Discrete manufacturing industry-oriented dynamic production plan scheduling method

A production planning and manufacturing technology, applied in manufacturing computing systems, computing, instruments, etc., can solve problems such as inability to deal with procedural delays, machine failure accidents in a timely manner, and affecting the application effect of advanced planning and scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

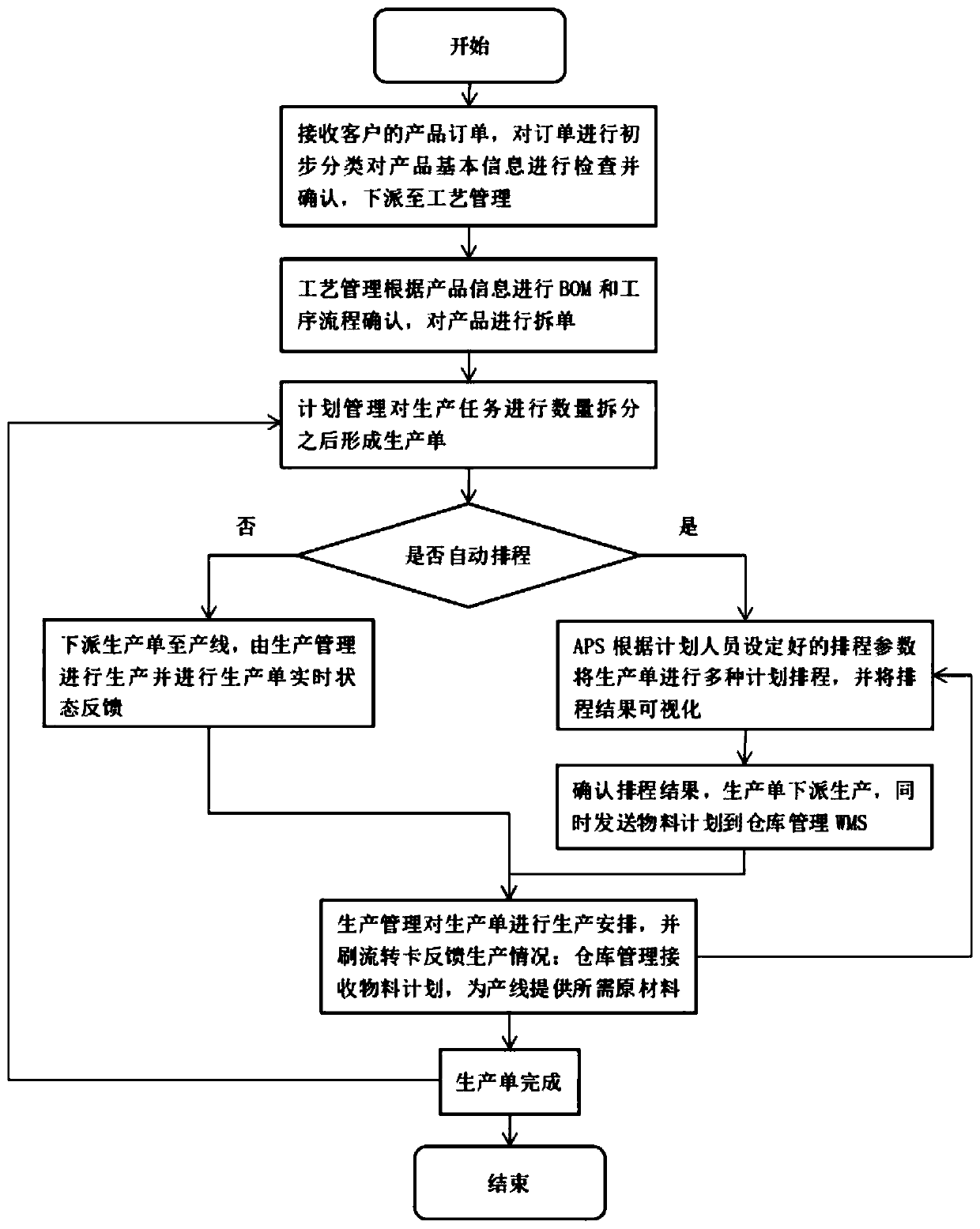

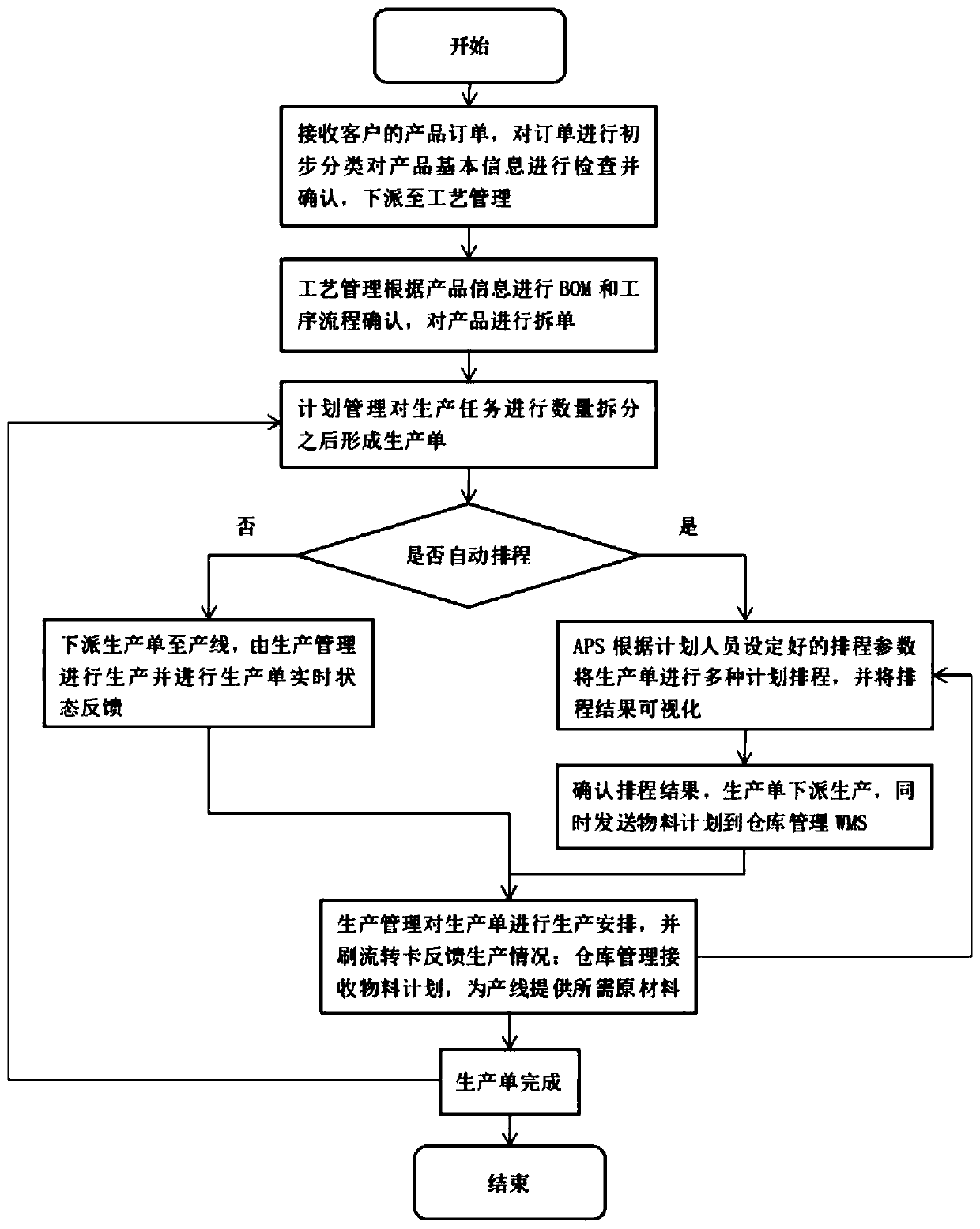

[0029] Such as figure 1 As shown, a dynamic production planning and scheduling method for discrete manufacturing, including the following steps:

[0030] (1) Order receiving: Receive the customer's product order, check and confirm the product information, and then send the order to the process management module to confirm the product process, and dismantle the order: according to the order product information and product process, the order can be automatically disassembled. Split the order into multiple production tasks including BOM and process flow;

[0031] (2) Product decomposition: The process management module confirms the material list and process flow according to the product information, dismantles the order products, generates productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com