A hole extrusion multiple strengthening device and method

A technology of strengthening device and hole extrusion, applied in the field of hole processing equipment, can solve the problems of high resource consumption, low processing efficiency, complex processing technology, etc., and achieve the effect of improving strengthening effect, improving processing efficiency and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a hole extrusion multiple reinforcement device is proposed.

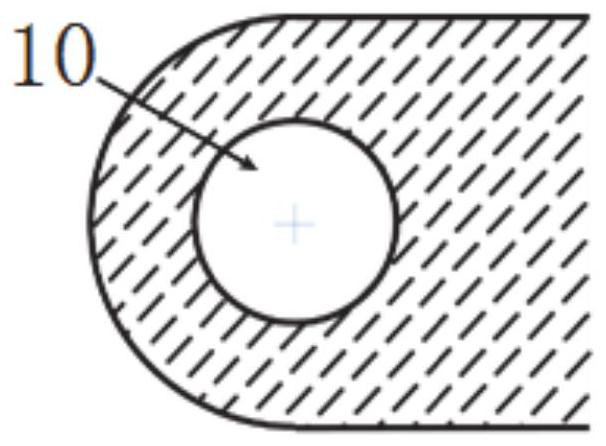

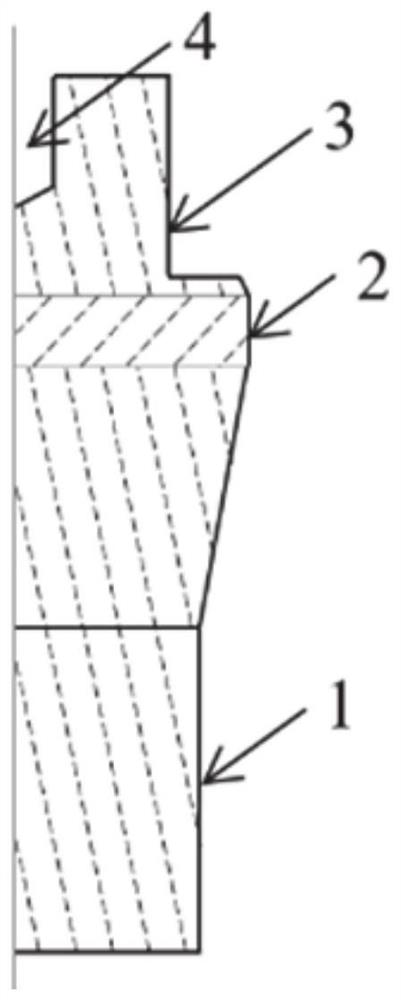

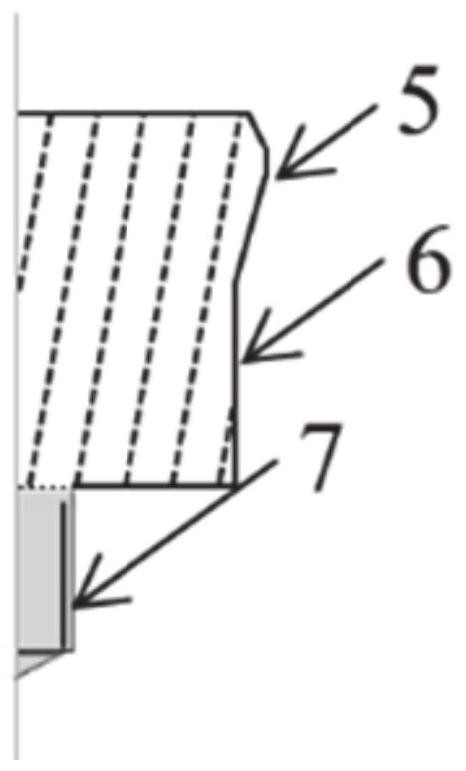

[0040] It mainly includes a mandrel, and the mandrel includes a first mandrel and a second mandrel, which are determined as the first mandrel at the front end and the second mandrel at the rear end in the order of passing through the hole 10 to be processed;

[0041] The function of the first mandrel is to extrude the light hole of the member with holes, and the function of the second mandrel is to extrude the bushing.

[0042] Both the first mandrel and the second mandrel have respective working ends, and the diameter of the working ends determines the size of the interference of the light hole or the extrusion process of the bushing.

[0043] The butt joint between the first mandrel and the second mandrel is the middle position of the whole mandrel, which is a columnar area with constant diameter. During subsequent ...

Embodiment 2

[0066] In another typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a hole extrusion multiple strengthening method is proposed, using the hole extrusion multiple strengthening device as described in Example 1.

[0067] Include the following steps:

[0068] Disassemble the first mandrel and the second mandrel, and set the bushing on the first mating section or the second mating section, butt the first mandrel and the second mandrel, so that the bushing is constrained outside the sheathing part lock up;

[0069] Apply lubricating fluid to the first mandrel, second mandrel, bushing and the wall of the hole to be treated before extrusion strengthening, and apply an external load to the mandrel, and drive the mandrel to pass through the hole to be treated and the bushing in sequence Pass;

[0070] performing first extrusion strengthening on the wall of the hole to be treated by using the first mandrel, and passing the first mandrel through th...

Embodiment 3

[0085] In yet another embodiment of the present disclosure, another hole extrusion multiple strengthening method is given by taking the press-fit bushing to strengthen the ear piece of 2024 aluminum alloy with holes as an example.

[0086] Include the following:

[0087] The bushing material is 300M steel, and the mandrel material is W18Gr4VCo5 tool steel. Such as figure 1 As shown, the member with a hole is an ear part, and the inner diameter of the hole is 40mm. The bushing used has an outer diameter of 40.4mm and an inner diameter of 34mm. It is required that the interference of the smooth hole extrusion of the perforated member is 2.5%, and the interference of the bushing extrusion is 1.5%.

[0088] 1. Preparation and processing integrated mandrel;

[0089] Such as figure 2 , 3 As shown, this step requires the mandrel to be divided into two sections, which are determined as the front end in the order of passing through the hole ( figure 2 ) and the backend ( ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com