Modular algae multiplication device assembly line

An assembly line and modular technology, applied in seaweed cultivation, climate change adaptation, horticulture, etc., can solve problems such as structural defects, unsuitable batch multiplication and layout, etc., achieve fast splicing and assembly, novel structure, and prevent water flow from dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

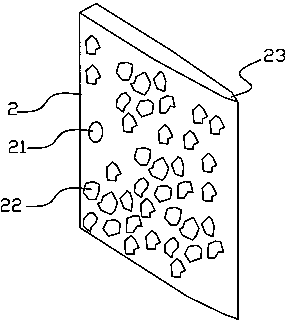

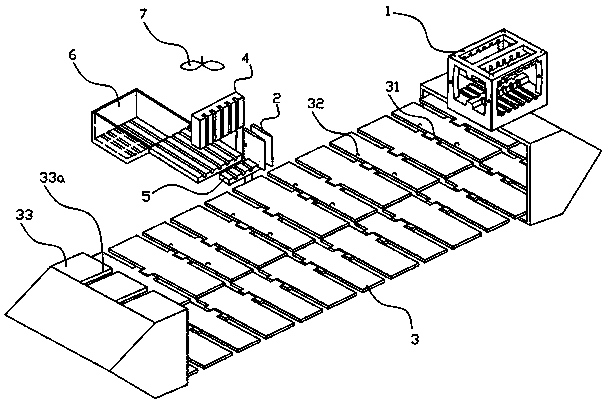

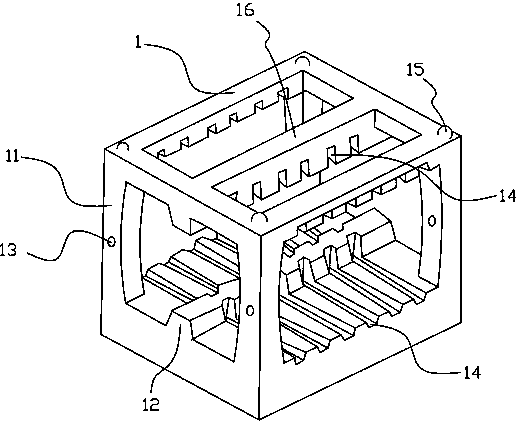

[0013] Example: refer to Figure 1 to Figure 3 , the modular algae multiplication device assembly line, including a chain conveyor belt 3, wherein: the chain conveyor belt 3 is shaped on a protruding traction convex ball 32; the two ends of the chain conveyor belt 3 are provided with end covers 33; There is a reserved slot 33a that can accommodate the passage of the traction convex ball 32; a lifting platform 5 is provided near the side of the chain conveyor belt 3; a reciprocating push plate 4 is provided near the top of the lifting platform 5; parallel chutes are formed on the upper surface of the lifting platform 5 The side near the lifting platform 5 below the reciprocating push plate 4 is provided with a soaking chute container 6; the soaking chute container 6 has a water tank that can hold liquid and one side of the water tank extends out to the vicinity of the lifting platform 5 along the mouth; The stretched edge surface is shaped on parallel chutes, and the chute exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com