Method for determining tool changing of tool

A tool and cutting force technology, applied in the field of tool change judgment, can solve the problems of model reliability and poor economy, and achieve high economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

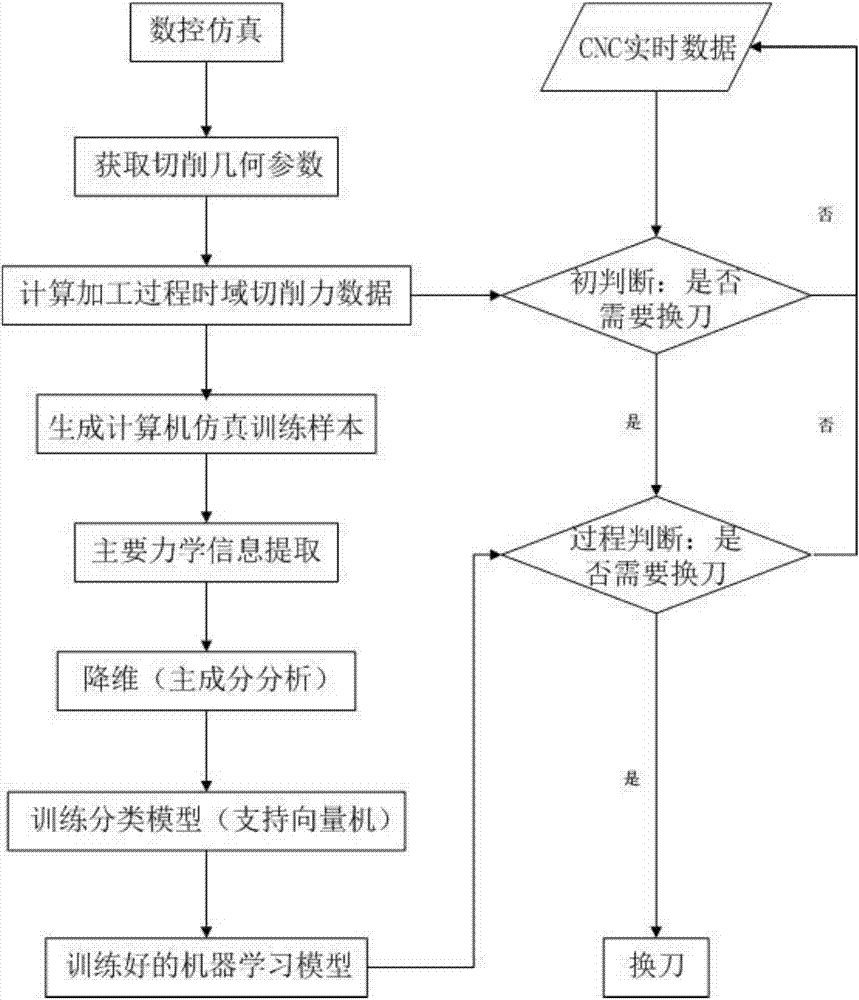

[0022] The judging method for tool change of the present invention comprises the following steps:

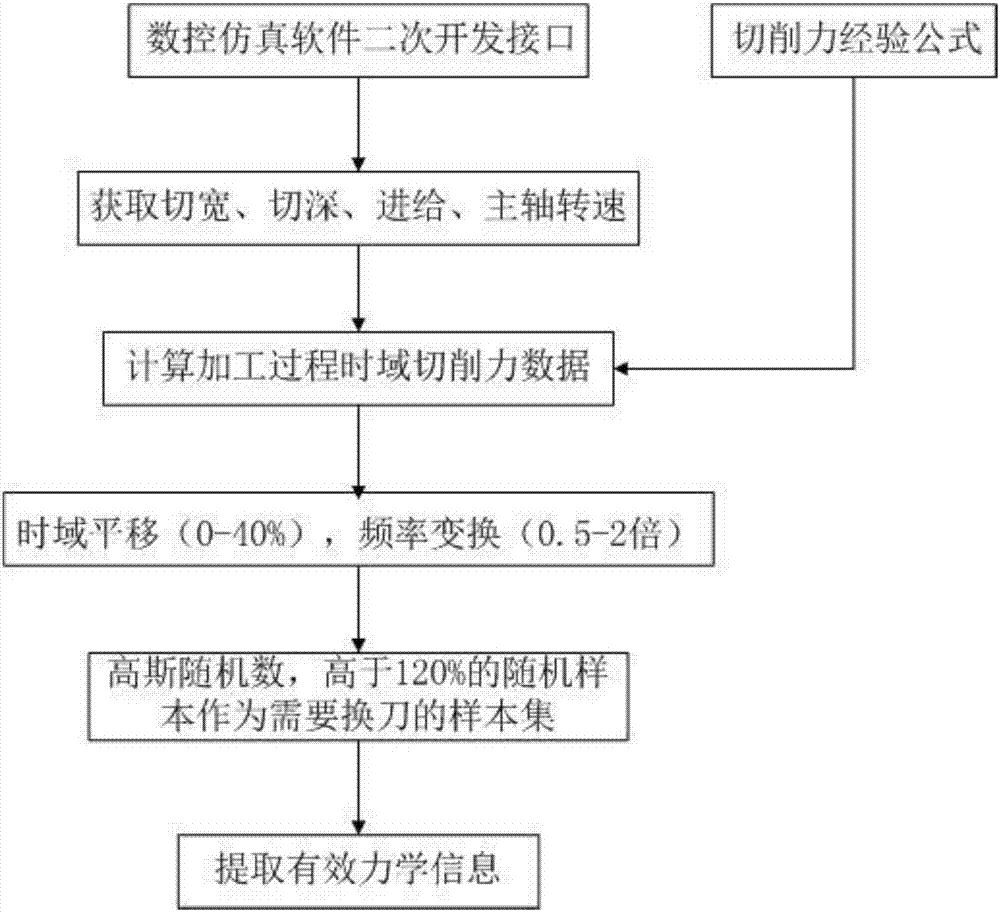

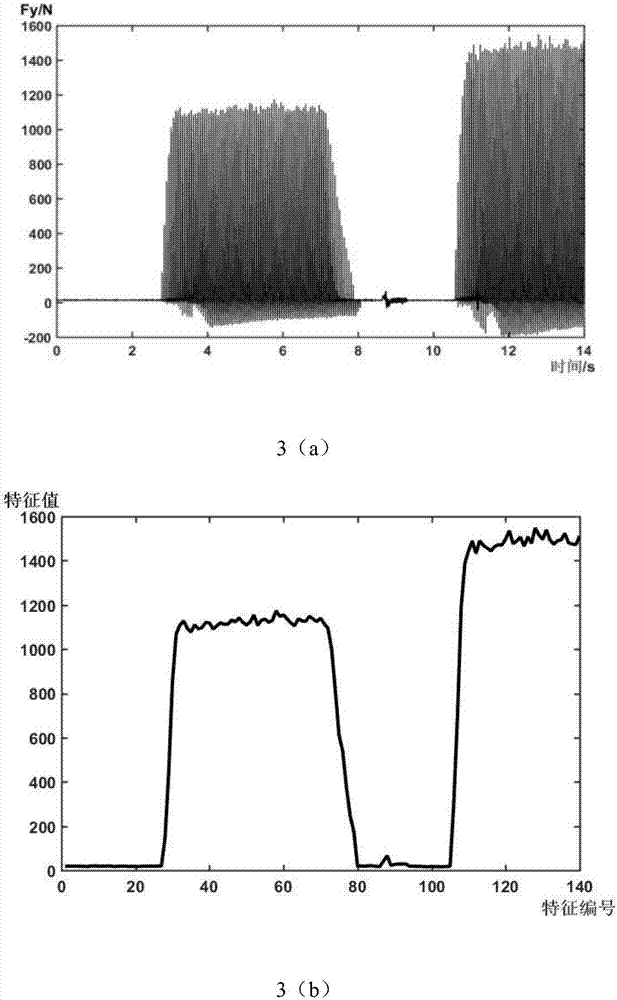

[0023] Step 1: NC simulation, obtain the cutting geometric parameters, and substitute them into the empirical formula log(F c / b)=log(k c1,1 )+(1-m c ) × logh, to obtain the time-domain cutting force data during the calculation process, and to generate computer simulation training samples based on this;

[0024] Step 2: Reduce the dimension of the sample, train the support vector machine classification model with Gaussian kernel, set the sensor to collect the cutting force signal in real time and compare it with the model. When the relative error is greater than 20%, it is judged that the tool needs to be changed.

[0025] Among them, the specific method of step 1 is as follows:

[0026] (1). Numerical control simulation: Take Vericut software as an example, set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com