Patents

Literature

288 results about "Manufacturing sector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cloud manufacturing service resource match and combination method based on performance fusion

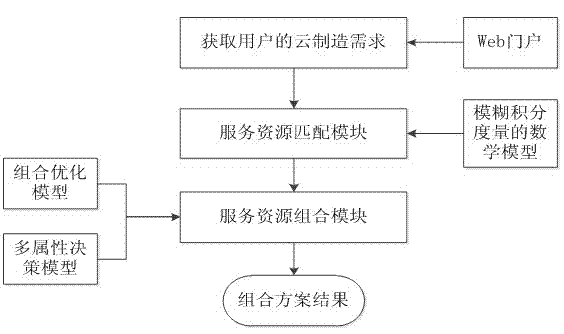

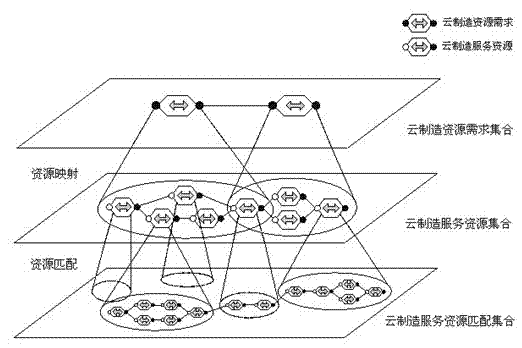

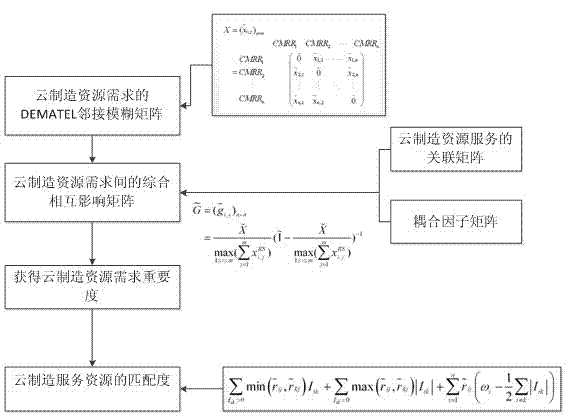

The invention discloses a cloud manufacturing service resource match and combination method based on performance fusion. According to a relationship between cloud manufacturing service resources and cloud manufacturing resource requirements of users, a cloud manufacturing service resource combination is divided into two stages of match and combination, a performance fusion model of the match and the combination is constructed, and combination schemes are evaluated and sequenced by means of a dynamic multi-attribute decision-making method to filter an optimal cloud service resource combination scheme. According to the cloud manufacturing service resource match and combination method based on performance fusion, the problem that current networking manufacturing resource match methods can't be directly used for achieving cloud manufacturing service match; and simultaneously, idle manufacturing cloud can be used for automatic rent-seeking on a cloud platform and is convenient, fast, safe and cheap for customers to use, a many-to-many mapping relationship of requirements and services is n:1:m, and by means of the many-to-many mapping relationship, a multi-layer and three-dimensional manufacturing service is provided for manufacturing industries.

Owner:ZHEJIANG UNIV

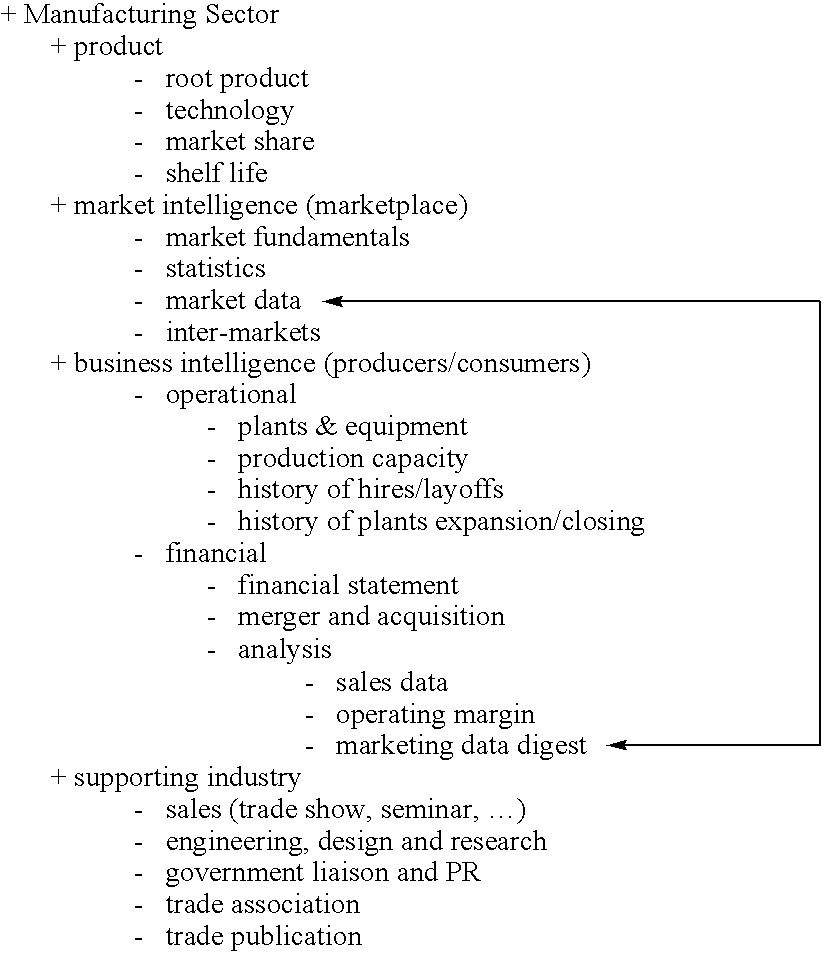

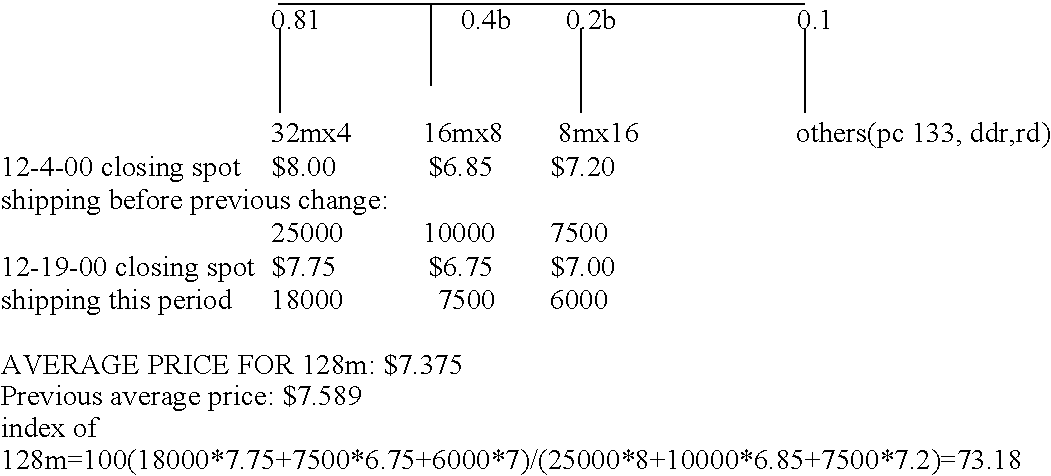

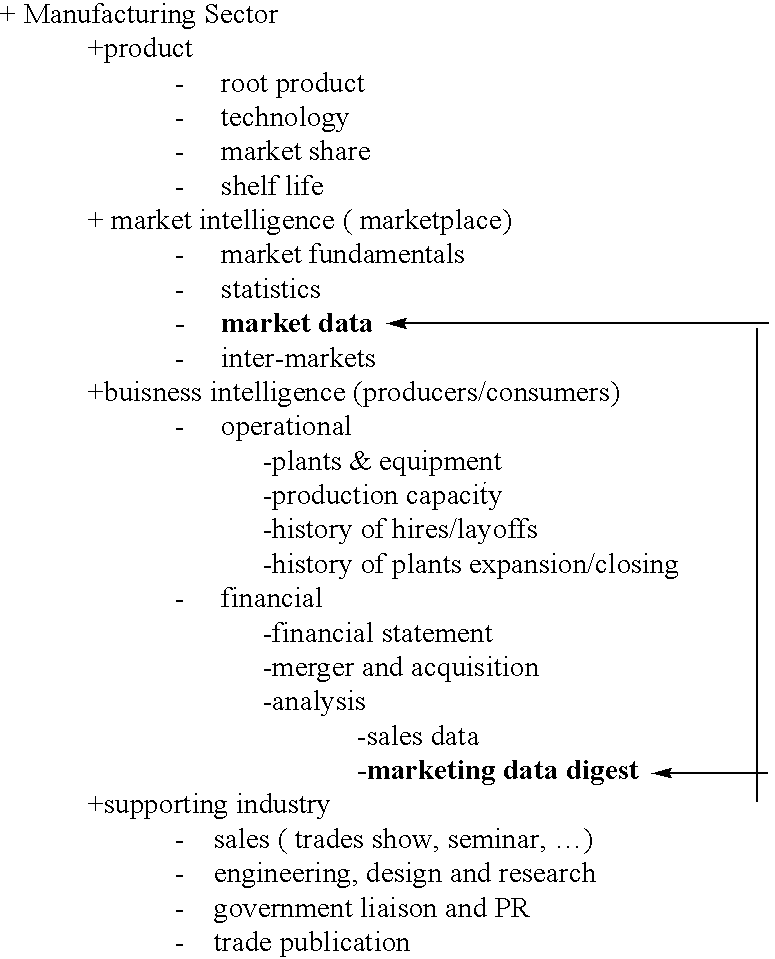

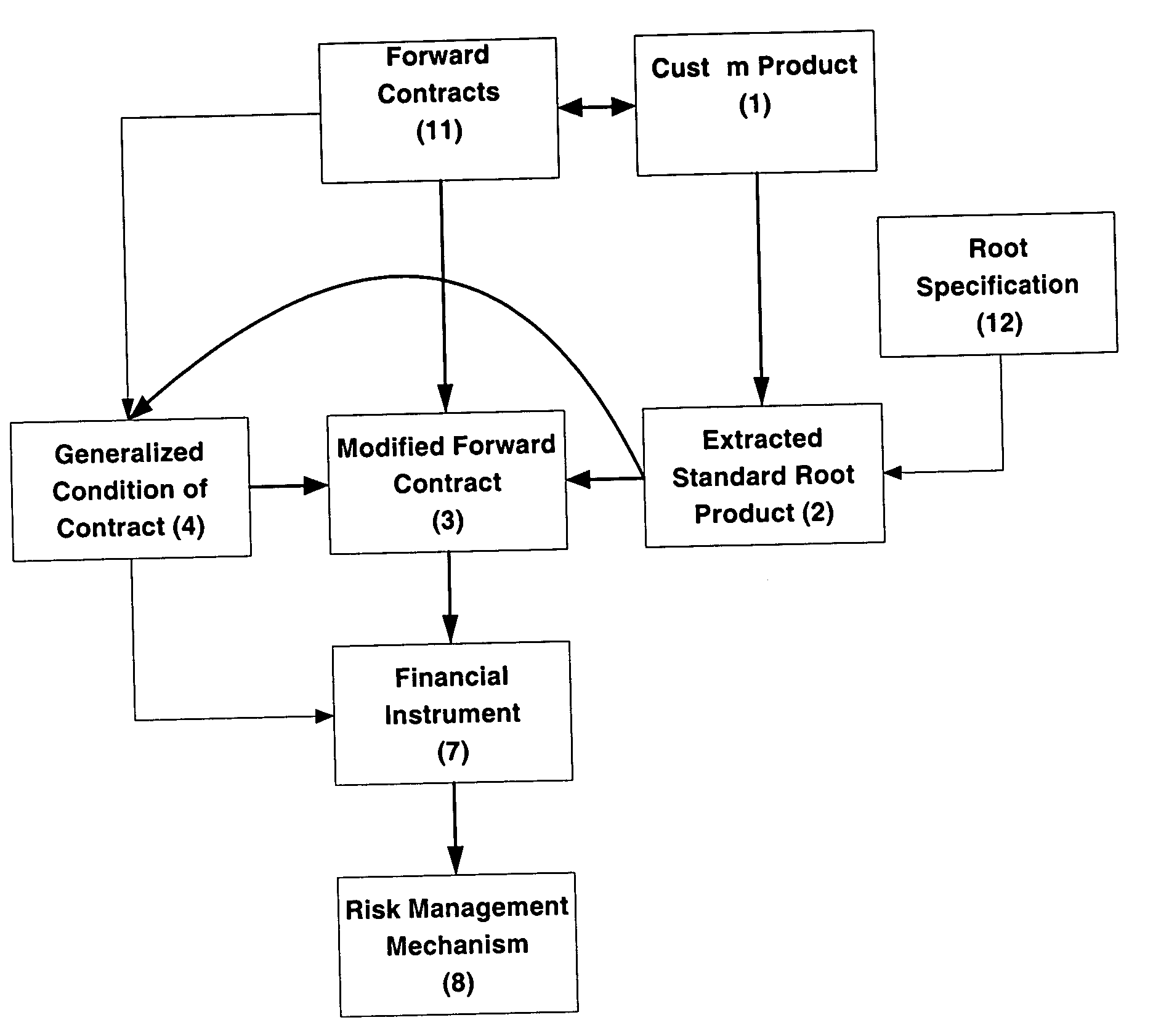

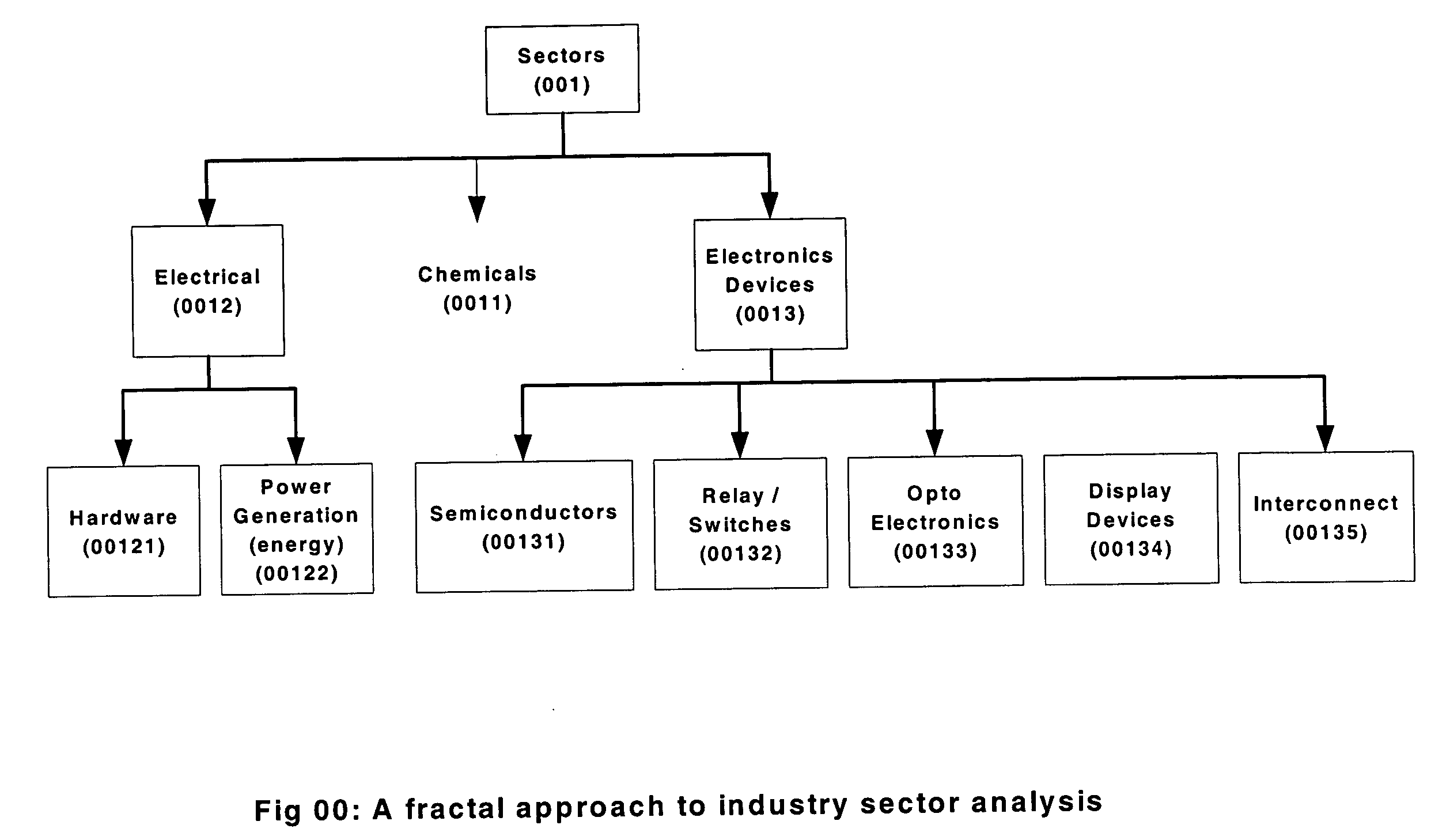

Financial instruments, derived from root products, are used as tools for risk management in manufacturing business

InactiveUS20040133502A1Global transparency of priceLow costFinanceResourcesMarket conditionsMarket intelligence

A method and system for design and development of financial instruments which enables businesses to benefit from the economic value of risk management. First the system develops a methodology, for specific sector, to extract root products. A database is designed to continually update the technical specifications of root products to ensure the uniformity of defined generic specification. Next the system database continually monitors, stores and analyzes the market intelligence required for determining the products marketing information. Finally, a flexible contract product is designed transforming these products to financial instruments. Such financial instruments are continuously updated, added and deleted as the technical and market conditions change

Owner:SADRE MAMOUD

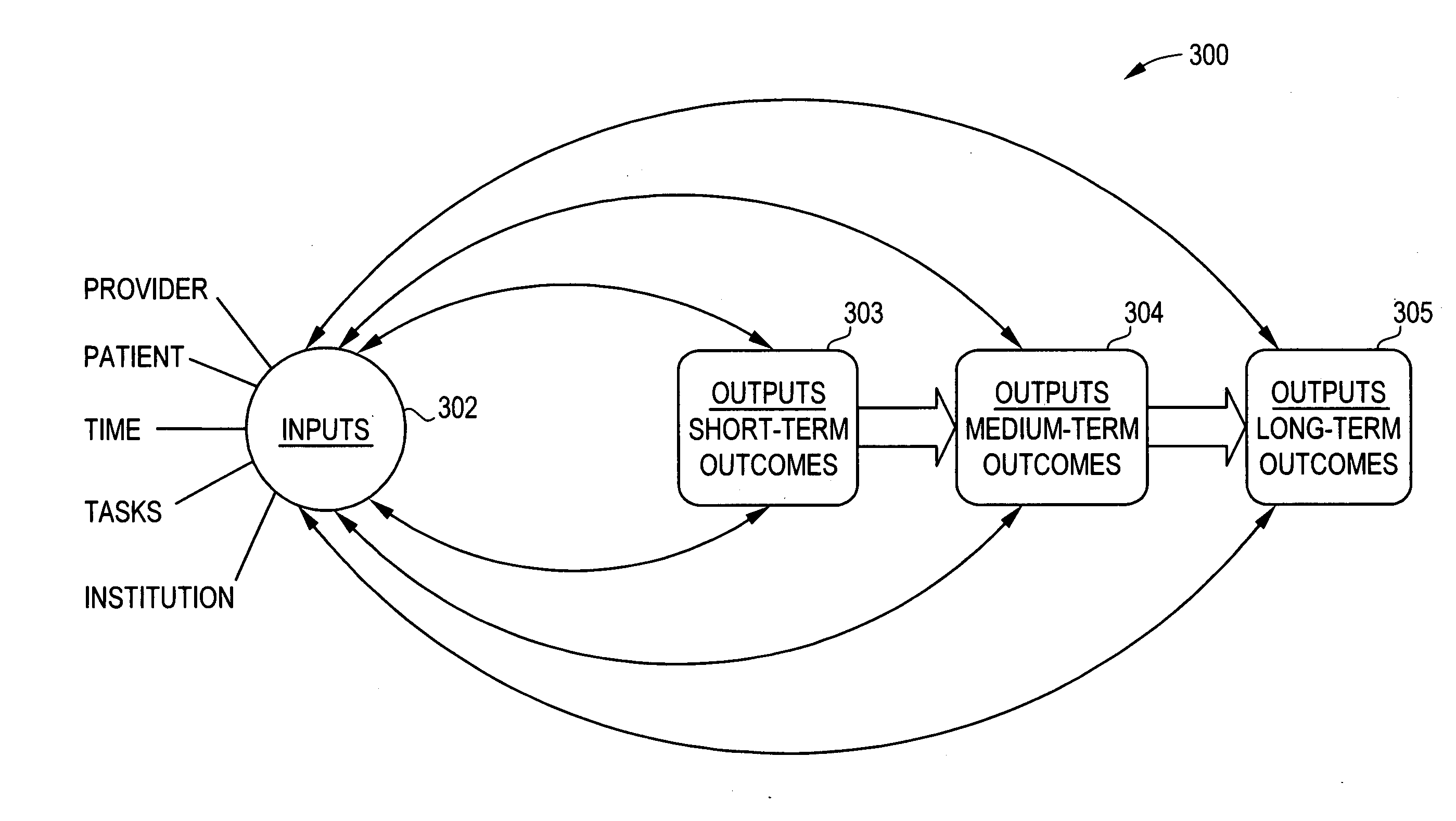

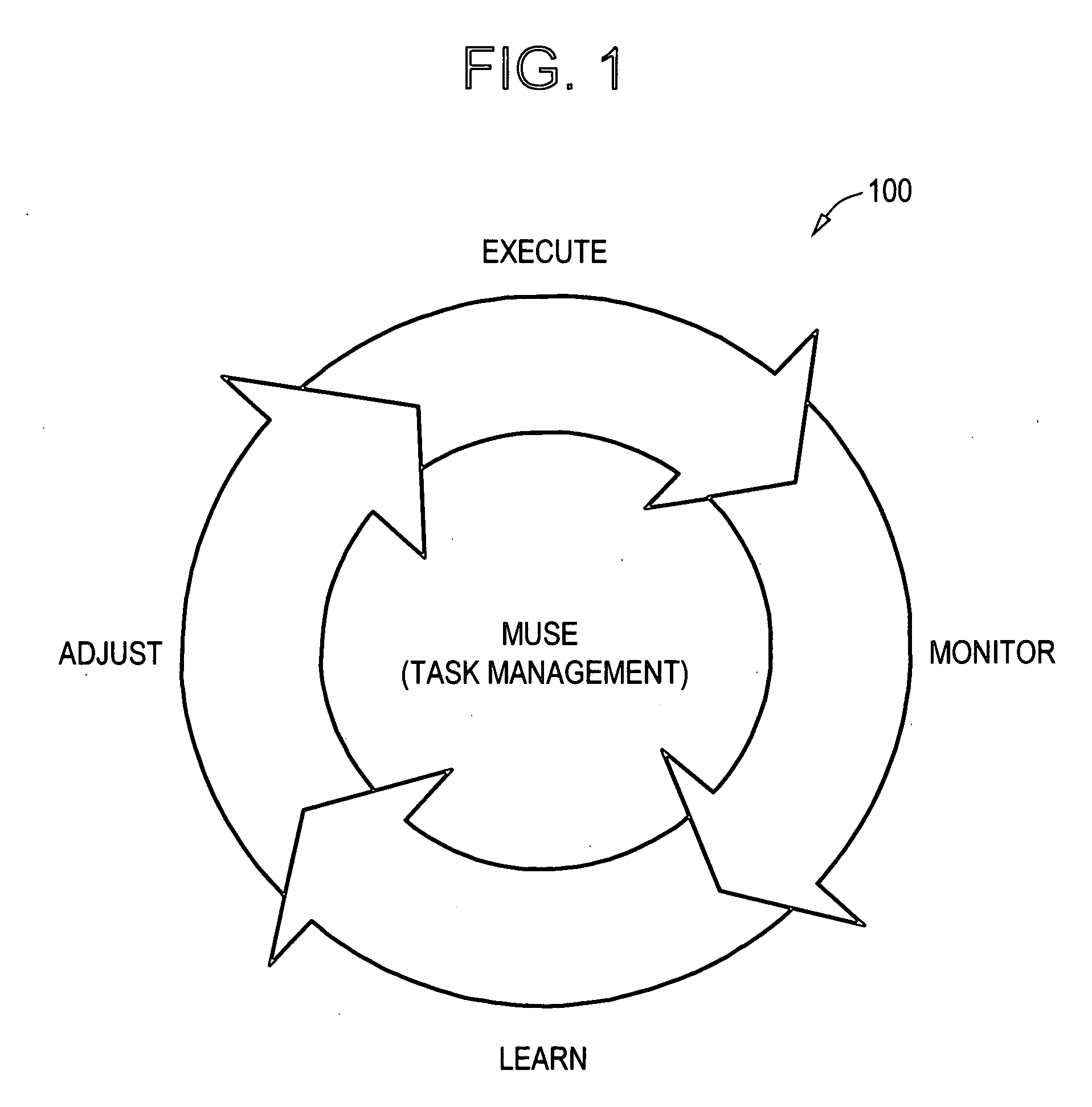

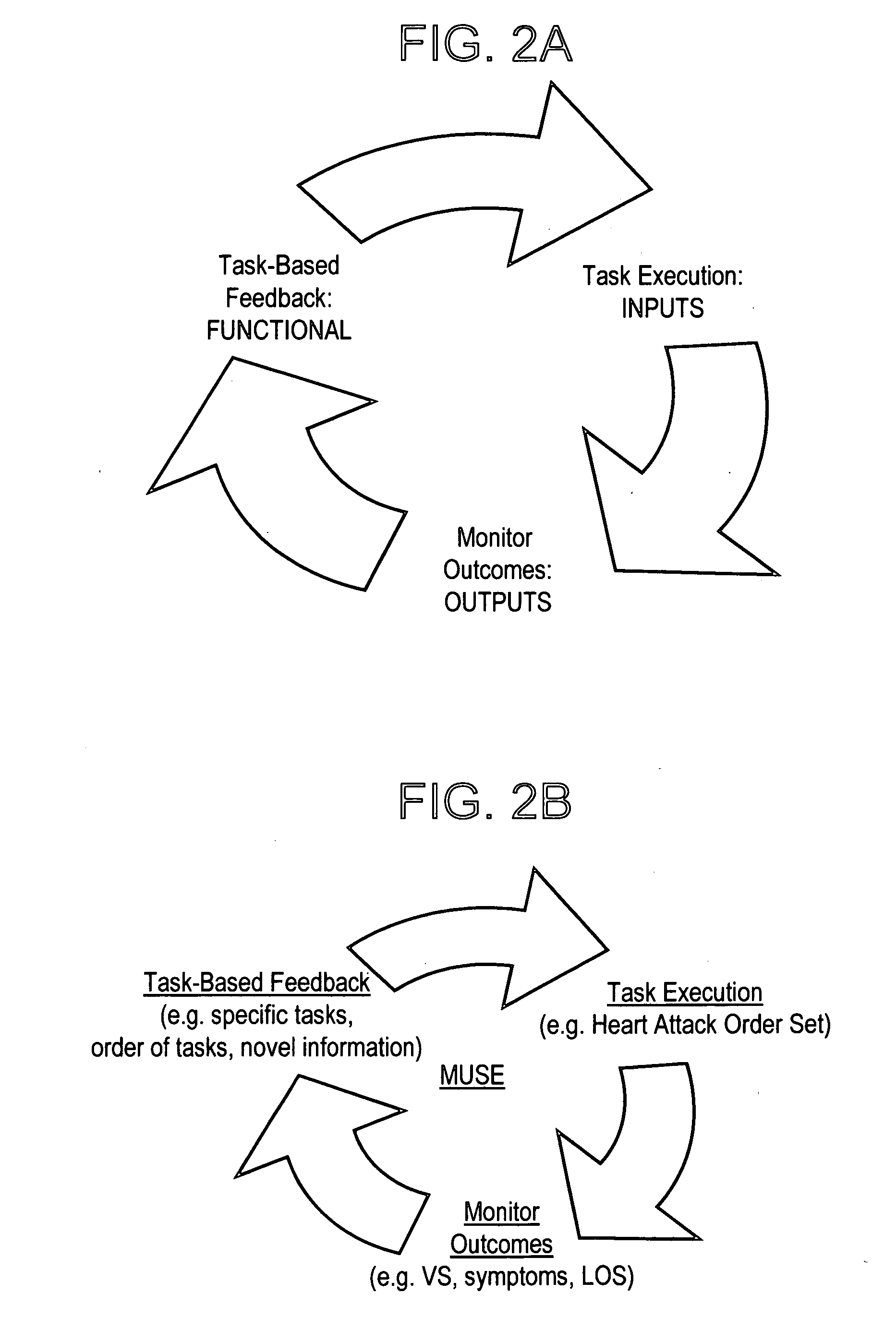

Systems and Methods for Delivering Continuous Quality Improvement to Complex Non-Manufacturing Industry

InactiveUS20100169119A1Quality improvementLarge outcomeMedical data miningHealthcare resources and facilitiesSoftware systemAdditive ingredient

A system and method is disclosed to functionally show how to use a technology-based continuous quality improvement platform with software integration to improve the execution of complex processes in a measurable way. The platform demonstrates how healthcare delivery, as one example of a complex process, is represented as an input-output system (inputs represent determinants of outcomes, and outputs represent the impact those determinants have on specific measures). The software system helps execute tasks, monitors responses (i.e. outputs), learns (by correlating inputs to outputs), and adjusts (by providing practical decision support to users); ultimately these are the basic steps to create a technology based continuous quality improvement methodology for complex systems.Healthcare as one example of a complex input-output model: Inputs represent the ingredients and contextual factors of healthcare delivery that would have impact on metrics that are tracked (i.e. outputs), one category of which include the execution of specific patient tasks. By monitoring outcomes (i.e. what has happened to the patient after the execution of said tasks), the system can statistically connect which specific inputs (or specifically which tasks) tightly correlate with outcomes. This correlation can then be utilized to generate task-based decision-support, recommending certain specific tasks be done and in which order because these tasks are tightly correlated with improved outcomes. This input-output methodology can be extended to all of healthcare delivery and also to other industries that can be structured within an input-output model.

Owner:HUSSAIN ANWAR A

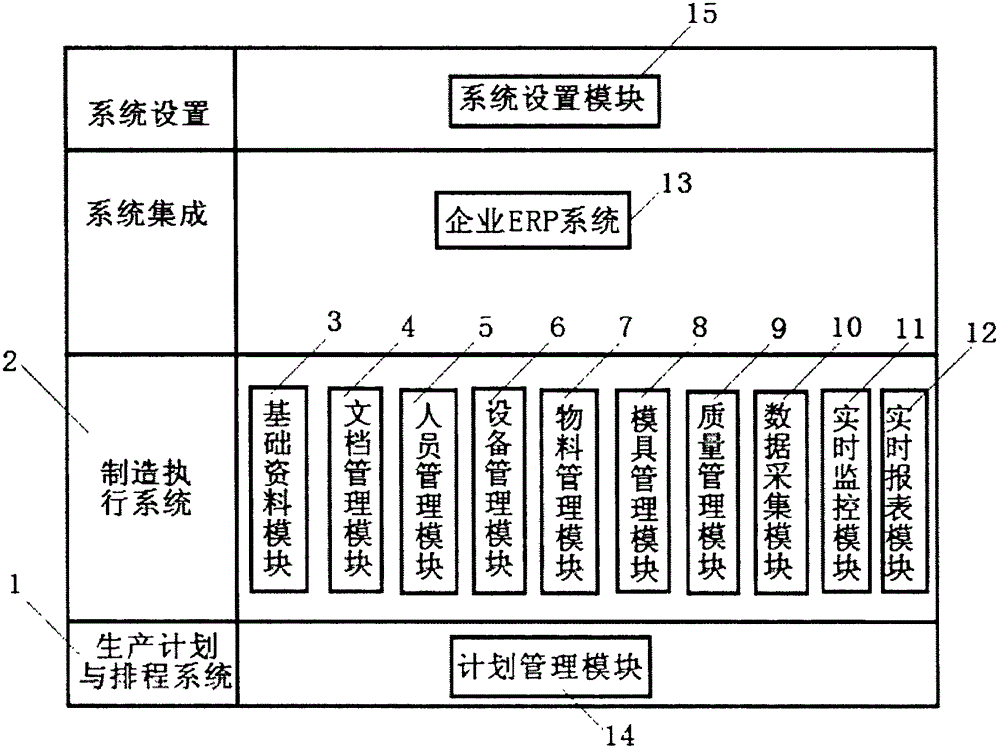

Manufacturing execution system

InactiveCN102945512ASolve the problem of real-time managementSolve the problem of real-time demand informationResourcesManufacturing computing systemsData acquisitionManufacturing execution system

The invention discloses a manufacturing execution system which comprises a production planning and scheduling system, wherein a manufacturing execution system is integrated on the basis of the production planning and scheduling system. The manufacturing execution system comprises a basic material module, a document management module, a personnel management module, an equipment management module, a material management module, a die management module, a quality management module, a data acquisition module, a real-time monitoring module and a real-time reporting module. An upper layer of the manufacturing execution system is integrated with an ERP (Enterprise Resource Planning) system of an enterprise, and a bottom layer of the manufacturing execution system is connected with a data acquisition device and a man-machine interaction terminal interface in a product field. According to the manufacturing execution system provided by the invention, the problem of real-time material demand information in the production field of the discrete manufacturing industry is solved, the material demand information can be timely sent to a warehouse by automatic system triggering or manual triggering, and the problems of monitoring and feeding back the efficiency of production equipment in real time are solved by the scientifically planned OEE (Overall Equipment Efficiency) management.

Owner:SUZHOU JIANGSHAN SOFTWARE SCI & TECH

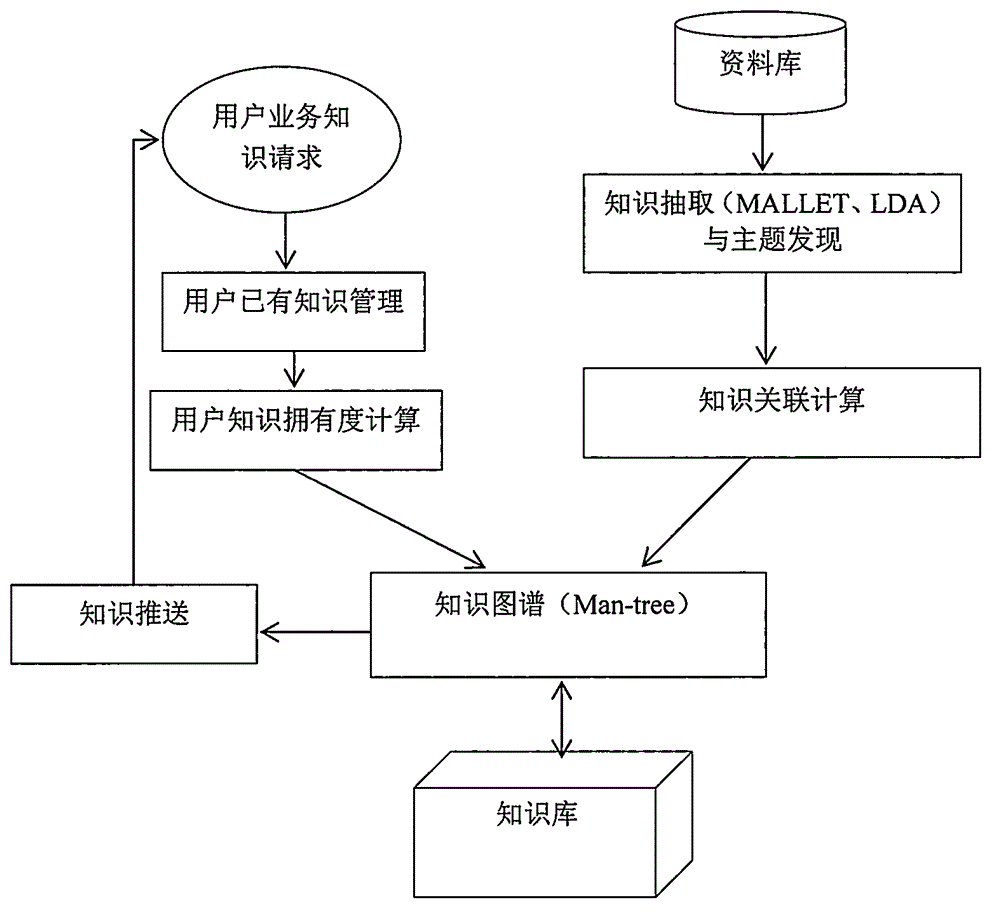

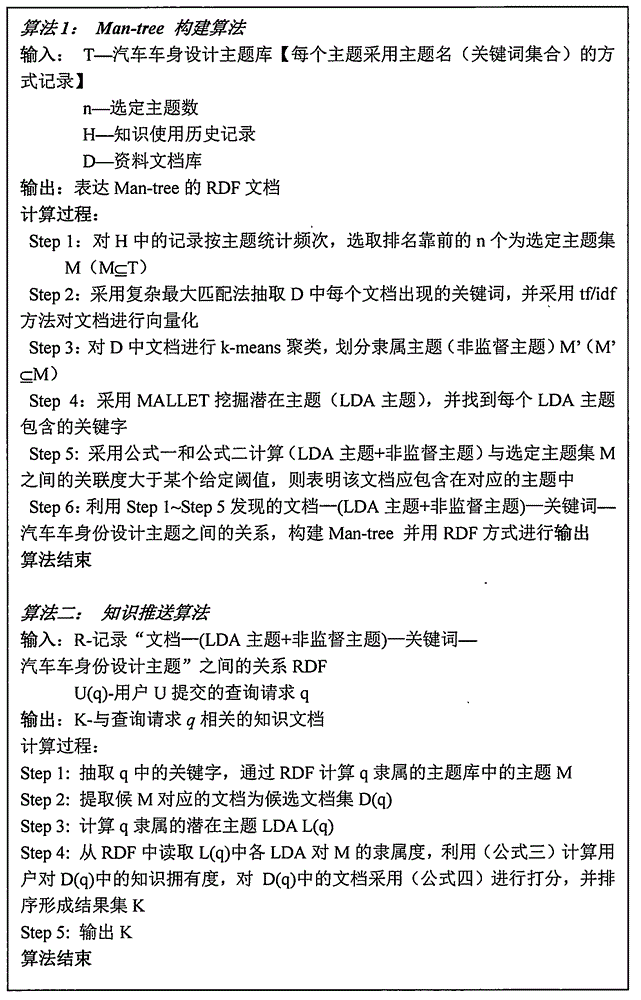

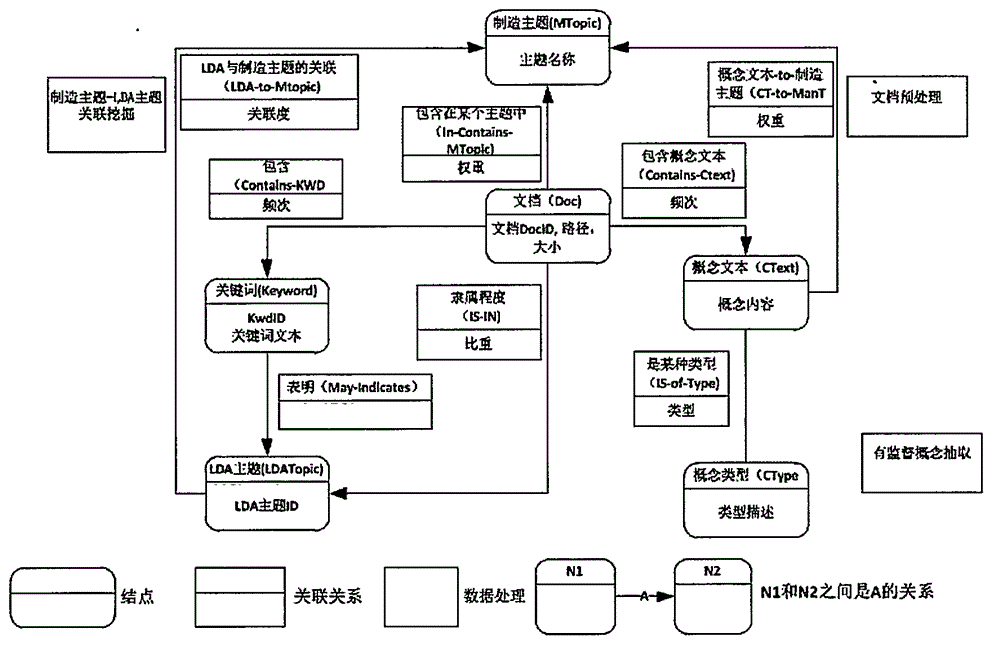

Manufacturing design knowledge individualized pushing method based on knowledge graph (Man-tree)

InactiveCN106156090AGood answerProof of feasibilitySpecial data processing applicationsPersonalizationKnowledge modelling

The invention belongs to the technical field of knowledge management and knowledge pushing oriented to manufacturing enterprises, particularly relates to a novel and efficient knowledge management and knowledge pushing method based on a knowledge graph and discloses a knowledge pushing method based on a manufacturing design knowledge graph structure (Man-tree). By means of the method, the comprehensiveness and accuracy of enterprise knowledge pushing can be effectively improved. The knowledge pushing method comprises the step that a knowledge modeling module, a knowledge extracting and subject discovering module, a knowledge graph Man-tree establishing module, a user knowledge possess degree calculation module and a knowledge pushing module are established by introducing an LDA method. By quantitatively evaluating the degree of the knowledge processed by a user, the knowledge graph is expanded, and semantic association between knowledge and the user is established. According to the specific technology, formation of a database, extraction of knowledge, discovery of knowledge association, knowledge storage design, and a quantitative calculating method for the degree of the knowledge processed by a user are included. The novel method for knowledge pushing in the manufacturing design field is given on the basis that the manufacturing design graph is proposed.

Owner:上海宽文是风软件有限公司

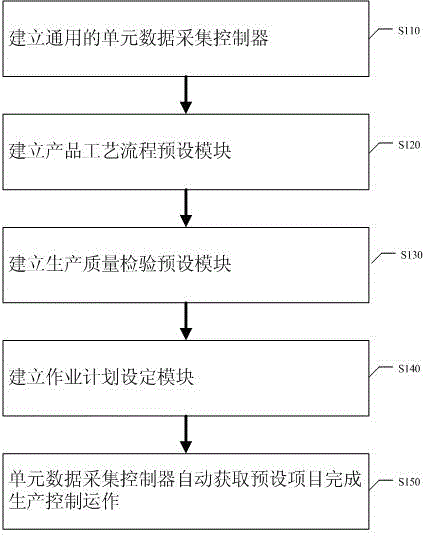

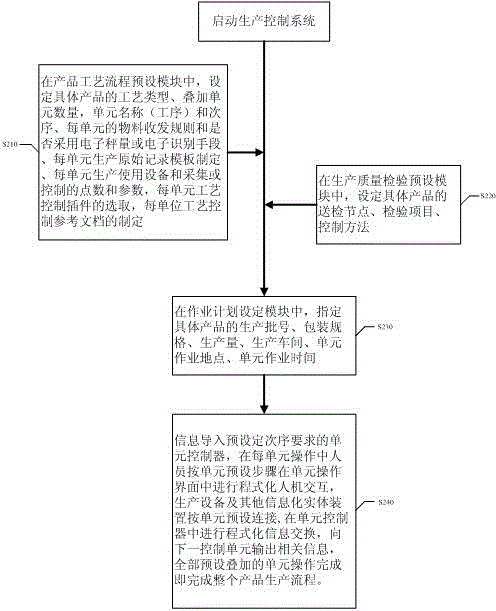

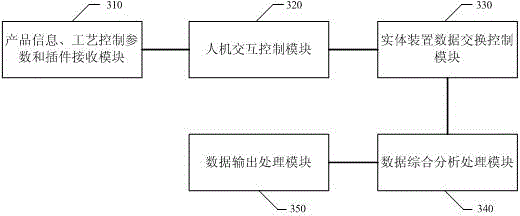

Realization method for general type production and manufacturing unit and control system thereof

ActiveCN104407576AImprove developmentSolve operational problemsTotal factory controlProgramme total factory controlWork planControl system

The invention relates to a realization method for a general type production and manufacturing unit control system. Different technical control processes of product production and manufacturing are decomposed into multiple independent production process computer input and output operation control units which are then substituted by one general virtual control device. The realization method comprises the following steps that one general virtual control device is established; a product technical process preset module is established; a production quality inspection preset module; a work plan setting module is established; and corresponding unit operation performed in a unit data acquisition controller according to a set sequence requirement is performed, stylized information exchange is performed, the related information is outputted to the next control unit and all the preset superimposed unit operation is completed so that the whole product production process is completed. Computer process control difficulty of manufacturing industry intermittence type and discrete type production is mainly solved by the method and the system so that system applicability and work efficiency are enhanced and product technical cost is reduced.

Owner:SHANGHAI YINDAO INFORMATION TECH

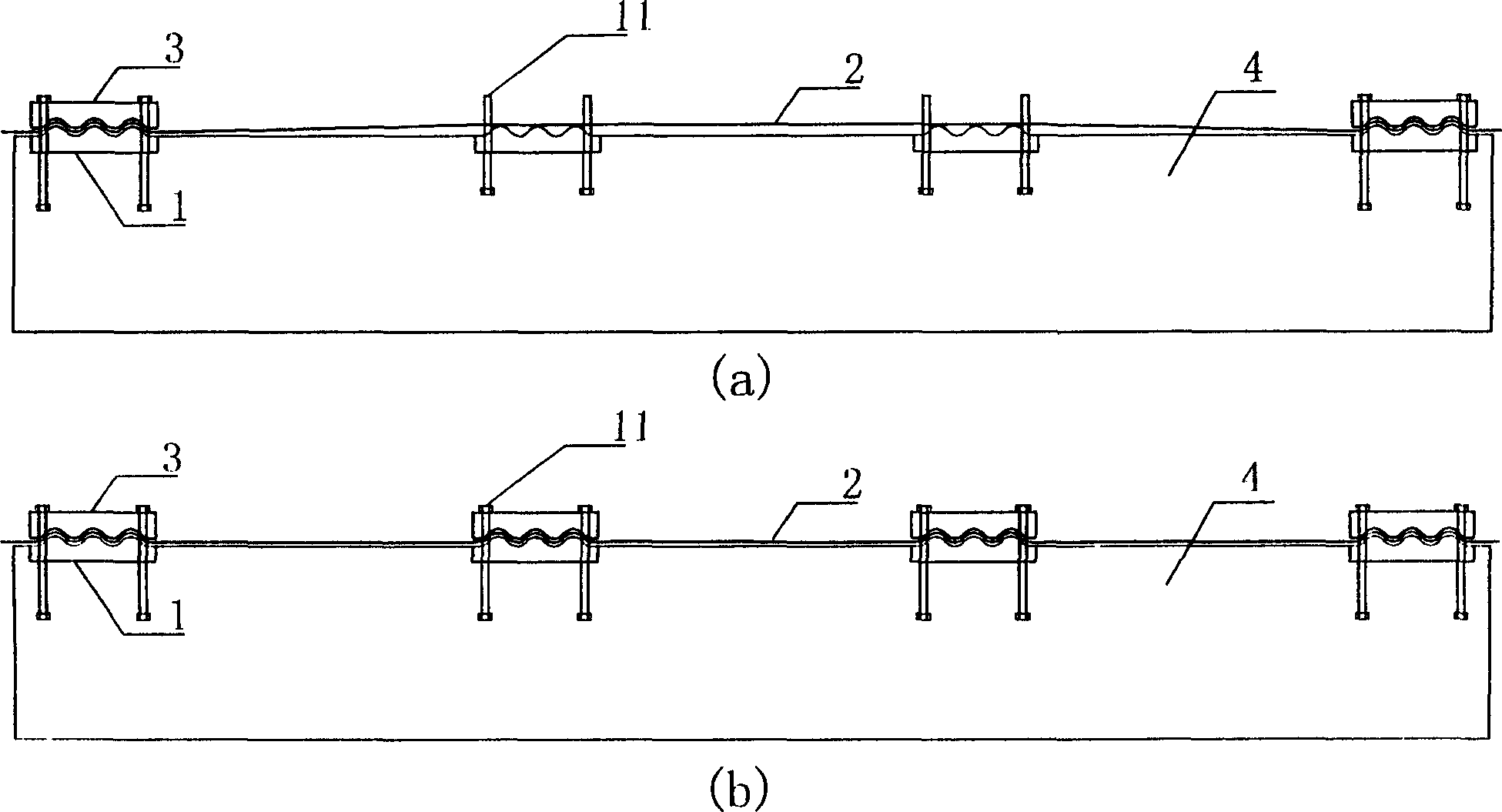

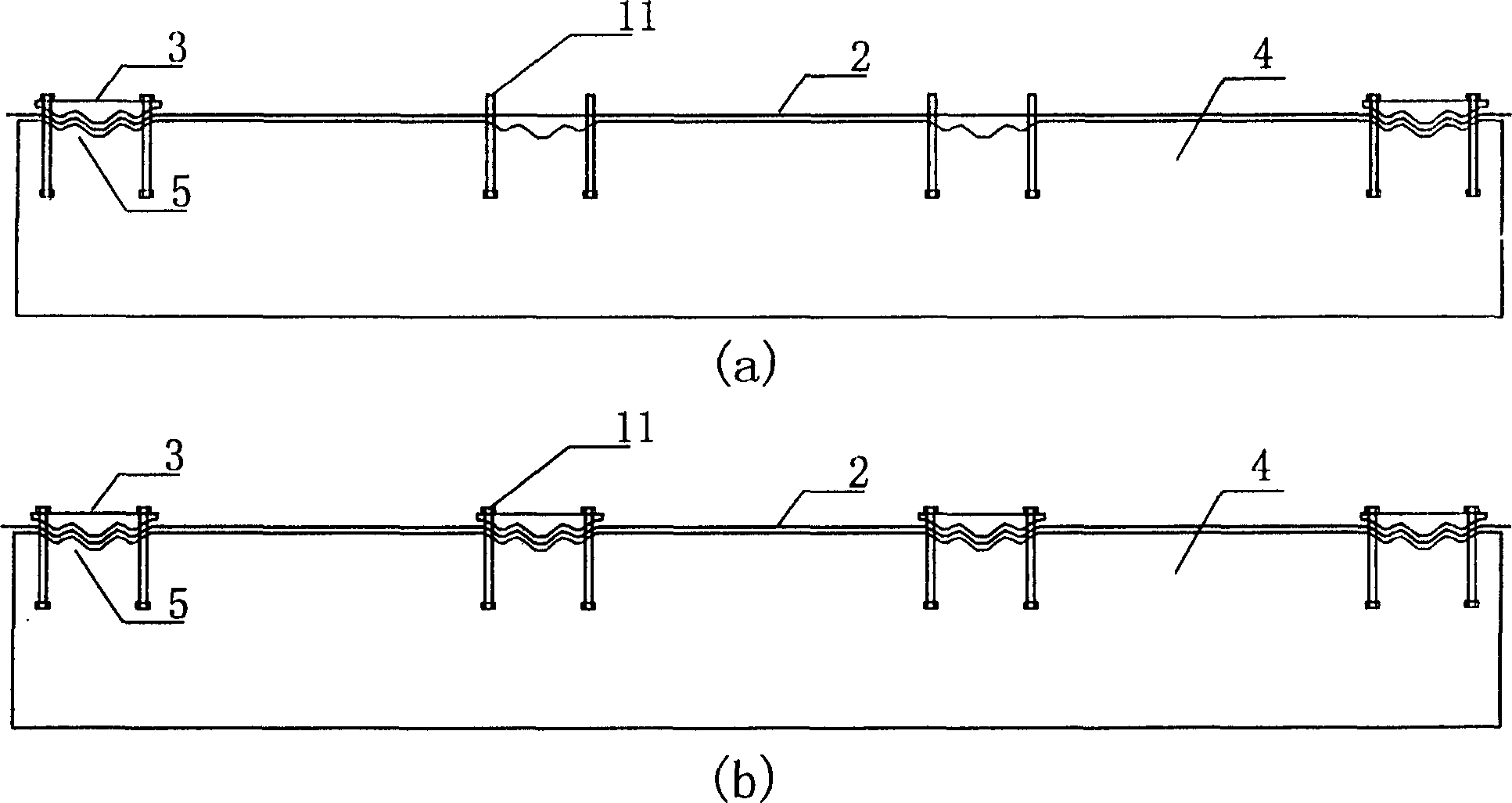

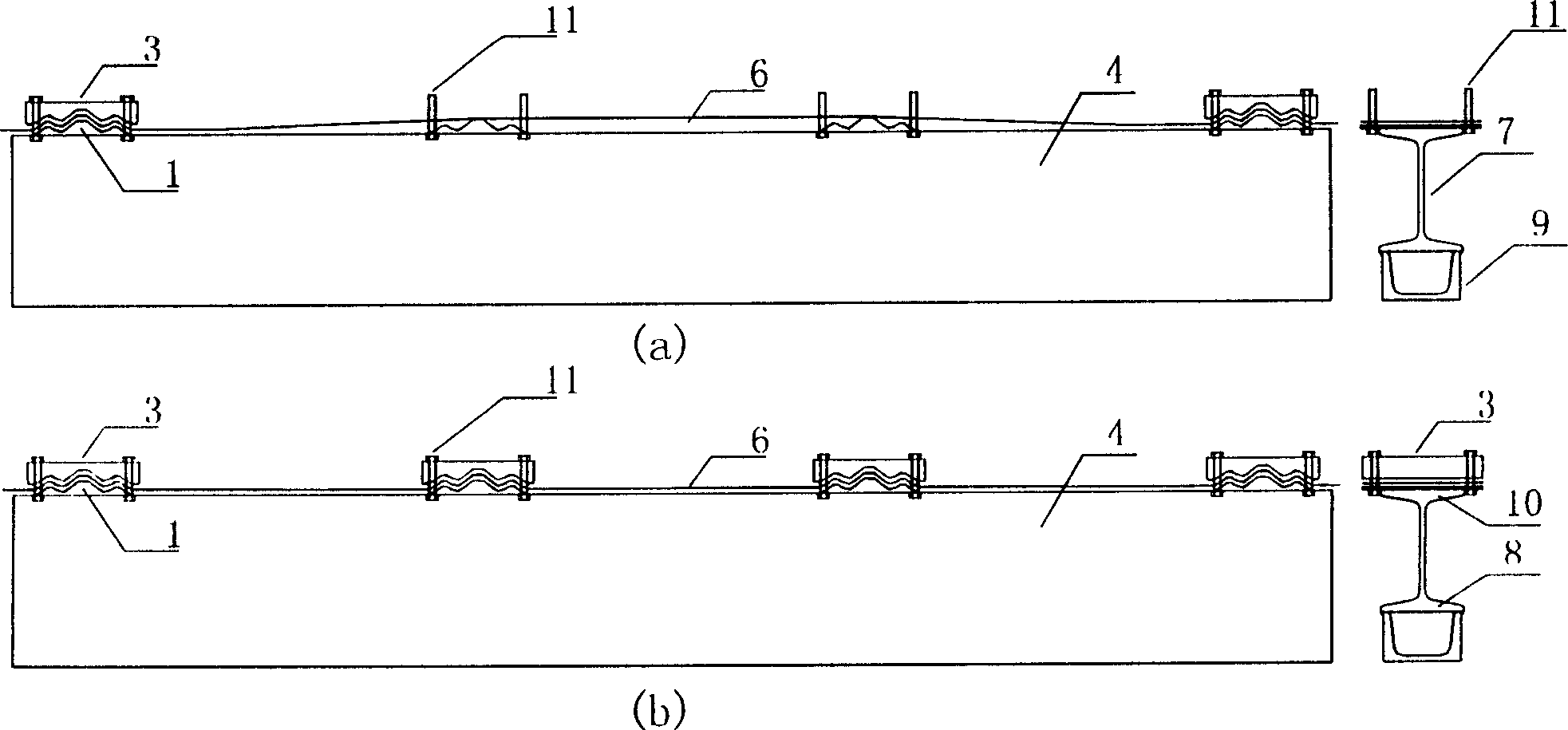

Construction method of prestressing force stretching high strength composite material and anchoring

A prestress stretch and anchor method for high intensity compound material belongs to the construction of compound material reinforcement or civil engineering structure strengthening especially relates to the technical field of high intensity compound material prestress stretch and anchor to be the simple technology, convenient operation, high reliability, good engineering result, strong adaptability to the engineering structure with light weight, small size, rigid, strong carriage, strong ability of crossover, and widely used in bridge, large crossover industrial workhouses, sheds, docks, underground railways and part mechanical industries such as large scale hoist and transport equipments, ships and lorries.

Owner:重庆达力索缆科技有限公司

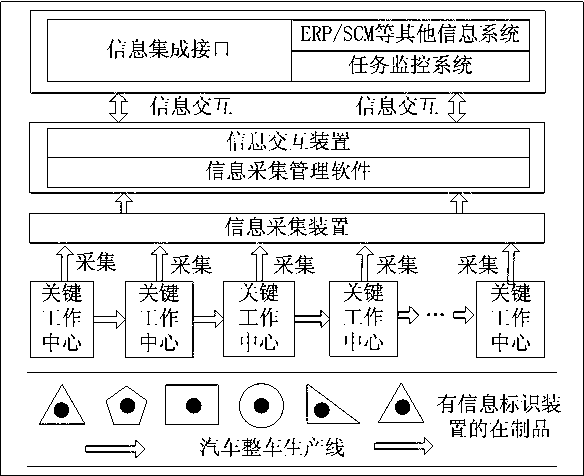

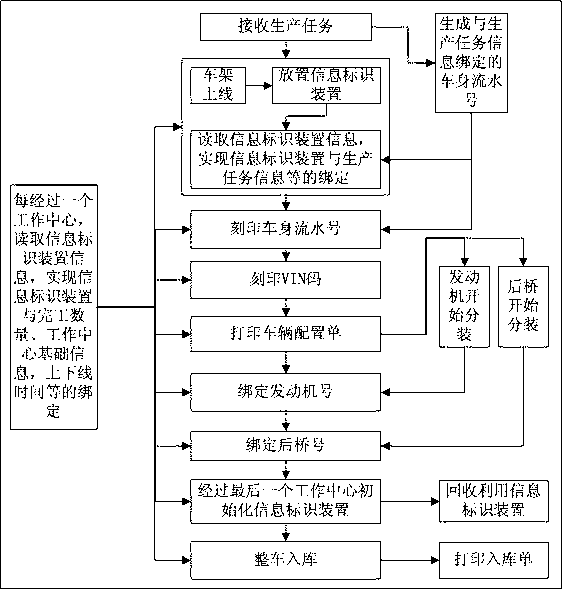

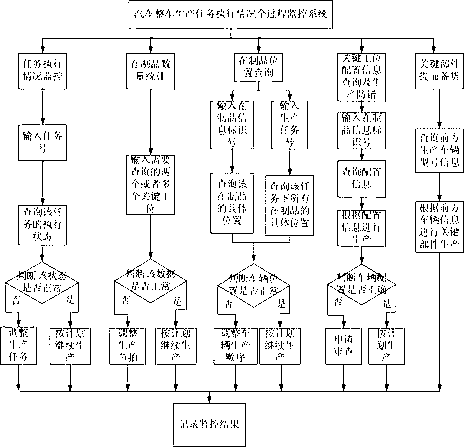

Method and system for monitoring overall process of finished vehicle productive task executive condition

InactiveCN103106617AImproving the ability to quickly respond to the marketIncrease production capacityData processing applicationsManufacturing computing systemsInformatizationBusiness enterprise

The invention discloses a method and a system for monitoring an overall process of a finished vehicle productive task executive condition and belongs to the technical field of manufacturing informatization. The method and the system for monitoring the overall process of the finished vehicle productive task executive condition are characterized in that the system comprises an information identification device, an information collecting device, an information interactive device, a printing device and an engraving device, other hardware, an information integration interface and information collecting management software. The method carries out integration, collecting and interaction to task information of a finished vehicle production process through the information integration interface, the information identification device, the information collecting device and the information interactive device, processes the task information through a task monitoring system, and finally achieves real-time monitoring to a finished vehicle productive task executive process. The method and the system for monitoring the overall process of the finished vehicle productive task executive condition can be widely applied to finished vehicle production enterprises, and have the advantage of being low in cost, strong in generality, and good in expansibility.

Owner:CHONGQING UNIV

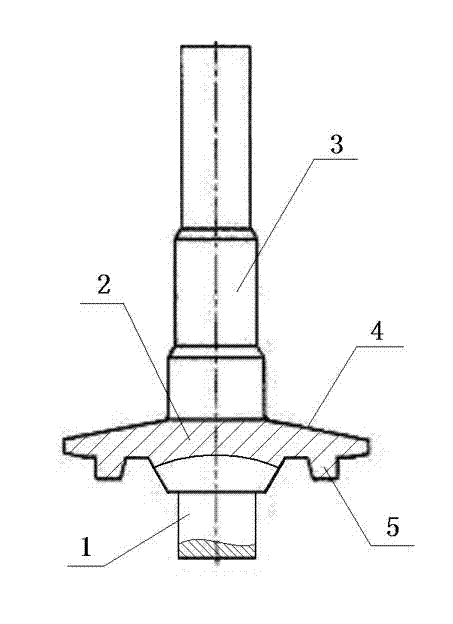

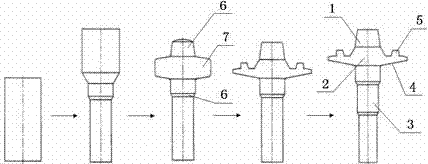

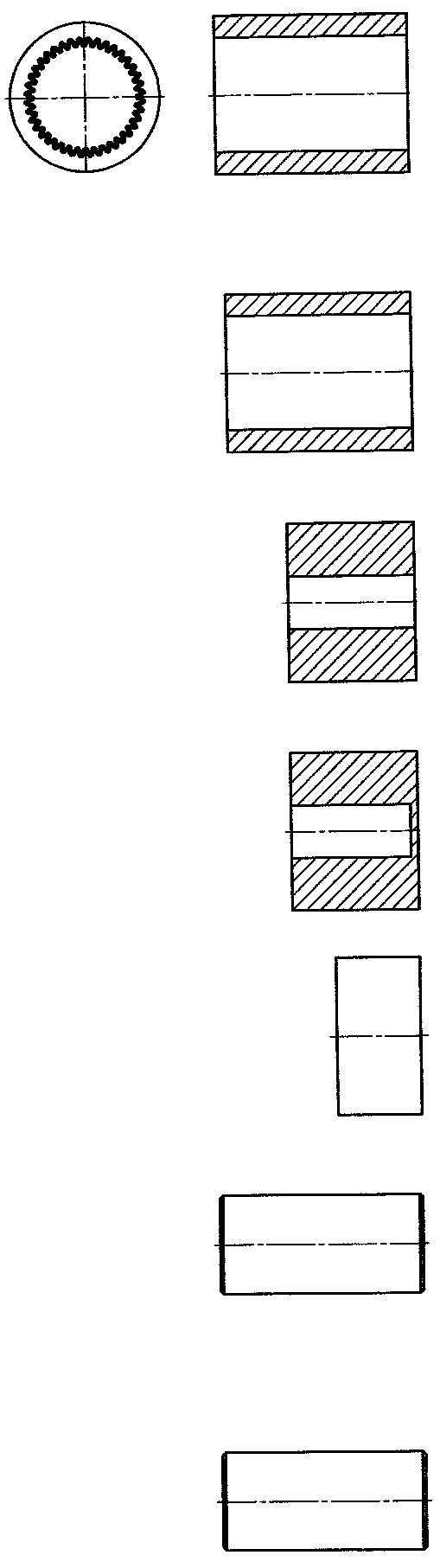

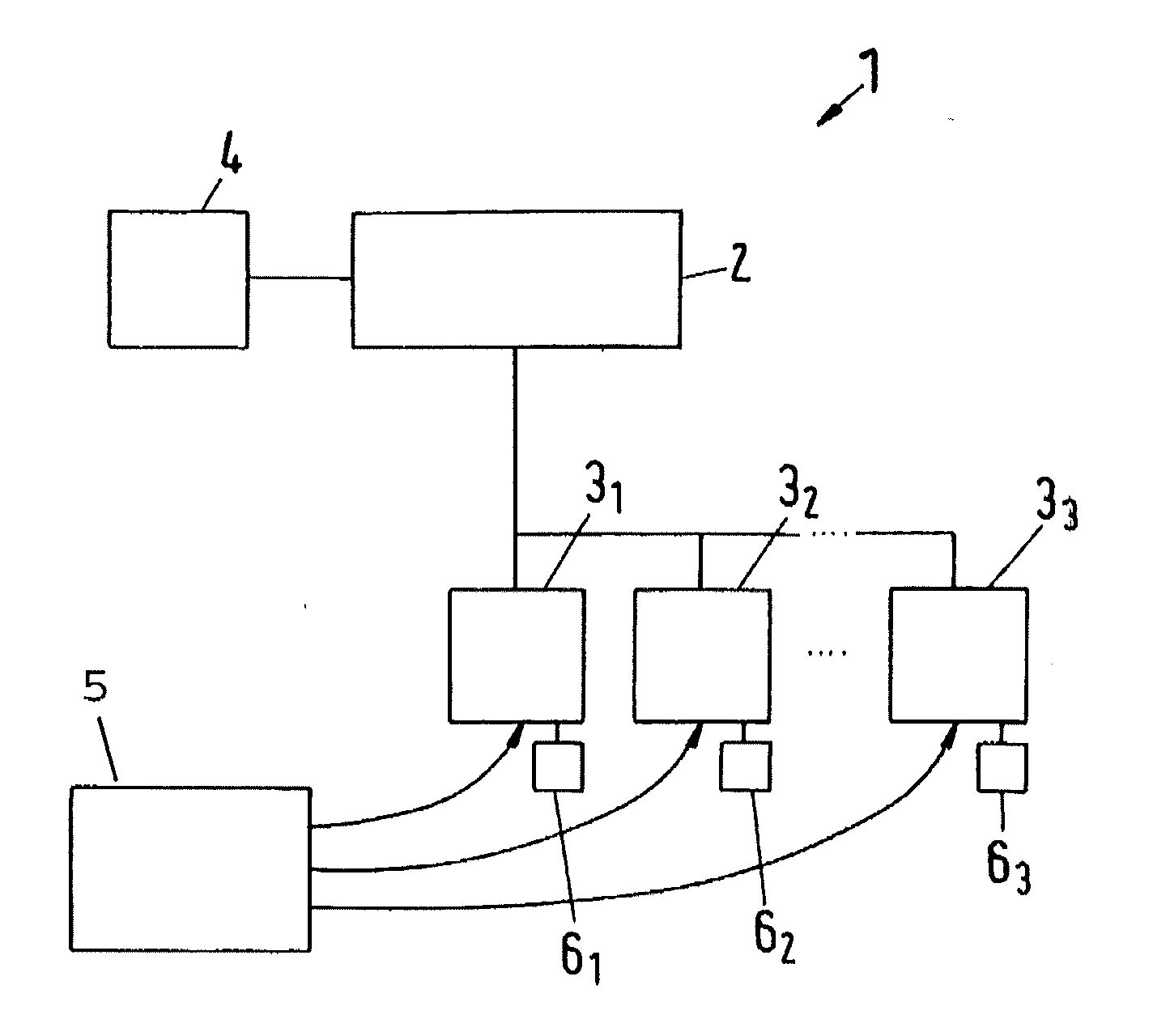

Automatically continuously variable transmission (CVT) V-shaped belt pulley axle finish-forging and plastic- molding process

The invention discloses an automatically continuously variable transmission (CVT) V-shaped belt pulley axle finish-forging and plastic-molding process including the steps of 1, warm forging and plastic molding, 2, annealing at low temperature, lathing including procedures of surface flash and burr removal, shot blasting, phosphating and saponification, and then reducing diameters of shanks of forge pieces subjected to cold squeezing and finishing until meeting the dimension requirements, and 3, finally molding by the cold squeezing and finishing process. Products produced by the process have the advantages of stable quality, high intensity and density and impact resistance; a great quantity of funding needed in the process of machining tooth surfaces by machine tools is reduced, production efficiency is high, raw materials are saved, the process of machining by the machine tools after hot forging is replaced, requirements for product precision are met, production cycle can be shortened, manufacturing cost can be lowered, and the process accords with the development trend of the manufacturing industry all over the world at present.

Owner:江苏威鹰机械有限公司

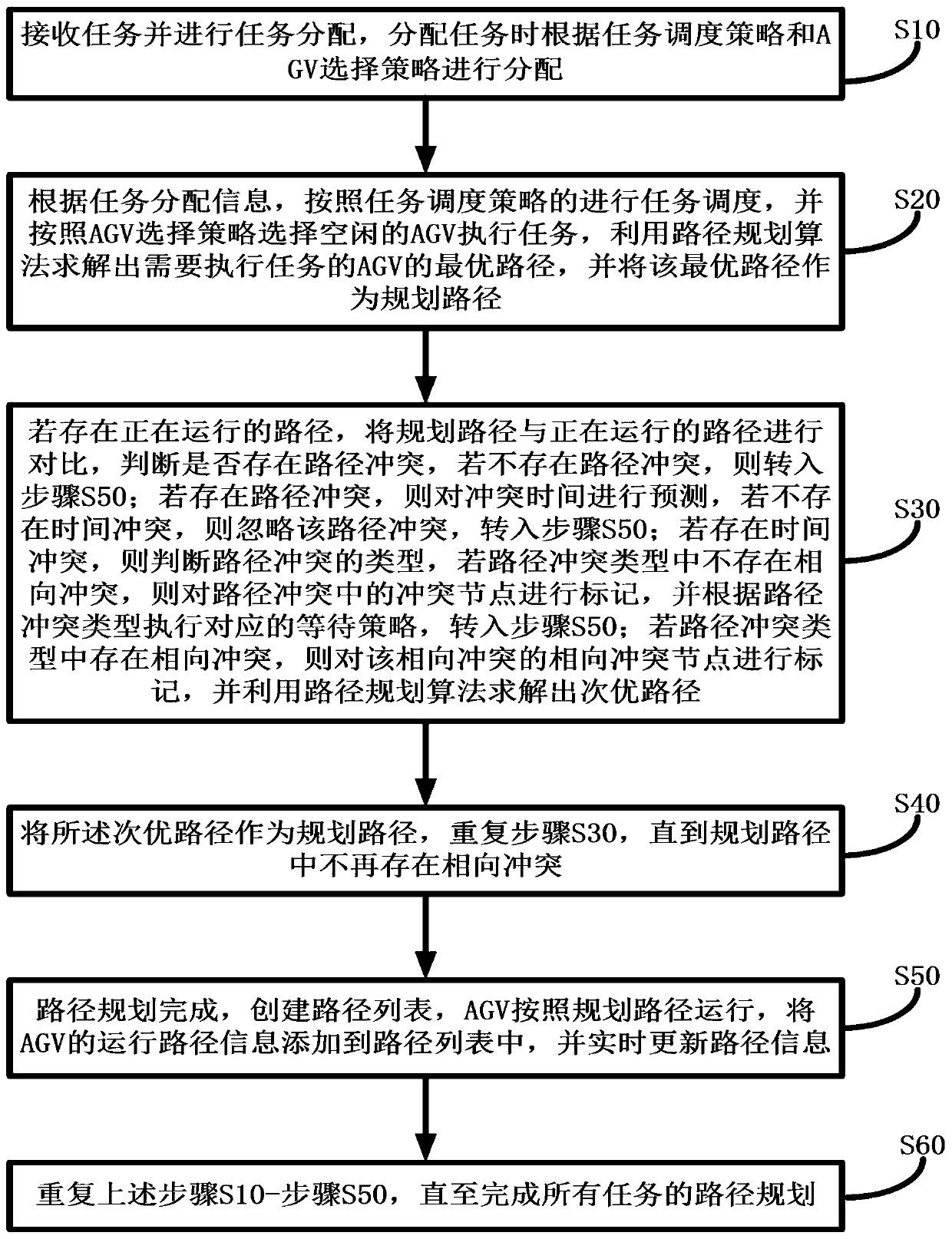

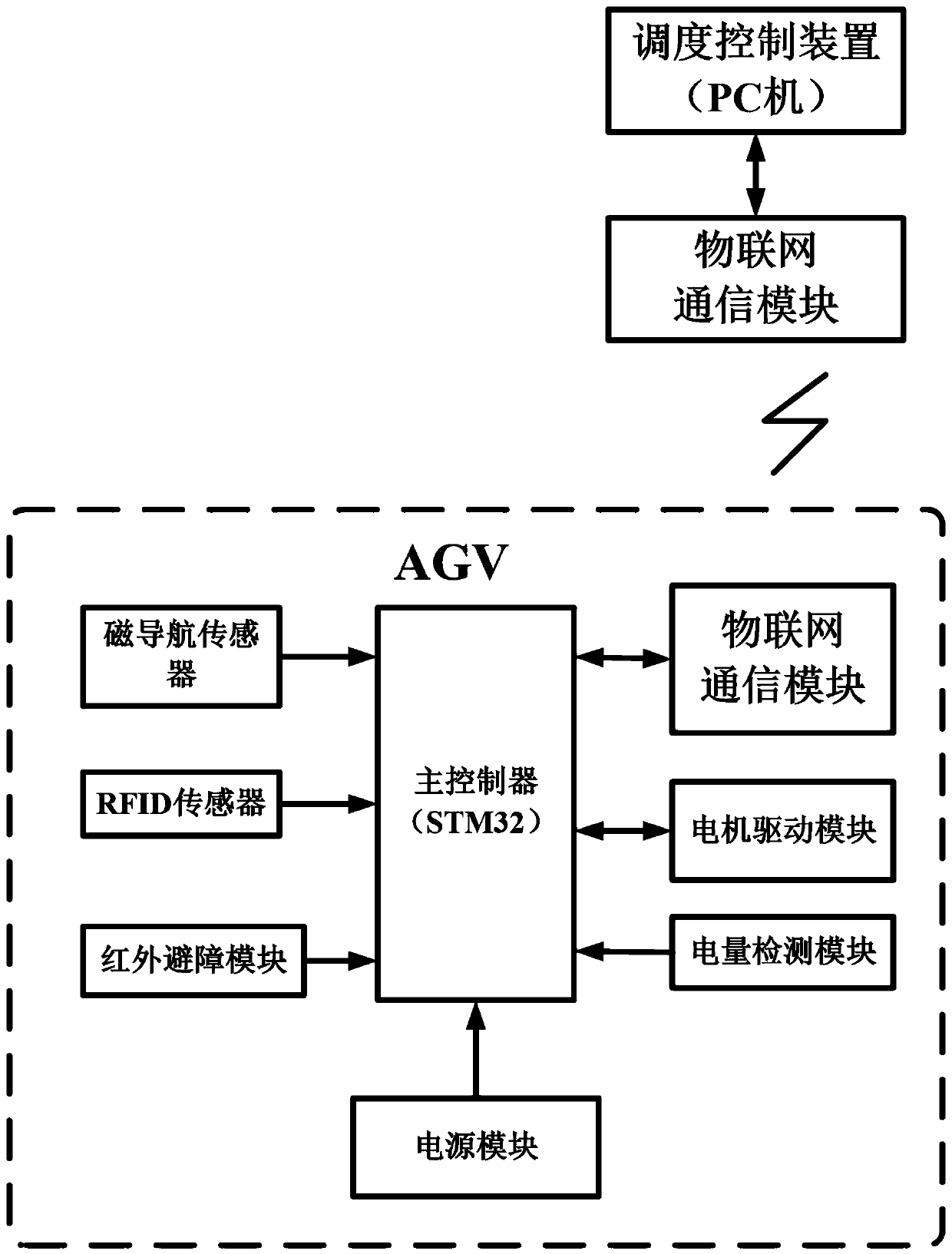

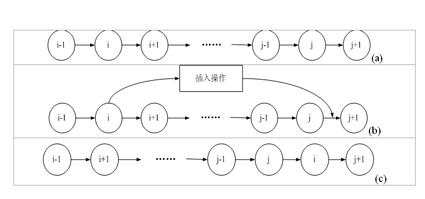

Multi-AGV collision-free operation path planning method and scheduling system

InactiveCN111596658AReduce waiting timeImprove efficiencyPosition/course control in two dimensionsVehiclesManufacturing sectorPlanning method

The invention discloses a multi-AGV collision-free operation path planning method and a scheduling system. According to the path planning method, a priority-based task scheduling strategy is adopted for scheduling; according to the method, tasks can be reasonably allocated, the efficiency of a scheduling system can be effectively improved, Meanwhile, the optimal path of each AGV is solved by adopting an AGV selection strategy based on priority and through an A * algorithm, so that the operation path is relatively smooth, the AGV waiting time is effectively reduced, and the operation efficiencyof the whole system is improved. The multi-AGV collision-free operation path planning method and the scheduling system provided by the invention can be widely applied to production factories in the manufacturing industry, traditional manual carrying and conveying belt transportation are replaced, intelligent transformation of the factories is accelerated, the labor cost is reduced, and the production efficiency is greatly improved.

Owner:DONGGUAN UNIV OF TECH

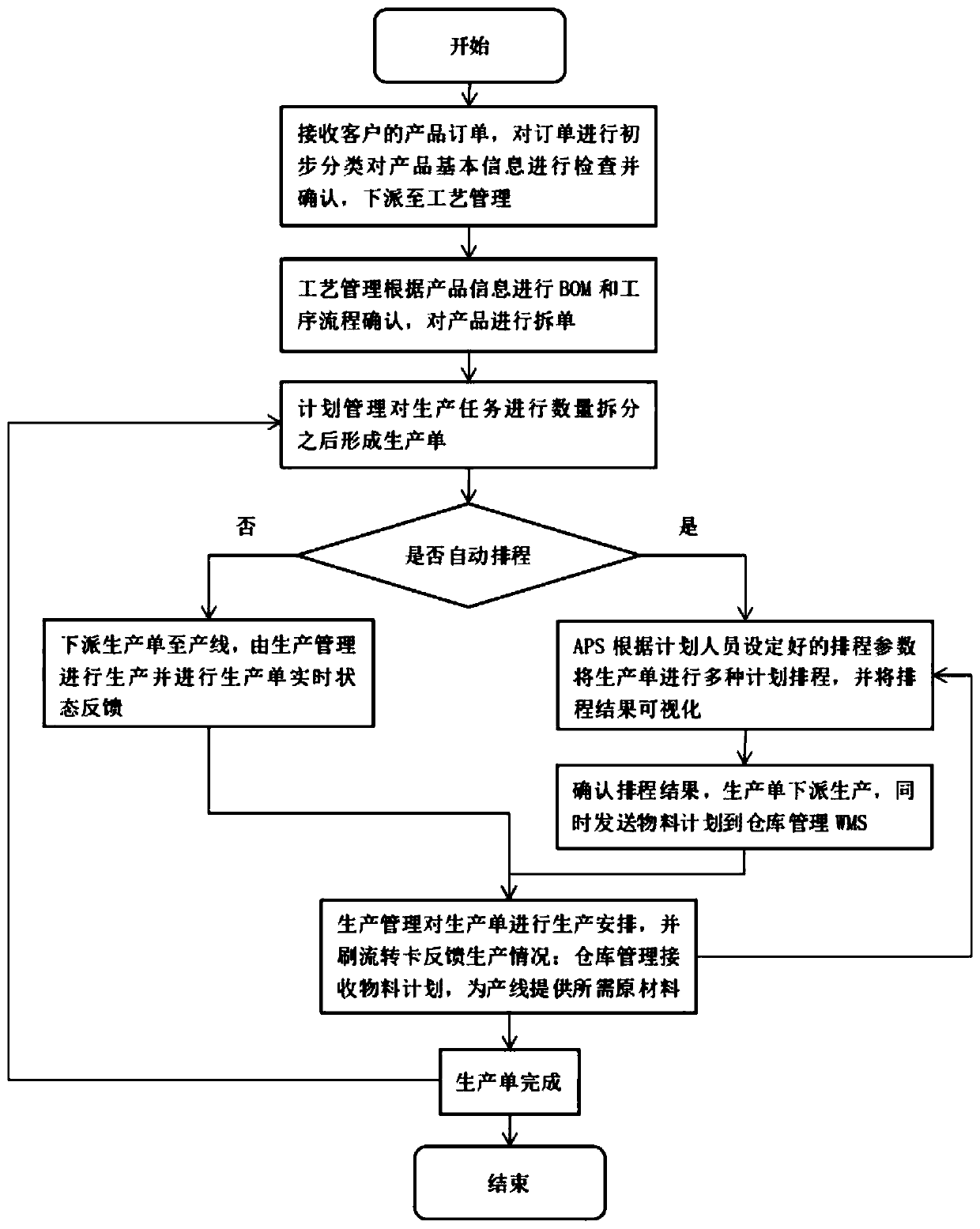

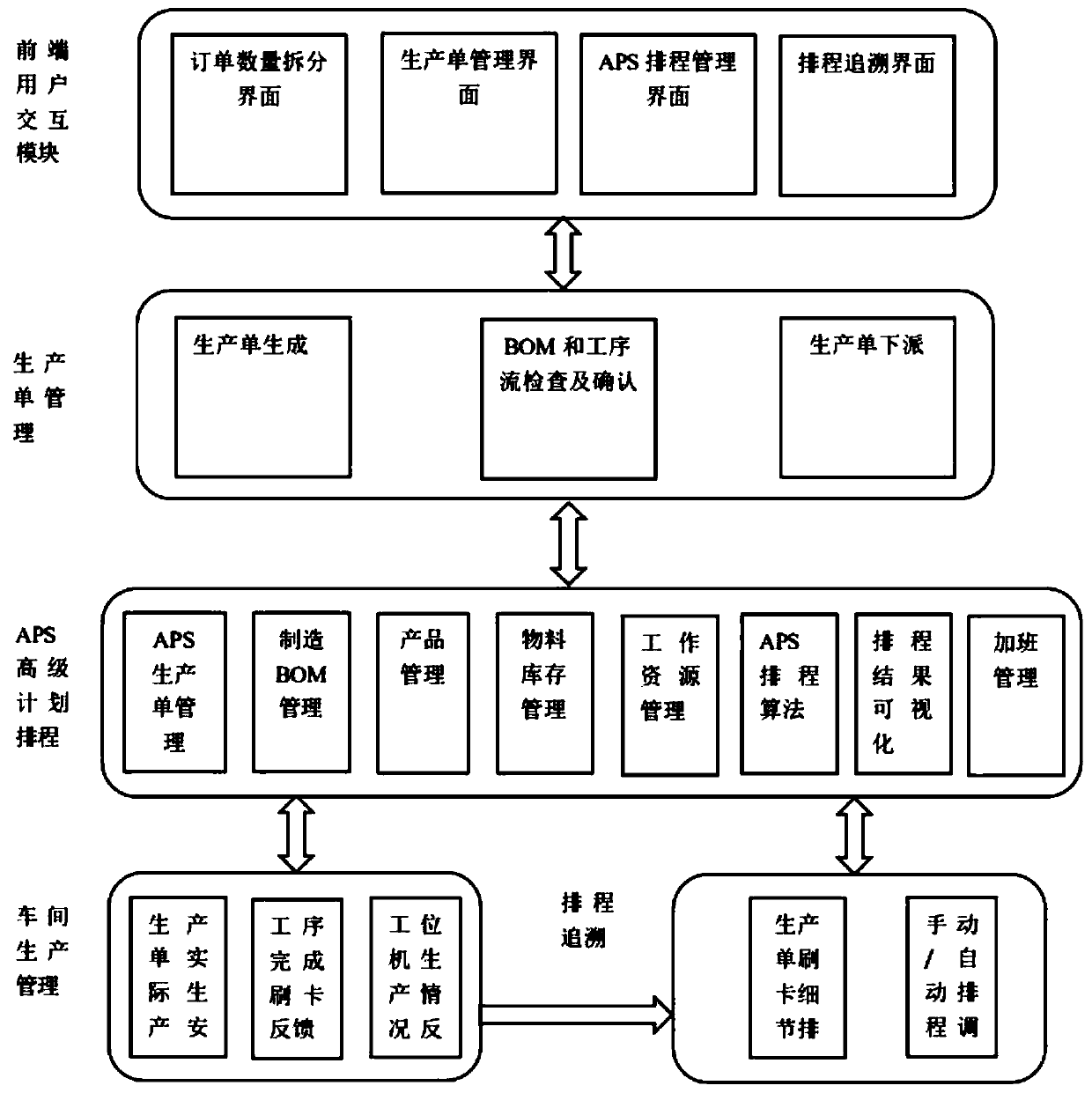

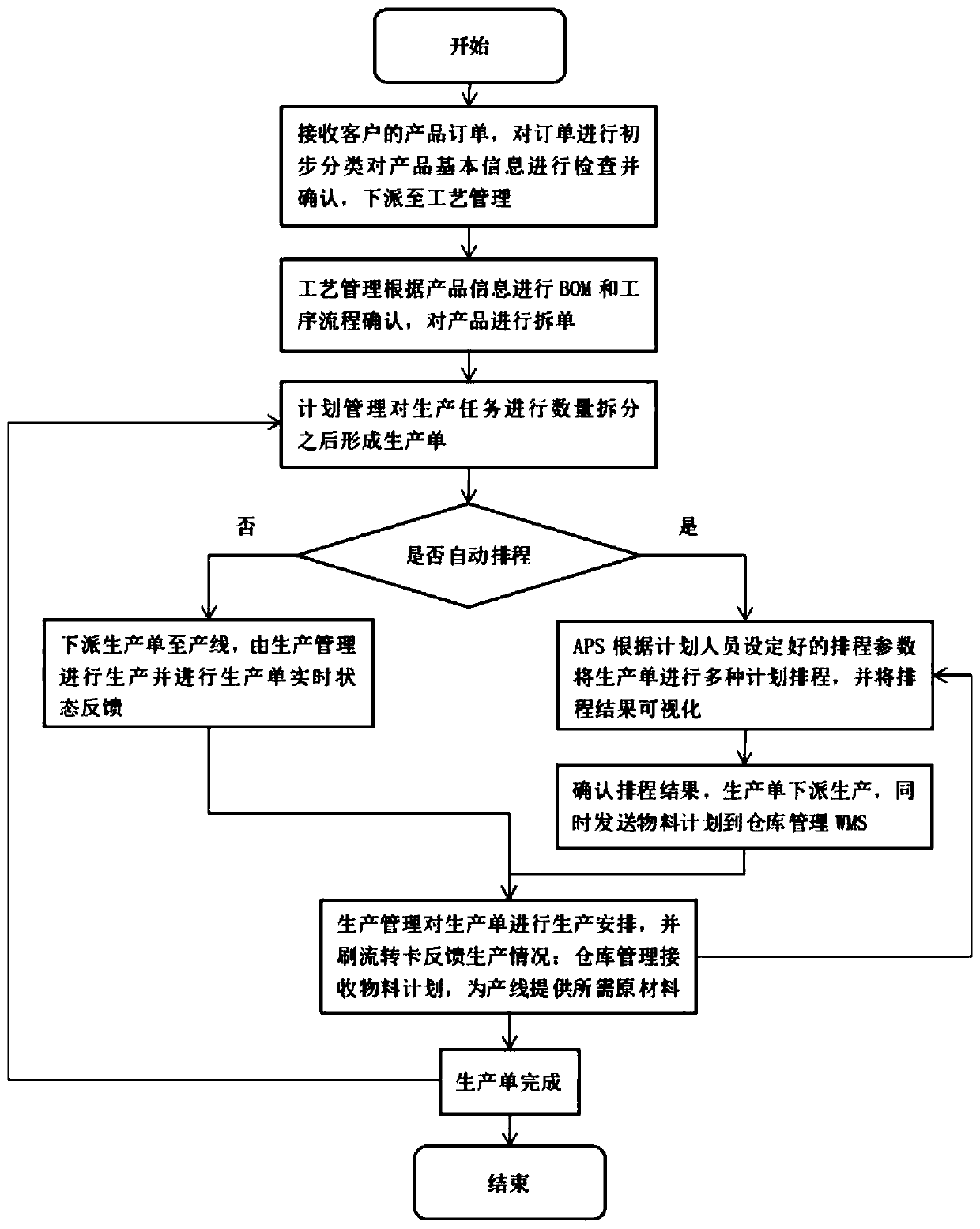

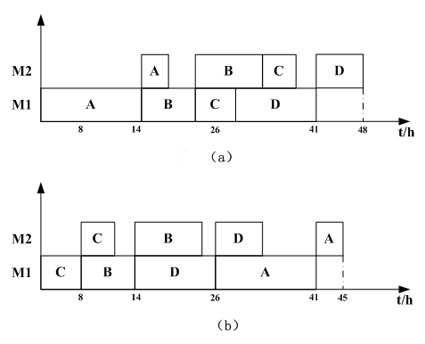

Discrete manufacturing industry-oriented dynamic production plan scheduling method

PendingCN111126748ARealize dynamic adjustmentAvoid influenceResourcesManufacturing computing systemsClosed loop feedbackResource utilization

The invention discloses a discrete manufacturing industry-oriented dynamic production plan scheduling method, which comprises the following steps of: firstly, a customer order is received, and a process management module splits the customer order to generate a production task according to product information; a plan management module generates a production order according to the production task, and an advanced plan scheduling module automatically schedules the production order according to scheduling parameters set by a planner and dispatches the production order for production according to ascheduling result; a production management module receives the production list and arranges production; a warehouse management module receives the material plan and prepares raw materials for the production line; and a scheduling tracing module feeds back the actual production information to the plan management module, dynamically adjusts a scheduling result, and forms closed-loop feedback from plan scheduling to actual production. According to the method, the scheduling result is dynamically adjusted according to unstable factors in actual production, the reasonable resource utilization rateis ensured, and the visual material plan and production plan are generated from multiple angles under the condition of considering enterprise resources, a production field and a dispatching method.

Owner:盐城雷来钧智能制造技术有限公司

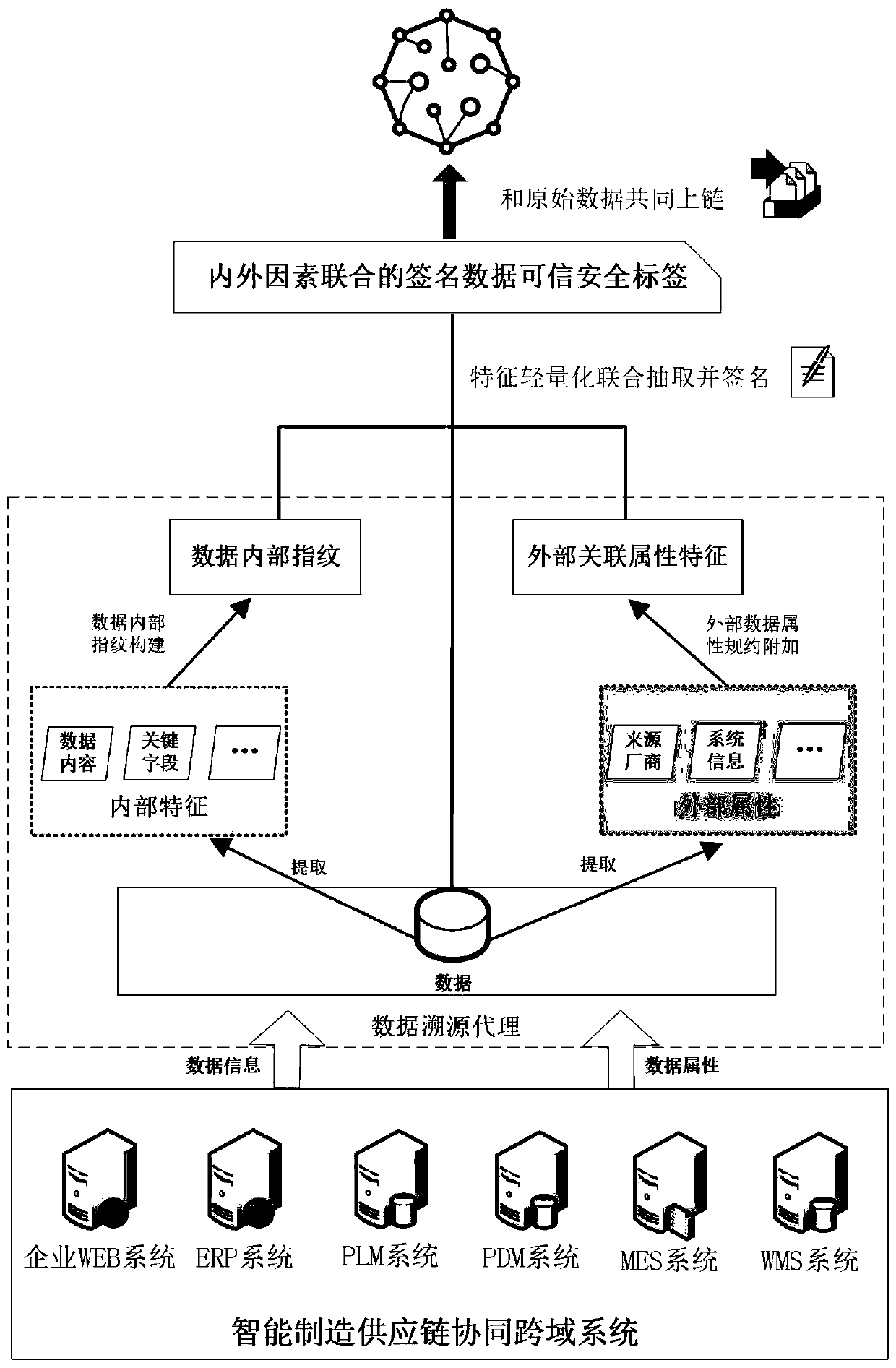

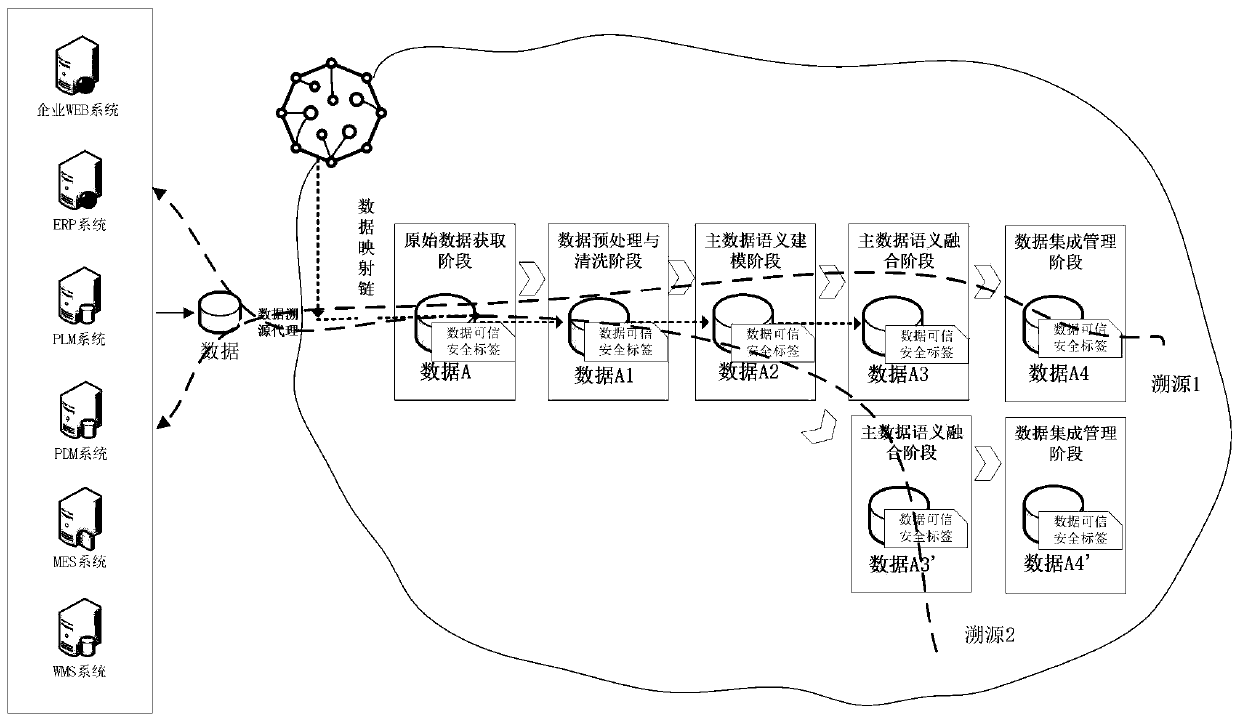

Manufacturing industry cross-domain heterogeneous data identity construction and tracing method based on block chain

ActiveCN110084070AUniqueness guaranteedGuaranteed to be tamper-proofFinanceDigital data protectionChain systemFingerprint

The invention provides a manufacturing industry cross-domain heterogeneous data identity construction and tracing method based on a block chain. The method comprises the steps that firstly, a data tracing proxy is preset in the multi-data processing stage of an intelligent manufacturing industry supply chain collaborative cross-domain system, and data interaction with the block chain system is achieved through the proxy; a data tracing proxy extracts data internal fingerprints which can be shared and are written into a database of each enterprise, a lightweight elliptic curve feature extraction algorithm is designed by combining external association attribute features of the data, internal and external cause joint features are further extracted and signed, and a data credible security label combining internal and external factors is constructed. Secondly, an intelligent contract is called, in the multi-data processing stage of the supply chain cooperative cross-domain system, a recordis generated and stored in a data mapping logic chain in a block chain, a multi-party consensus mechanism based on the block chain and a tamper-proof characteristic are combined with the automation capability of an intelligent contract in the block chain, and multi-scale and multi-data processing stage data identity chain tracing is realized.

Owner:INST OF INFORMATION ENG CAS

Risk management for manufacturing

InactiveUS20040083162A1Global transparency of priceLow costMarket predictionsFinanceMarket intelligenceMarket conditions

A method and system for design and development of financial instruments which enables businesses to benefit from the economic value of risk management. First the system develops a methodology, for specific sector, to extract root products. A database is designed to continually update the technical specifications of root products to ensure the uniformity of defined generic specification. Next the system database continually monitors, stores and analyzes the market intelligence required for determining the products relative market strength. Finally, a flexible contract product is designed transforming these products to financial instruments. Such financial instruments are continuously updated, added and deleted as the technical and market conditions change

Owner:SADRE MAMOUD

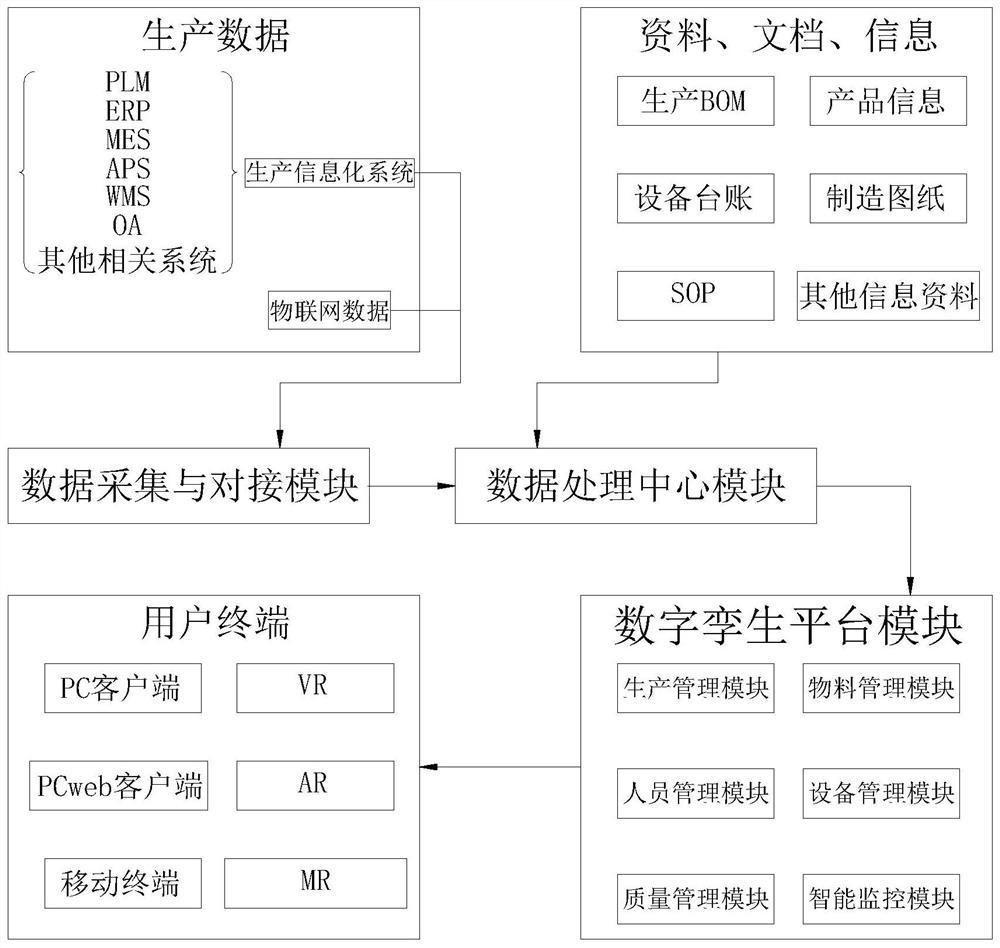

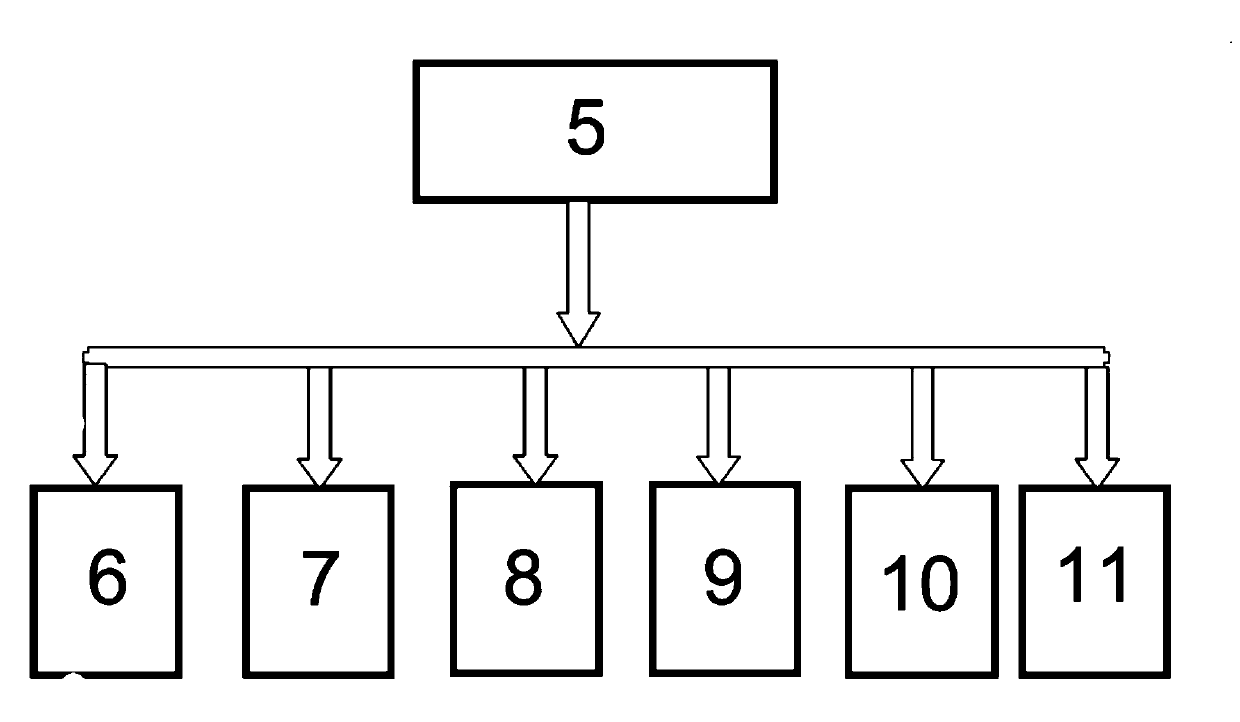

Manufacturing industry factory management system based on digital twin platform

PendingCN113534760ASolve the problem of fragmented and difficult unified system managementSolve the problem of not being able to obtain production information in real timeTotal factory controlProgramme total factory controlData informationData acquisition

The invention discloses a manufacturing industry factory management system based on a digital twin platform, which comprises a data acquisition and docking module, a data processing center module and a digital twin platform module, and the digital twin platform module comprises a production management module, a material management module, a personnel management module, an equipment management module, a quality management module and an intelligent monitoring module. All production data information can be integrated and summarized in a unified mode according to the actual production logic relation, so that an integrated scheduling management system is formed, the problems that production information is scattered and cannot be managed in a unified and systematic mode are solved, the problems that data are poor in readability and difficult to understand due to the fact that data are complex and disordered can be solved, the management efficiency is greatly improved, and the labor intensity of managers is reduced.

Owner:上海奇梦网络科技有限公司

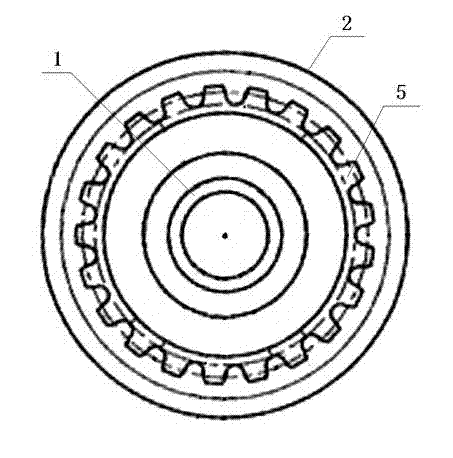

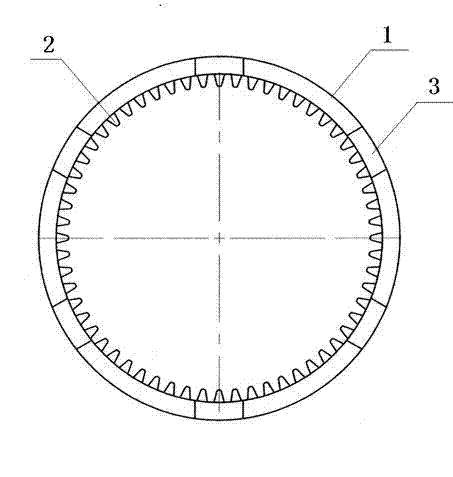

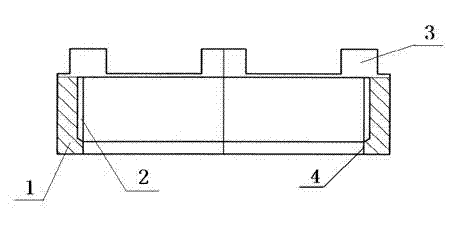

Precision forging plastic forming process for inner gear ring in planetary reducer

The invention discloses a precision forging plastic forming process for an inner gear ring in a planetary reducer. The precision forging plastic forming process includes the following steps: (1), warm forging plastic forming is carried out; (2), normalizing, reforming, sand blasting, phosphating, surface saponification and treatment are carried out; and (3), cold forging plastic forming is carried out. By means of the process, a product is stable in quality, accumulative errors among tooth profiles are small, the rate of finished products is high, the working efficiency is improved, and the production cycle is short. A large amount of machining methods that a machine tool is adopted to carry out machining after hot forging are replaced, work quantities of machine tool machining are reduced, not only is the precision requirement met, but also the production cost is reduced and the production cycle is shortened, and meanwhile, the process also meets the trend of development of the worldwide manufacturing industries.

Owner:江苏威鹰机械有限公司

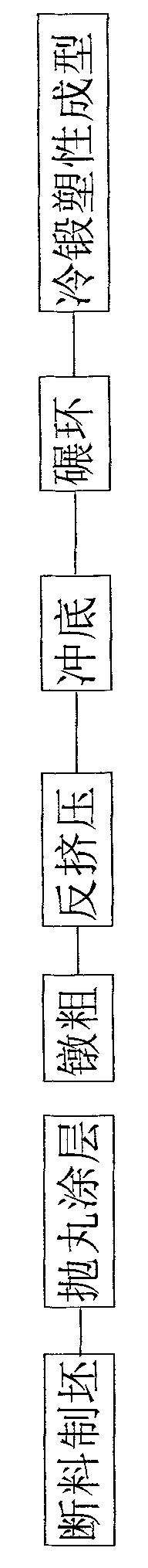

Automatic zinc plating system and zinc plating process

InactiveCN103290348AReduce the chance of being oxidizedReduce the chance of oxidationMolten spray coatingAutomatic controlEngineering

The invention relates to an automatic plating system and a zinc plating process. The automatic plating system includes an automatic control system, a workbench, a zinc plating system, a rotary drive system, a workpiece transfer system, a workpiece degreasing and derusting system, and a heating system. Specifically, the workpiece transfer system is disposed at the front end of the workbench, the rotary drive system is arranged on the workbench, and the workpiece degreasing and derusting system, the heating system and the zinc plating system are arranged on a path over the workbench in order. The movement execution of each component is all controlled by the automatic control system. In the invention, the traditional hot dip galvanizing procedure us reformed, the automatic control system is introduced, and the required raw materials, the workpiece rotation speed, the nozzle discharge flow, the nozzle movement speed, and the surface temperature of the workpiece's coated area and other key indexes are calculated accurately, so that the production procedure can be more automated, the production process is greener, and the product quality control is leaner. Thus, the zinc plating system and the zinc plating process are in line with the transformation and upgrading trends of the traditional manufacturing industry.

Owner:JIANGSU FLOHAR LAMPS MFG CO LTD

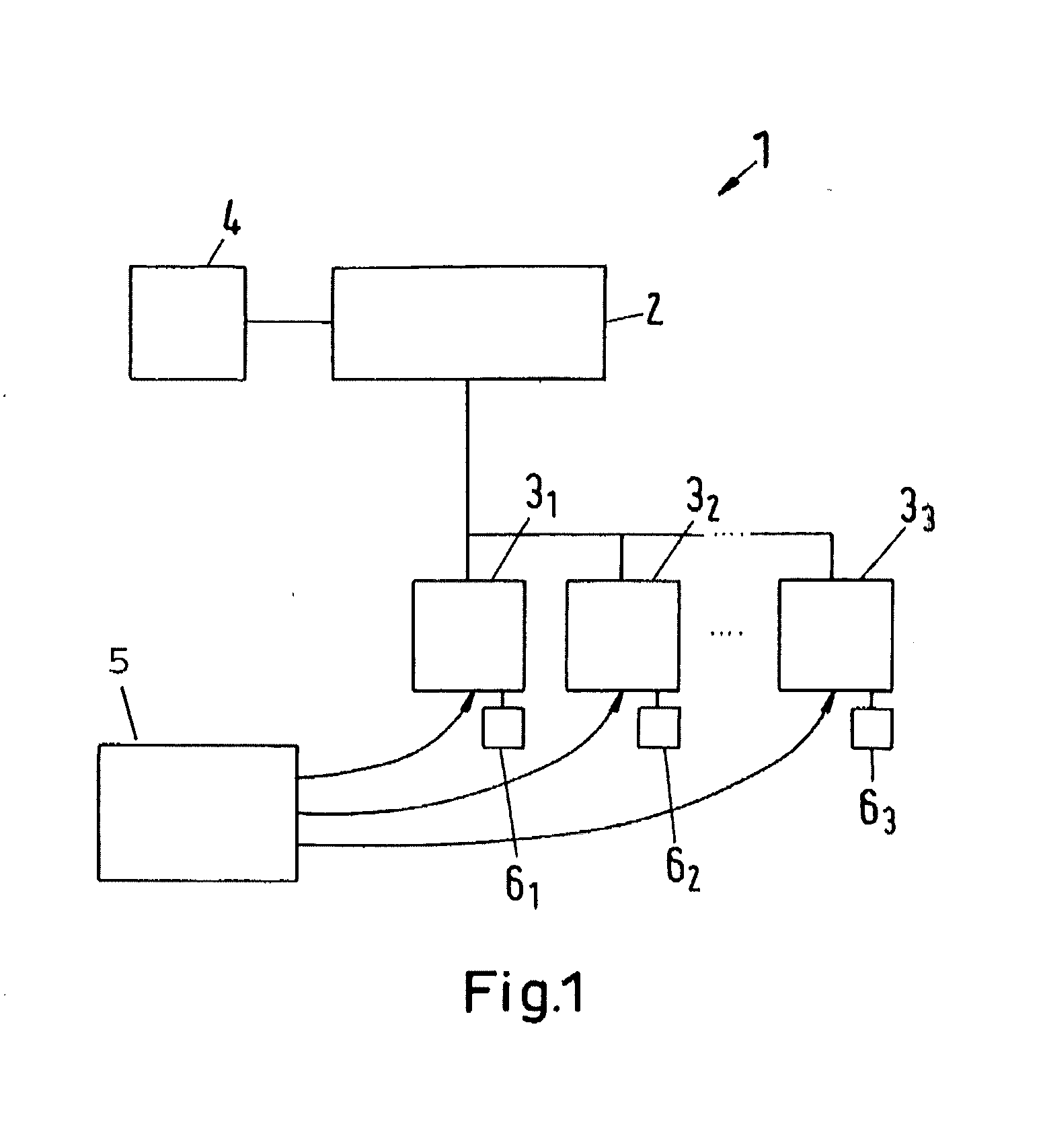

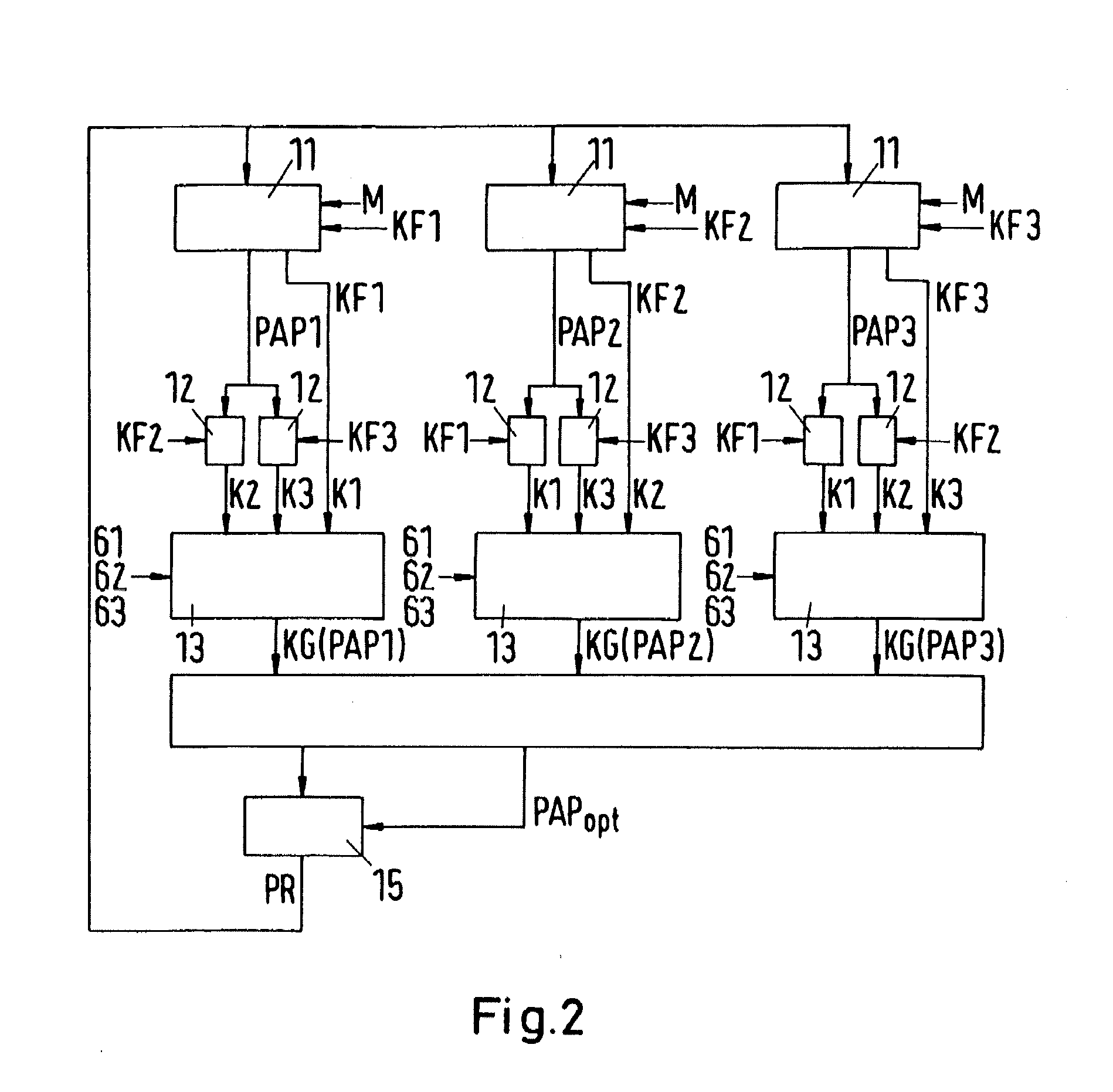

Method and device for optimising a production process

InactiveUS20130226648A1Easy to operateUse efficiencyResourcesProcess industryManufacturing engineering

A method and an apparatus are disclosed for operating a production plant in a production process in the manufacturing industry or the process industry by optimizing the operation of the production process, in which the efficient use of the available energy is taken into account as a further optimization variable.

Owner:ABB (SCHWEIZ) AG

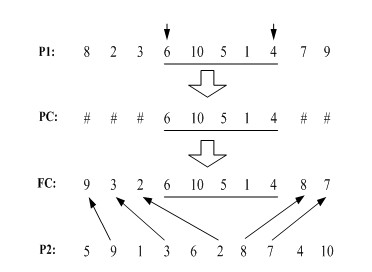

Method for scheduling machine part processing line by adopting discrete quantum particle swarm optimization

InactiveCN102073311AOptimal Scheduling SchemeEasy to operateBiological modelsTotal factory controlLocal search (optimization)Gantt chart

The invention discloses a method for scheduling a machine part processing line by adopting the discrete quantum particle swarm optimization, comprising the following steps: reading in the machine part processing process operation time, initializing a particle swarm, calculating the adaptation value of each particle, updating the individual optimal position and the global optimal position of each particle, carrying out global search on the basis of the discrete quantum particle optimization, carrying out local search and drawing a machine part processing sequence Gantt chart according to a global optimal scheduling scheme. The method disclosed by the invention improves the limitation of the traditional quantum particle swarm optimization in the production scheduling field, overcomes the defects that the quantum particle swarm is easy to be subjected to local optimization and has the advantages of high optimizing precision and high optimizing speed. The method is used for scheduling the machine part processing line, can solve to obtain an optimal scheduling scheme in a shorter time and is easy and convenient to operate. The principle has wide range of application and can be popularized to the producing and processing field of the manufacturing industry, the process industry and the like.

Owner:ZHEJIANG UNIV

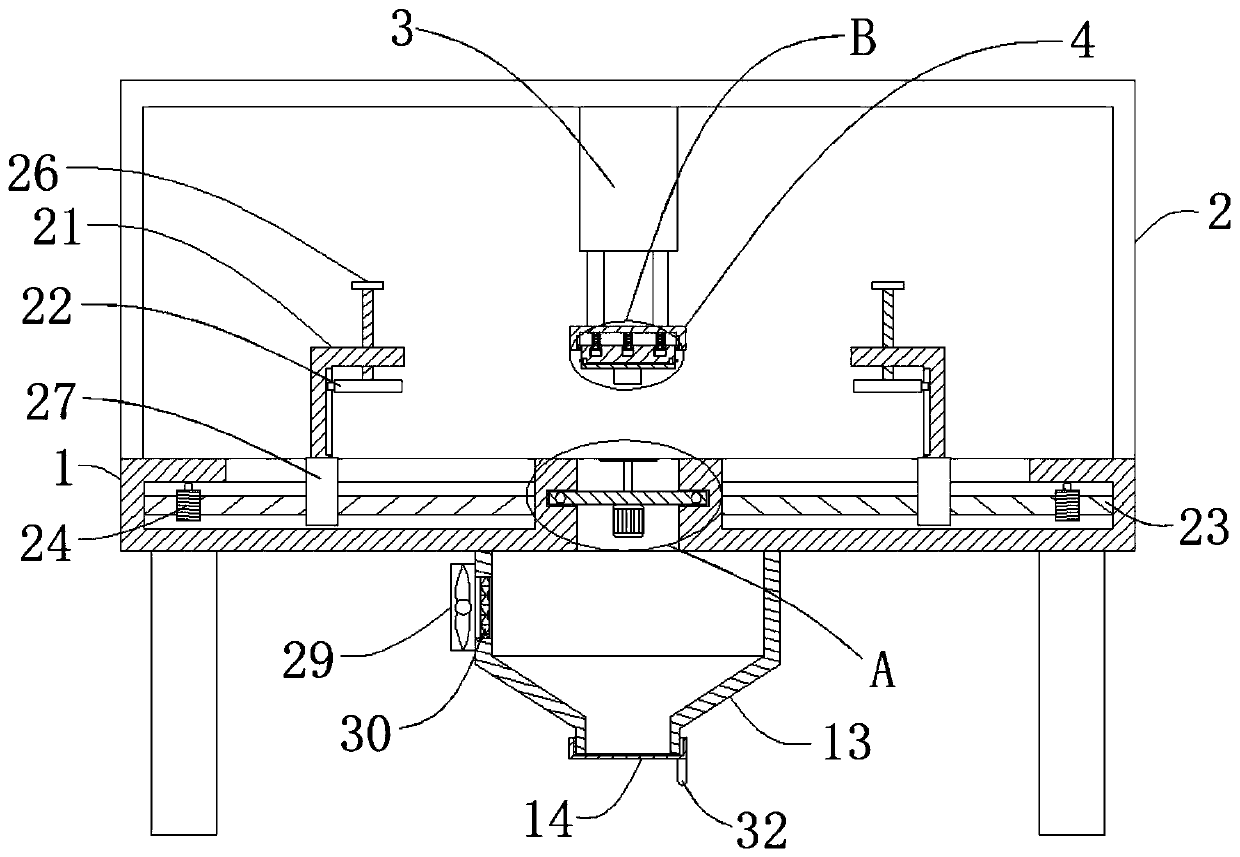

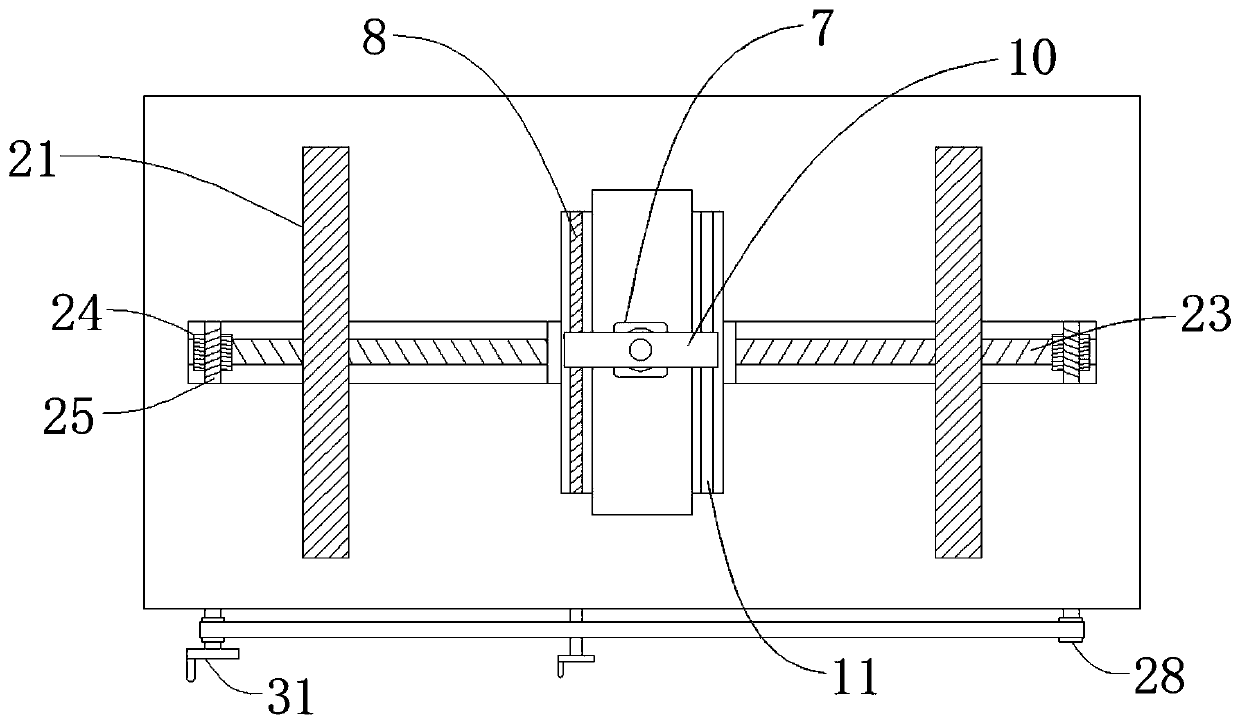

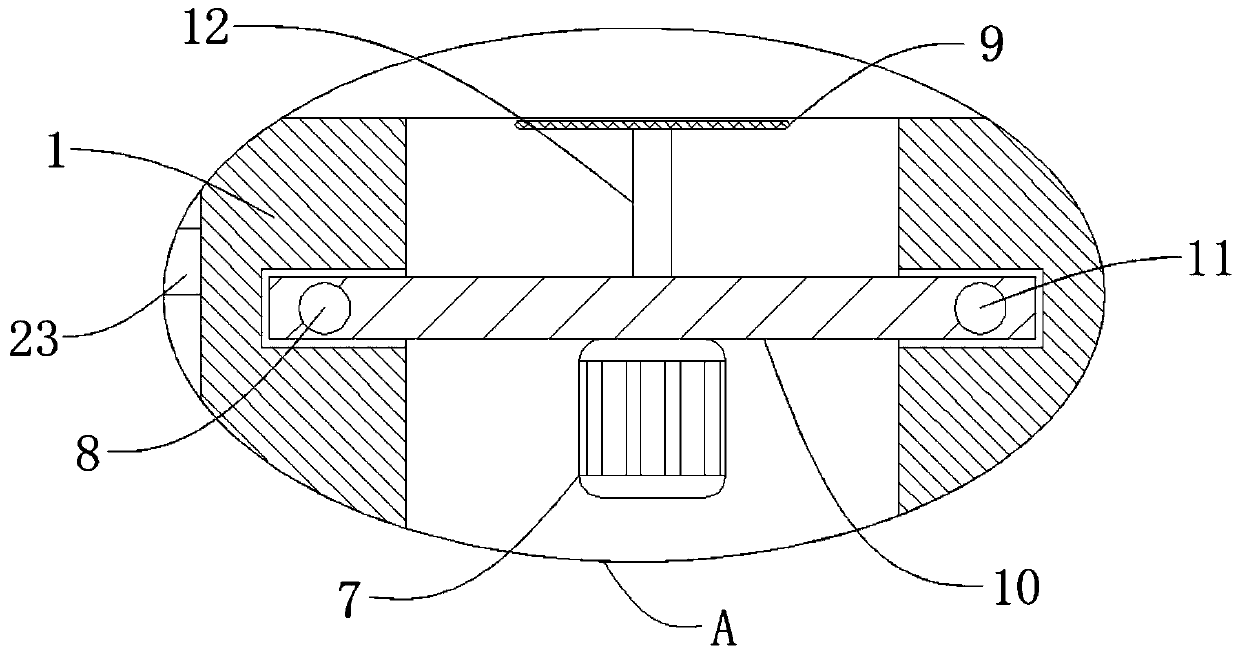

Punching device for hardware production

InactiveCN110756651APunching is effectivePunching device, effectively fixed by the providedShaping toolsMetal-working feeding devicesHydraulic cylinderPunching

The invention relates to the technical field of the manufacturing industry and discloses a punching device for hardware production. The punching device comprises a worktable; the upper end of the worktable is fixedly connected with a U-shaped plate; the lower end of the U-shaped plate is fixedly connected with a hydraulic cylinder; the lower end of the hydraulic cylinder is fixedly connected witha fixed plate; a mounting plate is arranged below the fixed plate; the fixed plate is connected with a buffer mechanism and is connected with the mounting plate by virtue of the buffer mechanism; a punching head is arranged below the mounting plate; the mounting plate is connected with a dismounting mechanism and is connected with the punching head by virtue of the dismounting mechanism; the upperend of the worktable is provided with an opening corresponding to the position of the punching head; a grinding mechanism is arranged inside the opening; and the grinding mechanism comprises a motor,a first threaded rod and a grinding plate. The punching device hardware production can be used for quickly and effectively punching a hardware plate and quickly and effectively grinding burrs of thebottom of a punched hole, improves the grinding efficiency, reduces the labor capacity of a worker and is beneficial to use by people.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Method of forming nanostructure on friction surface of metal friction pair and special composition thereof

ActiveCN102230063AImprove performanceApplicable to industrialization promotionAdditivesContact pressureRelative motion

The invention provides a method of forming nanostructure on the friction surfaces of metal friction pairs and a special composition thereof. The method is characterized by that: the special composition is added in a lubricant medium that the metal friction pairs used with the weight ratio of 0.01-2%, under the working condition of the metal friction pairs, the special composition particles are brought to the friction surfaces of the metal friction pairs by the lubricant medium, under the high contact pressure generated from the friction surfaces of the metal friction pairs and the repeated actions of the composite forces composed of extrusion and rolling generated by relative motions between the friction surfaces, the open grain structures on the friction surfaces are allowed to generate strong microscopic plastic deformation repeatedly by the special composition particles, the metal friction pairs run for 1-100 cumulative working hours, so that the nano-structured crystal layer on the respective friction surface of the metal friction pair is online realized respectively, with the particle size of less than 100 nanometer, and the thickness of the nano-structured crystal layer of 2-10 micrometer. The invention has the advantages of extremely simple processing, extremely high production efficiency, low processing cost, no processing energy consumption and the like, is very suitable for large range industrialization and large scale production, having a far-reaching influence on machinery equipment manufacturing industry and mechanical parts processing industry.

Owner:孙静

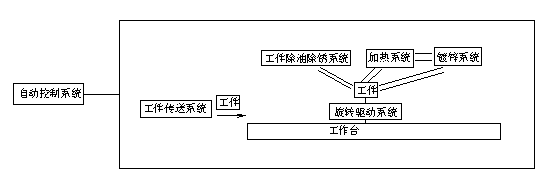

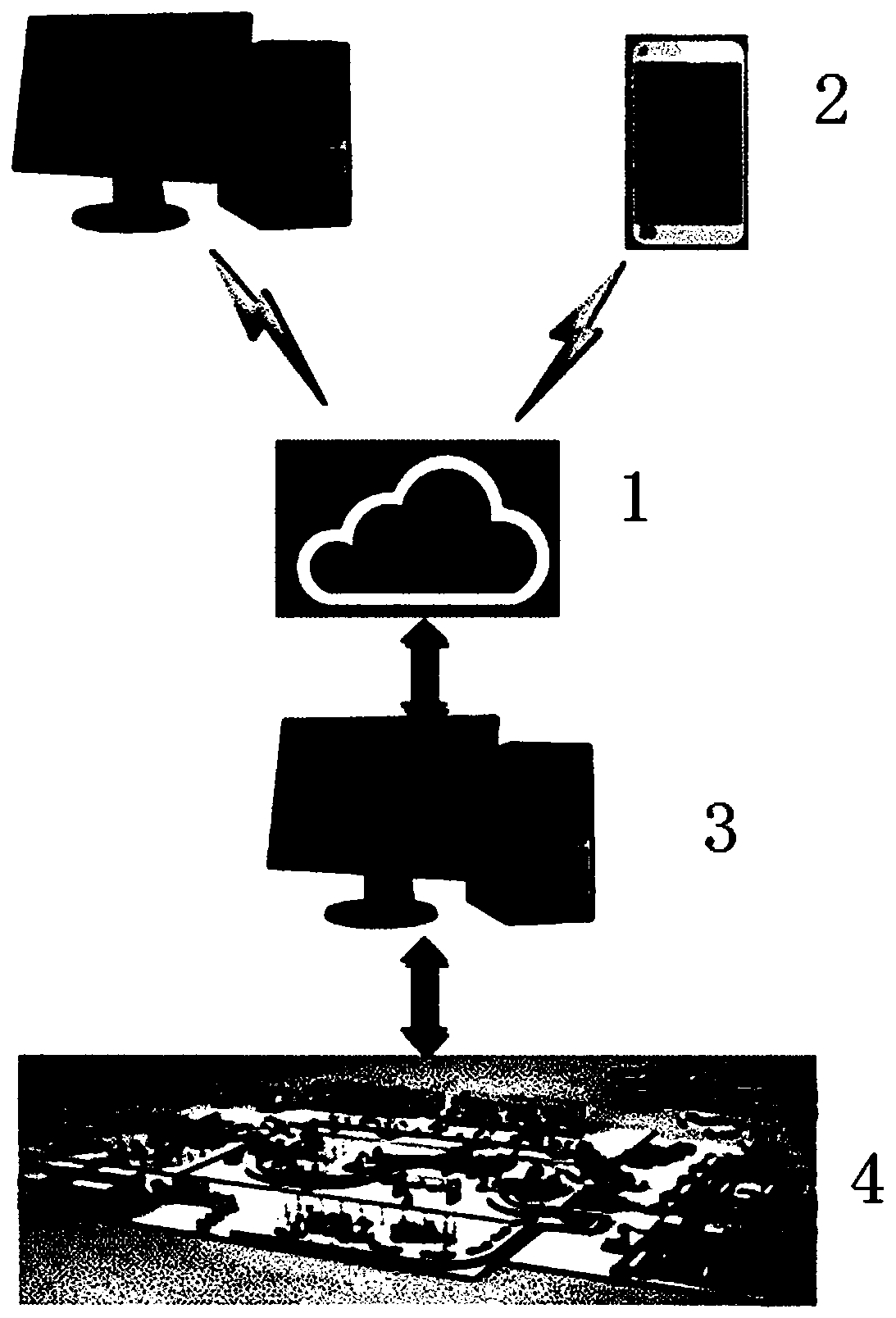

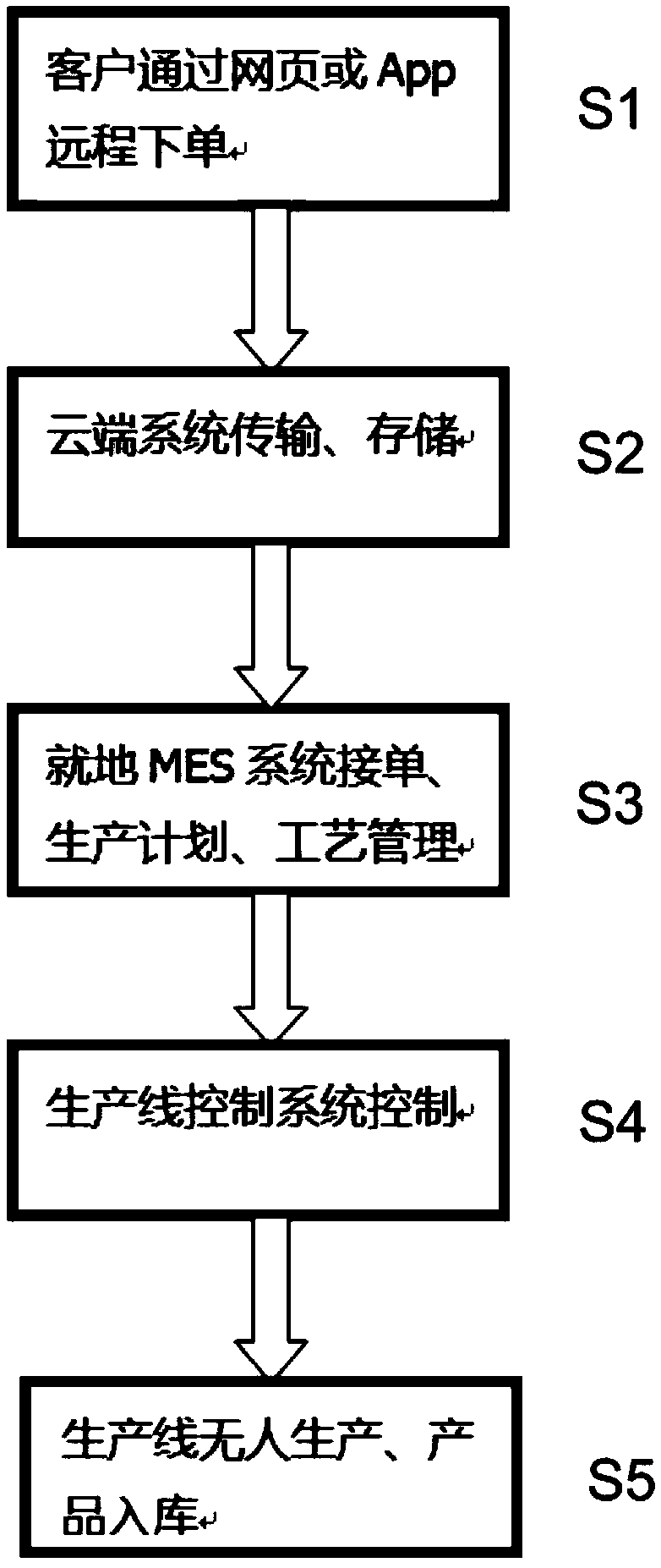

Control system and control method of customized intelligent production line

PendingCN111090263AImprove industrial manufacturing efficiencyTotal factory controlProgramme total factory controlManufacturing execution systemIndustrial engineering

The invention discloses a control system and control method of a customized intelligent production line. The control system comprises a remote user client, a cloud background system, a manufacturing execution system, and an industrial robot production line which are in communication junction in sequence. The control system realizes the application of the structure of a manufacturing industry industrial control system to a customized production line of industrialized products, and the integration of automation and informatization, completes the goals of customized ordering and unmanned production, greatly improves the industrialized manufacturing efficiency and is suitable for the intelligent control of various processing and manufacturing industries or products.

Owner:杨宇

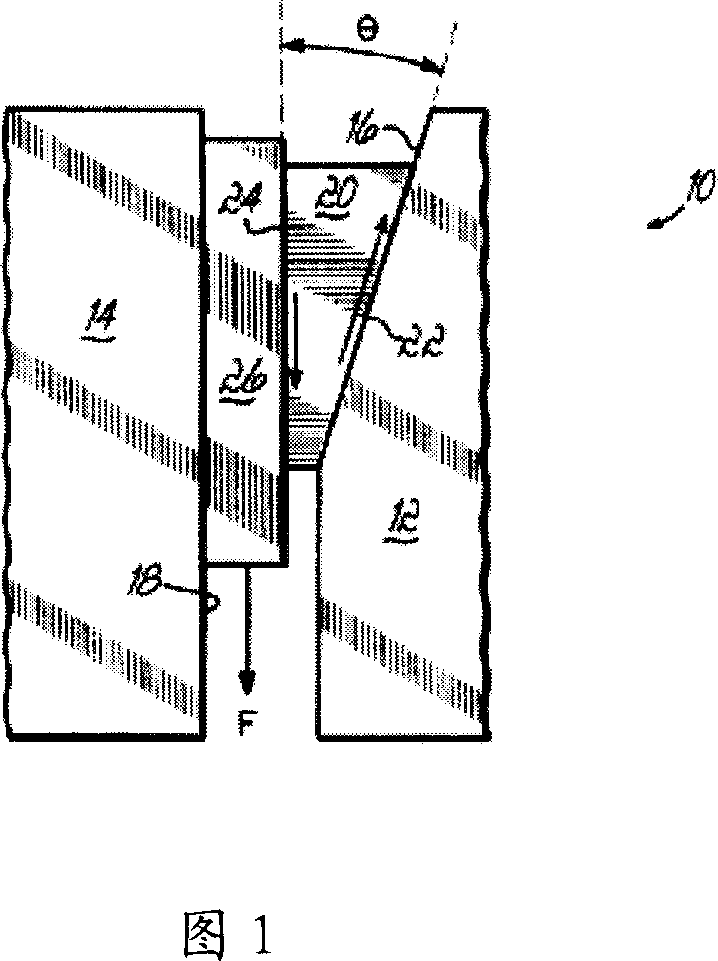

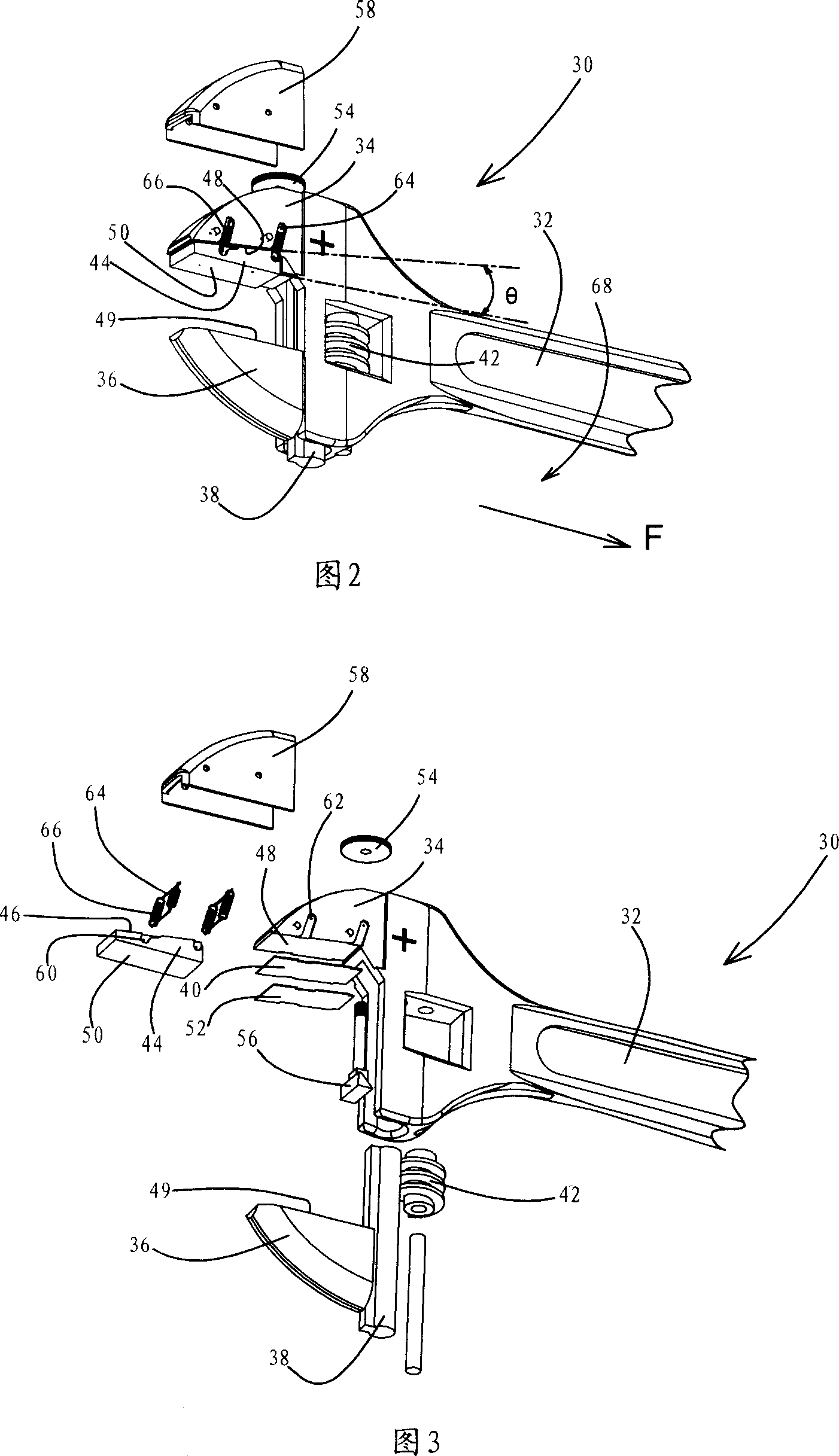

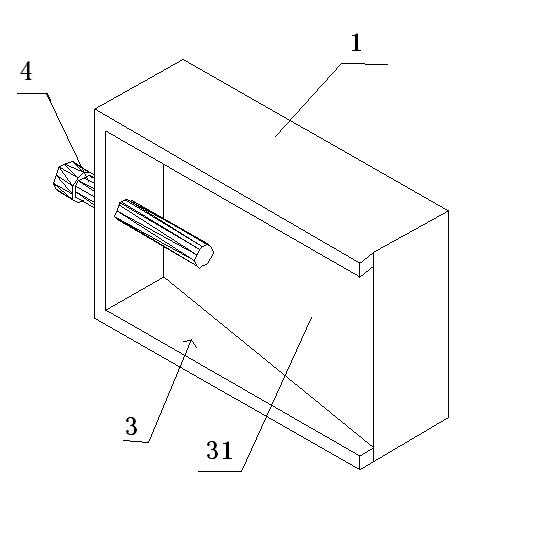

Self-clamping mechanism

InactiveCN101070868AEnlarge the effective surfaceSave energySpannersWrenchesStatic friction coefficientEngineering

The invention relates to a clamping apparatus. The clamping apparatus comprises a support and a clamping element. The clamping member has a surface a in sliding confronting engagement with the support surface A, and a second surface b for engaging the surface of an object to be clamped by the mechanism. The first and second surfaces of the clamping member are disposed at a predetermined angle, theta, is defined by inequality (K+tan(theta)) / (1+Ktan(theta)) is less than or equal to M, formula M represents coefficient of friction of rest between fastening motion element and clamped object, K represents a coefficient of friction of rest between fastening motion element and A supporting plane. The clamping apparatus can clamp objects regardless of static, motility or force of impact applied to the objects, and the clamping apparatus does not require or scarcely require applying energy and not happen exorbitance fastening motion or clipping loosely objects. The clamping apparatus can be extensive use in mechanical layout, machining and manufacturing sector, also can be use in rail facility, bridge and farmery field.

Owner:SHENZHEN ZIJINWANG TECH

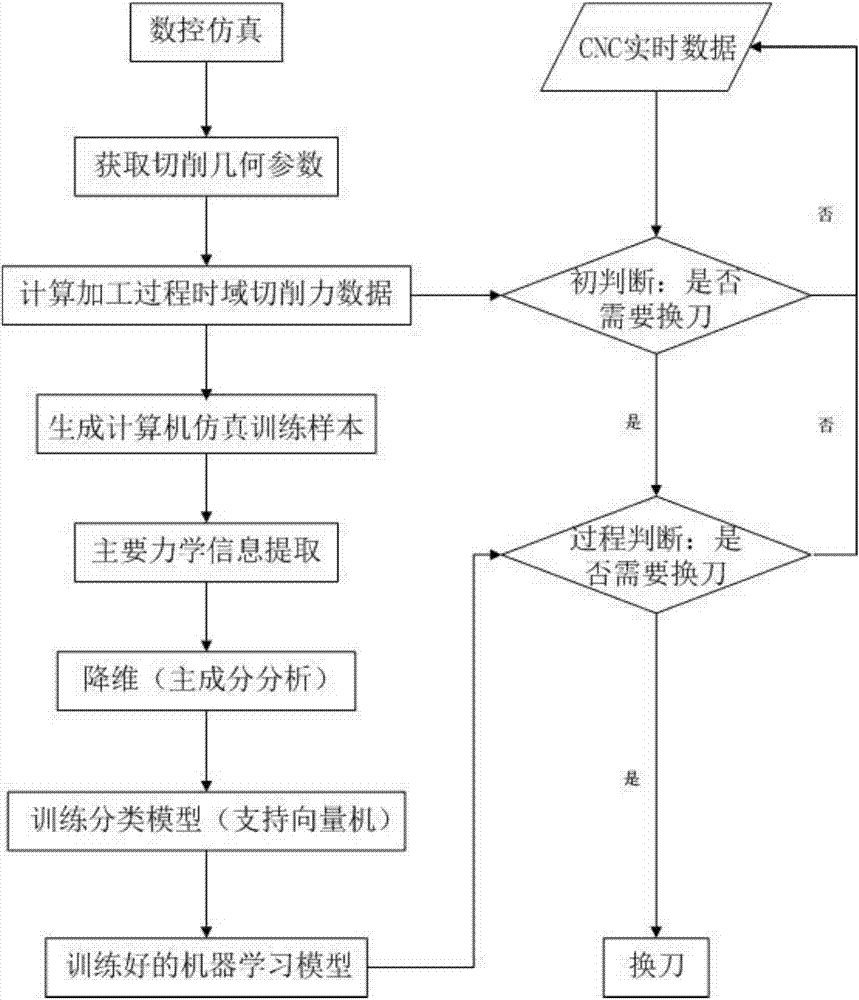

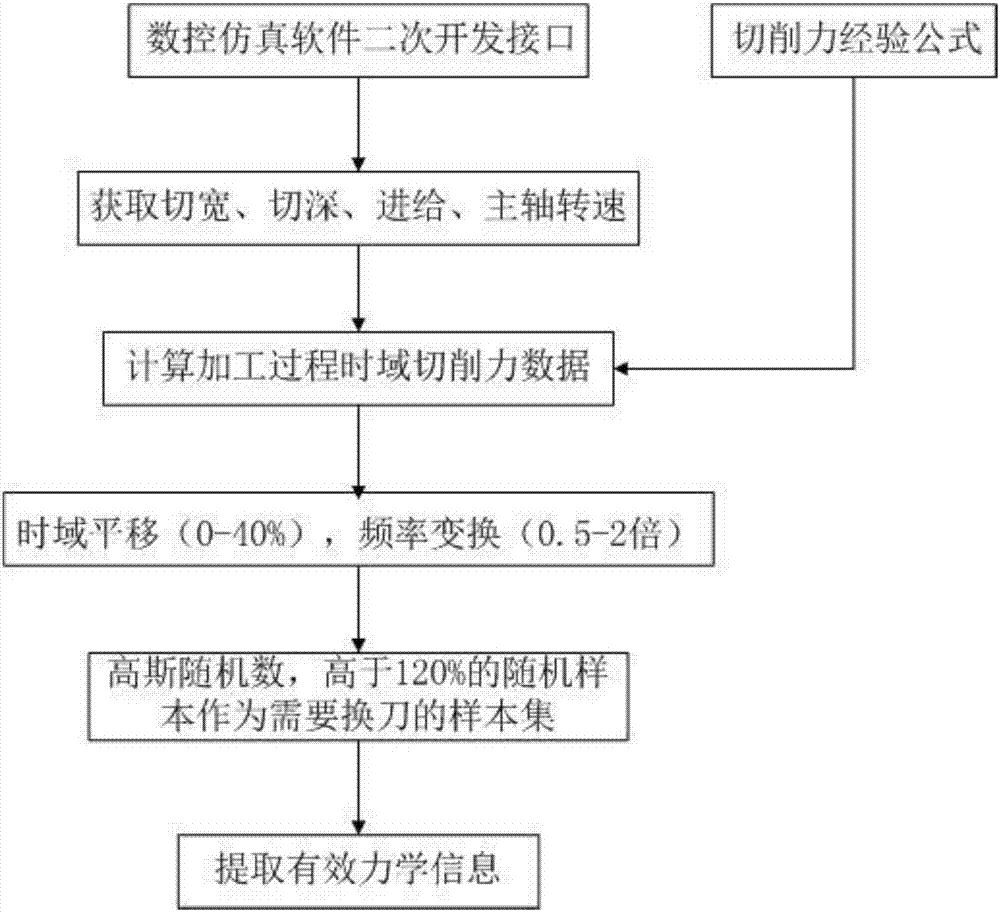

Method for determining tool changing of tool

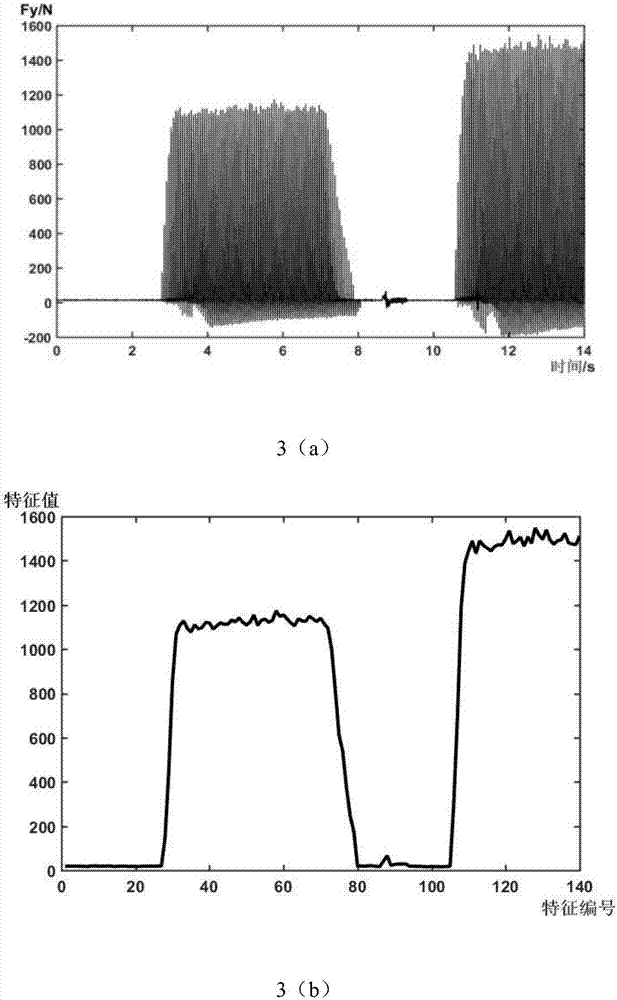

ActiveCN107505850ASolve the problem that interferes with the judgment of cutting forceImprove economySimulator controlEngineeringCutting force

The invention, which belongs to the technical field of mechanical manufacturing tool state monitoring, discloses a method for determining tool changing of a tool. In the prior art, wearing of a tool during the actual production process affects the processing quality of a workpiece greatly; and the efficiency of the traditional tool monitoring way is low. However, according to the method provided by the invention, the working state of the tool is reflected visually by a cutting force; and the study on the relevant calculation method is mature. On the basis of geometric simulation of the tool, calculation is carried out by using a corrected cutting force empirical formula to obtain a cutting force sample; and a sample is placed into a machine learning frame and a training result can be applied to actual processing. The method can be applied to various cutting processes and has the great significance in promoting intelligent realization of the manufacturing industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

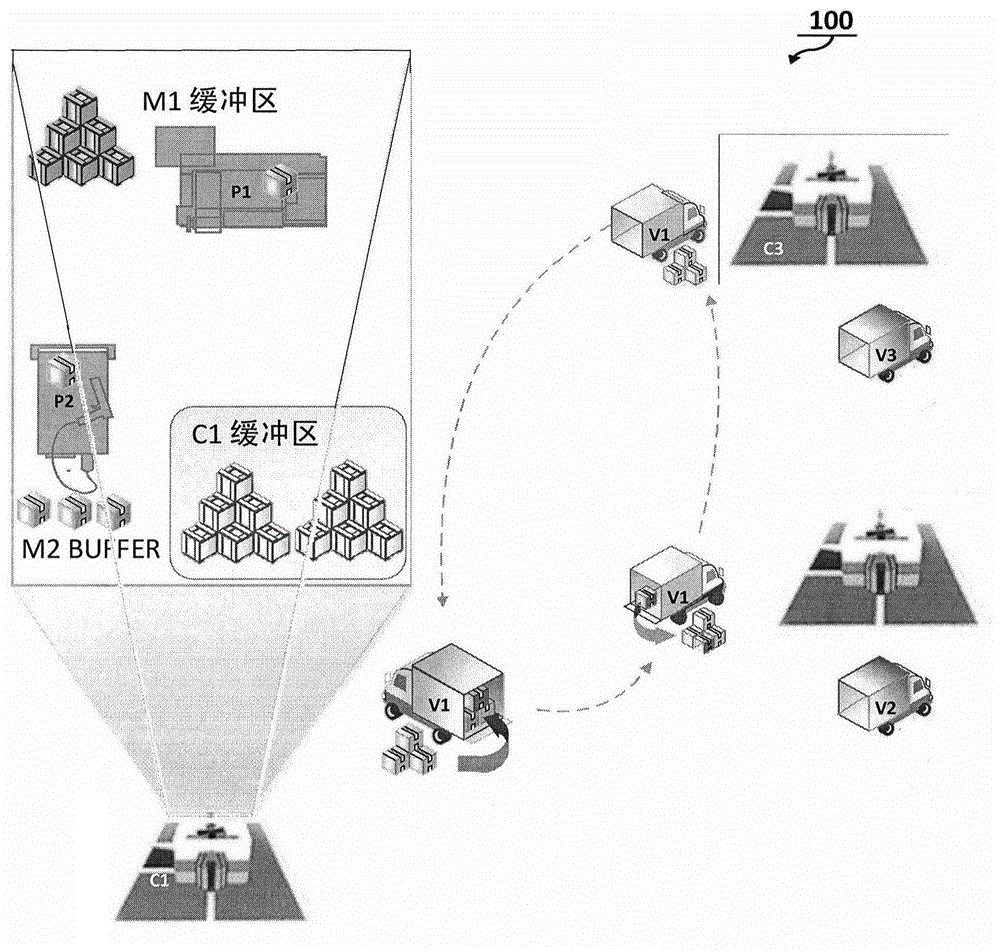

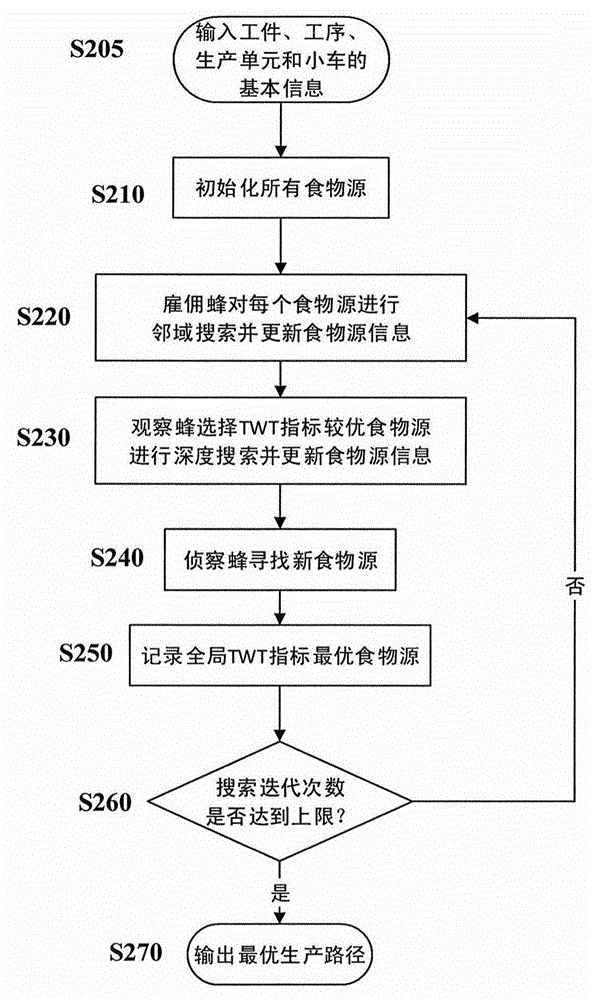

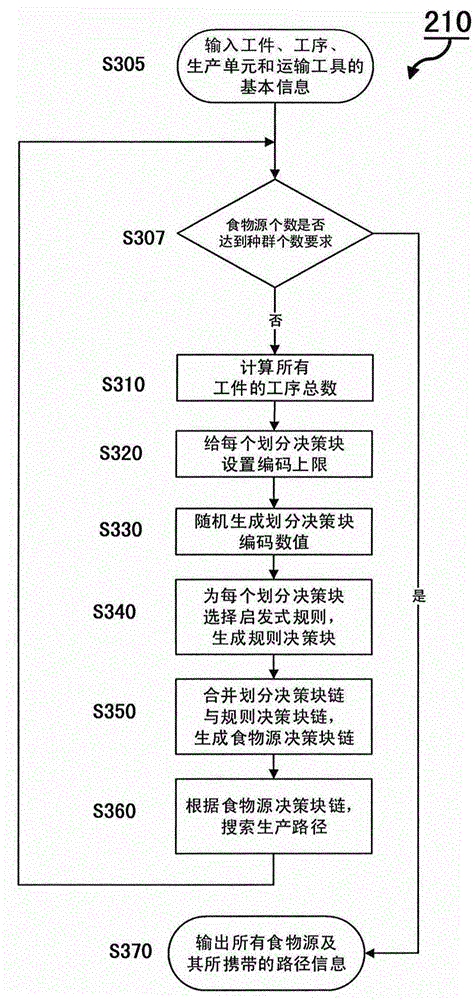

Workpiece production path searching method based on decision blocks and swarm algorithm

InactiveCN104809523AThe ability to optimize the solution is improvedReduce production completion timeForecastingManufacturing computing systemsLocal optimumCompletion time

The invention discloses a workpiece production path searching method based on decision blocks and a swarm algorithm, aiming to solve the problem about cross-cell production path searching with limited transport capability in a cross-cell transport environment. On the basis of the dynamic decision blocks and the improved disperse swarm algorithm, current optimal paths are optimized and updated continuously. The workpiece production path searching method has the advantages that the decision blocks have dynamic characteristics and their capabilities of jumping out of a locally optimal solution in a scout bee stage are improved, so that performance of a global solution is improved, the problems of machine idleness and workpiece accumulating and stacking during production of the equipment manufacturing industry can be solved, processing and transporting are coordinated and optimized, production efficiency is improved and completion time is shortened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Precision forging plastic molding process for internal toothed rings of planetary speed reducers

InactiveCN103706754AProduct quality is stableImprove yieldMetal-working apparatusWheelsPlastic moldingForging

The invention discloses a precision forging plastic molding process for internal toothed rings of planetary speed reducers. The precision forging plastic molding process includes steps of 1, performing warm forging plastic molding; 2, performing low-temperature annealing and cylindrical lathe cutting to reduce wall thickness difference caused by extrusion, and performing shot blasting, phosphating and saponification treatment; 3, performing cold forging plastic molding. The precision forging plastic molding process has the advantages that the quality of products manufactured by the process is stable, accumulated errors among tooth profiles are few, the yield is high, the production efficiency can be improved, the production period is short, a machining method for extensively machining internal toothed rings by the aid of machine tools after the internal toothed rings are subjected to hot forging can be replaced, accordingly, machining workload on machine tools can be reduced, precision requirements can be met, the manufacturing cost can be reduced, the manufacturing period can be shortened, and the precision forging plastic molding process conforms to the development trend of the manufacturing industry in the present world.

Owner:江苏威鹰机械有限公司

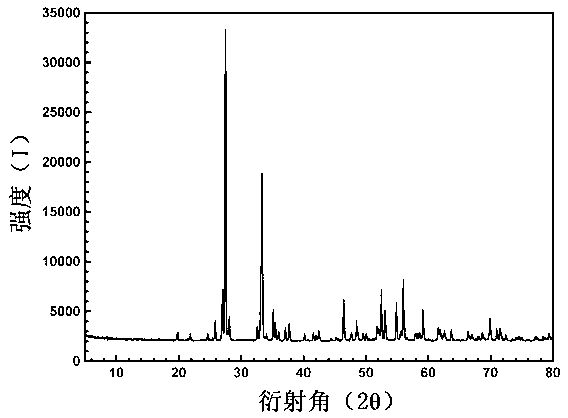

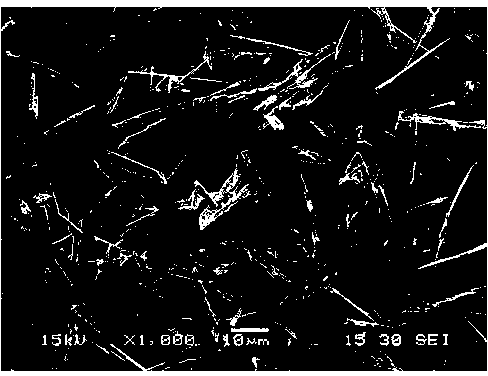

Rodlike bismuth oxide and preparation method thereof

InactiveCN103101975ANo pollution in the processSimple processNanotechnologyBismuth compoundsPotassium hydroxideSodium hydroxide

The invention relates to a rodlike bismuth oxide and a preparation method thereof. The rodlike bismuth oxide has a diameter of 0.5-3 microns, a length of 10-60 microns, a length-diameter ratio of over 10, and purity over 99%. The preparation method specifically consists of: acidifying certain amount of a bismuth salt by nitric acid, then adding deionized water, carrying out stirring dissolving, then adding the solution into an ammonia water, sodium hydroxide or potassium hydroxide solution, and performing a one-step hydro-thermal treatment so as to obtain the rod-like bismuth oxide. The preparation method provided by the invention has the characteristics of no environmental pollution, simple process, wide adjustable range of parameters, strong repeatability, as well as low production cost, thus being applicable to mass industrial production. The prepared rodlike bismuth oxide can be widely used in industrial catalysis, the medical industry, the special glass manufacturing industry, the electronic industry, new materials, and other fields.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

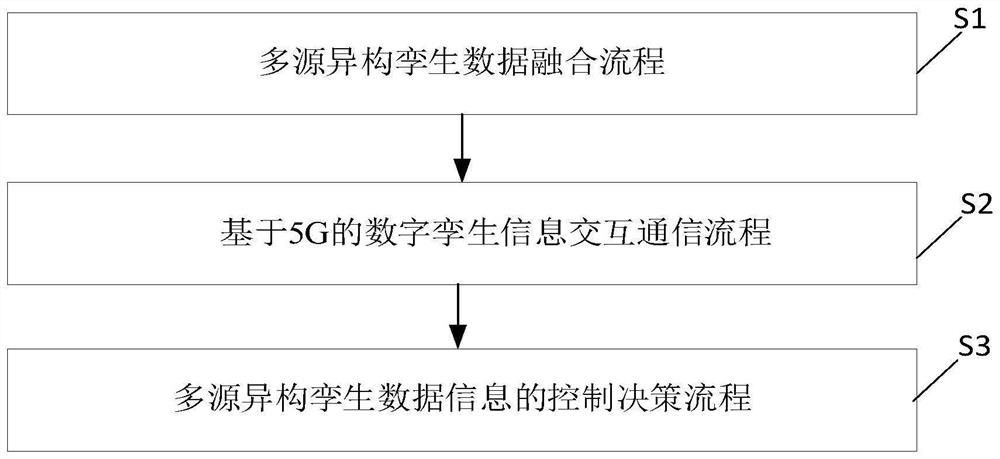

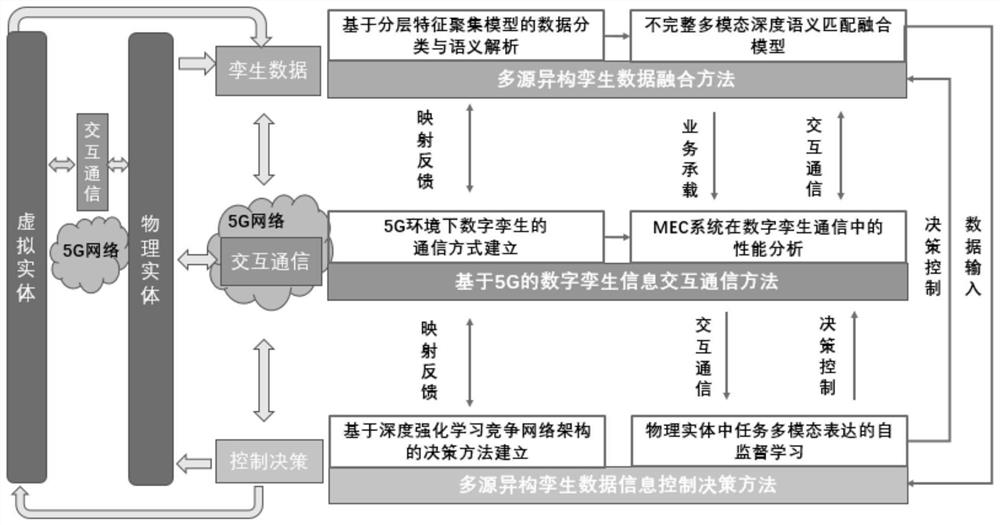

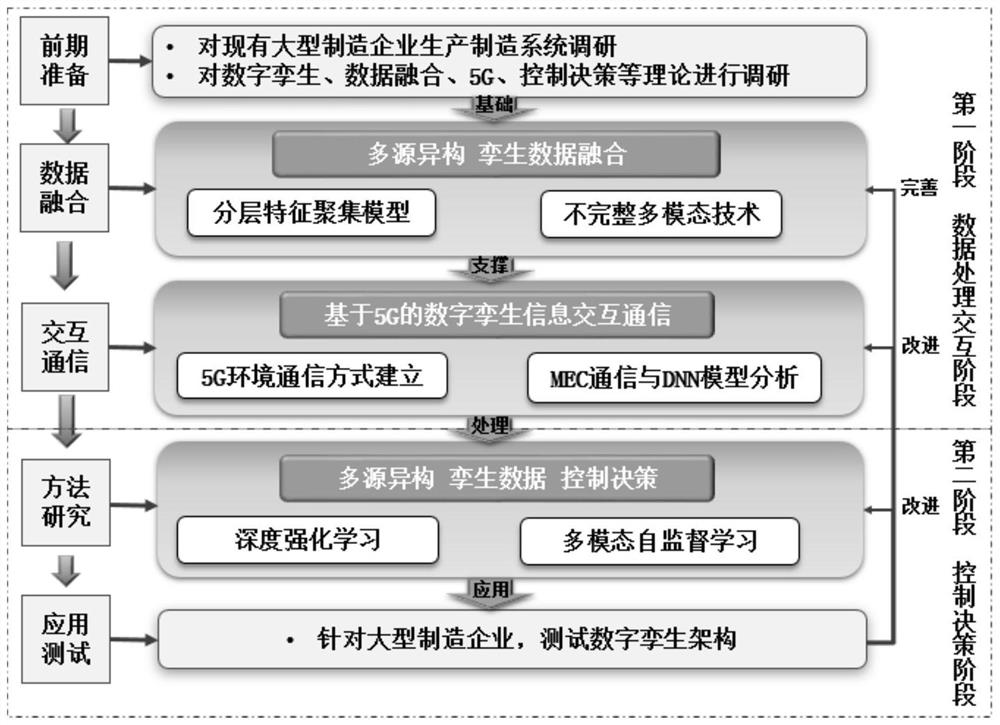

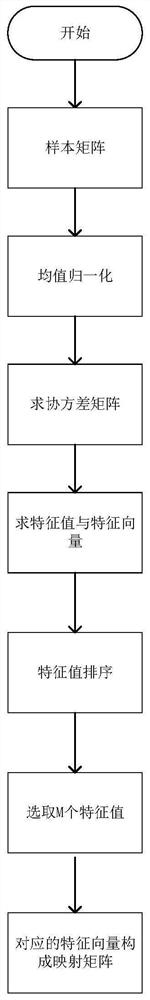

Decision control method and system for digital twin information of intelligent factory based on 5G driving

ActiveCN114637262ARealize online simulationRealize virtual reality mappingTotal factory controlProgramme total factory controlSmart factoryDecision control

The invention discloses a decision control method for intelligent factory digital twin information based on 5G driving. The method comprises the following steps: S1, carrying out a multi-source heterogeneous twin data fusion process; s2, a digital twin information interaction communication process based on 5G; and S3, a control decision process of the multi-source heterogeneous twin data information. According to the invention, a 5G-based digital twinning communication mode can be constructed, real-time twinning data-driven online simulation is realized, virtual-real mapping and interaction are really realized, the real-time performance of decision-making and control to terminals and applications and the autonomy and intellectualization of reaction are ensured, the upstream and downstream cooperation of an industrial chain of the manufacturing industry is promoted, and the development of the industrial chain of the manufacturing industry is promoted. And in an actual production environment, a reinforcement learning method and a self-supervised learning method are utilized to learn compact and multi-modal representation of data in an input network, so that decision-making and control efficiency of resource configuration, production planning, real-time scheduling, supply chains, logistics and the like is improved, and the method adapts to production management and control under dynamic factor disturbance.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

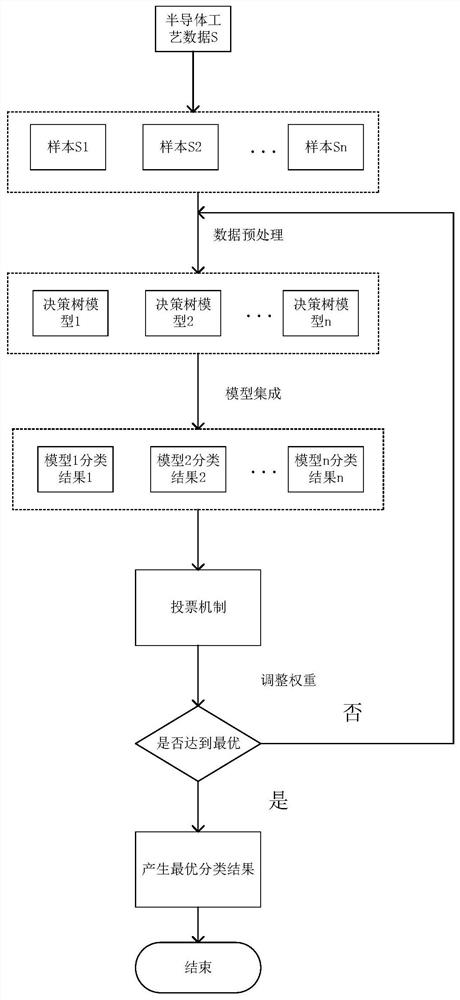

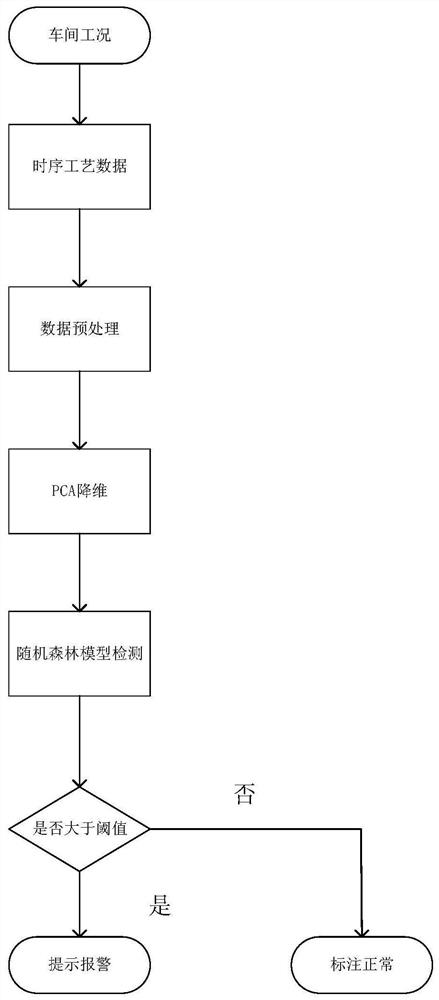

Manufacturing industry-oriented field process behavior abnormal behavior detection method

ActiveCN111708343APredict security postureQuickly find outliersProgramme controlElectric testing/monitoringPrincipal component analysisDimensionality reduction

The invention relates to a manufacturing industry field process abnormal behavior detection method, which is mainly used for researching a detection method based on a behavior characteristic knowledgebase for manufacturing industry field process abnormal behavior detection, and is used for constructing a random forest abnormal detection model based on a random forest algorithm. According to the specific implementation method, PCA method dimension reduction is carried out on process data of an industrial field, feature selection is carried out by adopting an integrated rule tree model, and theprocess data is classified by adopting a random forest algorithm. Each path of the random forest corresponds to one rule, good interpretability is achieved, the classification accuracy is greatly improved, a large number of input variables can be processed, and even if process data contains missing values, the classification result can still reach high accuracy. A behavior characteristic knowledge base and a real-time emergency decision-making framework of an unknown behavior scene are fused, and abnormal behaviors are early warned in advance by predicting behavior detection of industrial field process data.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

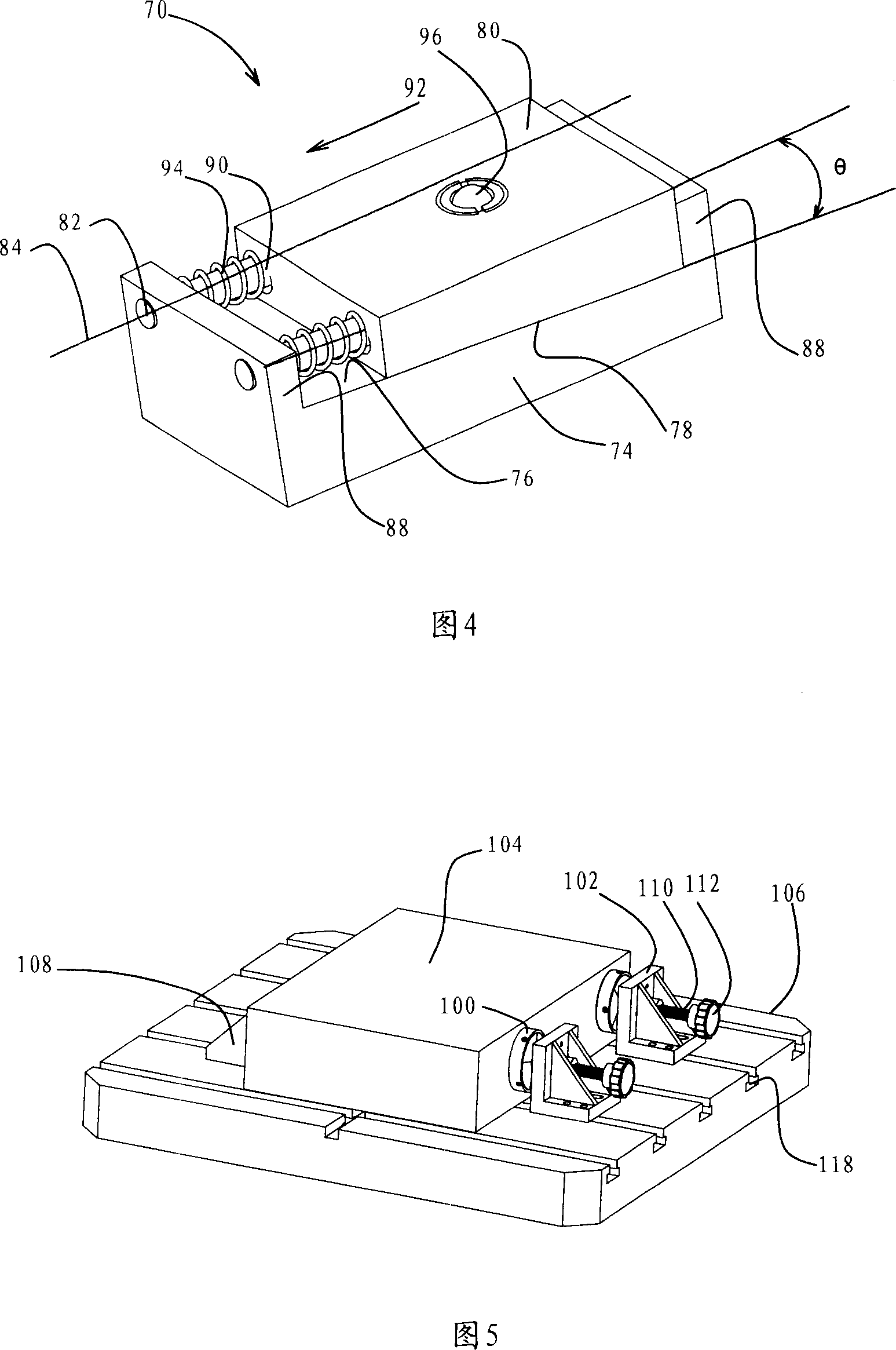

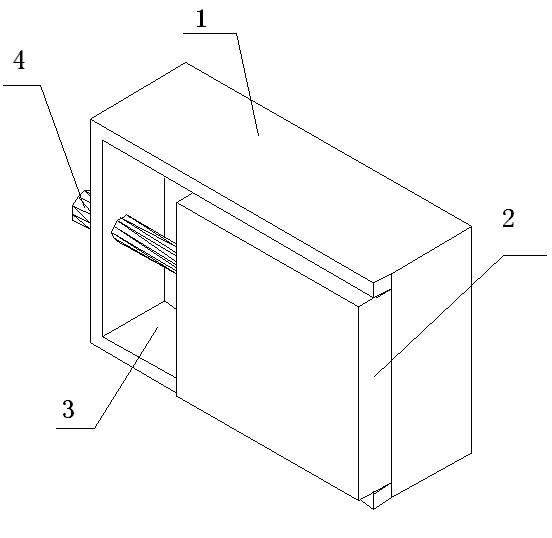

Cushion block with adjustable height

InactiveCN102672635AMeet the needs of adjustable heightPrecise height adjustmentWork holdersMechanical equipmentScrew thread

The invention relates to a cushion block with adjustable height, which comprises a base, wherein the base is provided with a sliding groove; the bottom of the sliding groove is provided with a sliding groove inclined plane; the sliding groove is internally provided with a sliding block capable of moving in the sliding groove; the sliding block and the sliding groove are matched with each other; the base is connected with an adjusting bolt through a thread; and one end part of the adjusting bolt is fixed to one end of the sliding block. According to the invention, the sliding block is pushed through screwing the adjusting bolt, so that the sliding block slides on the inclined plane of the base, the effect for accurately adjusting the integral height is achieved, and processing and manufacturing expense can be reduced obviously; and the cushion block with adjustable height is simple in structure, is convenient and stable to operate, meets the requirement that the height of cushion iron can be adjusted in the modern manufacturing industry, and can be applied to fixtures, inspection tools and other mechanical equipment.

Owner:苏州金牛精密机械有限公司

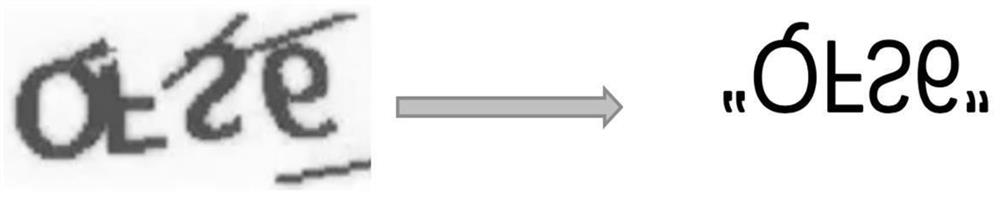

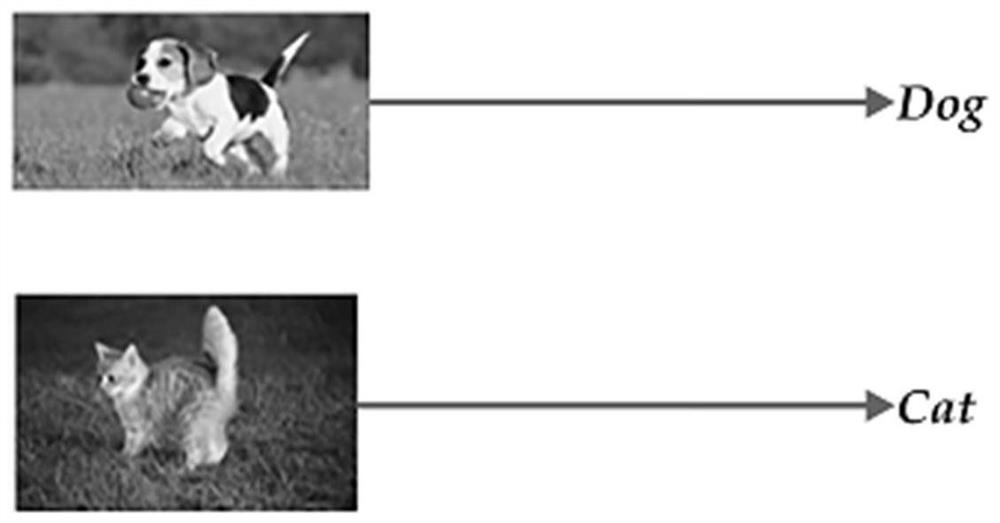

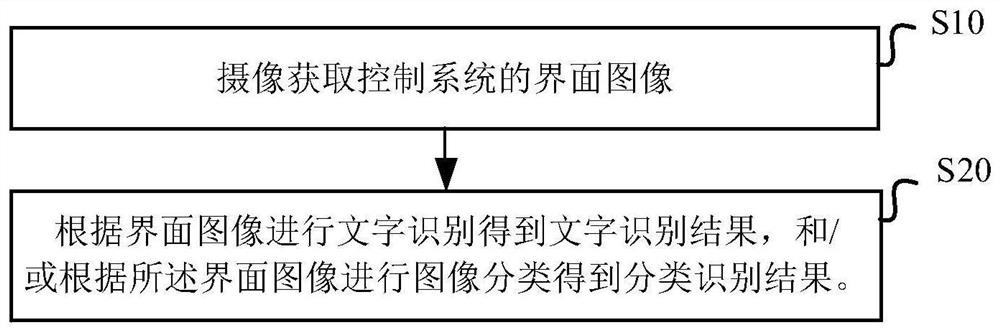

Non-invasive camera shooting reading method and system based on deep learning

PendingCN111652225ARealize visual managementEliminate the need for manual transcriptionCharacter and pattern recognitionExecution for user interfacesInformatizationText recognition

The embodiment of the invention provides a non-invasive camera shooting reading method and system based on deep learning. The method comprises: firstly, obtaining an interface image of an industrial control system through camera shooting; and then, performing character recognition according to the interface image to obtain a key data field recognition result, and / or performing image classificationaccording to the interface image to obtain a classification recognition result. On the premise that production equipment does not need to be invaded, real-time acquisition and visual management of key production data of the industrial personal computer system can be flexibly achieved without limitation. In the application of manufacturing enterprises, the step of manual copying by workers is omitted, the workers can be helped to better manage the industrial personal computer, the data result can also assist managers in improving the decision-making efficiency, and a guarantee is provided forinformatization of the enterprises and intelligent decision making of big data.

Owner:HANGZHOU WEIMING XINKE TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com