Automatic support moving intelligent control method for hydraulic support for mining

A technology of hydraulic support and intelligent control, which is applied to mine roof support, mining equipment, earthwork drilling, etc., can solve the problem that the layout method of the original parts, the steps of moving the frame and the control sequence are not further disclosed, and the sensor layout method and control mechanism are not disclosed. , less steps in the rack-moving procedure, etc., to achieve the effect of improving the speed of automatic rack-moving, improving the efficiency of lowering the column, and shortening the lifting time of the column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

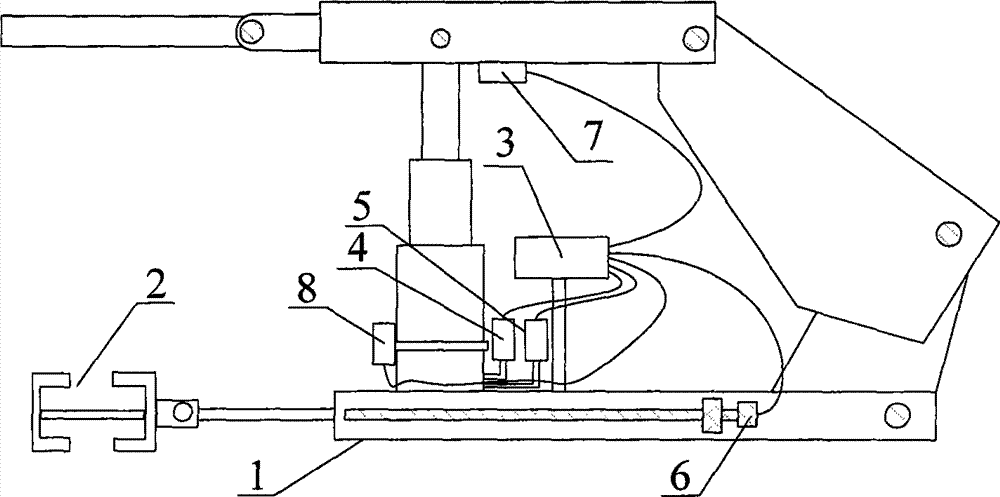

[0022] See attached figure 1 , which describes a working face hydraulic support installed with the hydraulic support automatic moving intelligent control system of the present invention. The hydraulic support moving detection system includes hydraulic support, support controller, travel sensor, pressure sensor, angle sensor, height sensor and pipeline pressure sensor; the hydraulic support is arranged along the coal mining face to support the roof of the working face, and each hydraulic support At least one pressure sensor is installed on the hydraulic support to measure the roof support pressure of the hydraulic support; at least one travel sensor is installed on each hydraulic support to measure the moving stroke of each hydraulic support; at least one angle sensor is installed on each hydraulic support to use To measure the running posture of the hydraulic support during the moving process; install at least one height sensor on each hydraulic support to measure the height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com