Automatic production line for common lighter

A technology of automatic production line and lighter, which is applied in combustion ignition, incandescent ignition, igniter with fuel, etc., can solve the problems of unstable product quality, low processing accuracy, poor automation, etc., and achieve convenient maintenance and maintenance. , quick response adjustment, the effect of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

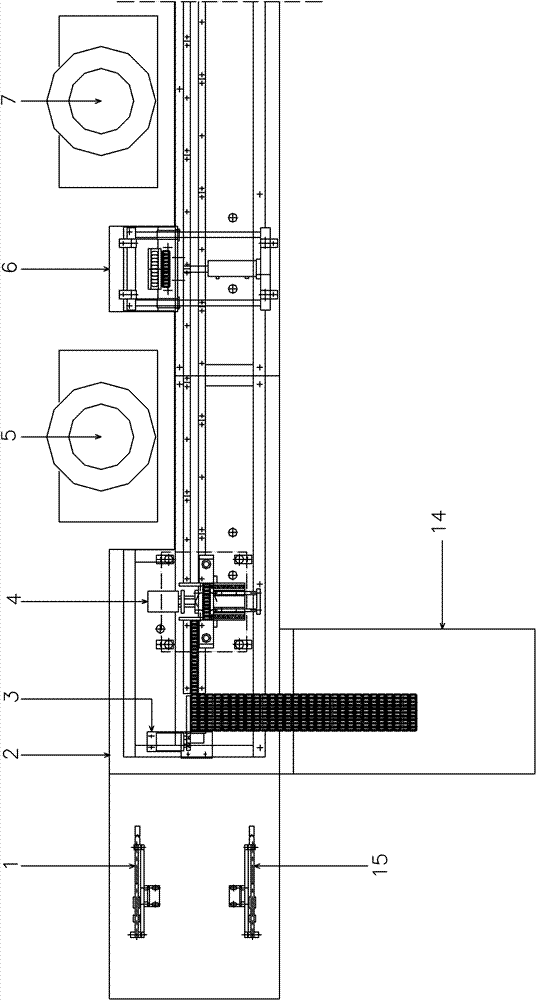

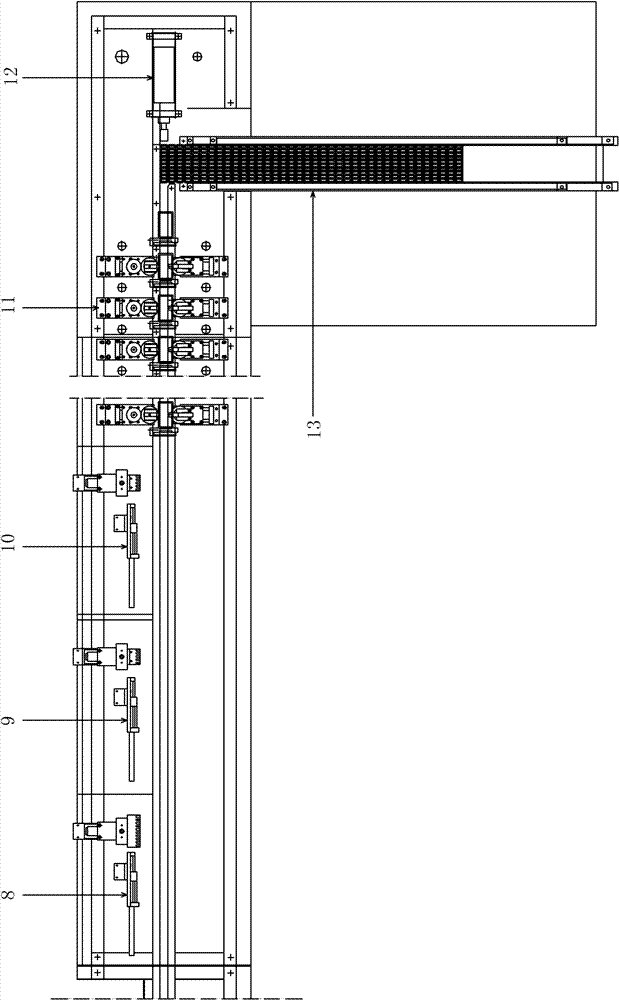

[0019] The specific embodiment of the present invention is as figure 1 , figure 2 As shown, a kind of common lighter automatic production line, comprises frame 2 and control device, is provided with transmission line on frame 2, and one end of this transmission line is provided with the main feeding mechanism 12 that is used for the automatic feeding in cycle work, also sets respectively along transmission line There is an organic shell conveying station 13, an automatic fire test station 11, a manual fire test station, an outer machine head directional assembly station 6, a press head station 4 for finished product assembly, and a flame used for setting the finished product lighter. The final fire discharge station is adjusted to a uniform height and screens defective products. This production line consists of figure 1 The second half shown and figure 2 shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com