Fish-belly beam components of the inner support system of foundation pit support

A support system and foundation pit support technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of non-standard connection size, non-reusable, low support rigidity, etc., to achieve convenient disassembly and transportation, and save Construction cost, effect of large construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

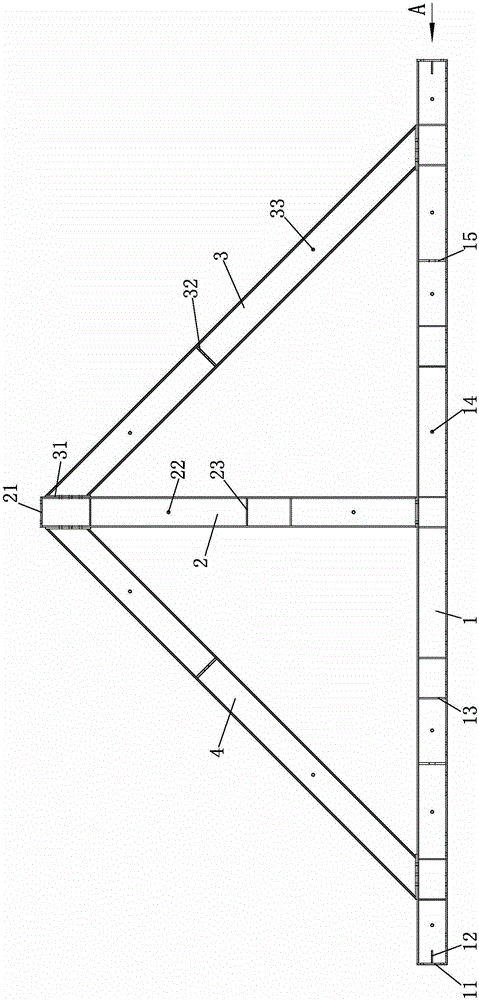

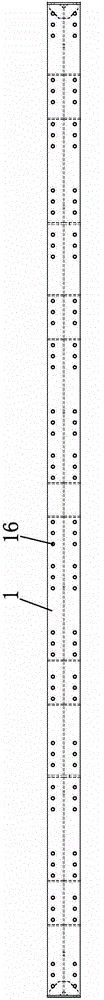

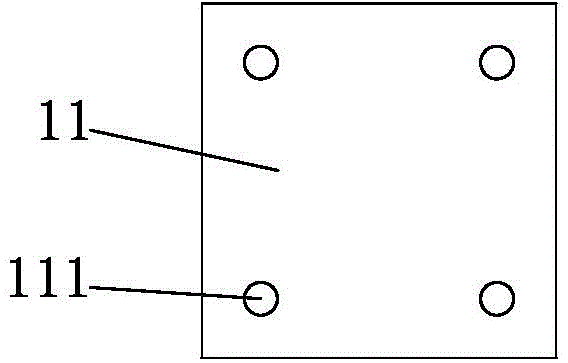

[0013] Such as figure 1 The fish-belly beam components of the internal support system of the foundation pit support shown include the lower chord part 1, the web part 2, and the diagonal bracing parts 3 and 4 made of H-shaped steel, and the two ends of the H-shaped steel of the lower chord part 1 It is a cross-section and is welded and fixed with a square flange plate A11, such as image 3 As shown, there are four flange holes A111 on the square flange plate A11, and the four flange holes A111 are distributed in a square shape. 200mm, the diameter of the flange hole A111 is 28mm, the grooves on both sides of the H-shaped steel of the lower chord part 1 are provided with flange reinforcement gussets 12, and the flange reinforcement gussets 12 are respectively connected to the square The flange plate A11 and the web of the H-shaped steel of the lower chord part 1 are vertically welded and fixed, and the grooves on both sides of the H-shaped steel of the lower chord part 1 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com