Novel dual temperature controlled electric kettle socket

A dual temperature control, electric kettle technology, applied to the socket device of electric kettle, the field of new dual temperature control electric kettle socket, can solve the problems of disassembly of components, affecting the life of the electric kettle socket, and the fixing method is not firm, and achieves a simplified structure. , prolong life, not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

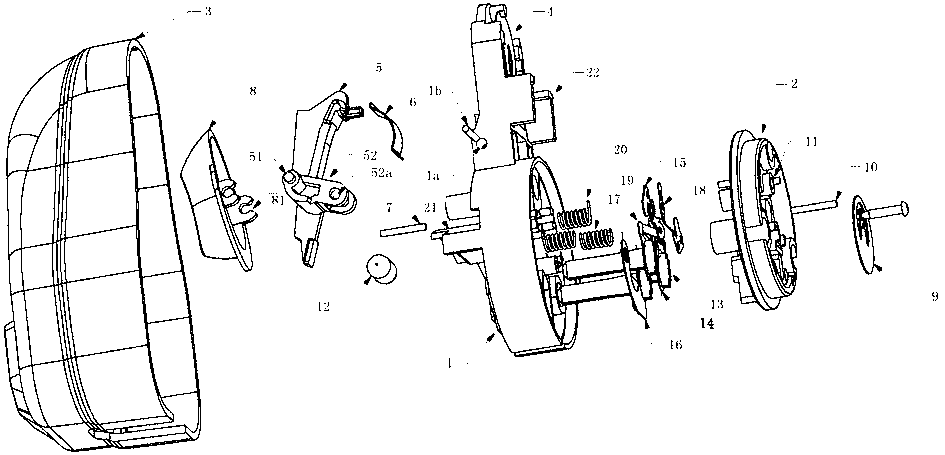

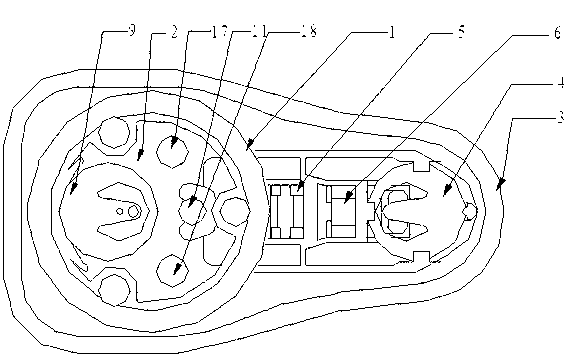

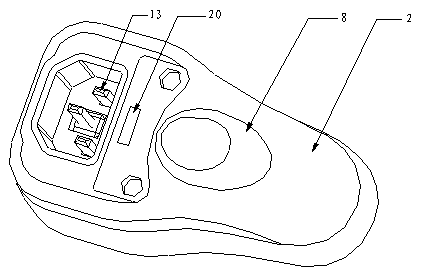

[0029] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

[0030] one of them Figure 1 to Figure 3 The reference signs in are: dual temperature control base 1, fixing hole 1a, pin 1b, cover plate 2, dual temperature control protective cover 3, steam metal sheet 4, button 5, edge 51, positioning pin body 52, positioning pin Hole 52a, spring leaf 6, steam push rod 7, switch 8, U-shaped bayonet 81, anti-dry metal sheet 9, anti-dry push rod 10, safety column 11, neon lamp 12, insert 13, N extremely static Contact piece 14, L pole static contact piece 15, grounding contact piece 16, L pole moving contact piece 17, N pole moving contact piece 18, contact spring 19, safety spring 20, waterproof baffle plate 21, steam hole limiting piece 22.

[0031] The new dual temperature control electric kettle socket includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com