Alga multiplication device assembling ship

An algae and conveyor belt technology is applied in the field of algae multiplication device assembly ship, which can solve the problem of no large-scale multiplication application, and achieve the effects of novel structure, preventing water flow from dispersing, and fast splicing and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

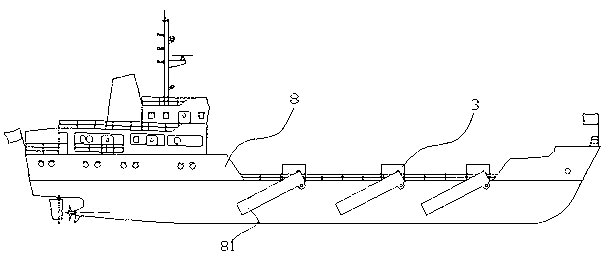

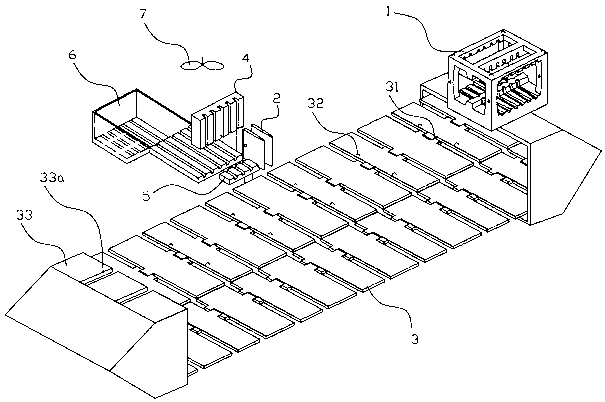

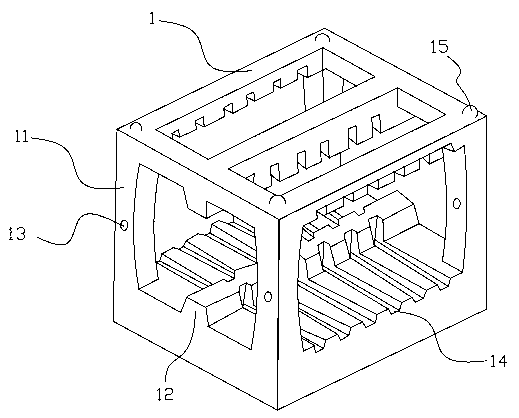

[0014] Example: Reference Figure 1 to Figure 3 , The algae proliferation device assembly ship includes a hull 8 equipped with an assembly line device, in which: the side of the hull 8 is provided with a guide groove 81; the assembly line device has a chain conveyor belt 3; the conveyor belt 3 is made with a raised traction convex ball 32; Both ends of the chain conveyor belt 3 are provided with end covers 33; the end cover 33 is provided with a reserved groove 33a that can accommodate the traction convex ball 32 to pass through; a lifting platform 5 is provided near the side of the chain conveyor belt 3; There is a reciprocating push plate 4; the upper surface of the lifting platform 5 is equipped with parallel chutes; the side of the lifting platform 5 near the reciprocating push plate 4 is provided with a soaking chute container 6; the soaking chute container 6 has a liquid One side of the water tank extends along the mouth to the vicinity of the lifting platform 5; the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com