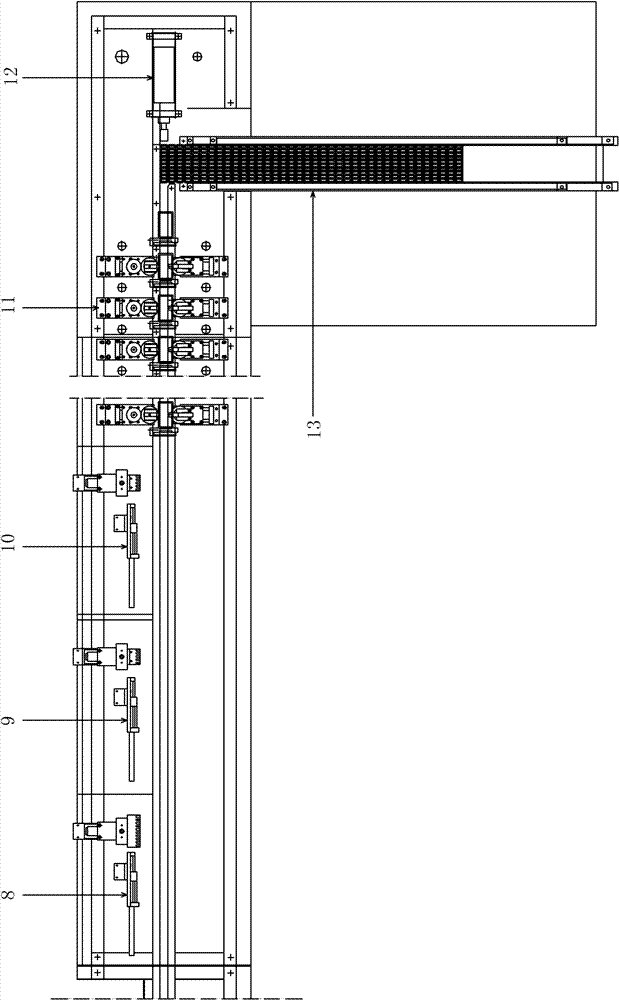

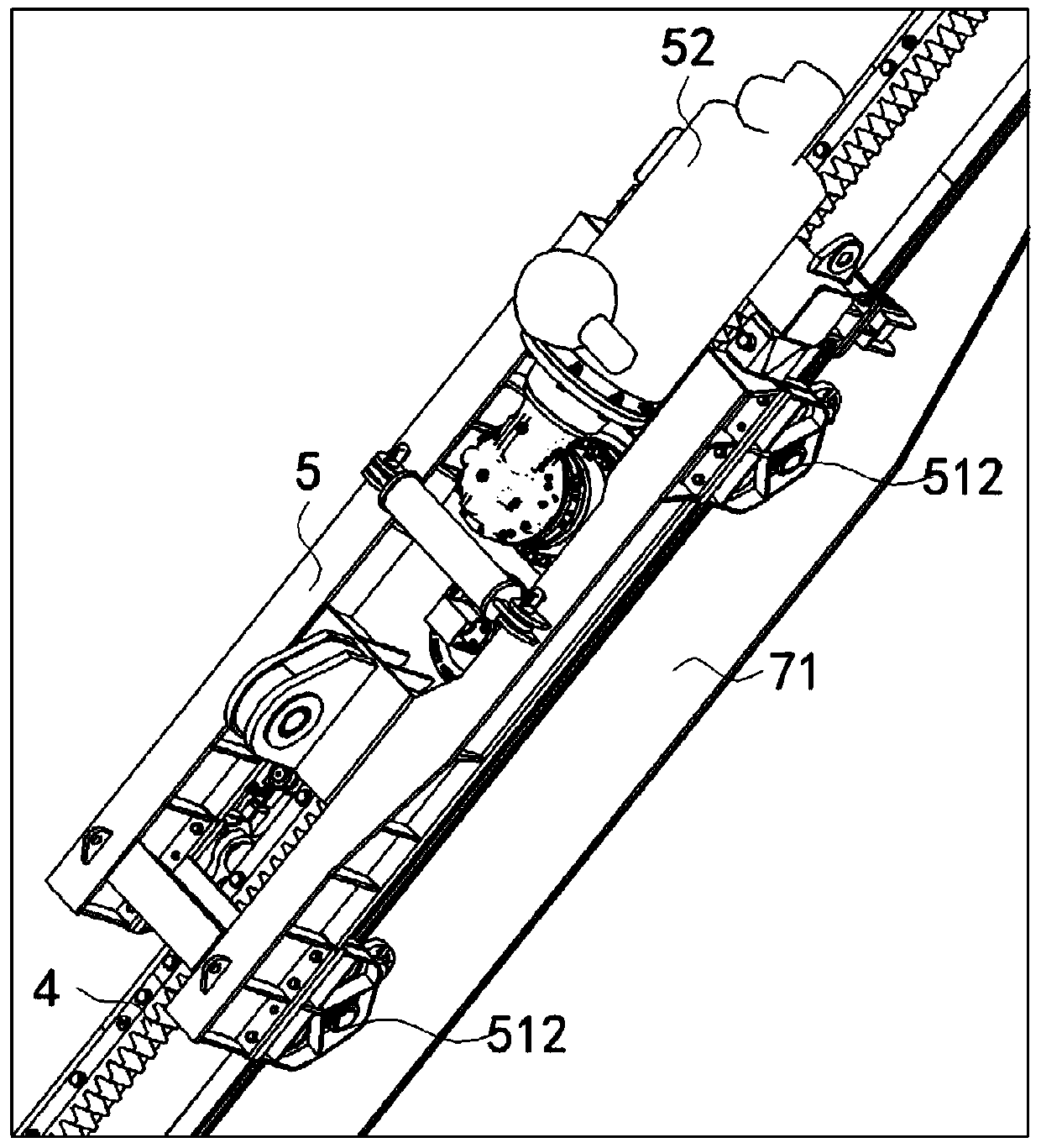

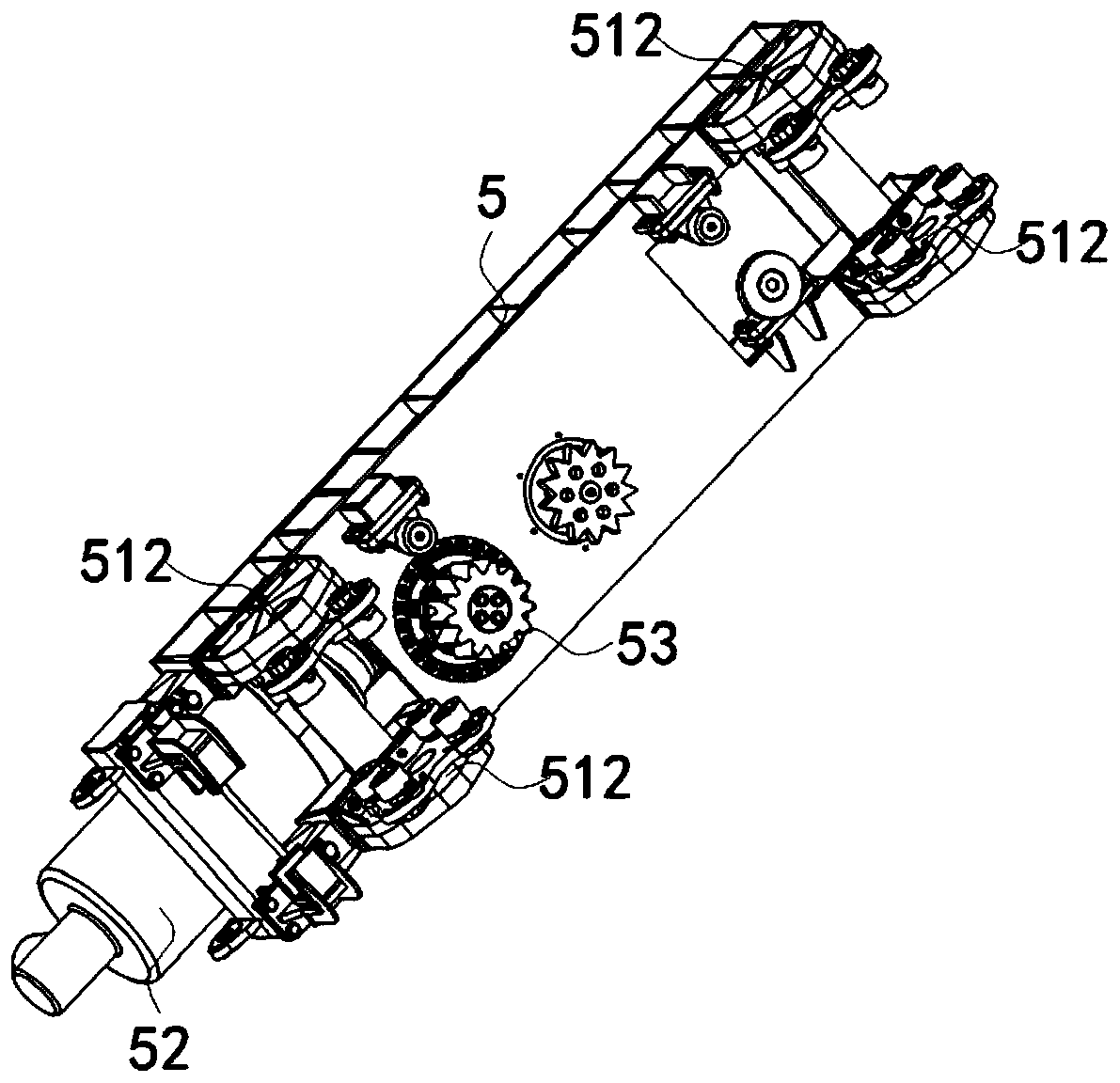

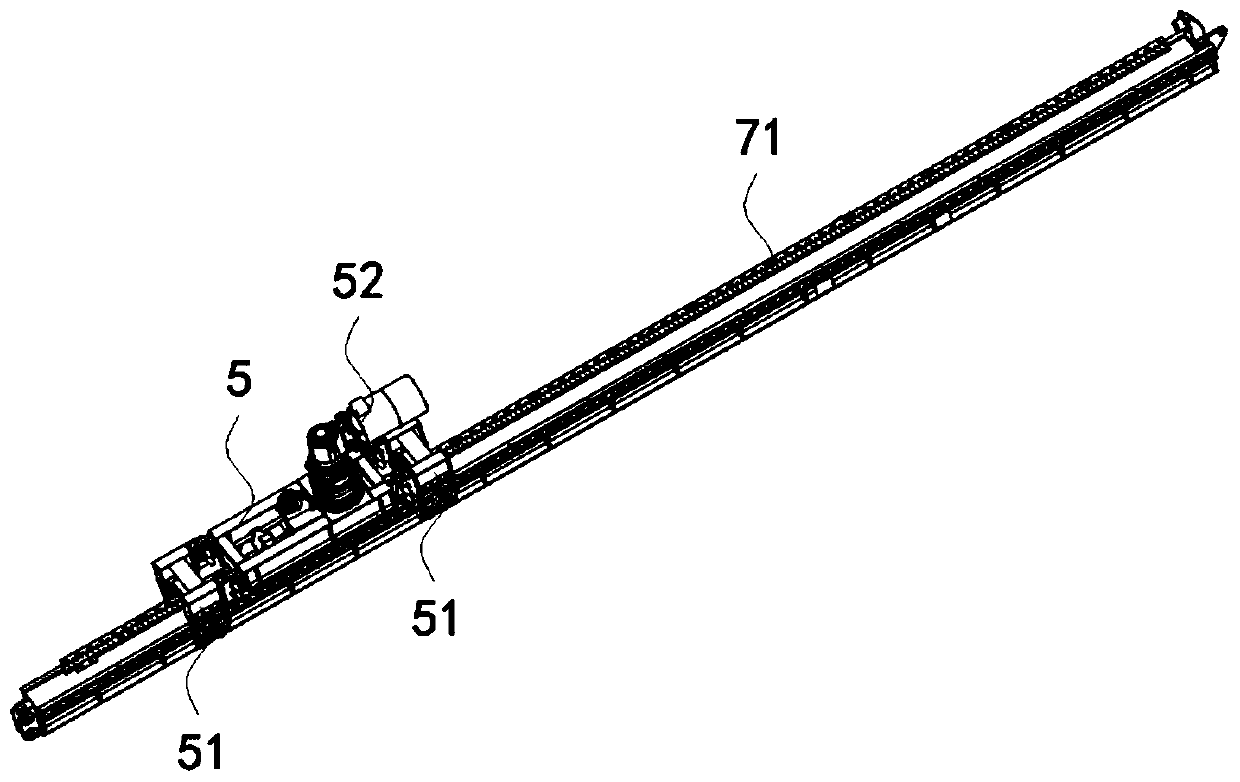

Assembly method and structure of pulley guide rail and its power catwalk

ActiveCN111502562BReduce difficultyImprove assembly efficiencyDrilling rodsDrilling casingsGear wheelTraveling block

The invention discloses an assembly method and structure of a pulley guide rail and a power catwalk, belonging to the technical field of power catwalks. A method for assembling a pulley guide rail of the present invention includes the following steps: S1: place the pulley on the top of the guide rail assembly, and the gears assembled at the bottom of the pulley engage with the rack on the top of the guide rail assembly; S2: slide the roller disc unit The clips are embedded on both sides of the guide rail assembly; S3: On the guide rail assembly, the pulley and the roller disc unit are connected by connecting pieces to form an integral structure. When the invention is adopted, the pulley and the roller disc unit are mutually independent structures, and there is no mutual restriction between the installation action of the pulley and the installation action of the roller disc unit, so that the action process of the pulley being installed on the guide rail assembly and the The action process of installing the roller disc unit on the guide rail assembly becomes simple and easy, which reduces the difficulty of the assembly process of the pulley guide rail, improves the assembly efficiency, and achieves the purpose of assembly.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

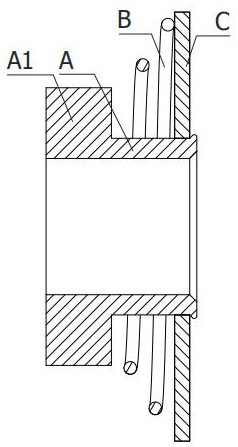

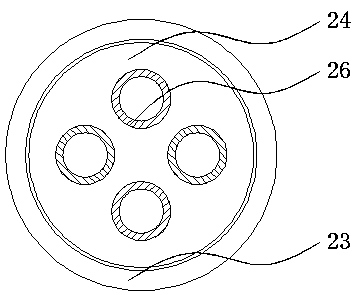

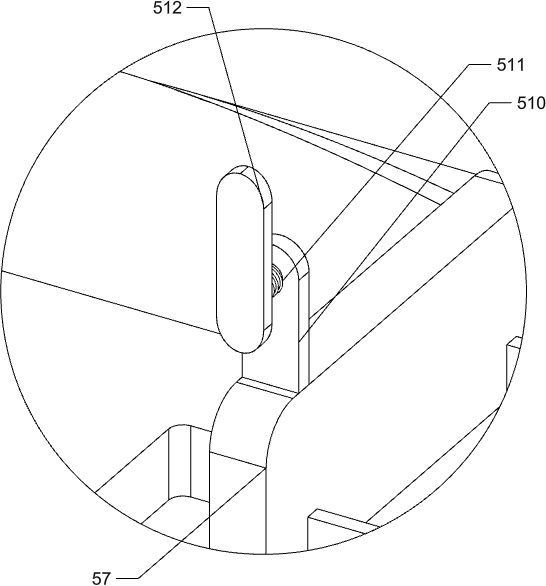

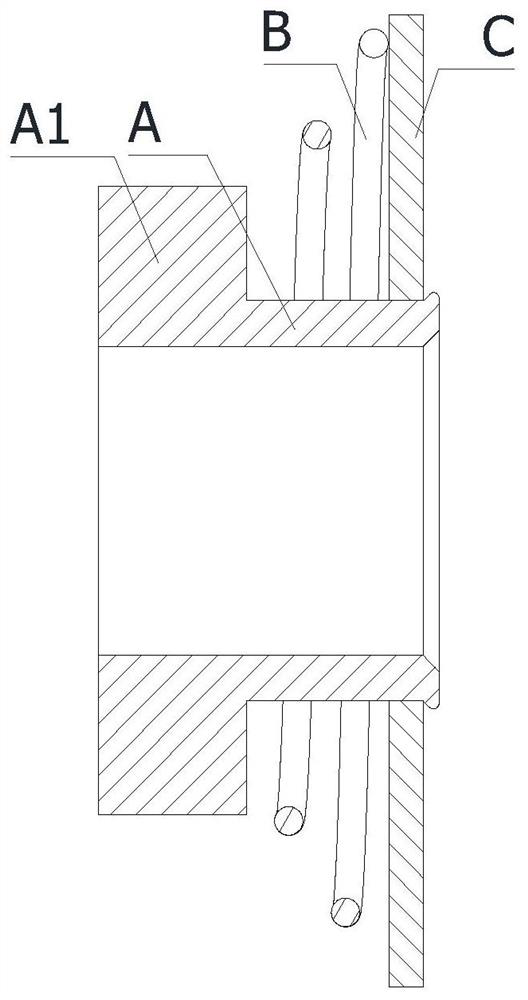

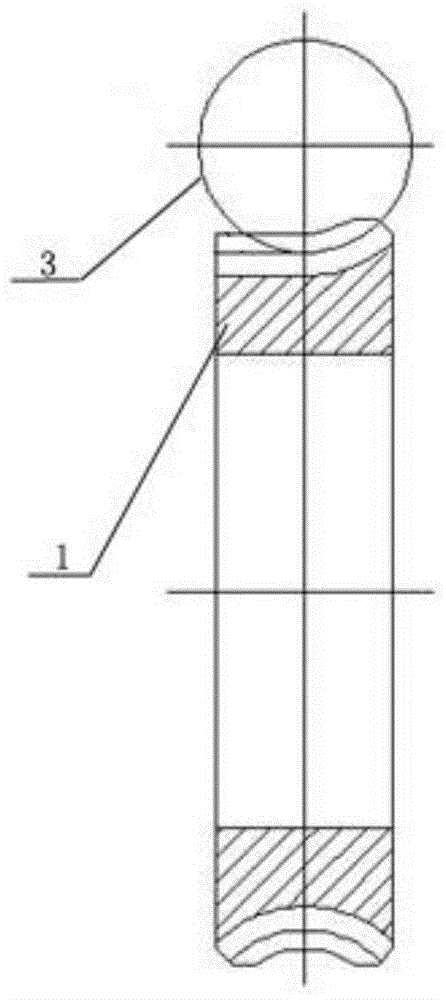

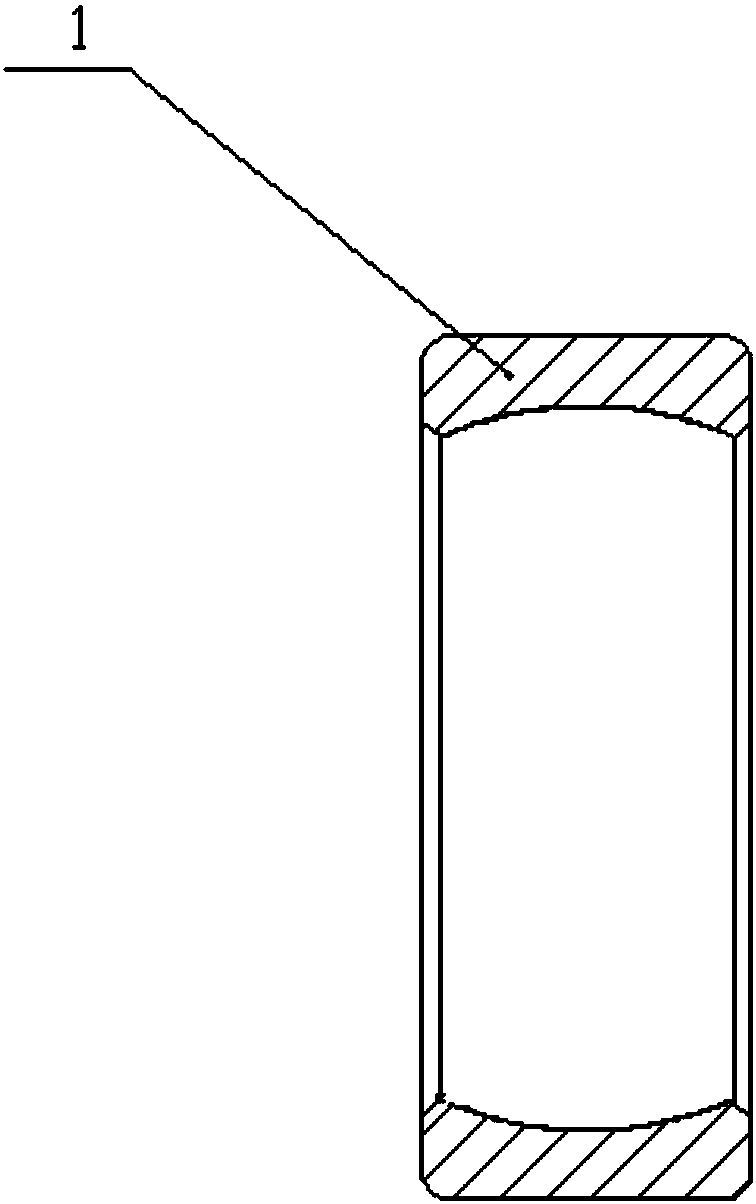

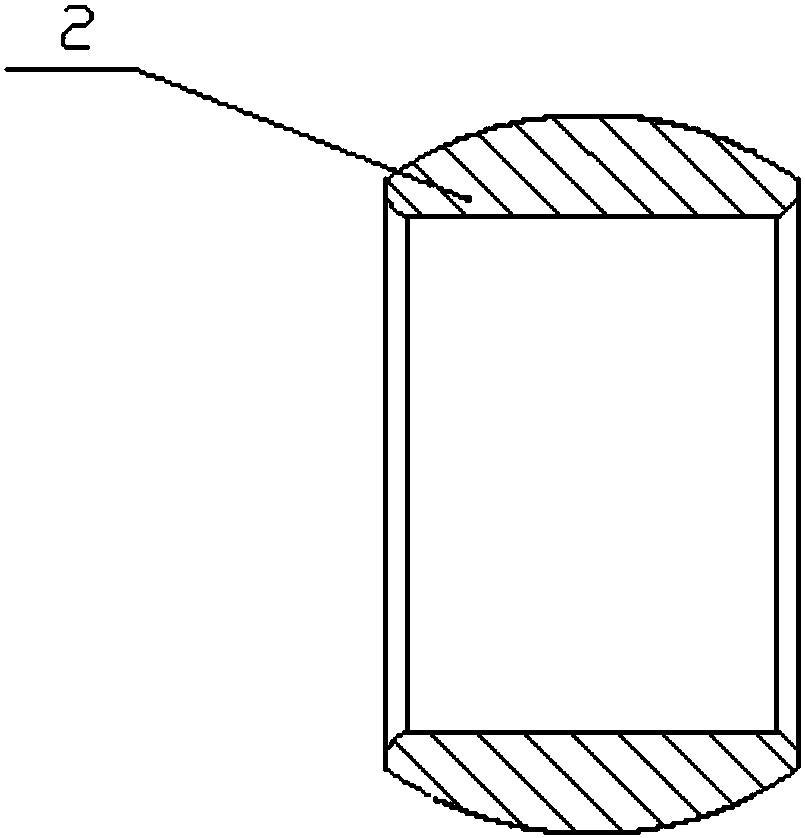

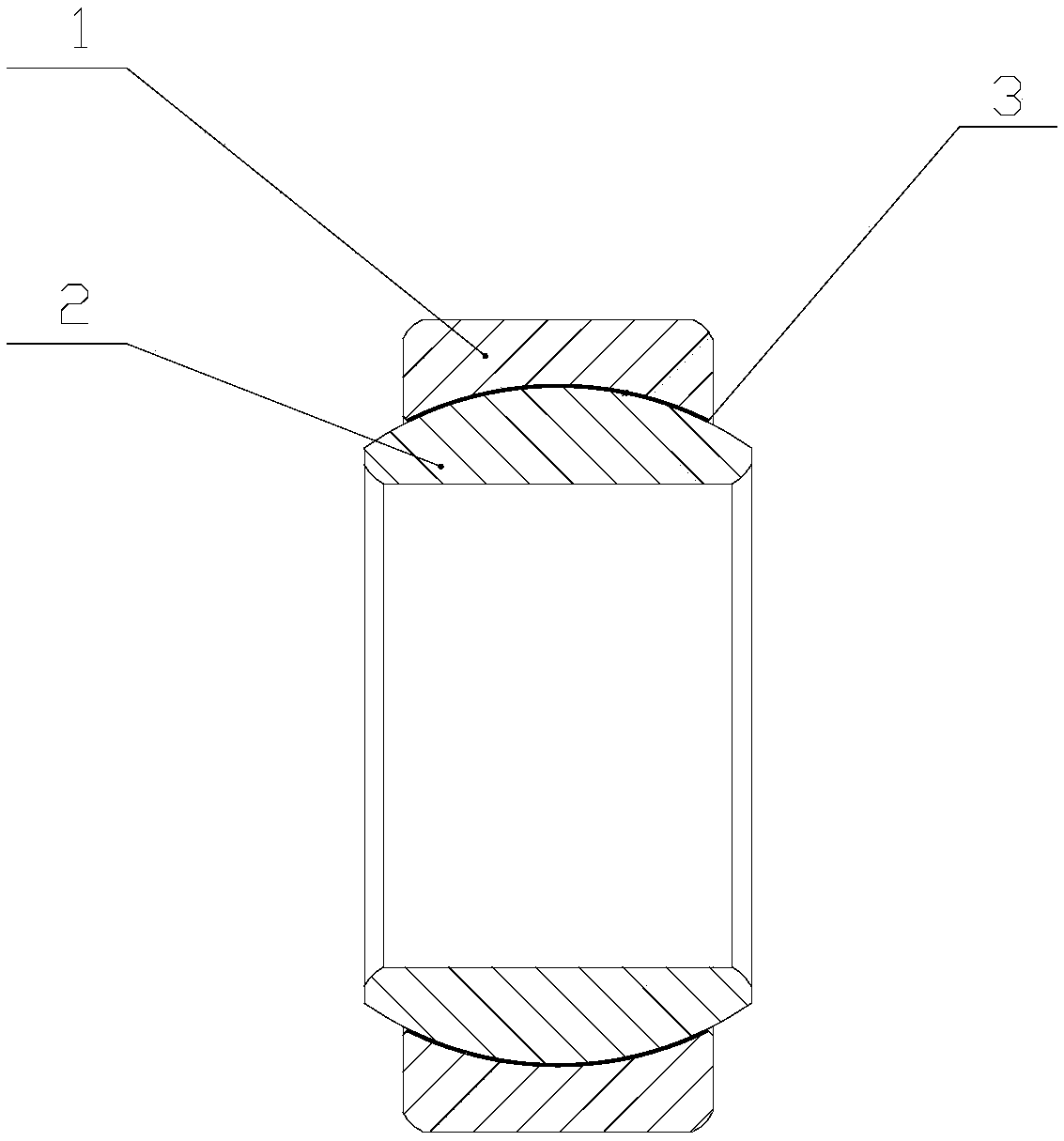

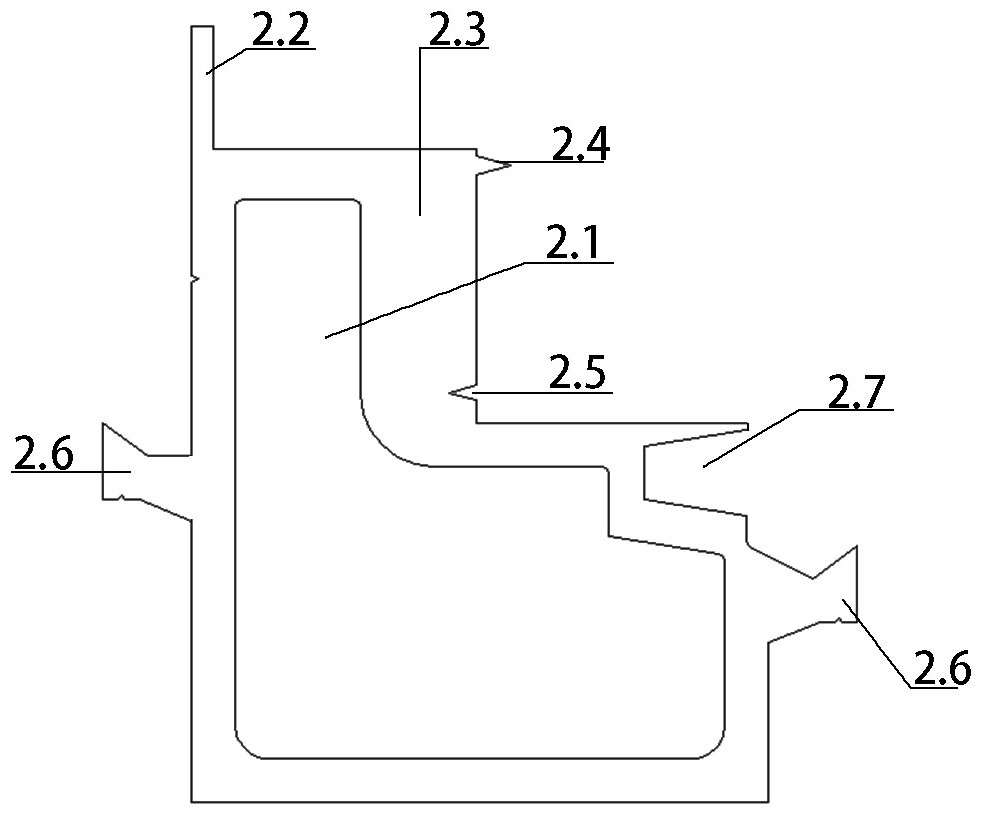

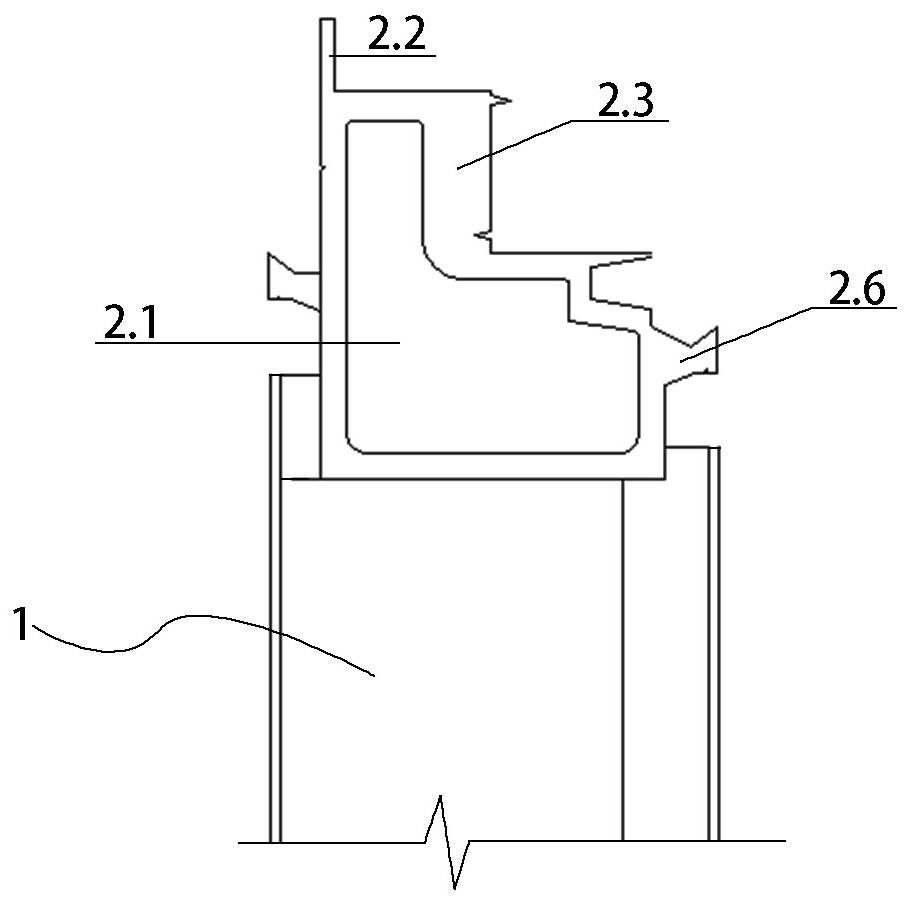

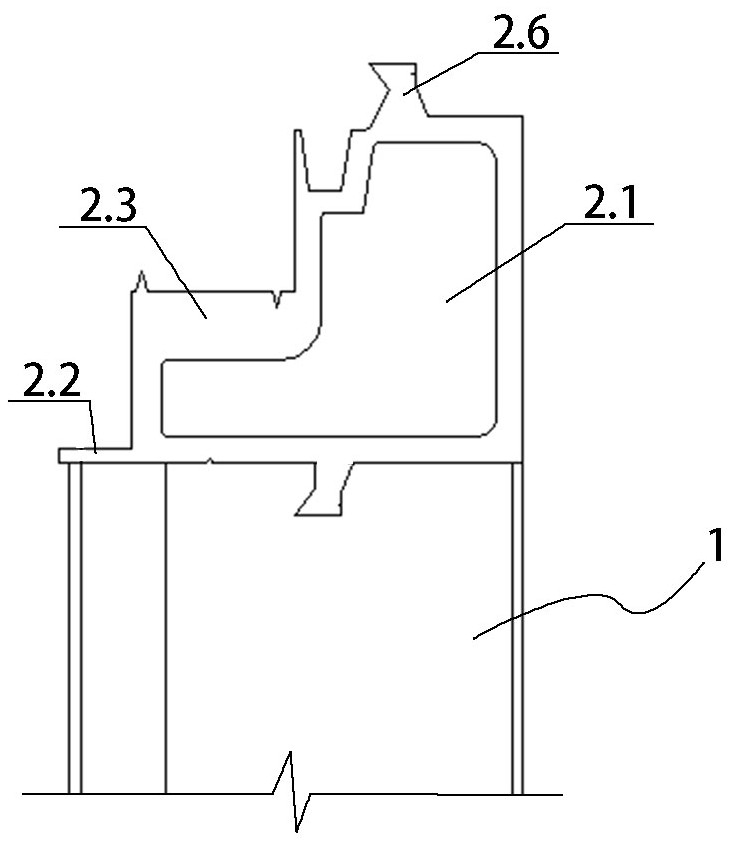

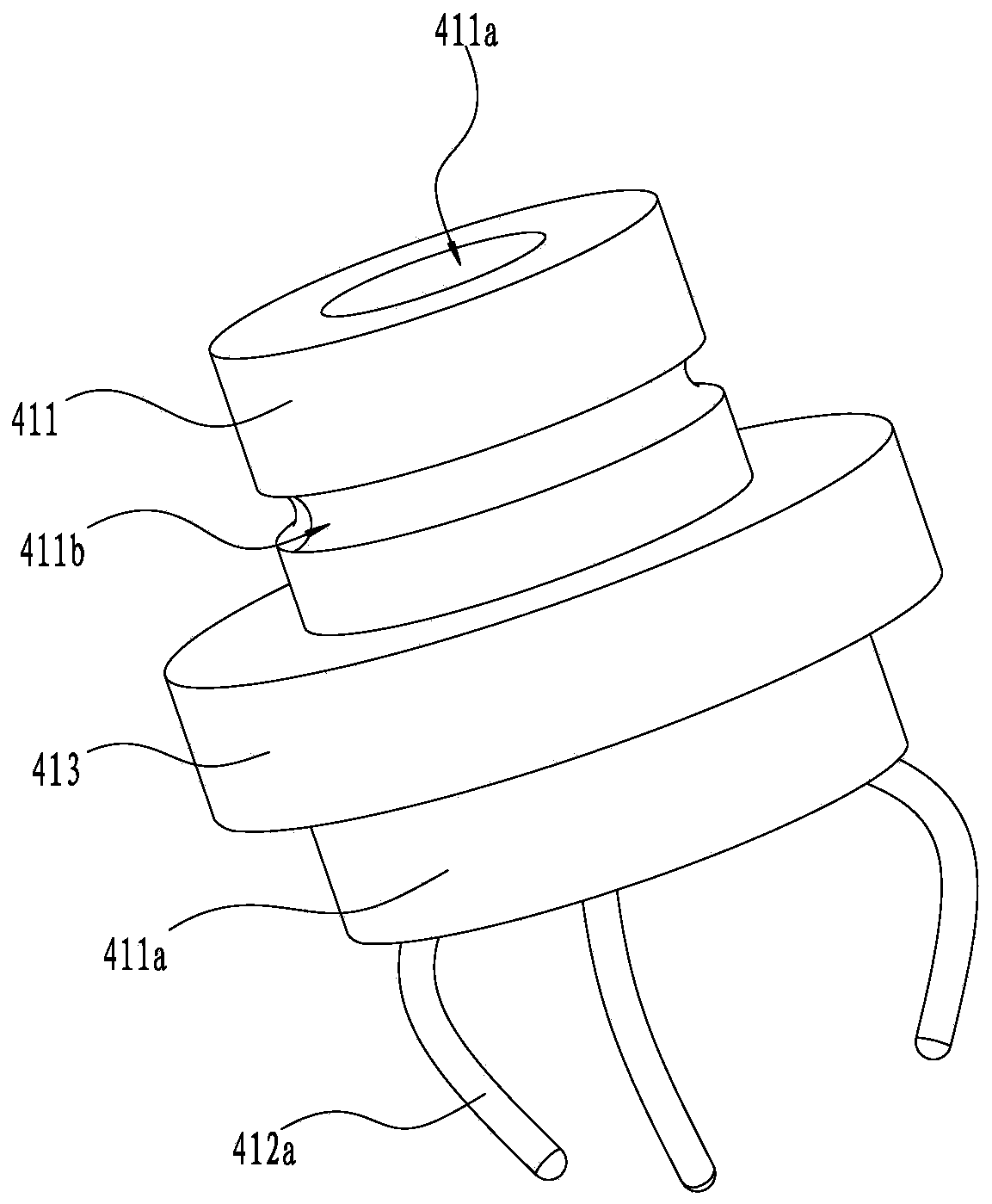

Shape memory alloy bearing and assembling method thereof

InactiveCN108223569AEnsure high precision requirementsAffect performanceShaftsBearing componentsRoom temperatureShape-memory alloy

The invention provides a shape memory alloy bearing. The shape memory alloy bearing comprises a bearing outer ring (1), a bearing inner ring (2) and a self-lubricating layer (3), wherein the bearing outer ring (1), the self-lubricating layer (3) and the bearing inner ring (2) are sequentially arranged from outside to inside; a first groove is formed in the inner side of the bearing outer ring (1);an arc surface matched with the first groove is arranged on the outer side of the bearing inner ring (2); the self-lubricating layer (3) is arranged in the first groove; and the self-lubricating layer (3) is arranged outside the arc surface. After the bearing inner ring of the shape memory alloy bearing is assembled and formed according to a conventional process, the shape of the bearing inner ring is changed at a low temperature, the size of the outer spherical surface of the bearing inner ring is reduced to be smaller than the size of the opening part of the bearing outer ring, then the bearing inner ring is assembled into the bearing outer ring, finally, the bearing is placed at the room temperature, and the bearing inner ring recovers to an original shape so as to achieve the purposeof assembly.

Owner:上海市轴承技术研究所有限公司

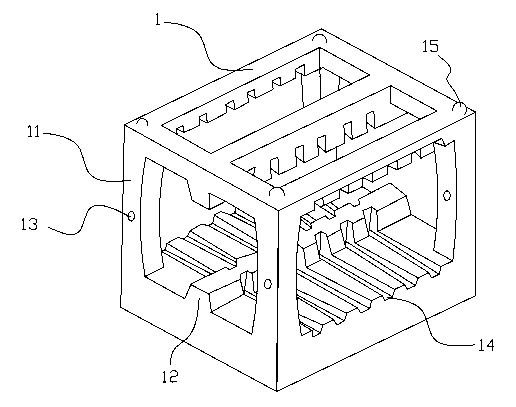

5G transmitting assembly assembling equipment

ActiveCN113070780ARealize intermittent conversionRealize the pick-up functionGrinding drivesGrinding machinesStructural engineeringMechanical engineering

The invention discloses 5G transmitting assembly assembling equipment, and particularly relates to the technical field of 5G transmitting base stations. The 5G transmitting assembly assembling equipment comprises a support, a convex rubber part and an arc-shaped metal part, the cross section of one end of the convex rubber part is rectangular, a convex groove is formed in the arc-shaped metal part, a fixed disc is fixedly mounted at the upper end of the support, an arc-shaped discharging opening is formed in one side of the fixed disc, a rotary disc is rotationally connected to the outer side of the fixed disc, and discharging receding openings are formed in the periphery of the interior of the rotary disc. Through rotation of a crescent rotating block and a shifting rod, intermittent conversion of stations is achieved in one direction, the function of taking a convex rubber part is achieved in the other direction, and on the other hand, the purpose of assembling the convex rubber part and an arc-shaped metal part is further achieved; and meanwhile, a baffle is pushed through the shifting rod, a polishing piece can continuously swing back and forth, the purpose of polishing the convex rubber part is achieved, and the purpose of discharging can be achieved by extruding a discharging rod on the shifting rod.

Owner:陕西立博源科技有限公司

Global modular fast-installation shelters and special-shaped aluminum profiles, butt-joint aluminum profiles and construction methods

ActiveCN110331814BApplicable deliverySmall footprintBuilding insulationsArchitectural engineeringAir tightness

Global modular fast-installation shelter and special-shaped aluminum profiles, butt aluminum profiles and construction methods, the adjacent panels of the shelter are connected by butt-joint aluminum profiles; butt-joint aluminum profiles include two snap-fit joints of profiled aluminum profiles and buckle covers; The cross-section of the aluminum profile is L-shaped, and the connecting plates of the two special-shaped aluminum profiles are combined and connected by bolts, and the concave and convex parts form a tongue-and-groove connection; Cooperate with the blocking plate to realize the sealing of the connection seam. The invention adopts the method of making modules in the factory and splicing and assembling on site, which has low cost, less land occupation, convenient installation, short construction time, high strength, structural strength and rigidity all meet the requirements, and strong seismic performance; Simple and reliable; the overall keel frame is easy to bear heavy equipment boxes; filled with polyurethane foam, it has good air tightness and high structural strength; there is no special requirement for on-site construction conditions, green and environmentally friendly, and cost-effective.

Owner:衡水通广通信导航设备有限公司

Modular algae multiplication device assembly line

InactiveCN103299932BQuickly reach the purpose of assemblyTo achieve the purpose of assemblyClimate change adaptationPisciculture and aquariaAssembly lineEngineering

The invention discloses a modular algae multiplication device assembly line which comprises a chain-type conveying belt, wherein the conveying belt is provided with a raised traction convex ball; both ends of the chain-type conveying belt are provided with tail end covers; the tail end covers are provided with preserved grooves capable of allowing the traction convex ball to pass through; a lifting platform is arranged near the lateral surface of the chain-type conveying belt; a reciprocating push plate is arranged near the upper part of the lifting platform; the upper surface of the lifting platform is provided with parallel chutes; a soaking chute container is arranged near the lifting platform and on one side below the reciprocating push plate; the soaking chute container is provided with a water tank capable of accommodating liquid and an edge opening on one side of the water tank extends outwards to the position near the lifting platform; the extending edge opening surface of the lifting platform is provided with parallel chutes and the chutes extend to the bottom of the water tank along the side wall of the water tank; and a fan is arranged near the upper part of the reciprocating push plate. Therefore, the modular algae multiplication device assembly line has the advantages of novel structure, high splicing and assembling speed, low requirement on splicing accuracy and suitability for application to fishing rock arrangement in a large scale.

Owner:ZHEJIANG OCEAN UNIV

Purlin parts

ActiveCN103437363BTo achieve the purpose of assemblyFulfilling Assembly RequirementsExcavationsPurlinArchitectural engineering

The invention discloses an enclosing purlin component which comprises a bottom chord beam , a web member and diagonal bracings. The bottom chord beam, the web member and the diagonal bracings are all made of H-shaped steel. Square flange plates are fixed at the two ends of the bottom chord beam. Reinforcing plates, lug plates and drain holes are arranged in grooves in the two sides of the bottom chord beam. An outer side wing plate is provided with a plurality of connecting holes. Square flange plates are welded at the two ends of the web member. One end of the web member is connected with the inner side wing plate of the bottom chord beam through bolts. Reinforcing plates and drain holes are arranged in grooves in the two sides of the web member. The two end faces of each diagonal bracing are 45-degree inclined sections and are provided with rectangular flange plates. One end of each diagonal bracing is connected with the web member through bolts, and the other end of each diagonal bracing is connected with the bottom chord beam through bolts. Lug plates and drain holes are arranged in grooves in the two sides of each diagonal bracings. Two diagonal bracings are symmetrically arranged on the two sides of the web member. A web plate of H-shaped steel of the bottom chord beam, a web plate of H-shaped steel of the web member and web plates of H-shaped steel of the diagonal bracings are located in the same plane. The enclosing purlin component is convenient to detach and install, can be used repeatedly for multiple times, and achieves the purposes of saving construction cost and bringing convenience to construction.

Owner:杭州爱默乐实验设备有限公司

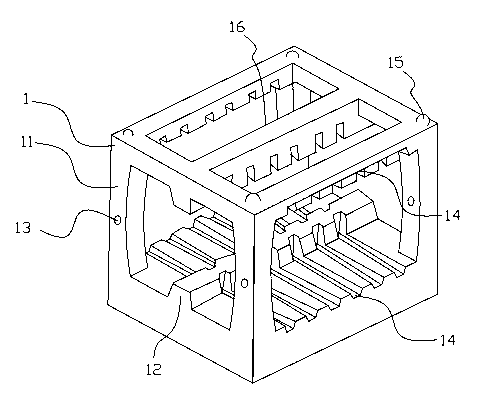

Ejection mechanism for ejecting blocking head

InactiveCN111468913AReduce manual operationsMeet production needsSpraying apparatusMetal working apparatusEngineeringManufacturing line

The invention relates to the field of power divider production, and particularly relates to an ejection mechanism for ejecting a blocking head, a blocking head assembling device and a feeding assembling device. The ejection mechanism comprises a clamping and conveying seat, a containing cavity positioned in the clamping and conveying seat and an ejection head installed in the containing cavity ina telescopic mode, wherein the containing cavity is provided with an inlet for moving the blocking head into the containing cavity and an outlet for moving the blocking head out of the containing cavity, and the opening and closing state of the outlet is adjustable; the ejection head and the outlet are arranged correspondingly; the inlet is positioned beside the direction of the distance between the ejection head and the outlet; and the ejection head can eject the blocking head restrained in the containing cavity out of the outlet and assemble the blocking head to a workpiece to be assembled after the outlet is opened. By the adoption of the scheme, the purpose of rapidly assembling the blocking head on a connector on a power divider shell can be achieved, the manual operation amount of production line personnel can be greatly reduced, the production requirement of an intelligent production line can be met, and then the production efficiency is improved.

Owner:安徽中巨机电设备有限公司

Alga multiplication device assembling ship

ActiveCN103270988BQuickly reach the purpose of assemblyTo achieve the purpose of assemblyClimate change adaptationPisciculture and aquariaMarine engineeringAssembly line

The invention discloses an alga multiplication device assembling ship which comprises a ship body. An assembly line device is mounted on the ship body. Guide grooves are arranged on the lateral sides of the ship body. Chained conveying belts are arranged on the assembly line device and protruding traction protruding balls are processed on the conveying belts. Tail end covers are arranged at two ends of the chained conveying belts, and reserved grooves for allowing the traction protruding balls to pass are processed on the tail end covers. Lifting platforms are arranged near to the lateral sides of the chained conveying belts, and reciprocate pushing plates are arranged near to the upward sides of the lifting platforms. Parallel sliding chutes are processed on the upper surfaces of the lifting platforms. Soaking sliding chute containers are arranged on one sides, below the reciprocate pushing plates, near to the lifting platforms. Each soaking sliding chute container is provided with a water tank capable of storing liquid and an edge opening on one side of each water tank extends outwards to be near to each lifting platform. Parallel sliding chutes are processed on the surfaces of the outward-extending edge openings, and extend to the bottoms of the water tanks along the side walls of the water tanks. The alga multiplication device assembling ship has the advantages of novel structure, rapidness in slicing and assembling, low requirement on slicing and assembling accuracy, and applicability to fish-shelter application distribution on a large scale.

Owner:ZHEJIANG OCEAN UNIV

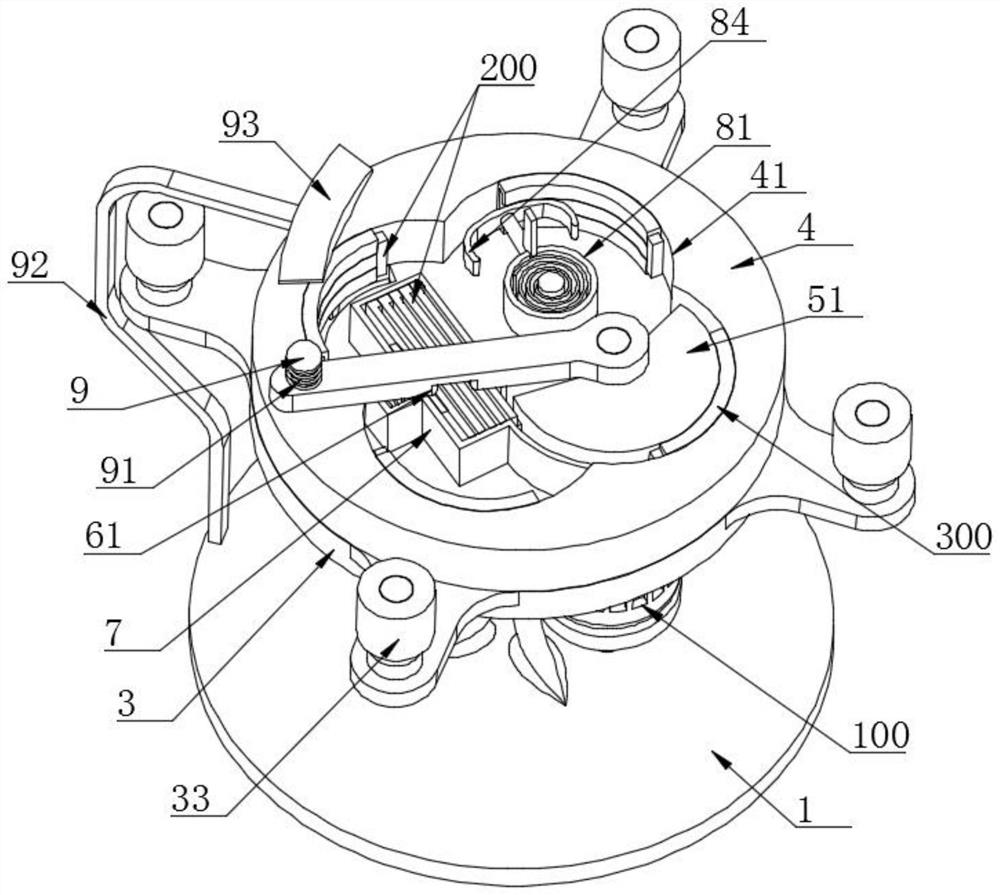

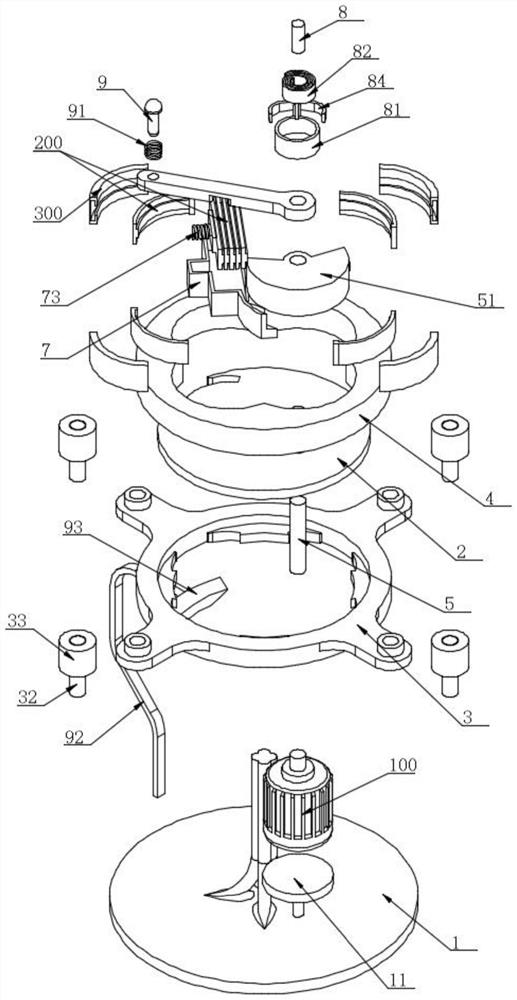

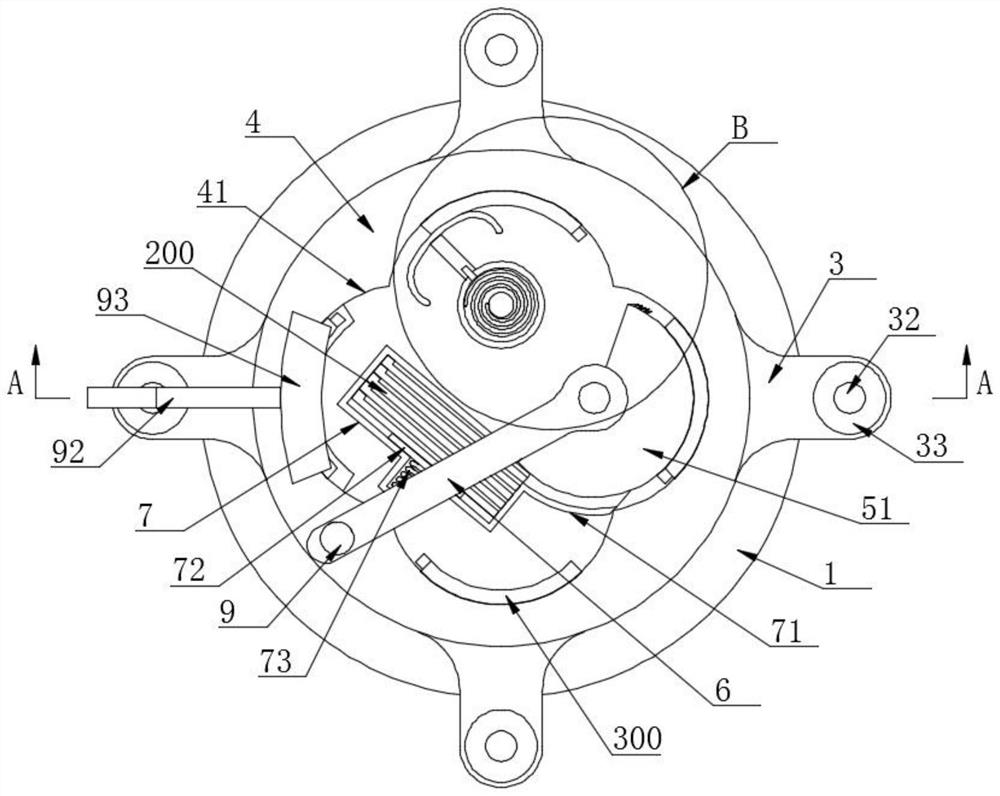

Automatic production line for common lighter

ActiveCN102168860BSafe and reliable workRealize closed-loop controlIncandescent ignitionFuel lightersProduction lineTransmission line

Owner:刘健萍

Pulley guide rail assembly method and structure and power catwalk of pulley guide rail assembly structure

ActiveCN111502562AReduce difficultyImprove assembly efficiencyDrilling rodsDrilling casingsGear wheelTraveling block

The invention discloses a pulley guide rail assembly method and structure and a power catwalk of the pulley guide rail assembly structure, and belongs to the technical field of power catwalks. The pulley guide rail assembly method comprises the following steps that S1, a pulley is placed on the top of a guide rail assembly, and a gear assembled at the bottom of the pulley is meshed with a rack atthe top of the guide rail assembly; S2, roller disc units are slidably clamped on both sides of the guide rail assembly; and S3, on the guide rail assembly, the pulley and the roller disc units are connected through connecting parts to form an overall structure. When the pulley guide rail assembly method is adopted, the pulley and the roller disc units are independent of each other, and no mutualrestriction relationship exists between the installation action of the pulley and the installation action of the roller disc units, so that the action process of installing the pulley on the guide rail assembly and the action process of the roller disc units installed on the guide rail assembly are simple and easy, the difficulty of the pulley guide rail assembly process is reduced, the assembly efficiency is improved, and the purpose of assembly is achieved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

A hole extrusion multiple strengthening device and method

ActiveCN112359189BImprove processing efficiencyImprove the strengthening effectEngineeringMechanical engineering

The disclosure provides a hole extrusion multiple strengthening device and method, which relate to the field of hole processing equipment, including a first mandrel and a second mandrel arranged coaxially and butted at the ends, and the first mandrel is sequentially provided with guides along the axial direction. section, the first reducing section and the first matching section, the second mandrel is provided with the second matching section and the second reducing section in sequence along the axial direction, the first matching section and the second matching section have the same diameter and are butted to form a The diameter of the large-diameter end of the first reducing section and the second reducing section is greater than the diameter of the sleeved part of the cylindrical sleeve of the bushing, facing the holed member that needs to be pressed to meet the assembly requirements. By improving the structure of the mandrel and preparing the multi-extrusion integrated mandrel, one-time continuous extrusion treatment of the hole wall and bushing required for the extrusion strengthening of the member with holes can greatly improve the processing efficiency and Further improved the enhancement effect.

Owner:SHANDONG UNIV

A kind of prefabricated building structure system and construction method

ActiveCN111779139BEasy to transportTo achieve the purpose of assemblyBuilding constructionsArchitectural engineeringStructural system

The invention relates to a prefabricated building structure system and a construction method, including a base plate, a plurality of clamping blocks are arranged on the upper side of the base plate, and the multiple clamping blocks are located in the circumferential direction of the base plate, and the base plate is clamped by the clamping blocks. A column is connected, the middle part of the column is sleeved with a first connecting ring, and the adjacent first connecting rings are integrally connected with a first coaming plate, and the column is socketed with a first coaming plate The second connecting rings on the upper and lower sides, a second coaming plate is connected between the plurality of second connecting rings, and two inclined plates are integrally connected on both sides of the upper end of the column, and the inclined plates are relatively The body is arranged obliquely, and a top cover snapped to the inclined plate is arranged on the top of the plurality of columns. The invention has the advantages of small carrying space required, convenient disassembly and multiple use.

Owner:浙江正立高科建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com