Patents

Literature

33 results about "Geometric simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

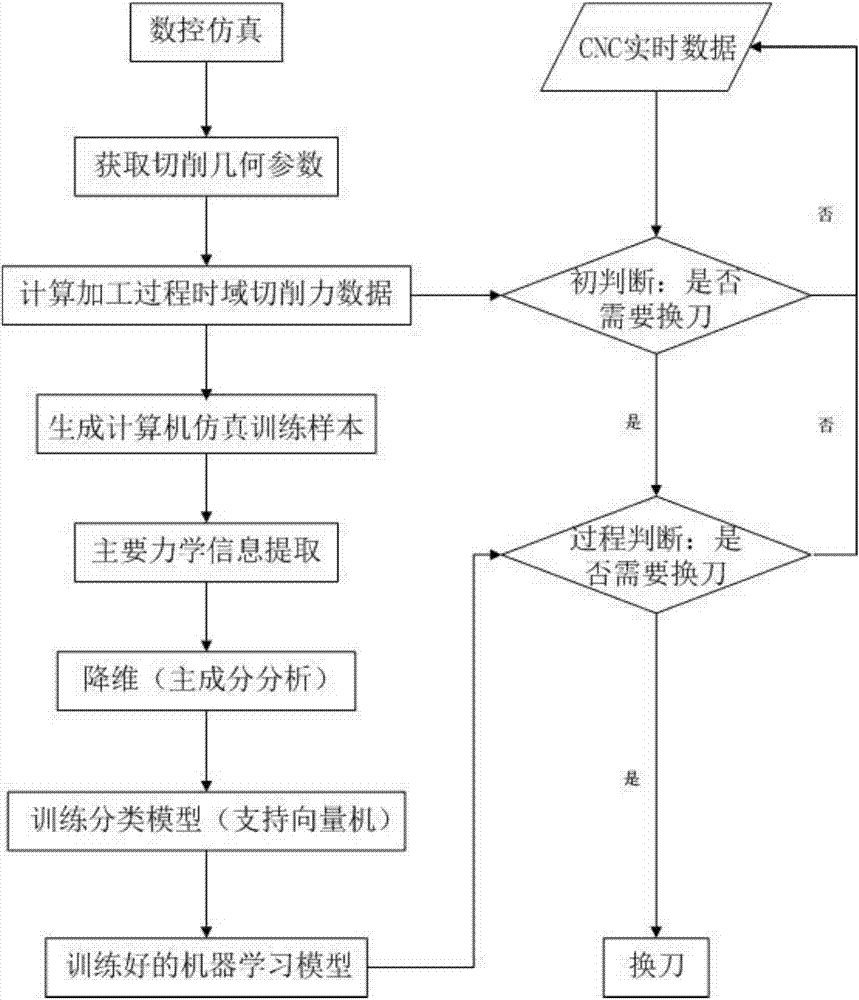

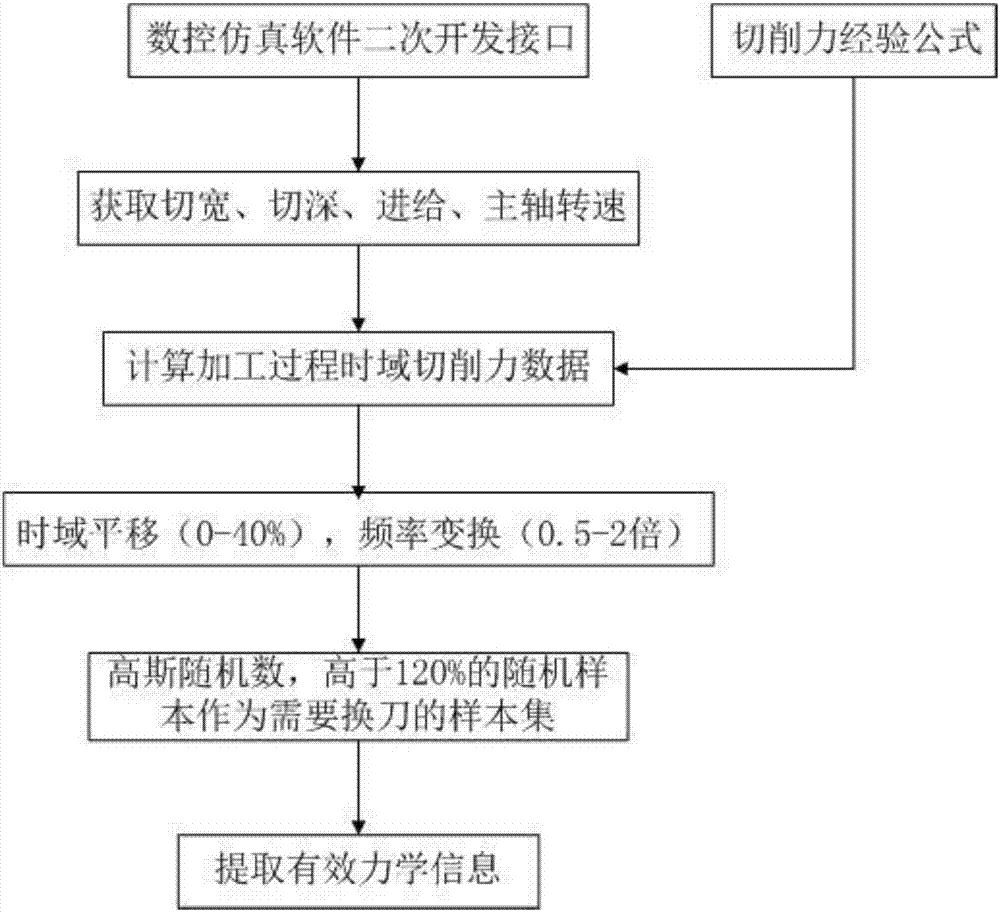

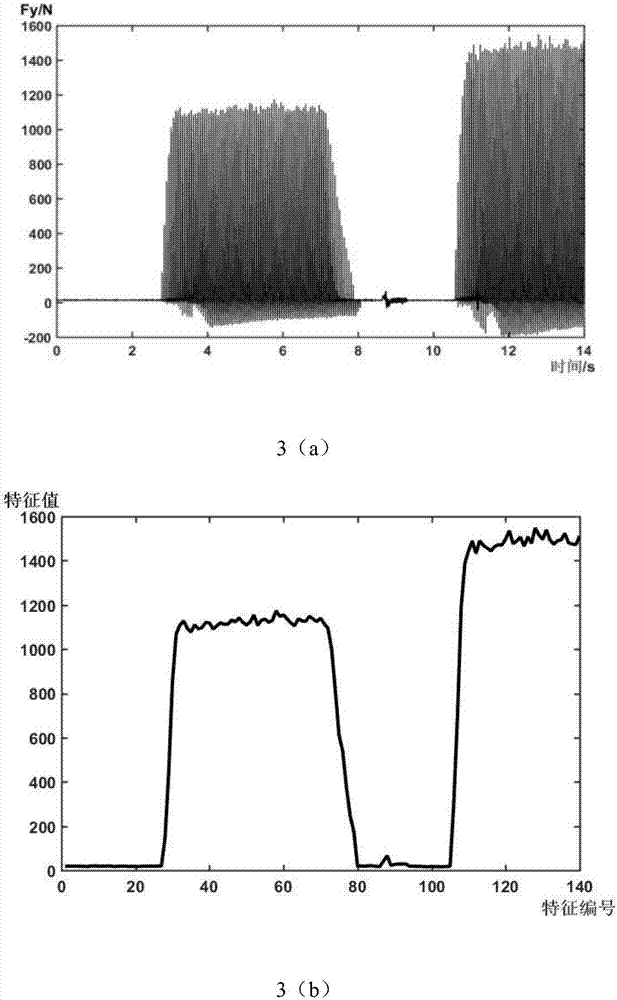

Method for determining tool changing of tool

ActiveCN107505850ASolve the problem that interferes with the judgment of cutting forceImprove economySimulator controlEngineeringCutting force

The invention, which belongs to the technical field of mechanical manufacturing tool state monitoring, discloses a method for determining tool changing of a tool. In the prior art, wearing of a tool during the actual production process affects the processing quality of a workpiece greatly; and the efficiency of the traditional tool monitoring way is low. However, according to the method provided by the invention, the working state of the tool is reflected visually by a cutting force; and the study on the relevant calculation method is mature. On the basis of geometric simulation of the tool, calculation is carried out by using a corrected cutting force empirical formula to obtain a cutting force sample; and a sample is placed into a machine learning frame and a training result can be applied to actual processing. The method can be applied to various cutting processes and has the great significance in promoting intelligent realization of the manufacturing industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

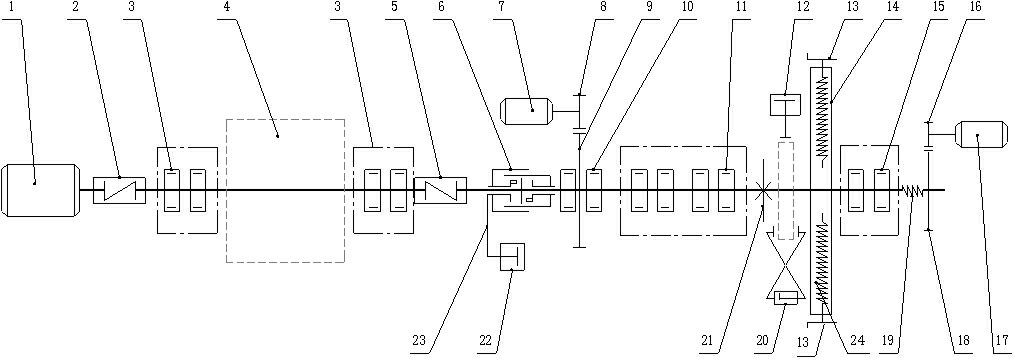

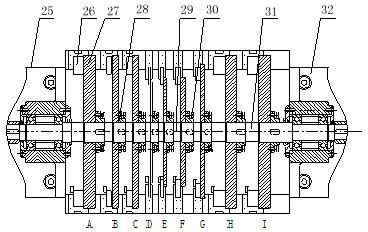

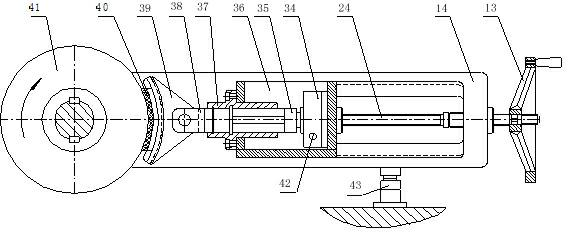

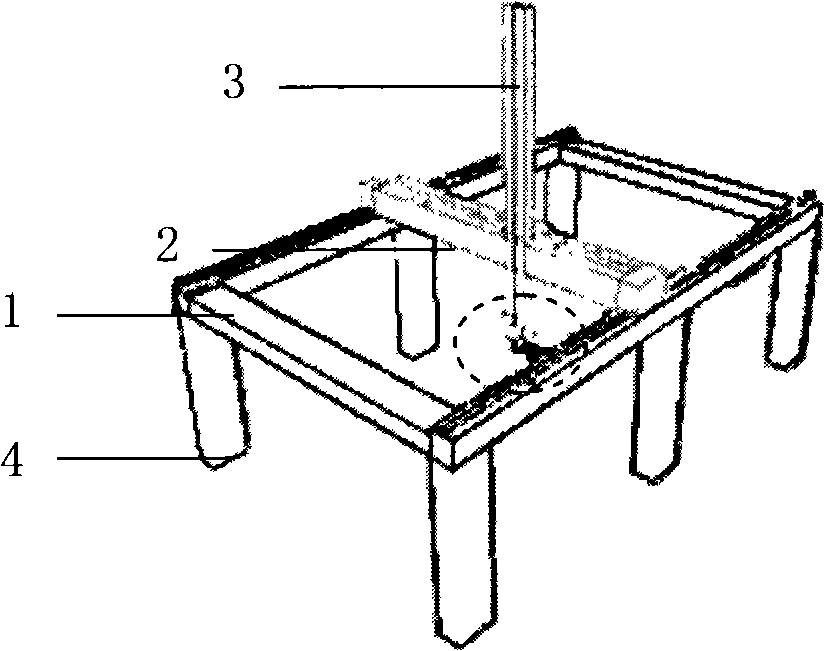

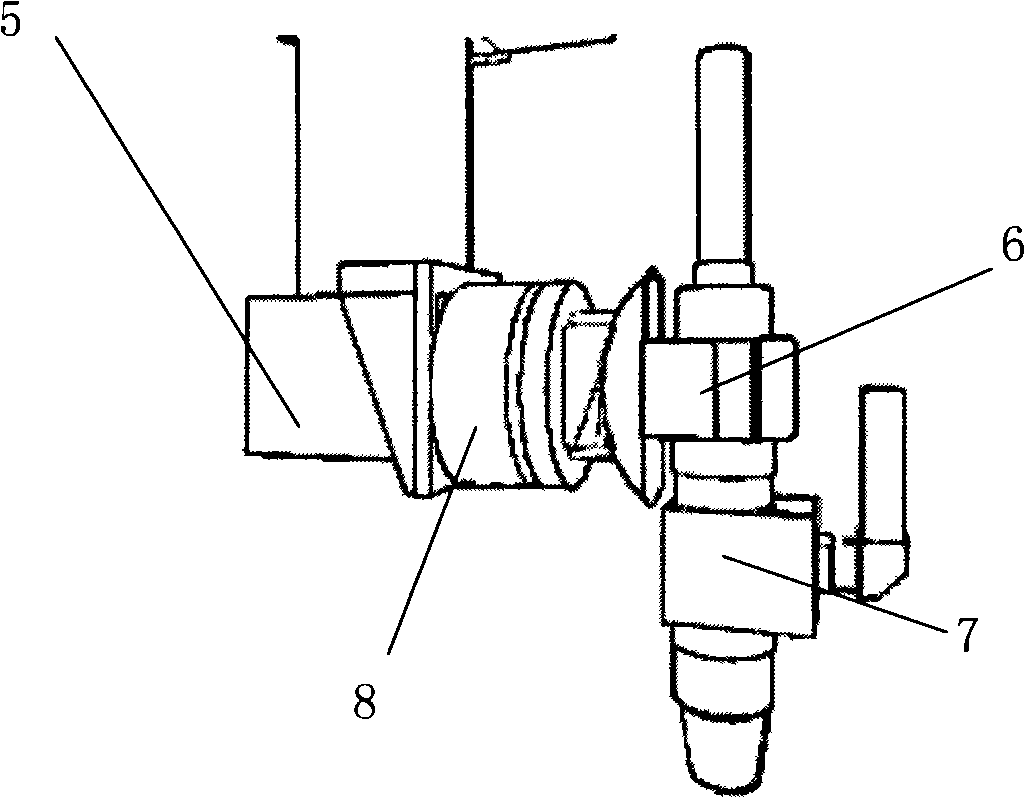

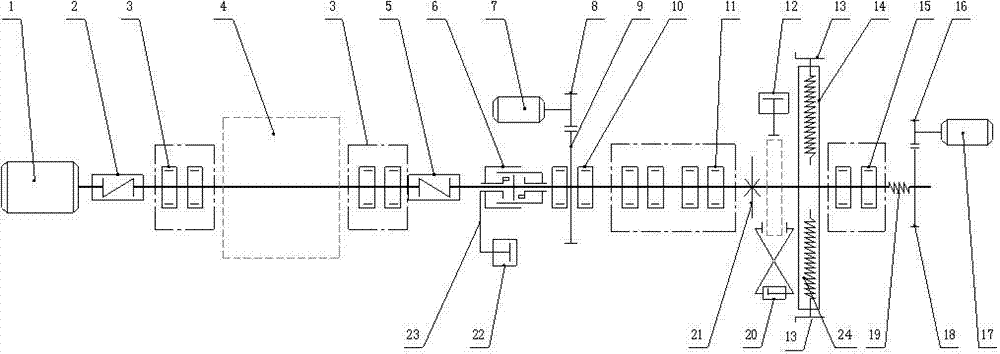

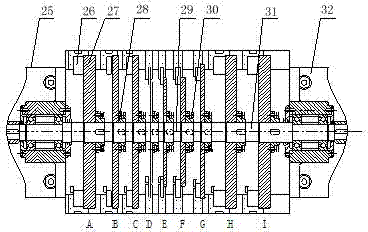

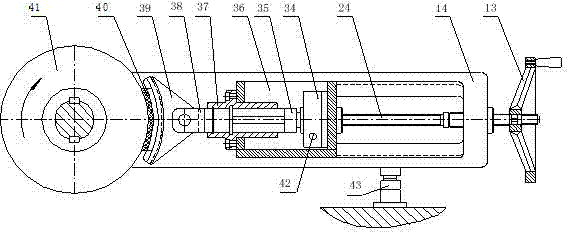

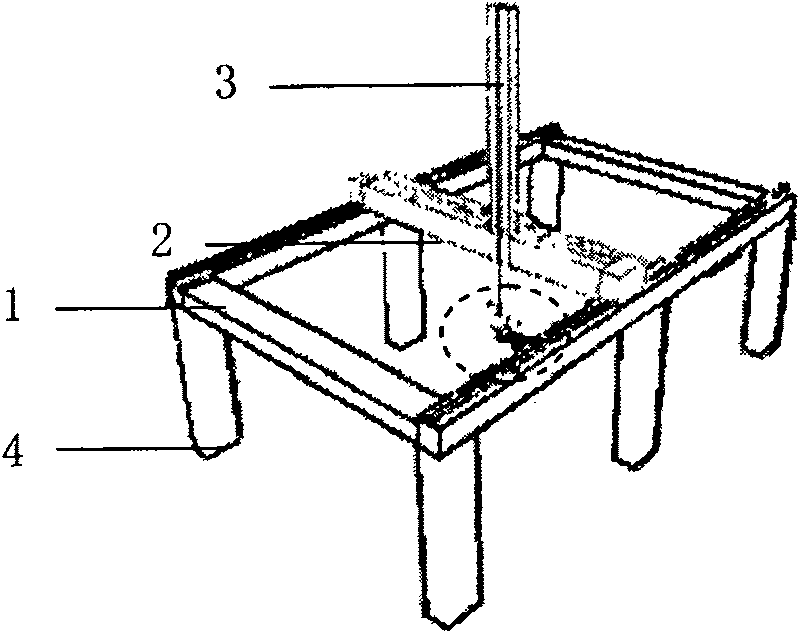

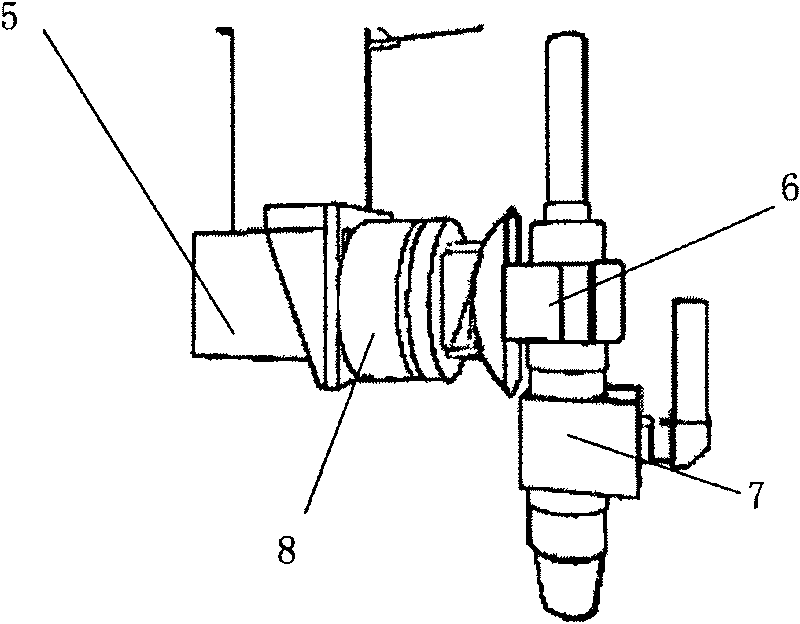

Shrink ratio test stand for testing performance of brake material for railway train

ActiveCN102323172AEasy to operateHigh technology contentStrength propertiesTest performanceSmall sample

The invention relates to a shrink ratio test stand for testing the performance of a brake material for a railway train. The analysis on the performance of the brake material is the important technical problem of research on all friction materials. The current standard regulates that the performance detection of all the brake materials for the railway and the railway trains can be tested on a 1:1 bench. Currently, few 1:1 railway train inertia braking benches are provided in China, so that the normal product detection is difficult to carry out. In the invention, a novel test bench for testing the performance of the brake material for the railway train, which consists of a driving mechanism, an inertia wheel configuration mechanism and the like, is arranged; a brake engineering principle isclosely combined; and a small sample geometric simulation shrink ratio test mode is used to be consistent with a 1:1 bench test mode. Due to the adoption of the shrink ratio test stand, a result corresponding to test data of the 1:1 bench can be obtained; and the consistency of the testing condition and the using working condition of the shrink ratio test stand in the whole testing process is really reflected. The shrink ratio test stand is convenient to operate and has complete functions and high technology content. The gap of the industry in China is filled. The rapid development of the field of the brake material in the industry is promoted.

Owner:刘学耕

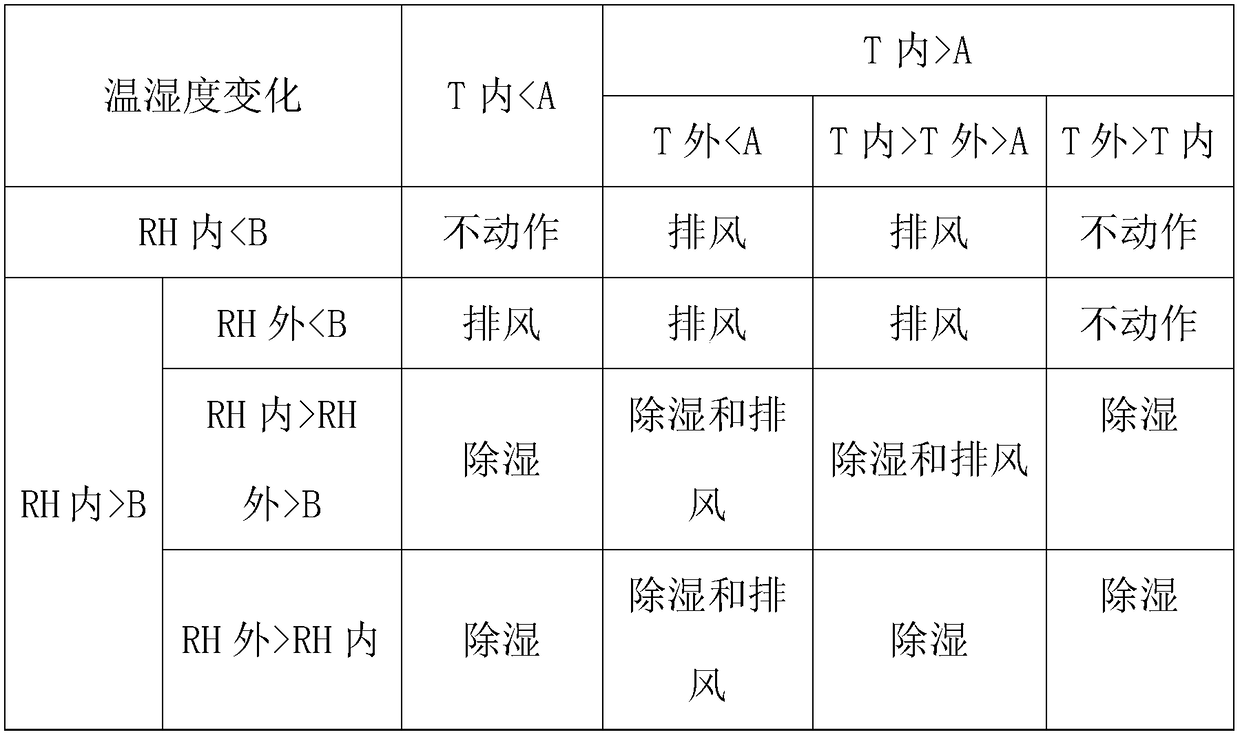

Distribution room environment adjusting system adjusting method based on sensor optimization arrangement

ActiveCN109412050AEffective controlImprove accuracySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsWork periodRoom temperature

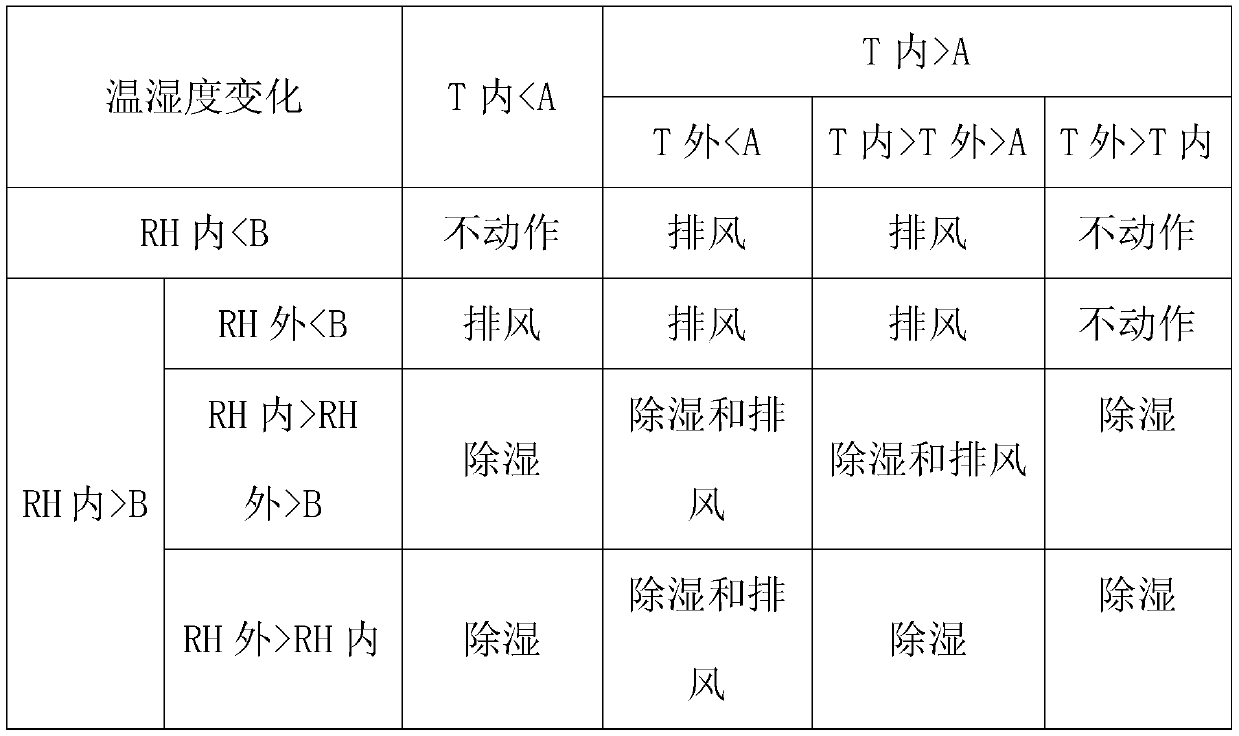

The invention discloses a distribution room environment adjusting system adjusting method based on sensor optimization arrangement. The adjusting method comprises a sensor optimization arrangement method and an adjusting system adjusting method; the sensor optimization arrangement method comprises the following steps of establishing a three-dimensional geometric simulation model of a transformer substation distribution room by utilizing Ansys, performing distribution room temperature field and humidity field simulation analysis on the simulation model by means of Ansys, obtaining temperature field and humidity field distribution simulation graphs at different heights, and selecting temperature and humidity sensors for distribution through the simulation graphs. The problem of accidents caused by that the indoor temperature and humidity monitoring points are small in distribution and unreasonable in distribution is solved; and 2, on the aspect of a control strategy, once it is monitoredthat the environment has certain unqualified point, all equipment are started, and the whole environment can be adjusted together; and consequently, the method is not accurate enough, while unnecessary equipment is started, so that the working time of equipment is prolonged, the energy consumption is increased, and the purposes of energy conservation and emission reduction cannot be achieved.

Owner:GUIZHOU POWER GRID CO LTD

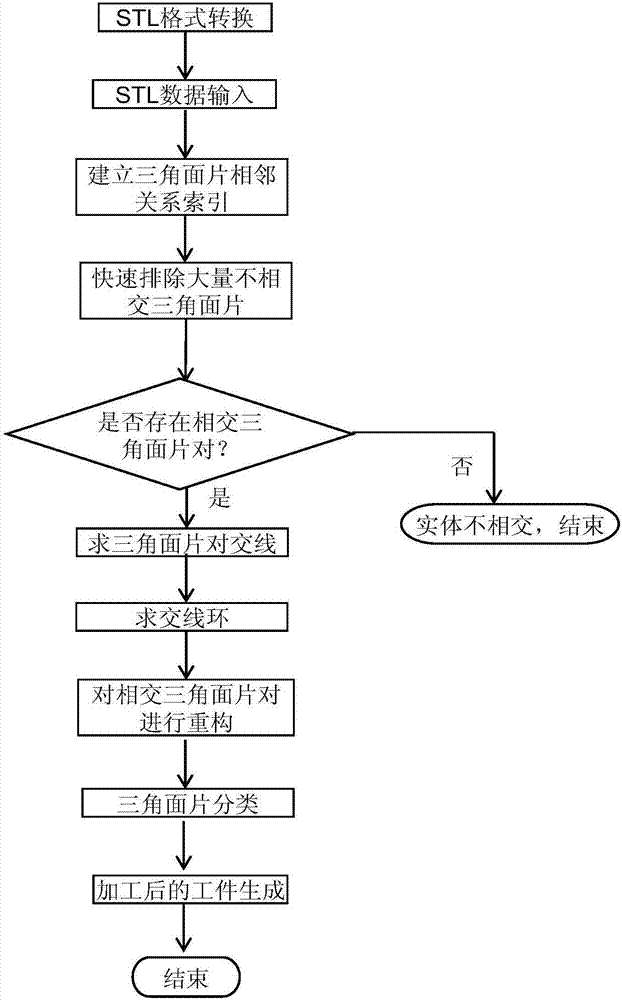

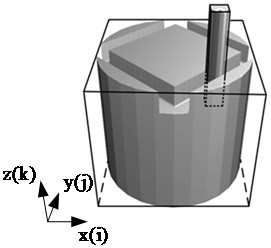

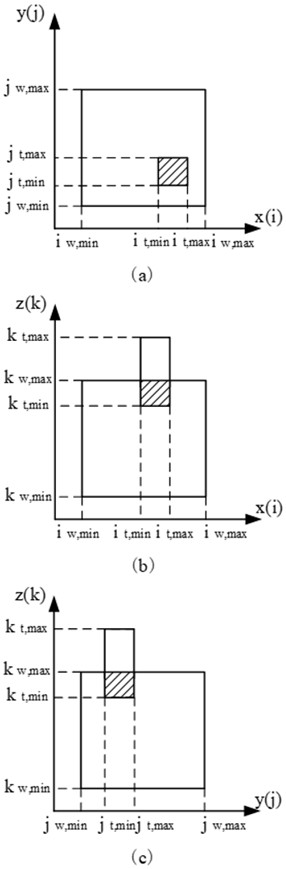

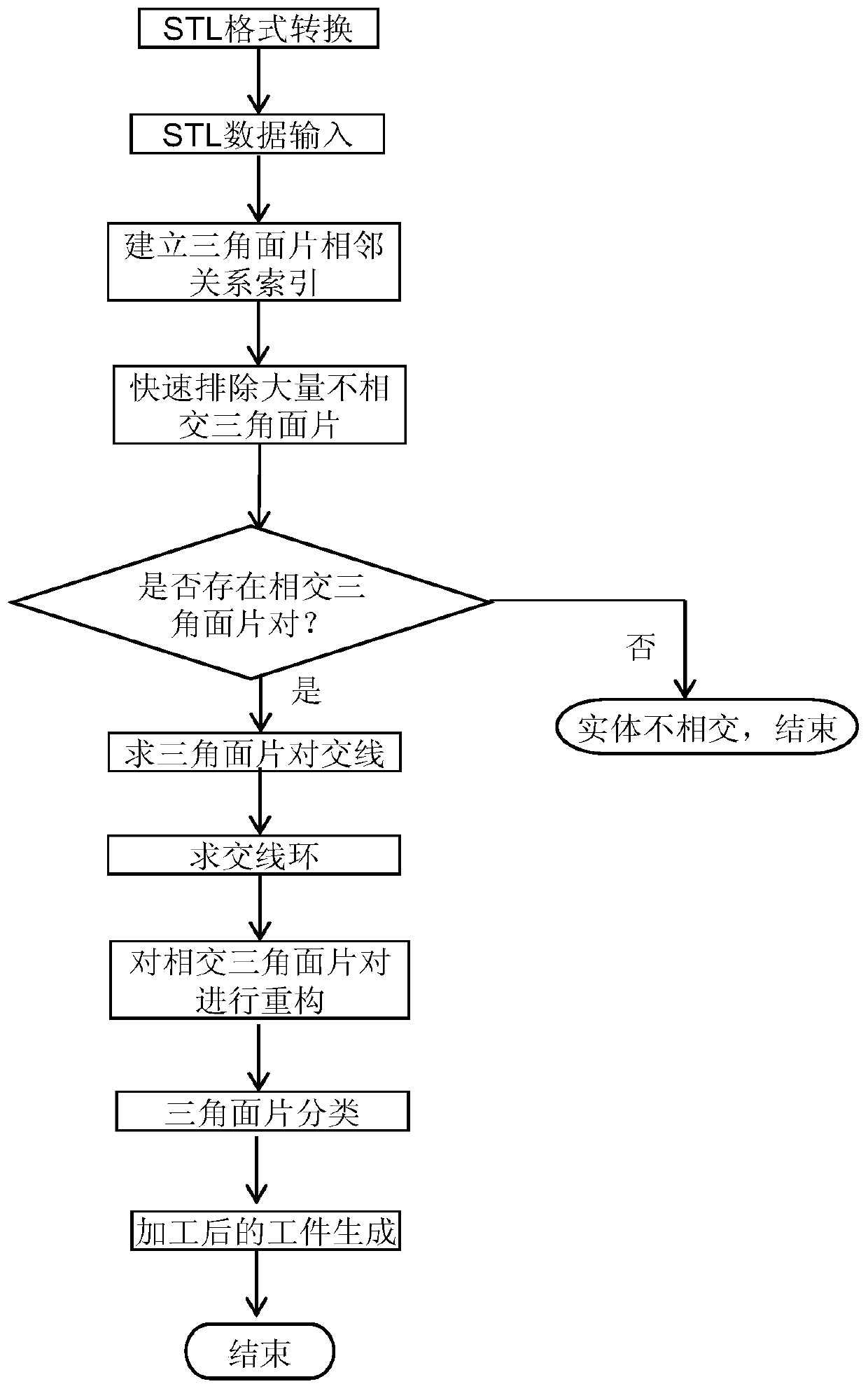

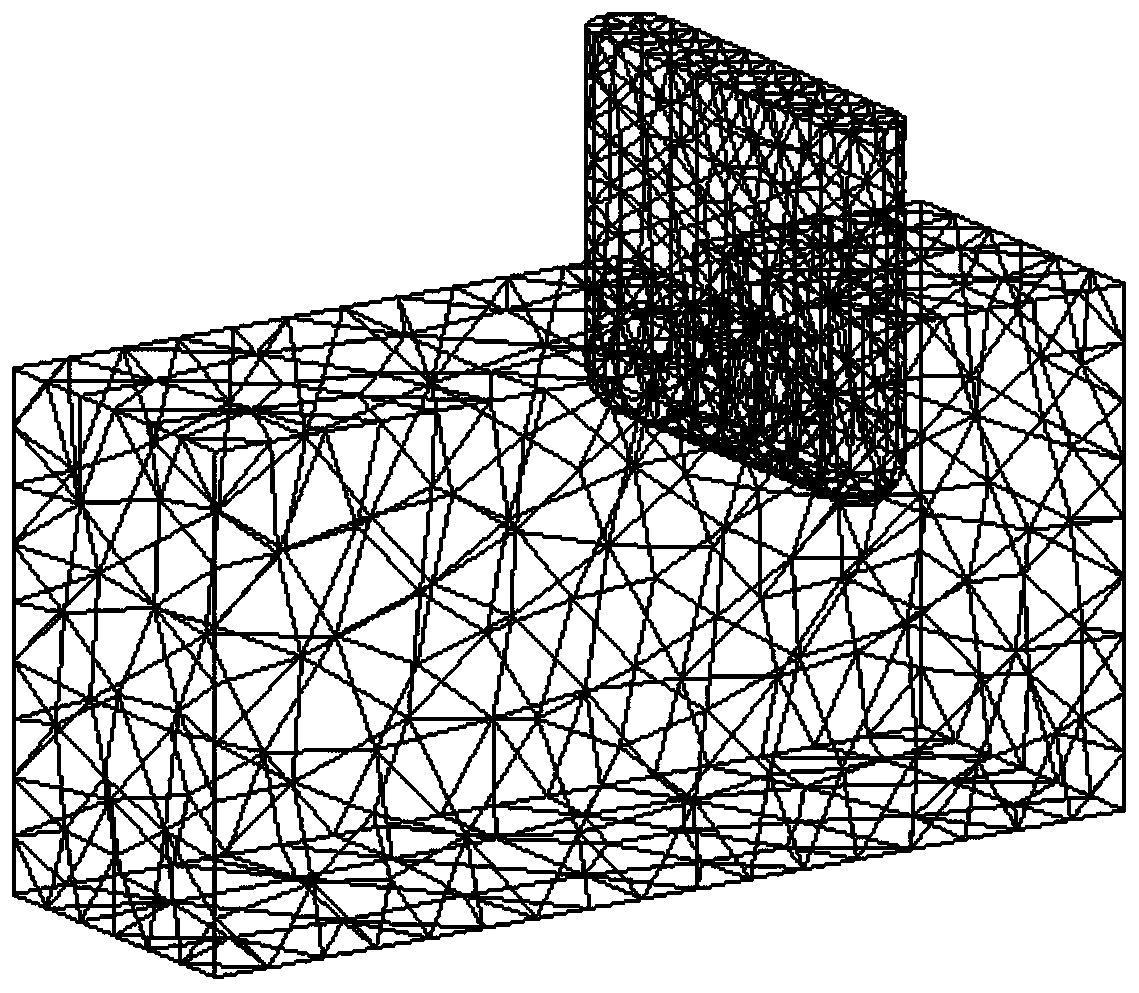

STL-model-based material removal algorithm in numeral control machining geometric simulation

ActiveCN107037738AReduce complexityImprove cutting efficiencySimulator controlMaterial removalComputer science

The invention relates to an STL-model-based material removal algorithm in numeral control machining geometric simulation, comprising the following steps: transforming a CAD-generated processed workpiece and a tool swept volume into the STL format; accessing the STL models of the tool swept volume and the processed workpiece; establishing the relationship index for the triangular patches of the tool swept volume and the processed workpiece surface; establishing the smallest-possible enclosing boxes for the workpiece and the tool swept volume; screening and removing the non-intersecting triangular patches; using the dot product and the cross product of vector to create a vector determining model; determining whether the triangular patches intersect to obtain a set of intersecting triangular patch pairs; solving the intersecting lines of the intersecting triangular patch pairs; solving the intersecting line ring; reconstructing the triangular patches involved in the intersecting of the processed workpiece and the tool swept volume; classifying the triangular patches; and with the kept surface of the processed workpiece and the surface involving in the processing of the tool swept volume form a new enclosed surface to develop a workpiece model after the materials are removed.

Owner:TSINGHUA UNIV

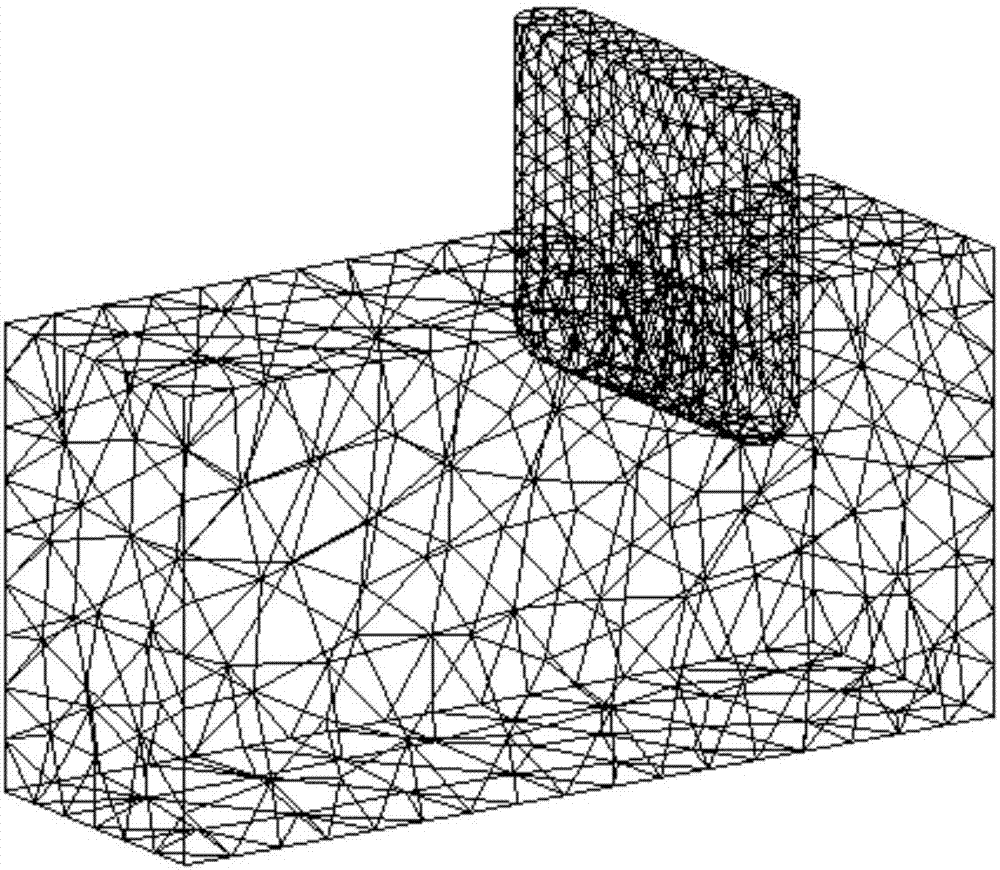

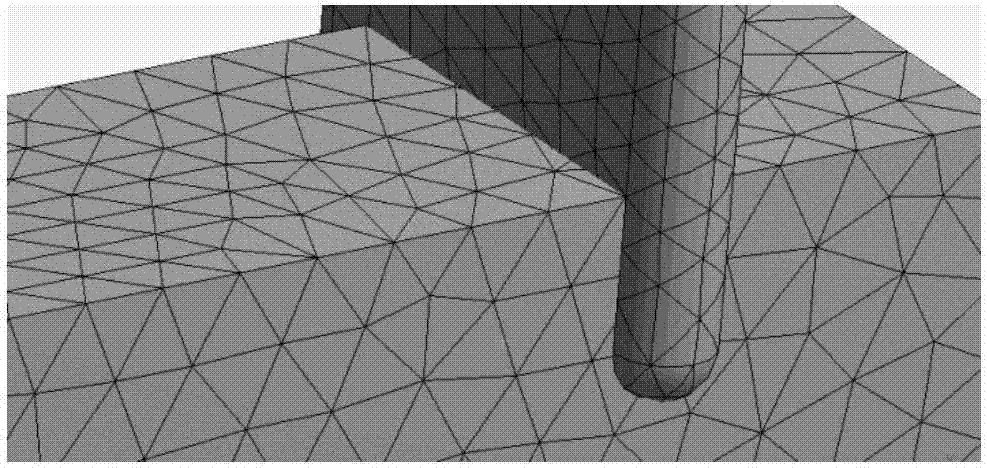

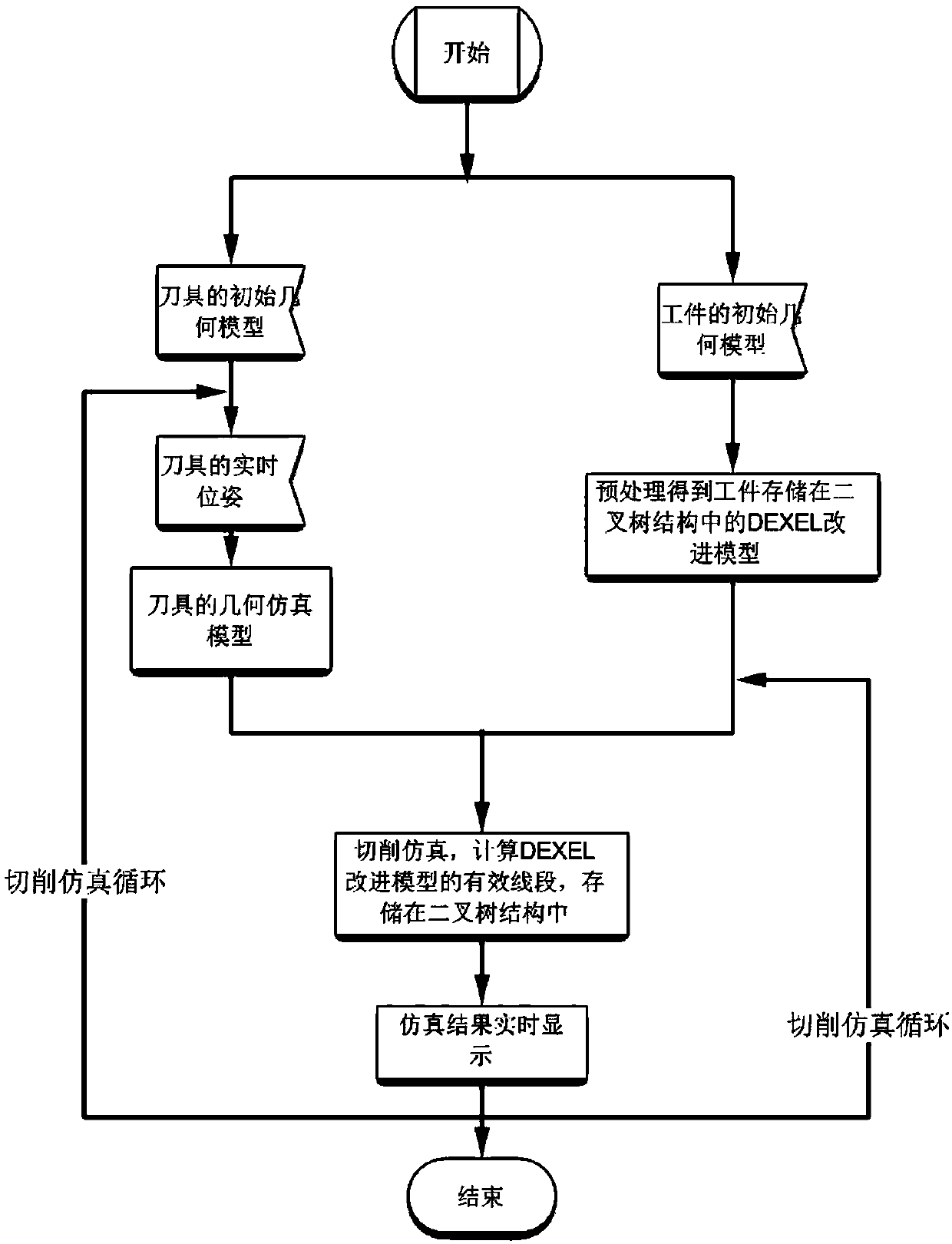

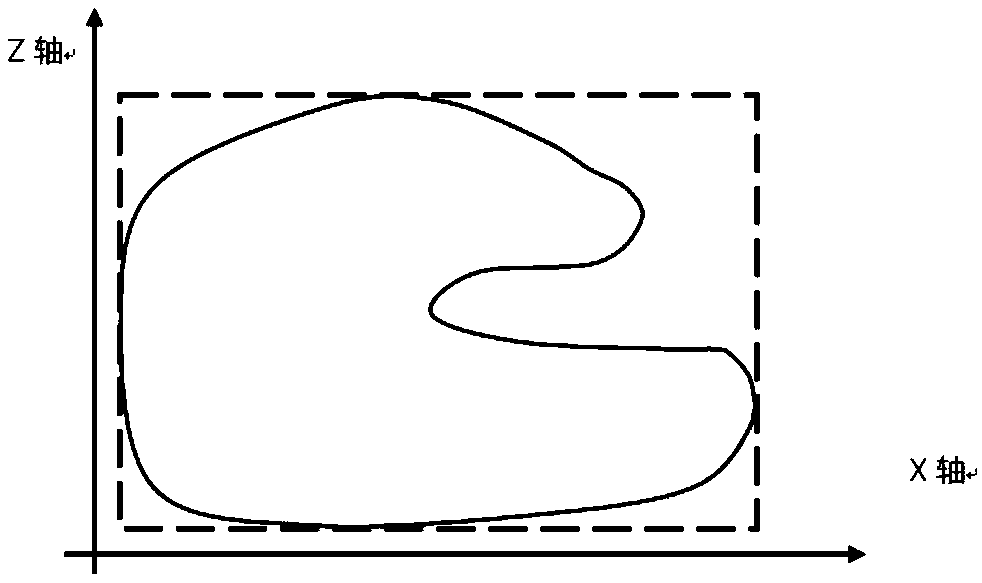

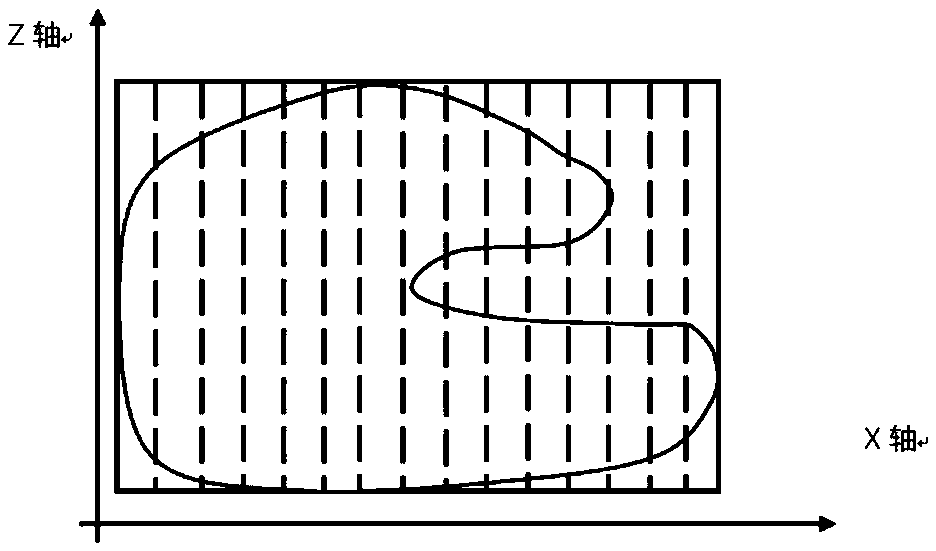

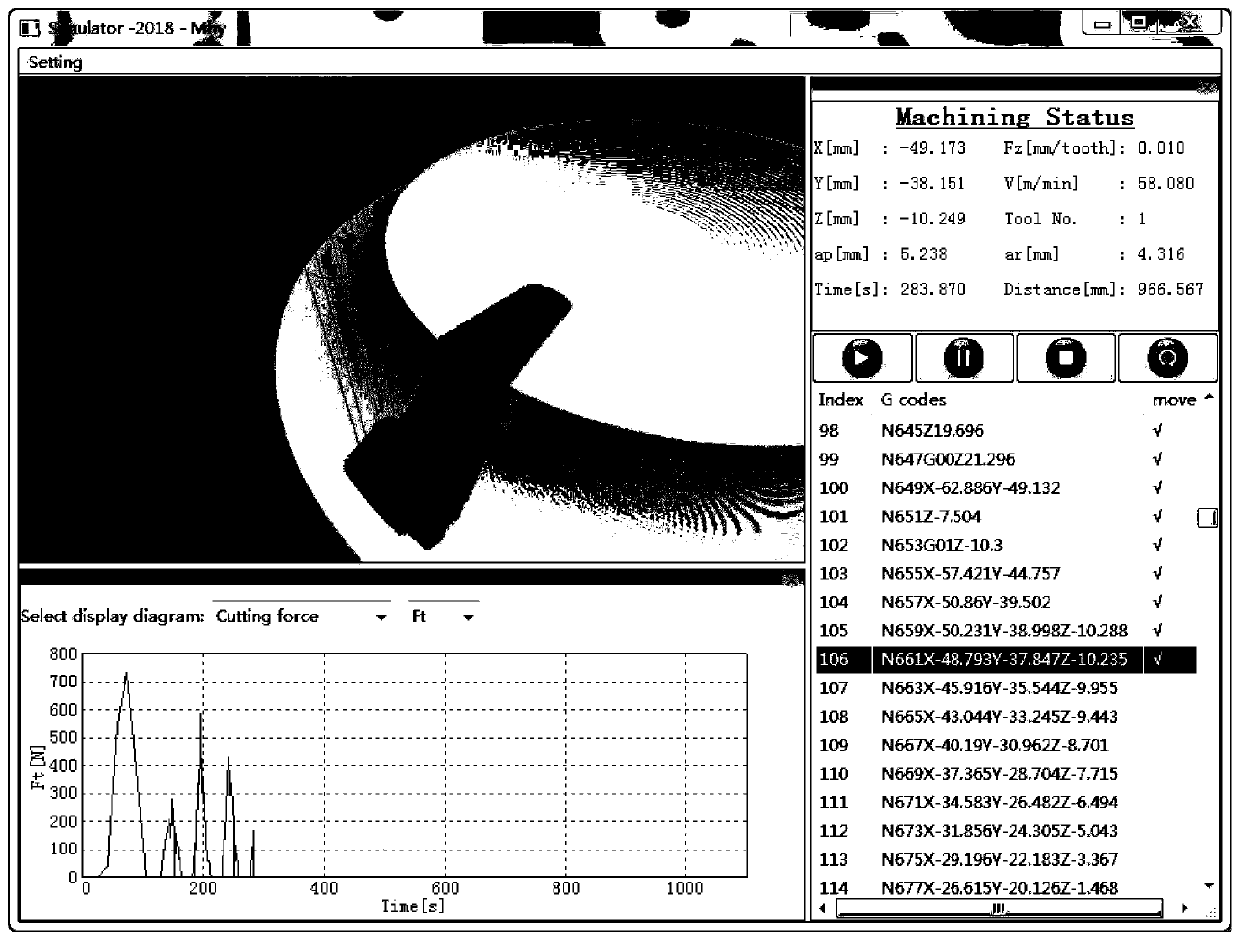

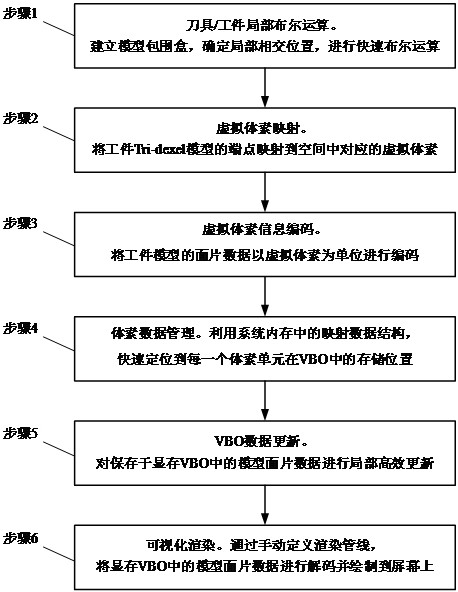

Cutting simulation implementation method for real-time machining monitoring

PendingCN110955934AImproved storageImproved search functionalityGeometric CADDesign optimisation/simulationNumerical controlReal-time simulation

The invention discloses a cutting simulation implementation method for real-time machining monitoring. The method includes: firstly, establishing a geometric simulation model of a cutter for the cutter; establishing a DEXEL improved model of a workpiece for the workpiece, performing cutting simulation operation by using a geometric simulation model of a cutter and the DEXEL improved model of the workpiece to obtain an updated DEXEL improved model of the workpiece, and finally constructing the updated DEXEL improved model into a triangular patch display model to realize real-time display. According to the method, a data storage and search structure of a Depth Element, Dexel real-time modeling algorithm and a geometric simulation model of a cutter are optimized, the simulation speed of the numerical control cutting (including turning and milling) real-time simulation process is increased, and cutting simulation oriented to real-time machining monitoring is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Layout method for temperature and humidity sensor of environment automatic regulation system of substation distribution room

ActiveCN109358677AAccurate temperature and humidityAvoid manual interventionSimultaneous control of multiple variablesSimulationEngineering

The invention discloses a layout method for the temperature and humidity sensor of the environment automatic regulation system of a substation distribution room, comprising the following steps of: using Ansys to establish a three-dimensional geometric simulation model of the substation power distribution room; using the Ansys to perform temperature field and humidity field simulation analysis of distribution room on the simulation model; acquiring temperature field and humidity field distribution simulation graphs at different heights; and performing the layout of the temperature and humiditysensor according to the simulation graphs. The layout method for the temperature and humidity sensor of the environment automatic regulation system of a substation distribution room solves the technical problem in the prior art that, the sensor arrangement for monitoring the temperature and humidity environment of the substation distribution room depends on manual experience or installation convenience, and the data acquired by the arranged sensor is not representative for describing the environment parameters of the distribution room, so that the temperature and humidity condition of the substation distribution room cannot be comprehensively monitored and understood, and the effective control cannot be performed to regulate the environment parameters of the distribution room.

Owner:GUIZHOU POWER GRID CO LTD

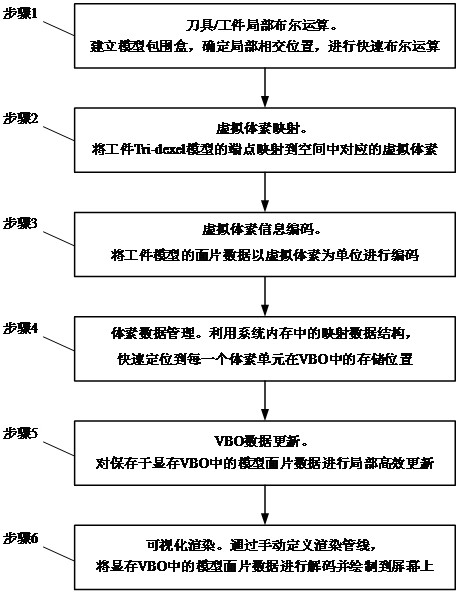

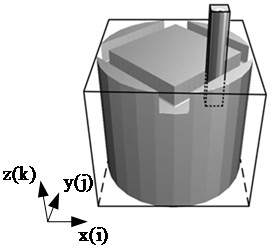

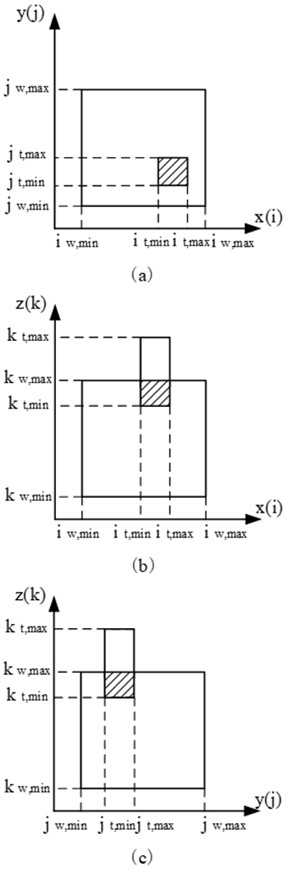

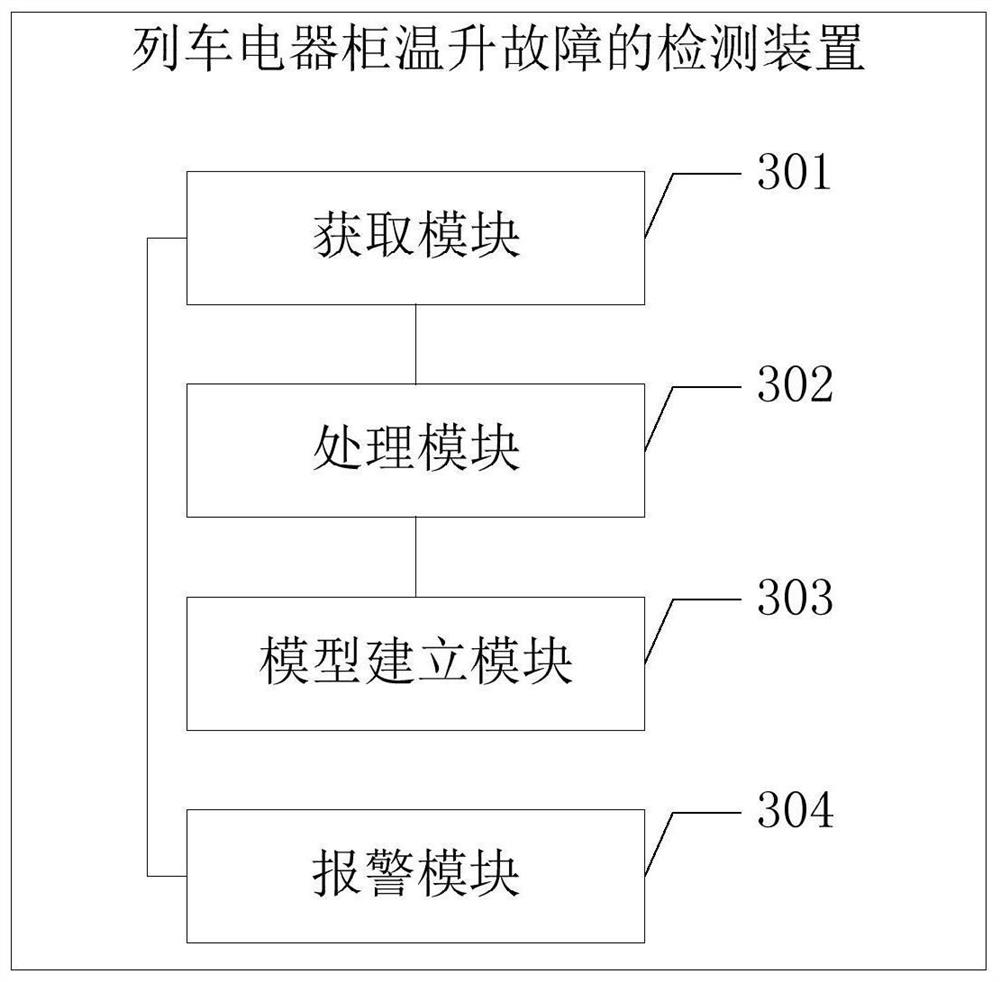

VBO-based efficient geometric simulation method for cutting process

ActiveCN113343546AReduce consumptionImprove Simulation EfficiencyGeometric CADDesign optimisation/simulationVideo memoryVoxel

The invention discloses a VBO-based efficient geometric simulation method for a cutting process. The method comprises the following steps: performing local Boolean operation on a tool / workpiece, establishing a model bounding box, determining a local intersection position, and performing rapid Boolean operation; virtual voxel mapping: mapping end points of the workpiece Tri-dexel model to corresponding virtual voxels in a space; virtual voxel information coding: coding the surface patch data of the workpiece model by taking a virtual voxel as a unit; voxel data management: mapping a storage mode of voxel data in a video memory VBO to a system memory; VBO data updating: performing local efficient updating on the model patch data stored in the video memory VBO; and performing visual rendering, manually defining a rendering pipeline, decoding the model patch data in the video memory VBO, and drawing the decoded model patch data on a screen. According to the method, redundant calculation in the simulation process can be reduced, local dynamic updating of the workpiece model is achieved, and the efficiency of geometric simulation in the cutting machining process is greatly improved.

Owner:BEIHANG UNIV

Dummy laser processing procedure geometric simulation method

InactiveCN101308523ASave human effortSave moneySpecial data processing applicationsProcess optimizationLaser processing

The invention discloses a geometric simulation method in the virtual laser flexible processing course. The method comprises the establishment of a virtual processing platform, the trajectory planning based on CAD data, the trajectory optimization, the triangular simplification algorithm based on processing head effect, and a collision detection model. The invention can help observe the processing movement course in the computer visualization environment, visually display the collision interference and unreasonable processing trajectory in processing robots and other equipment as well as workpieces by laser, and forecast the processing defects in an early stage, so as to provide an effect basis for process parameter adjustment and process optimization, so as to save manpower, material resources, time and cost.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

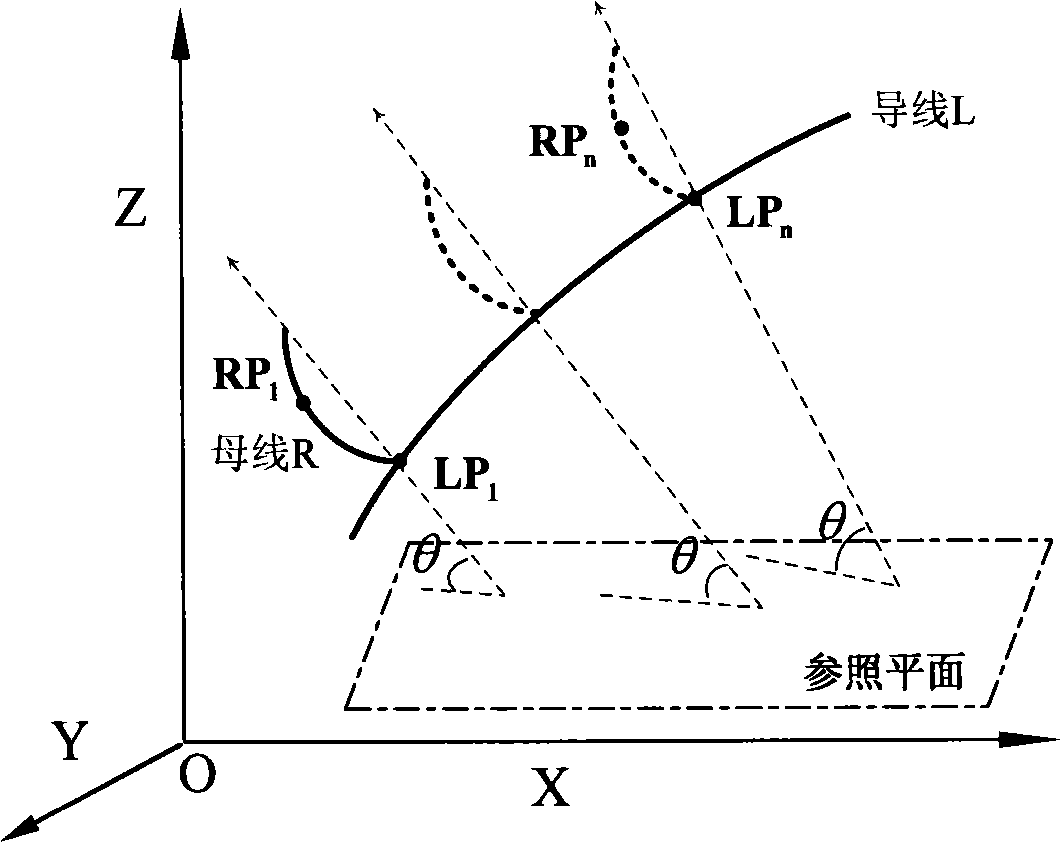

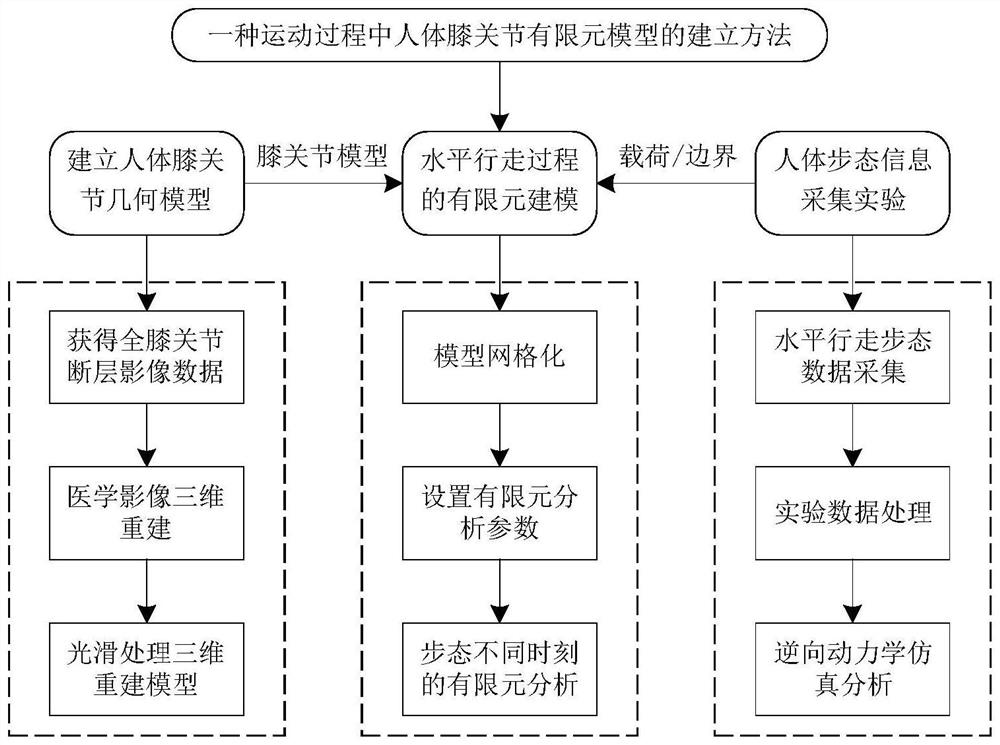

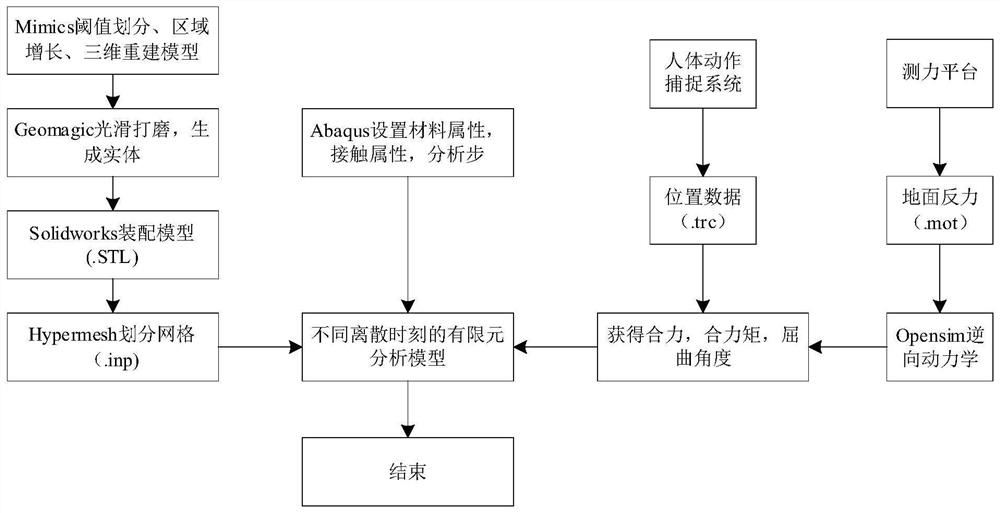

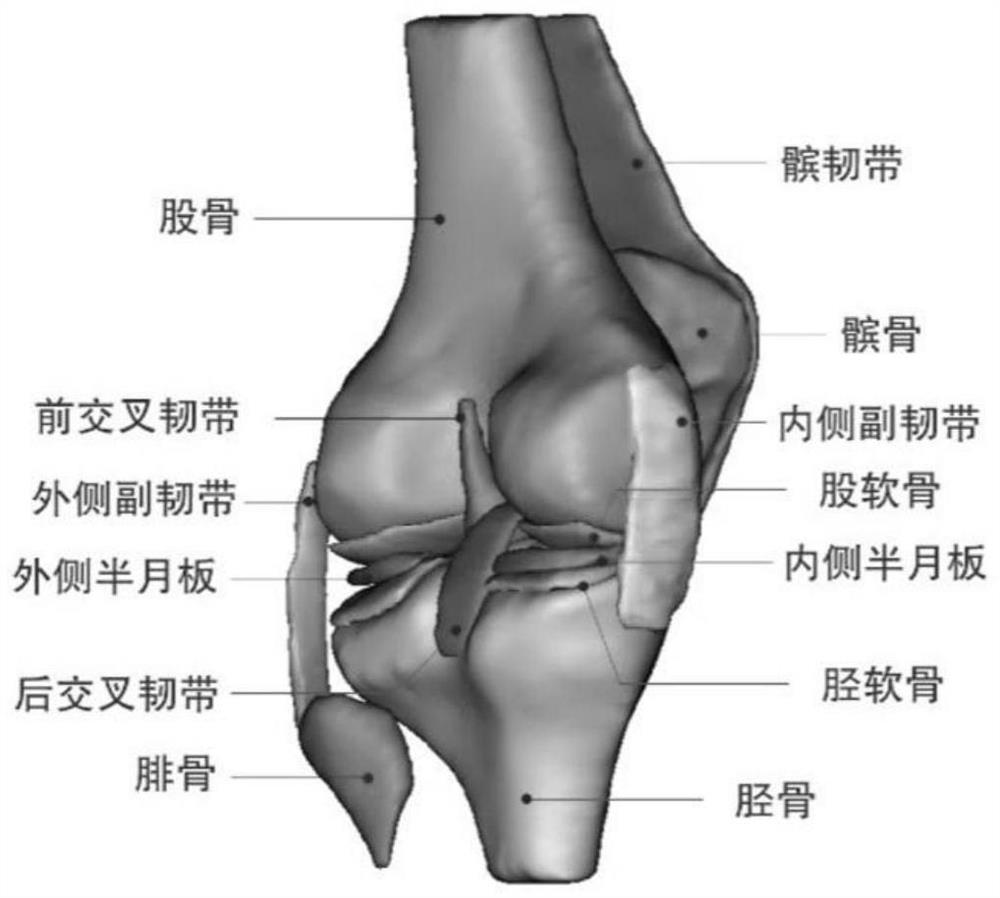

Method for establishing human knee joint finite element model in movement process

ActiveCN112733404ASmall layer thicknessAccurate Image DataSustainable transportationDesign optimisation/simulationHuman bodyArticular surfaces

The invention relates to a method for establishing a finite element model of a human knee joint in a movement process, which comprises the following steps of: establishing a geometric model of the human knee joint, acquiring gait information of the human body, establishing the finite element model, and obtaining a stress distribution condition of a joint surface through finite element simulation to predict biomechanics in the knee joint in the movement process. In-vivo knee joint kinematics and a knee joint anatomical model are combined by adopting geometric simulation and simulation means, a three-dimensional motion capture system ViconT40S and Opensim are combined for simulation analysis, and a human body whole body muscle bone model with variable Opensim is utilized to match the human body metrology size of an experimenter, so that errors in simulation calculation are effectively controlled; and the accuracy of inverse kinematics and inverse dynamics solution is improved, so that the obtained final data is more accurate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

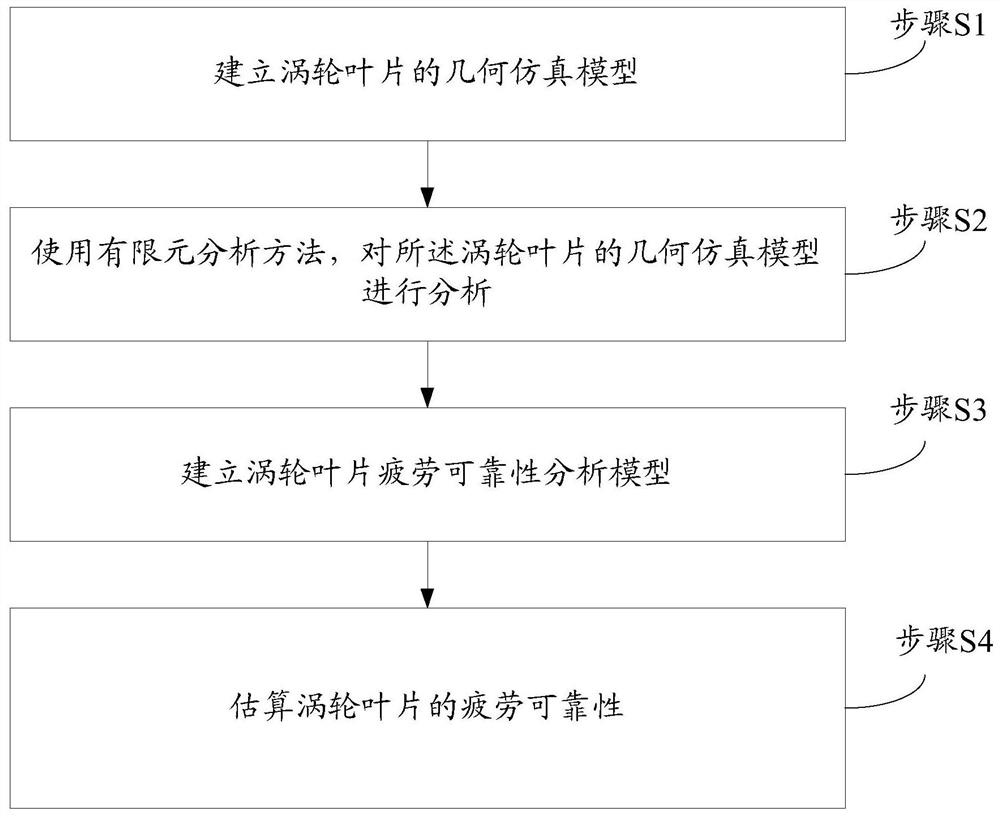

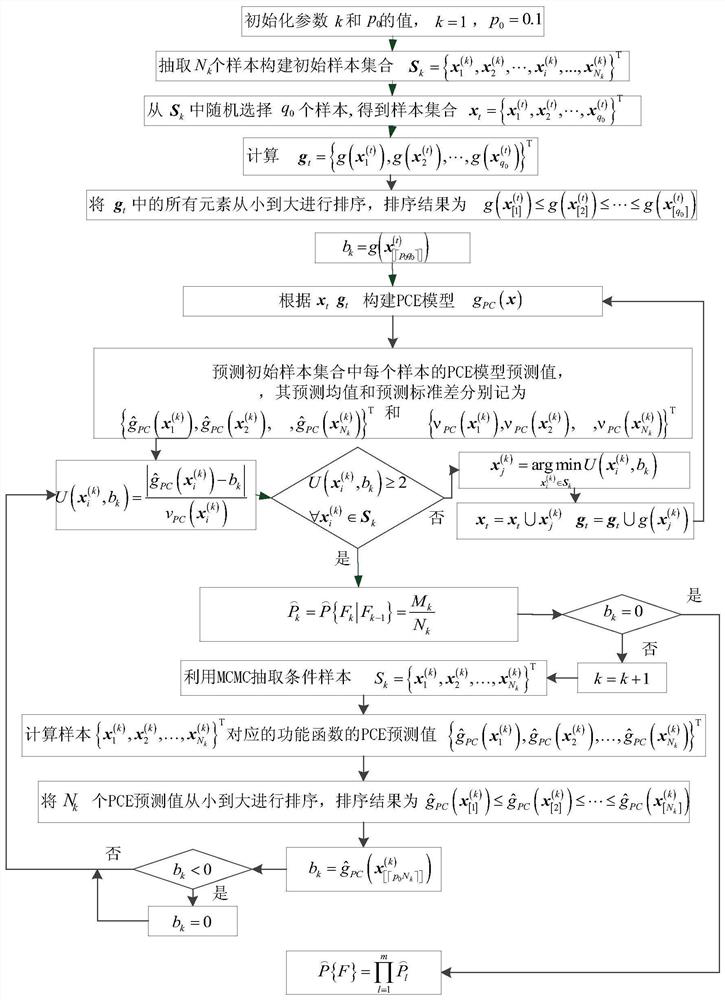

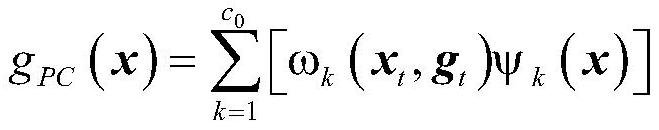

Turbine blade fatigue reliability analysis method combining subset simulation with PCE

ActiveCN111783216AImprove analysis accuracyImprove analysis efficiencyGeometric CADDesign optimisation/simulationPerformance functionTurbine blade

The invention provides a turbine blade fatigue reliability analysis method combining subset simulation with PCE. The turbine blade fatigue reliability analysis method comprises the following steps that a geometric simulation model of a turbine blade is established; analyzing the geometric simulation model of the turbine blade, and determining an n-dimensional random vector x = {x1, x2,..., xn} T influencing the fatigue life of the turbine blade and a relationship between the n-dimensional random vector x = {x1, x2,..., xn} T and the design life of the turbine blade; establishing a turbine blade fatigue reliability analysis model to obtain a performance function y = g (x) of turbine blade failure; and estimating the fatigue reliability of the turbine blade. The method has the advantages that on one hand, under the condition of the same calculated amount, the analysis precision of the method on the fatigue reliability of the turbine blade is higher than that of a traditional PCE method in the prior art; and on the other hand, compared with a traditional numerical simulation method in the prior art, the resource consumption for analyzing the fatigue reliability of the turbine blade islow, the time is short, and therefore the efficiency of analyzing the fatigue reliability of the turbine blade is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

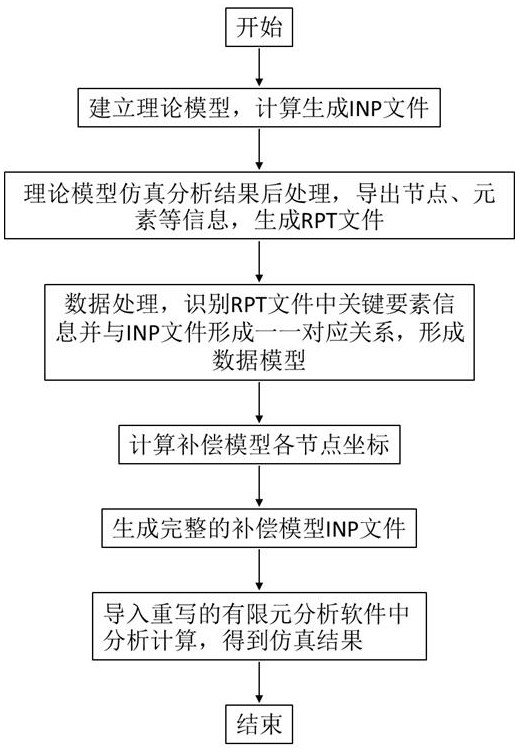

Rapid modeling method for composite material tool compensation profile simulation verification

ActiveCN112149324AImprove verification efficiencyHigh precisionDesign optimisation/simulationSpecial data processing applicationsModelSimMechanical engineering

The invention relates to the technical field of composite material manufacturing and curing deformation simulation, and discloses a rapid modeling method for composite material tool compensation profile simulation verification. The method specifically comprises the following steps: establishing a theoretical geometric simulation model, and calculating to generate an INP file; post-processing the theoretical geometric simulation model, exporting information such as all nodes, film surface nodes and elements of the part, and generating an RPT file; identifying key element information in the RPTfile, and forming a one-to-one correspondence relationship with the INP file; calculating node and element information of the compensation model tool and the part; establishing a complete compensationmodel INP file; and importing into the simulation software again to submit the operation. The creation process of the tool compensation profile is simplified, the expected improvement effect of the tool compensation profile on the curing deformation of the composite part can be quickly verified, the verification efficiency and precision of the tool compensation model are improved, and the methodhas important significance for improving engineering application of the simulation technology.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

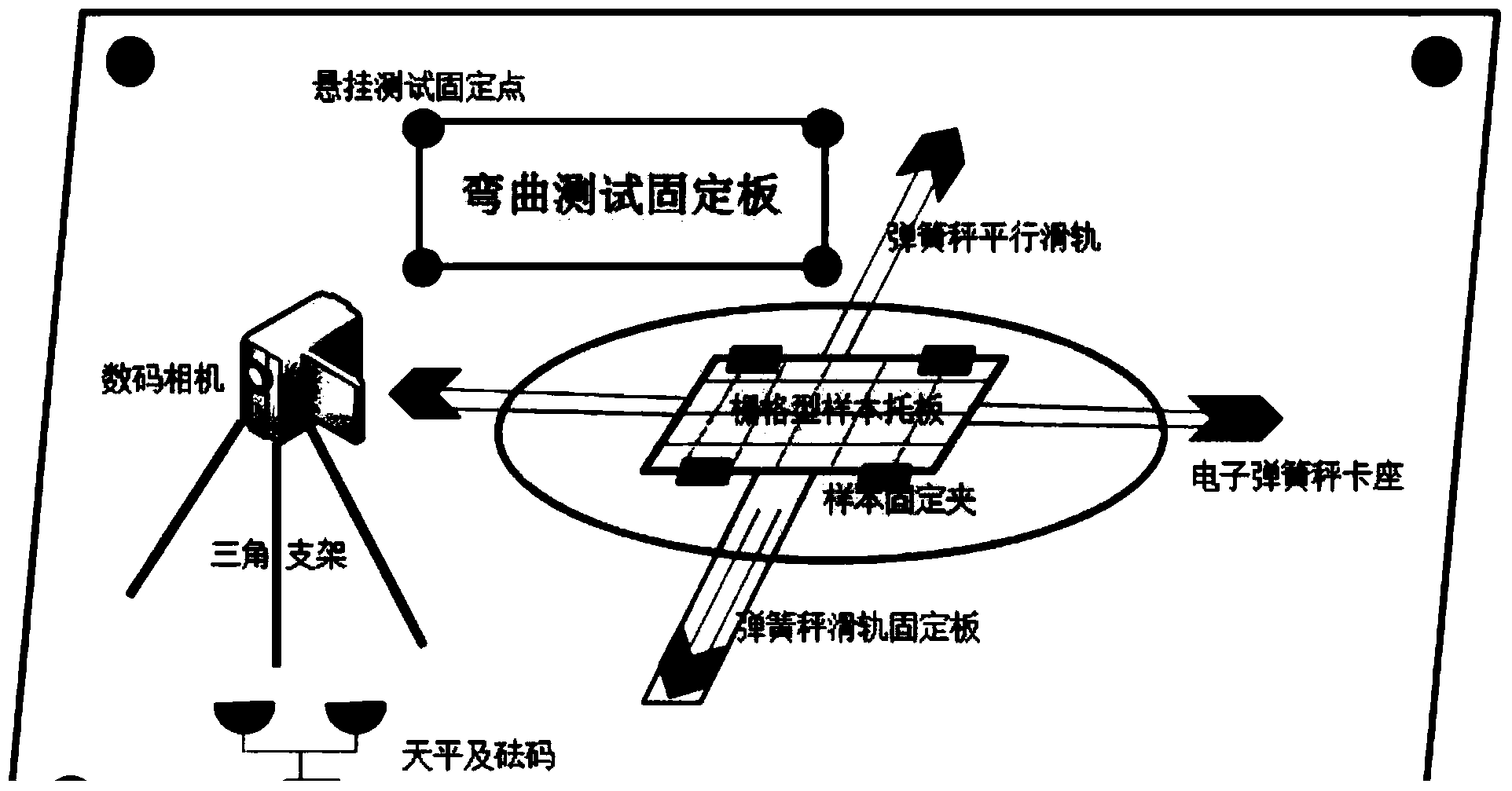

Method for generating fabric simulation model on basis of geometrical measurement

The invention discloses a method for generating a fabric simulation model on the basis of geometrical measurement, which comprises the following steps of: selecting a common garment fabric sample; carrying out material measurement of geometric attributes on the basis a fabric; carrying out geometric constraint deformation simulation on the basis of the fabric; carrying out geometric simulation verification on the basis of the fabric. The embodiment of the invention is implemented; the method obtains corresponding characteristic parameters which express the overhang characteristic of the fabric by directly measuring the real fabric sample, is directly applied to geometric simulation of the fabric and overcomes the defects of complex system and high cost on the basis of the physical KES-FB (Kawabata Evaluation System Fabric) and the like.

Owner:GUANGZHOU ZHONGDA DIGITAL HOME ENG TECH RES CENT +1

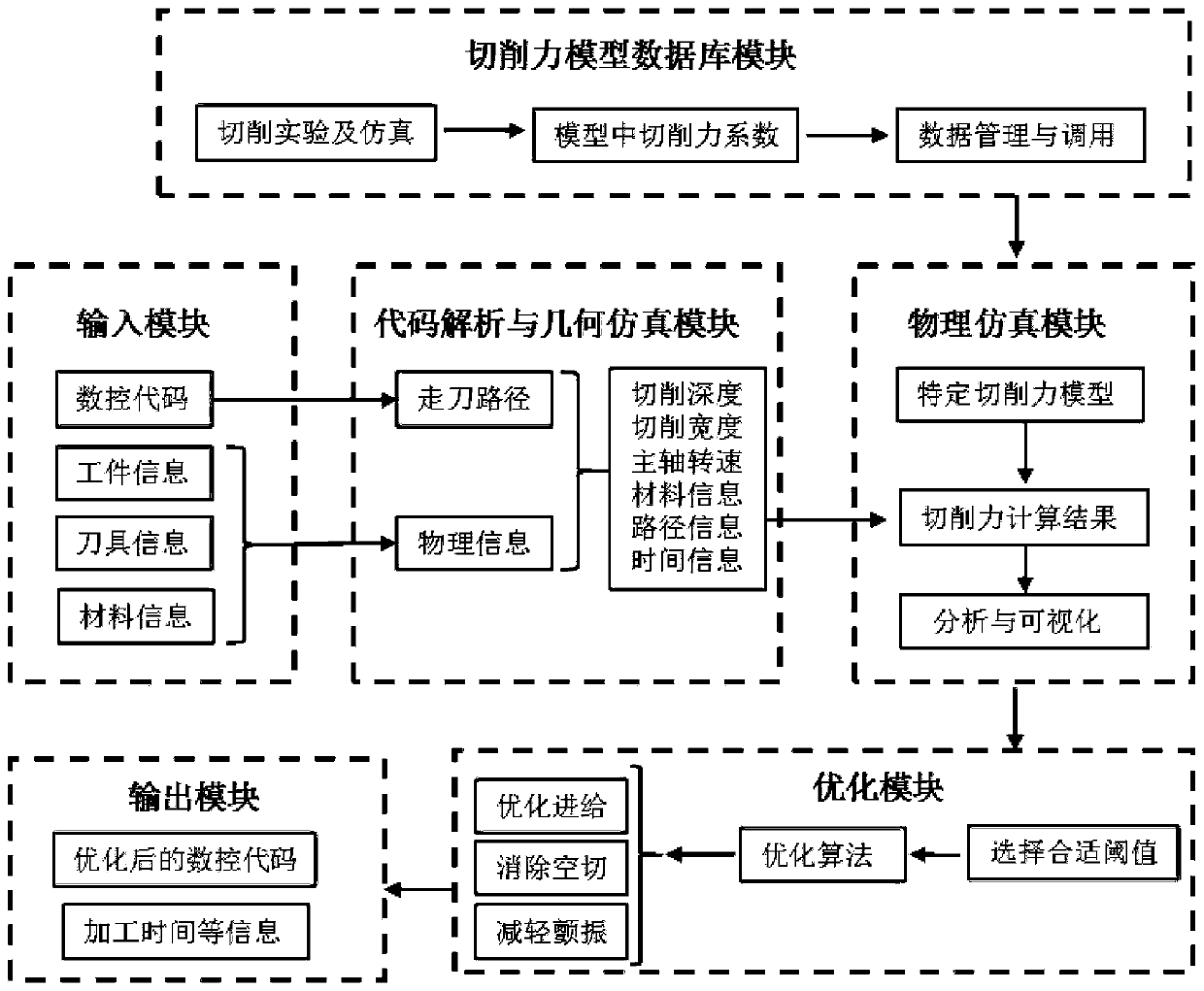

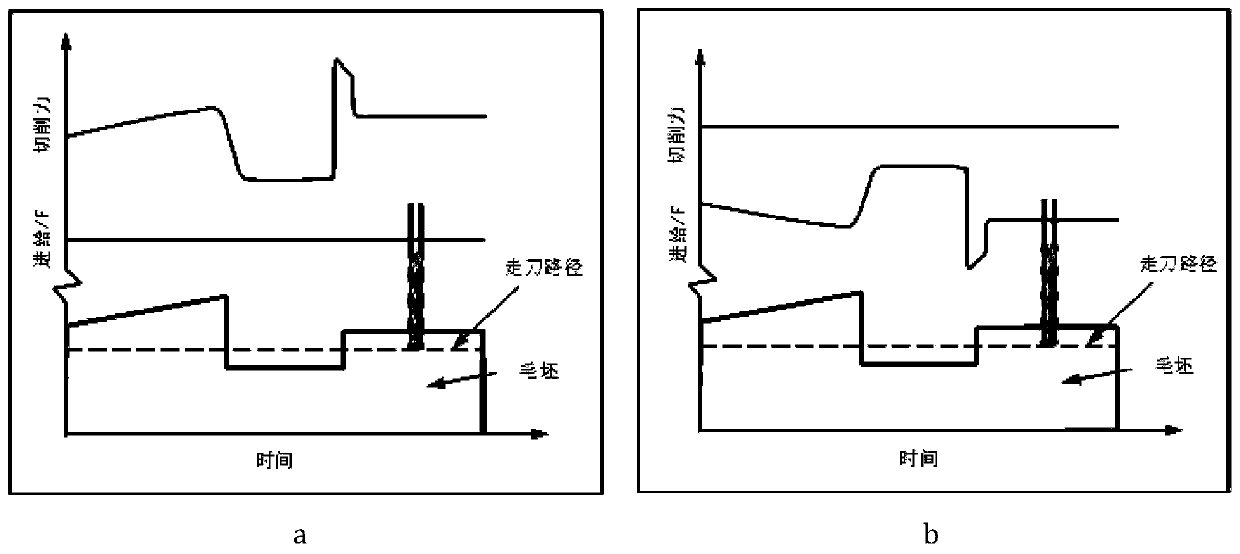

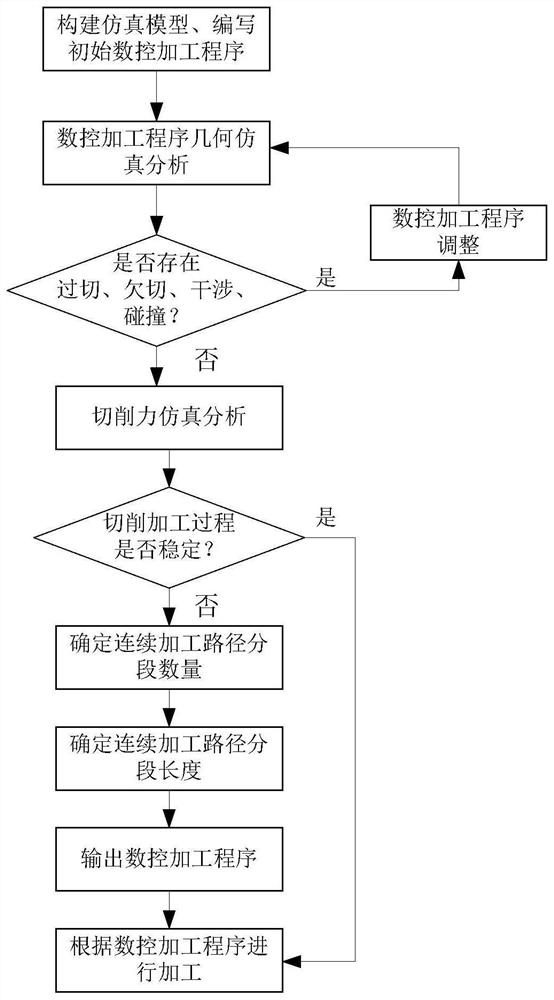

Numerical control machining optimization system and method based on physical simulation

ActiveCN110750074AReduce wearEliminate empty cutting pathsNumerical controlNumerical controlInformation transmission

A numerical control machining optimization system and method based on physical simulation is provided. The system comprises an input module, a code parsing and geometric simulation module, a physicalsimulation module, an optimization module and an output module that are successively connected, and a cutting force model database module connected to the physical simulation module. The input moduletransmits a read numerical control path file and physical information to the code parsing and geometric simulation module. The code parsing and geometric simulation module transfers specific parameterinformation of a full process cycle determined through parsing and simulation to the physical simulation module. The physical simulation module calculates a cutting force according to the parameter information by combining with a cutting force coefficient in the cutting force coefficient model database module, and transmits the cutting force to the optimization module. The optimization module generates a new machining code through an optimization process, and transmits the new machining code to the output module. The output module converts the new machining code into a numerical control codethat can be directly read by a machine tool, and outputs the numerical control code. According to the numerical control machining optimization system and method based on physical simulation, machiningefficiency is improved, and tool abrasion is reduced.

Owner:SHANGHAI JIAO TONG UNIV +2

A heterogeneous data fusion method for urban and rural integrated management with three-dimensional space information service

PendingCN109947880AImprove storage efficiencyAdapt to visualization requirementsDatabase management systemsVisual data miningEnvironmental resource managementDimensional simulation

The invention discloses a heterogeneous data fusion method for urban and rural integrated management with three-dimensional space information service. The method comprises the steps of three-dimensional information service system construction and heterogeneous data fusion. The three-dimensional information service system mainly comprises two parts, collecting and inputting of three-dimensional graph data and collecting and inputting of attribute data; Collection and input of three-dimensional graph data are oriented to a three-dimensional simulation model established for buildings, Bridge andgreenbelt in the field of urban planning. farmland and the like; the three-dimensional simulation model comprises geometric simulation, Physical simulation, Behavior simulation and biosimulation. Theinvention relates to a heterogeneous data fusion method for urban and rural integrated management with three-dimensional space information service. Two threads of data preloading and real-time loadingare adopted to schedule topographic data in parallel, so that data scheduling can better adapt to visualization requirements, different data sources are subjected to immunolabeling, a green channel is opened for later repeated feedback, and the data storage efficiency is improved.

Owner:苏州晓齐信息科技有限公司

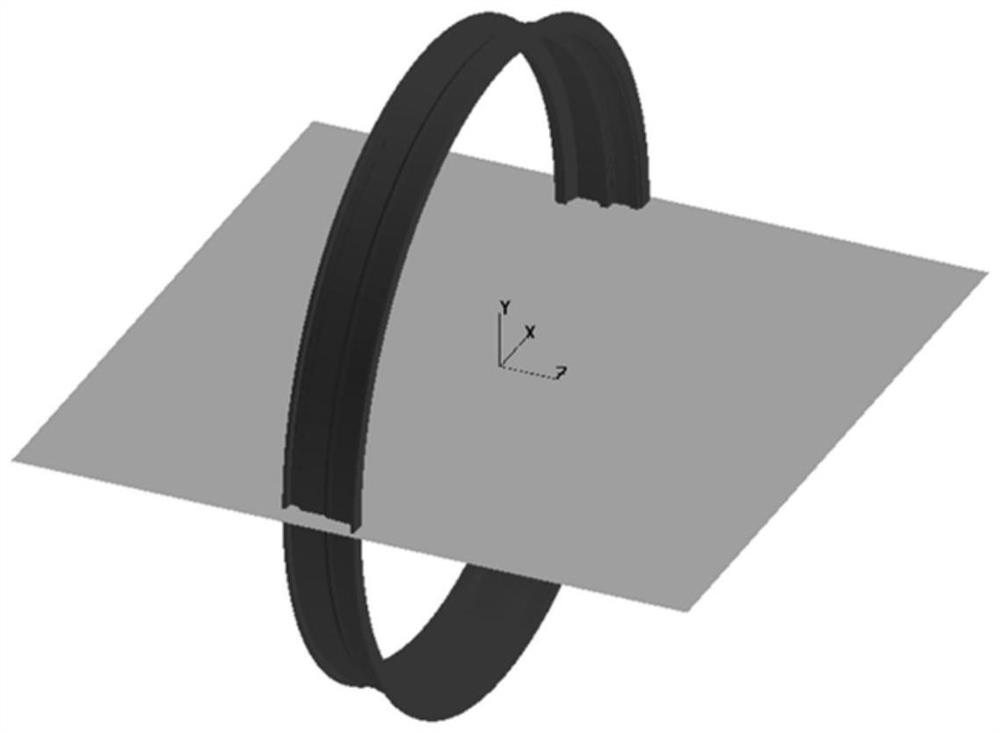

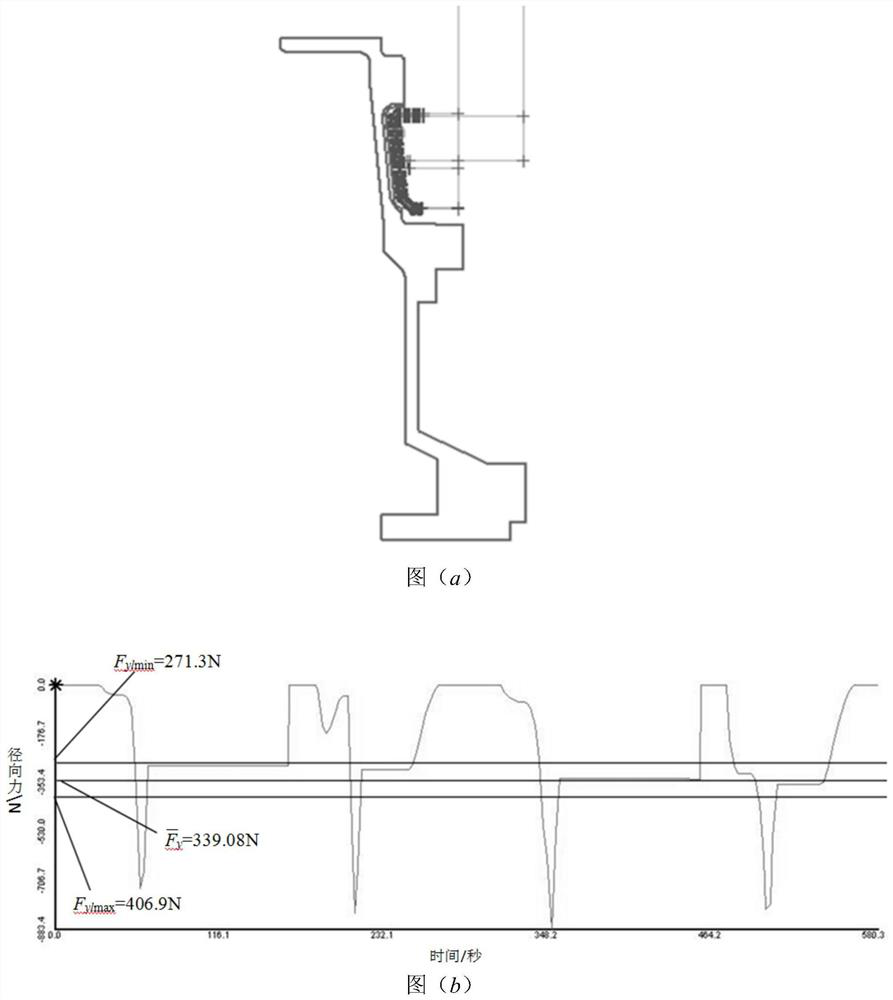

Integral annular casing numerical control machining optimization method based on surface roughness control

ActiveCN112034786AShorten the optimization cycleImprove processing qualityNumerical controlNumerical controlSurface roughness

The invention provides an integral annular casing numerical control machining optimization method based on surface roughness control. The method comprises the following steps that firstly, a simulation model of a casing part is constructed, an initial numerical control machining program is written, then geometric simulation and physical simulation are conducted, the stability of the numerical control machining process is judged according to a simulation analysis result of cutting force, for a continuous machining path which is unstable in the machining process, segmentation treatment of the path is conducted according to a surface roughness index, and cutting force simulation analysis is conducted on the numerical control machining program with the segmented path again until the numericalcontrol machining program for stabilizing the machining process is obtained. According to the method, the numerical control machining program optimization period can be shortened, the part machining quality is improved, the problem of cutting force fluctuation in the numerical control machining process is solved, and high universality and practicability are achieved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

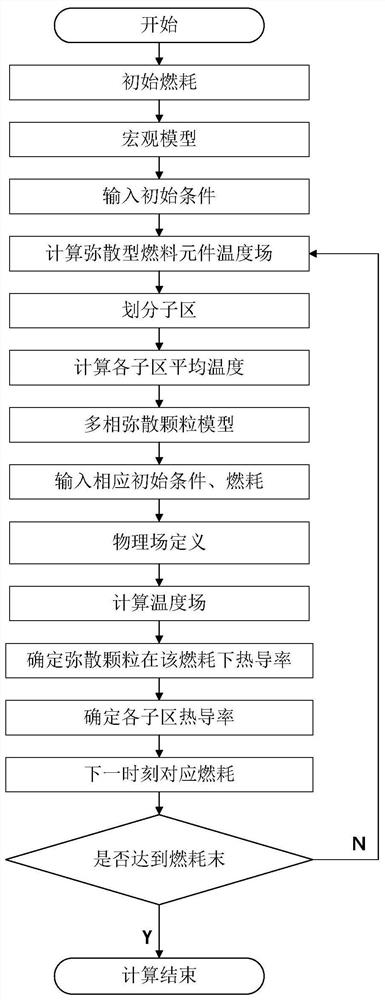

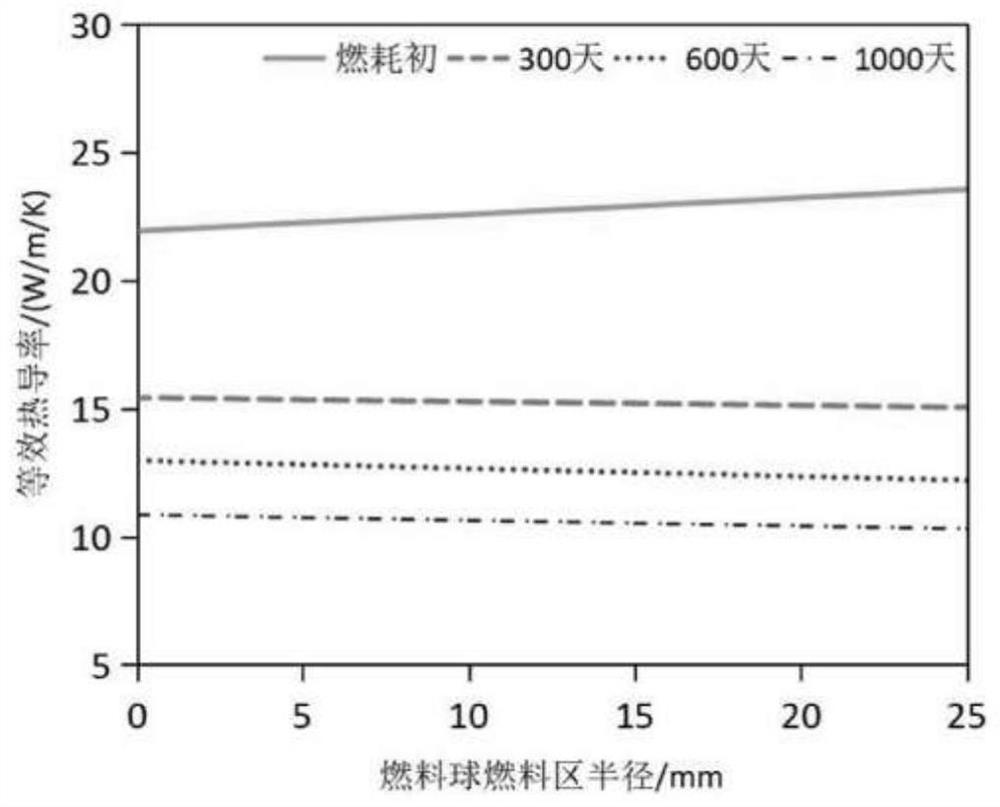

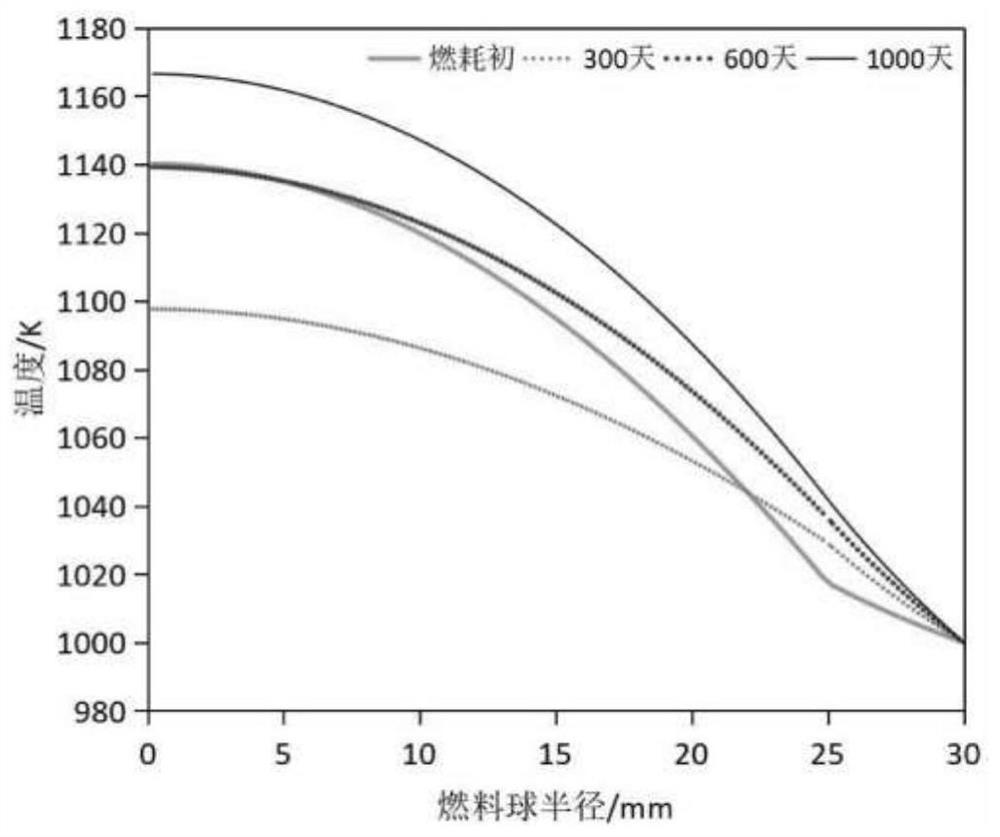

High-adaptability multi-phase particle dispersion type fuel element temperature field calculation method

PendingCN114077796AUnrestricted geometryVarious methodsDesign optimisation/simulationSpecial data processing applicationsEngineeringConductivity

A high-adaptability multi-phase particle dispersion type fuel element temperature field calculation method mainly comprises the following steps of: 1, establishing and setting a geometric simulation model of a fuel element and multi-phase dispersion particles; 2, importing control flow engineering software into the set geometric simulation model; 3, calculating an element temperature field at the current moment; 4, dividing to obtain element sub-regions; 5, calculating and storing the average temperature of the sub-regions; 6, using numerical simulation software to modify representative particle parameters and calculate a temperature field; 7, storing the heat conductivity of the particles and the base material of each sub-region; 8, calculating equivalent thermal conductivity of an element fuel area by using the theoretical model; 9, correcting the heat conduction parameters of the element; and 10, repeating the steps 3-9 until the end of the moment. According to the high-adaptability calculation method, the relation between the temperature field of the element and the temperature field of the dispersion particle can be established, real-time parameter mutual transmission is achieved, data of the heat conduction performance of the element is updated, and therefore the fuel element temperature field can be evaluated more effectively and accurately.

Owner:XI AN JIAOTONG UNIV

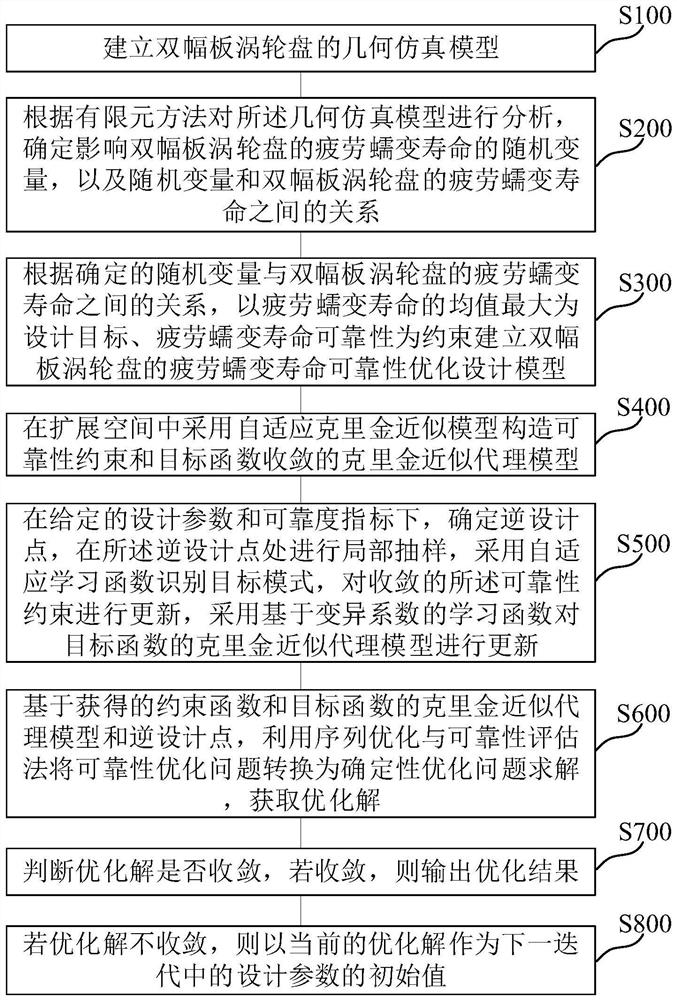

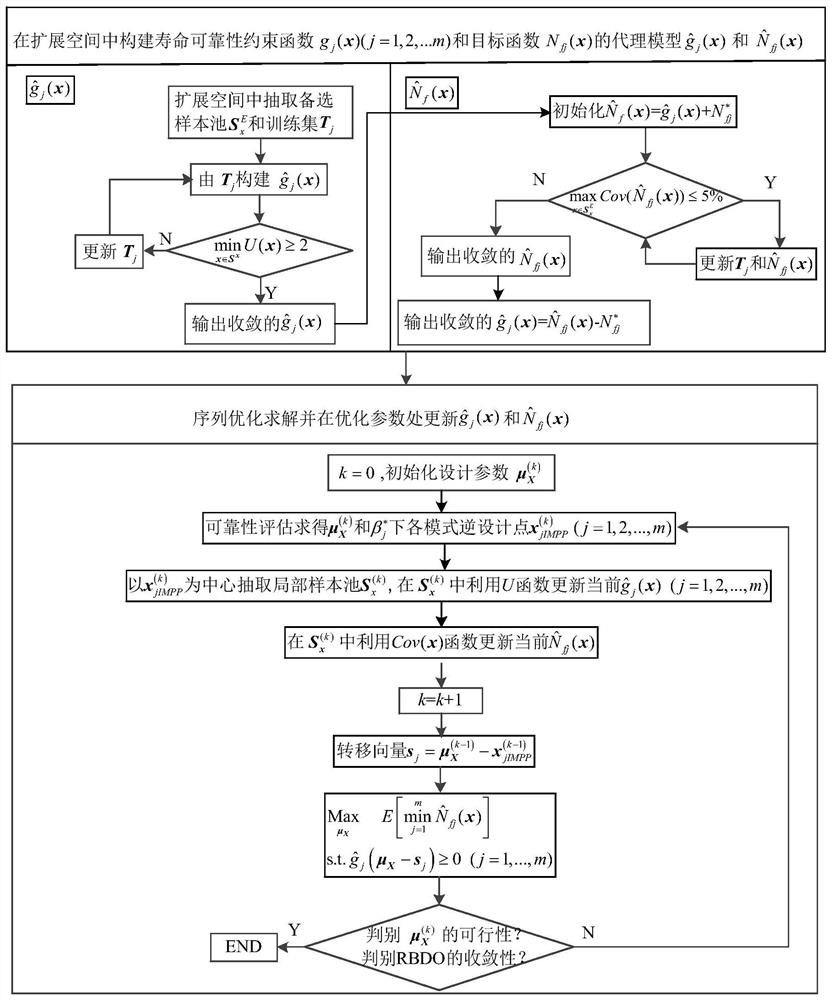

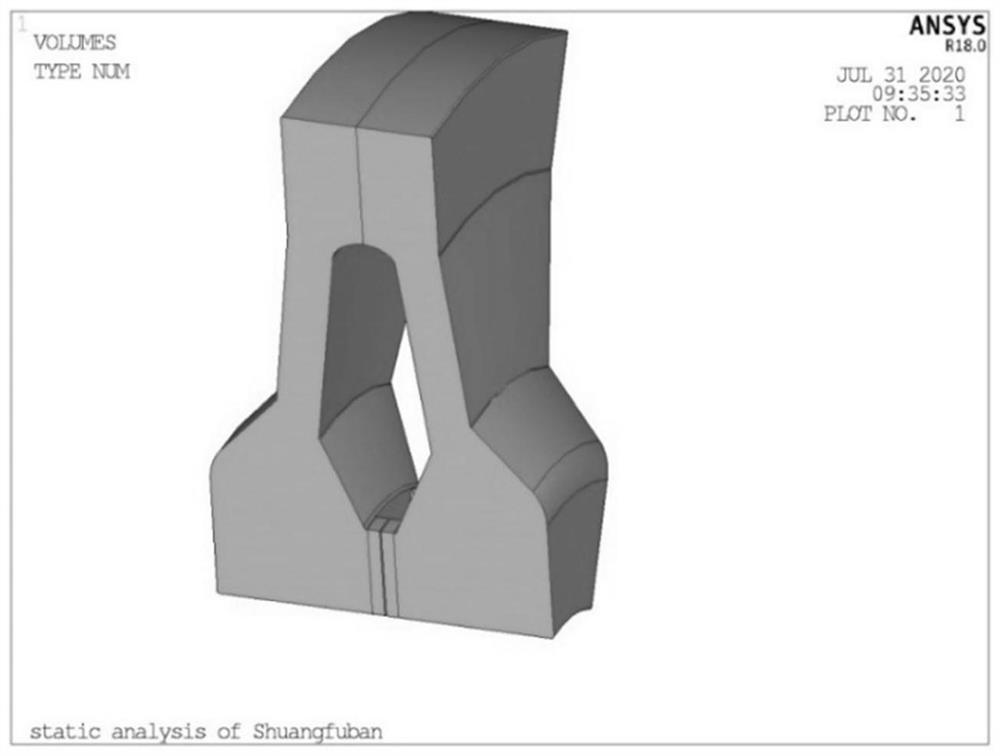

Proxy model-based fatigue creep life reliability optimization method for double-amplitude turbine disc

The invention provides a proxy model-based double-amplitude turbine disc fatigue creep life reliability optimization method. The optimization method comprises the following steps of: establishing a geometric simulation model of a double-amplitude turbine disc; determining the relationship between the random variable and the fatigue creep life of the double-center-plate turbine disc; establishing a fatigue creep life reliability optimization design model of the double-center-plate turbine disc; adopting an adaptive Kriging approximation model to construct a Kriging approximation proxy model with reliability constraint and objective function convergence in the expansion space; determining an inverse design point under given design parameters and reliability indexes, performing local sampling at the inverse design point, and updating the convergent reliability constraint and the Kriging approximation proxy model of the target function; converting a reliability optimization problem into a deterministic optimization problem by using a sequence optimization and reliability evaluation method to solve an optimal solution based on the obtained Kriging approximation agent model of the constraint function and the target function and the inverse design point; if it is judged that the optimal solution converges, outputting an optimization result.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Shrink ratio test stand for testing performance of brake material for railway train

ActiveCN102323172BEasy to operateHigh technology contentStrength propertiesTest performanceSmall sample

The invention relates to a shrink ratio test stand for testing the performance of a brake material for a railway train. The analysis on the performance of the brake material is the important technical problem of research on all friction materials. The current standard regulates that the performance detection of all the brake materials for the railway and the railway trains can be tested on a 1:1 bench. Currently, few 1:1 railway train inertia braking benches are provided in China, so that the normal product detection is difficult to carry out. In the invention, a novel test bench for testing the performance of the brake material for the railway train, which consists of a driving mechanism, an inertia wheel configuration mechanism and the like, is arranged; a brake engineering principle isclosely combined; and a small sample geometric simulation shrink ratio test mode is used to be consistent with a 1:1 bench test mode. Due to the adoption of the shrink ratio test stand, a result corresponding to test data of the 1:1 bench can be obtained; and the consistency of the testing condition and the using working condition of the shrink ratio test stand in the whole testing process is really reflected. The shrink ratio test stand is convenient to operate and has complete functions and high technology content. The gap of the industry in China is filled. The rapid development of the field of the brake material in the industry is promoted.

Owner:刘学耕

Arrangement method of temperature and humidity sensors in the environment automatic adjustment system of the power distribution room of the substation

ActiveCN109358677BAccurate temperature and humidityAvoid manual interventionSimultaneous control of multiple variablesEngineeringAtmospheric sciences

Owner:GUIZHOU POWER GRID CO LTD

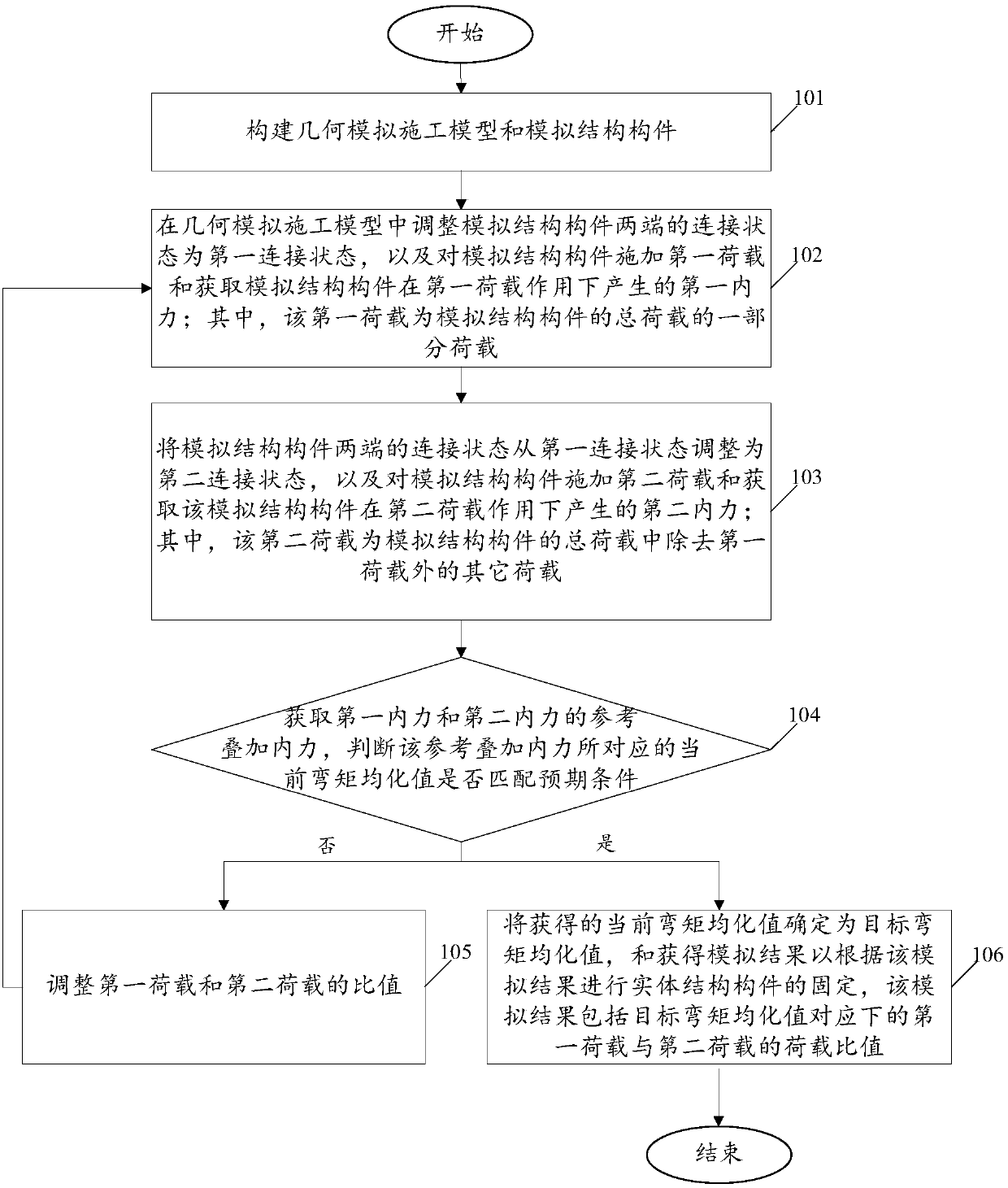

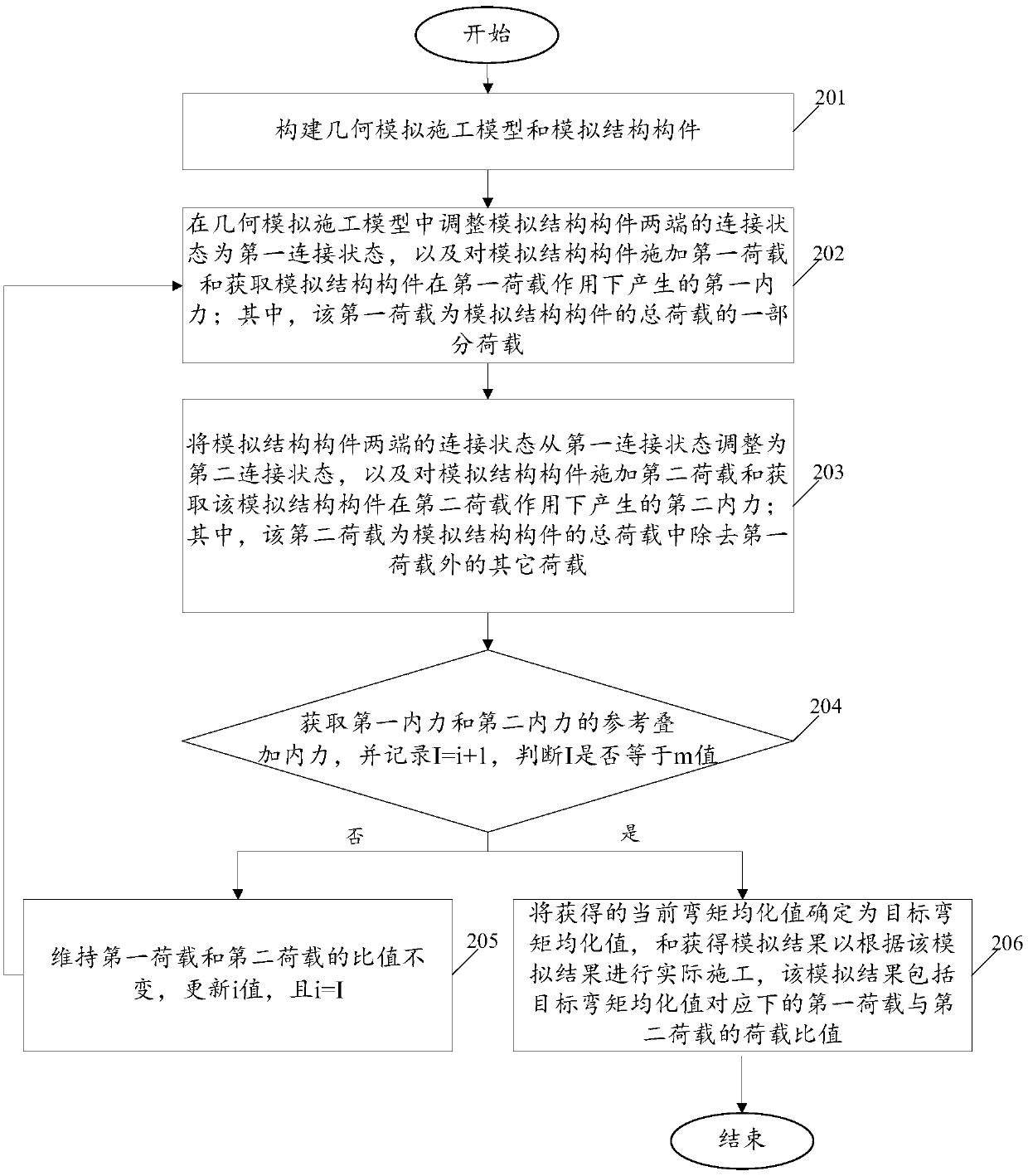

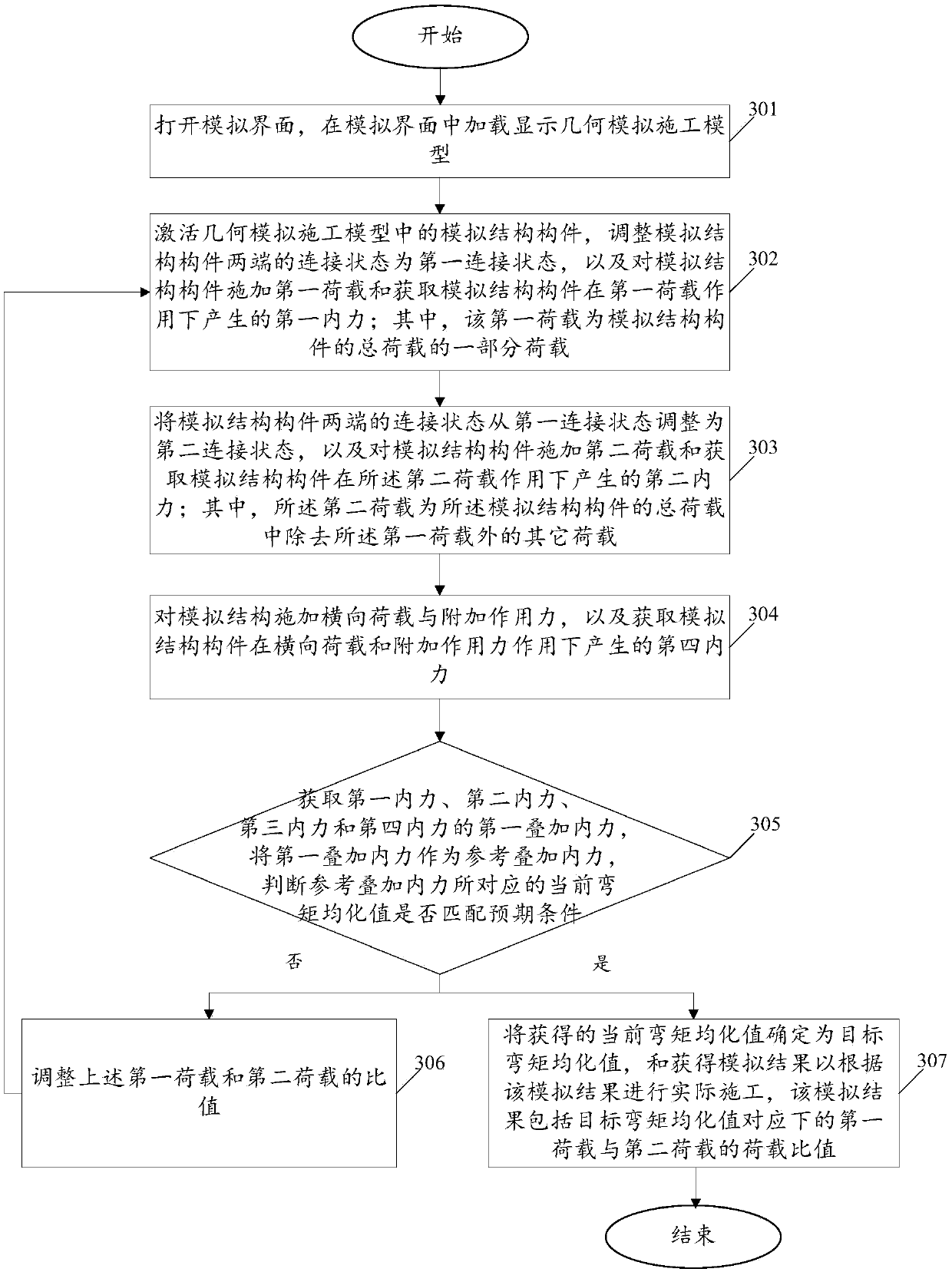

Method and device for fixing structural part

ActiveCN110516267AImprove structural performanceSpecial data processing applicationsStructure analysisLoad ratio

The embodiment of the invention discloses a method and a device for fixing a structural part. According to the method, the method comprises the following steps of: performing structural sectional molding simulation of two successive stages on a simulated structural part in a geometric simulation construction model, applying a first load in a first stage, applying a second load in a second stage, and obtaining a first internal force generated by the simulated structural part under the first load and a second internal force generated by the simulated structural part under the second load; judging whether the current bending moment homogenization value corresponding to the reference superposition internal force of the first internal force and the second internal force is matched with an expected condition or not; if not, repeatedly executing the simulation process until the current bending moment homogenization value is matched with the expected condition, and obtaining a simulation result comprising the load ratio of the first load to the second load corresponding to the target bending moment homogenization value so as to fix the solid structural part according to the simulation result; by simulating structure segmented forming, corresponding loads are applied in the corresponding stages for structure analysis, a feasibility scheme of structure segmented forming is obtained, andfeasibility guidance is provided for actual design and construction.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

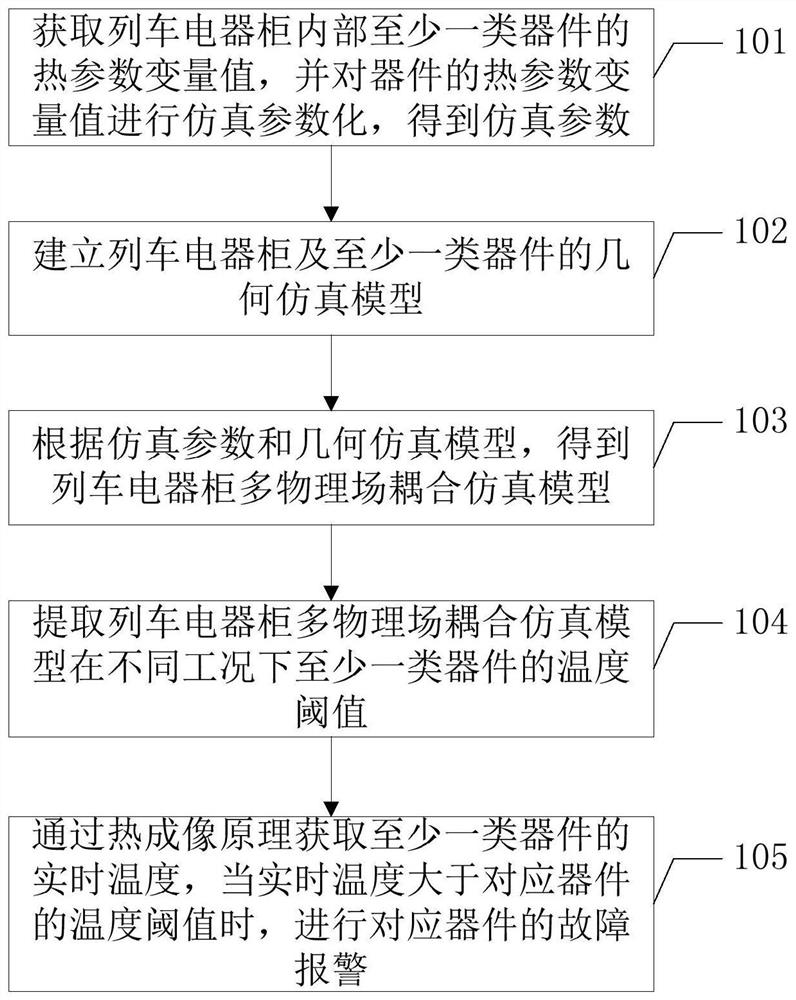

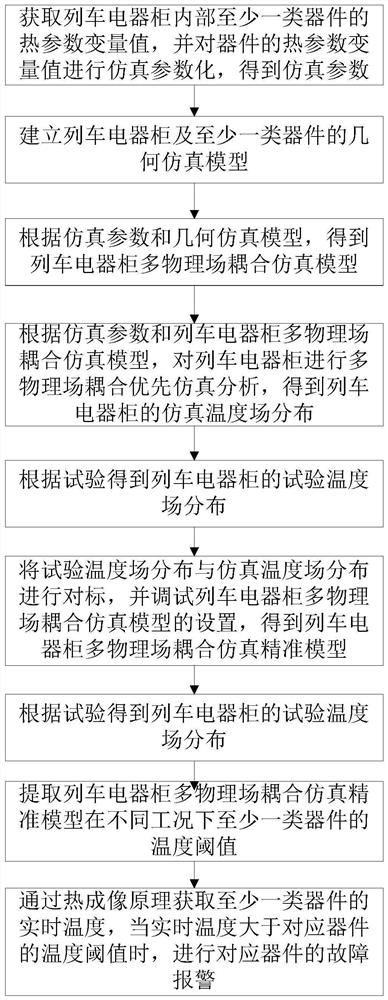

Detection method and device for temperature rise fault of train electric appliance cabinet and terminal device

ActiveCN113739926ASimple manufacturing processIntuitive display of working statusRadiation pyrometryDesign optimisation/simulationThermodynamicsModel extraction

The invention provides a detection method and device for a temperature rise fault of a train electric appliance cabinet and a terminal device, and the method comprises the steps of obtaining the thermal parameter variable values of at least one type of devices in the train electric appliance cabinet, and carrying out simulation parameterization of the thermal parameter variable values of the devices, and obtaining the simulation parameters; establishing a geometric simulation model of the train electric appliance cabinet and the at least one type of devices; according to the simulation parameters and the geometric simulation model, obtaining a train electric appliance cabinet multi-physics field coupling simulation model; extracting a temperature threshold value of the at least one type of devices of the train electric appliance cabinet multi-physics field coupling simulation model under different working conditions; obtaining the real-time temperature of the at least one type of devices through the thermal imaging principle, and when the real-time temperature is larger than the temperature threshold value of the corresponding device, carrying out fault alarming on the corresponding device. According to the invention, a complex monitoring module is not needed for circuit detection, and the overall temperature field of the train electric appliance cabinet is obtained by using the thermal imaging principle, so that the working state of the train electric appliance cabinet is more visually displayed, and the occurrence of judgment errors is further reduced.

Owner:CRRC TANGSHAN CO LTD

A VBO-based Efficient Geometry Simulation Method for Cutting Process

ActiveCN113343546BReduce consumptionImprove Simulation EfficiencyGeometric CADDesign optimisation/simulationVideo memoryVoxel

The invention discloses a VBO-based high-efficiency geometric simulation method of the cutting process, which comprises the following steps: local Boolean operation of the tool / workpiece, establishment of a model bounding box, determination of local intersection positions, and fast Boolean operation; virtual voxel mapping, the workpiece The endpoints of the Tri-dexel model are mapped to the corresponding virtual voxels in the space; virtual voxel information encoding, encoding the patch data of the workpiece model in units of virtual voxels; voxel data management, storing voxel data in the video memory VBO The storage method in the memory is mapped to the system memory; the VBO data update, the model patch data stored in the video memory VBO is locally and efficiently updated; the visual rendering, the rendering pipeline is manually defined, and the model patch data in the video memory VBO is decoded and drawn to the screen. This method can reduce redundant calculation in the simulation process, realize local dynamic updating of the workpiece model, and greatly improve the efficiency of geometric simulation in the cutting process.

Owner:BEIHANG UNIV

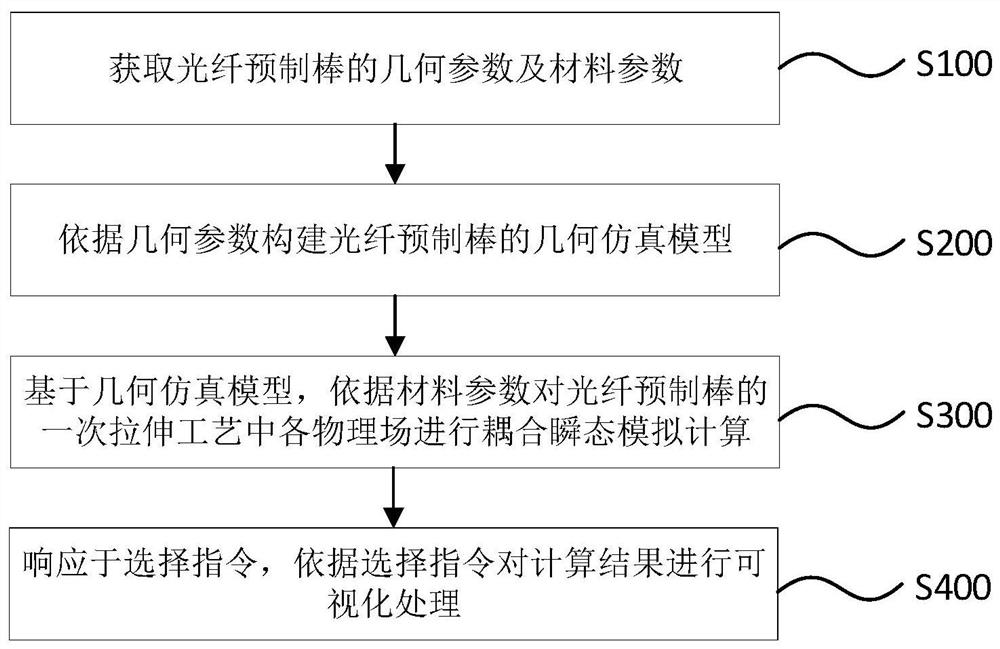

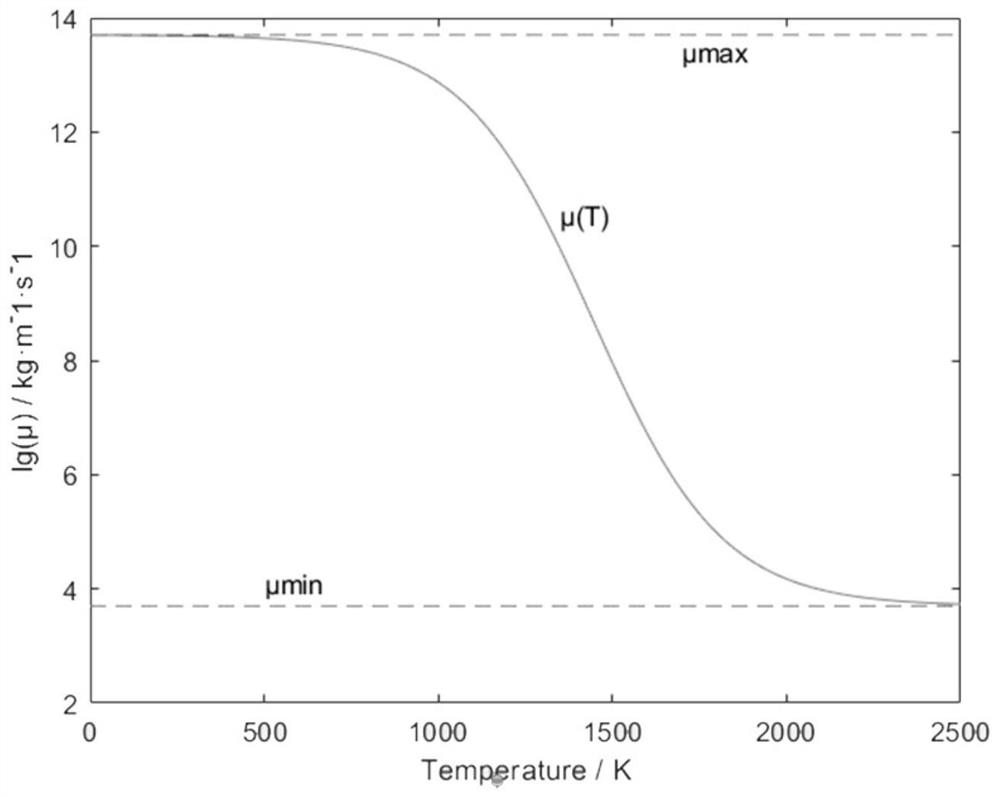

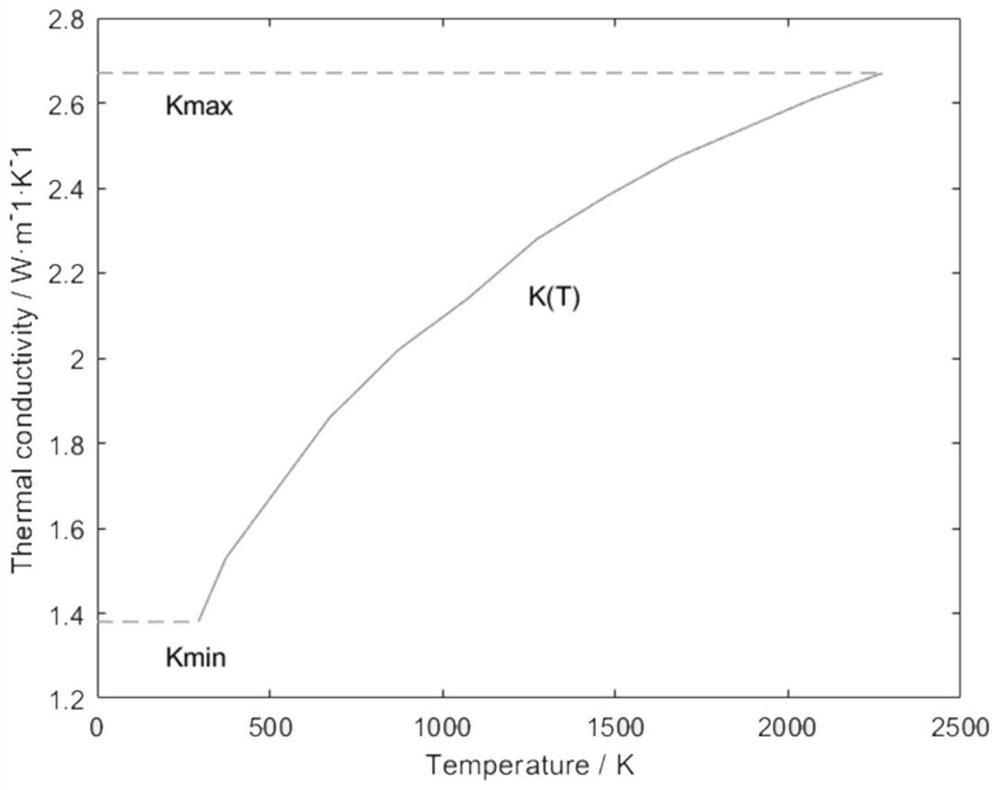

Optical fiber preform one-time drawing process simulation method and device

PendingCN112084723AAccurate acquisitionReduce consumptionDesign optimisation/simulationSpecial data processing applicationsGeometric modelingMaterials science

The embodiment of the invention provides an optical fiber preform one-time drawing process simulation method and device, and belongs to the technical field of optical fiber preforms. The method comprises the following steps: acquiring geometrical parameters and material parameters of an optical fiber preform; constructing a geometric simulation model of the optical fiber preform according to the geometric parameters; performing coupling transient simulation calculation on each physical field in the primary drawing process of the optical fiber preform according to the material parameters; and in response to the selection instruction, performing visualization processing on the calculation result according to the selection instruction. According to the invention, coupling transient simulationcalculation is carried out on each physical field in a primary drawing process of the optical fiber preform based on an optical fiber preform geometric model, so that parameters such as fluid velocity distribution, temperature distribution, pressure distribution, spatial point necking amount, rod diameter value after drawing and the like of the optical fiber preform in the drawing process are obtained and can be selectively visualized; and support is provided for optimization of one-time drawing process parameters of the optical fiber preform, the field test cost is effectively reduced, and the production efficiency is improved.

Owner:ZHEJIANG UNIV

Material Removal Method Based on STL Model in Geometric Simulation of NC Machining

ActiveCN107037738BReduce complexityImprove cutting efficiencySimulator controlComputational scienceAlgorithm

The invention relates to an STL-model-based material removal algorithm in numeral control machining geometric simulation, comprising the following steps: transforming a CAD-generated processed workpiece and a tool swept volume into the STL format; accessing the STL models of the tool swept volume and the processed workpiece; establishing the relationship index for the triangular patches of the tool swept volume and the processed workpiece surface; establishing the smallest-possible enclosing boxes for the workpiece and the tool swept volume; screening and removing the non-intersecting triangular patches; using the dot product and the cross product of vector to create a vector determining model; determining whether the triangular patches intersect to obtain a set of intersecting triangular patch pairs; solving the intersecting lines of the intersecting triangular patch pairs; solving the intersecting line ring; reconstructing the triangular patches involved in the intersecting of the processed workpiece and the tool swept volume; classifying the triangular patches; and with the kept surface of the processed workpiece and the surface involving in the processing of the tool swept volume form a new enclosed surface to develop a workpiece model after the materials are removed.

Owner:TSINGHUA UNIV

Dummy laser processing procedure geometric simulation method

InactiveCN101308523BSave human effortSave moneySpecial data processing applicationsProcess optimizationVirtual machining

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

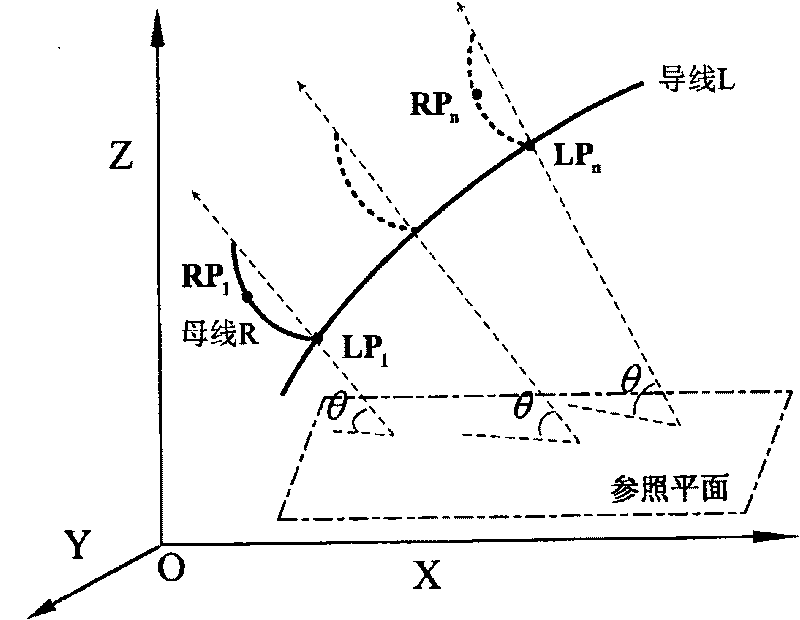

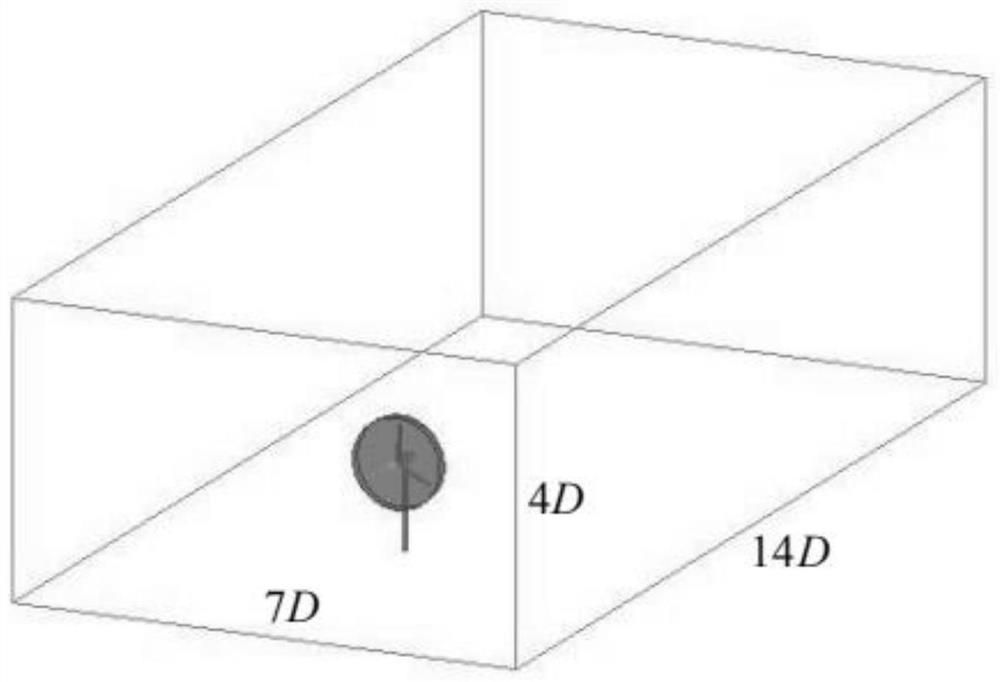

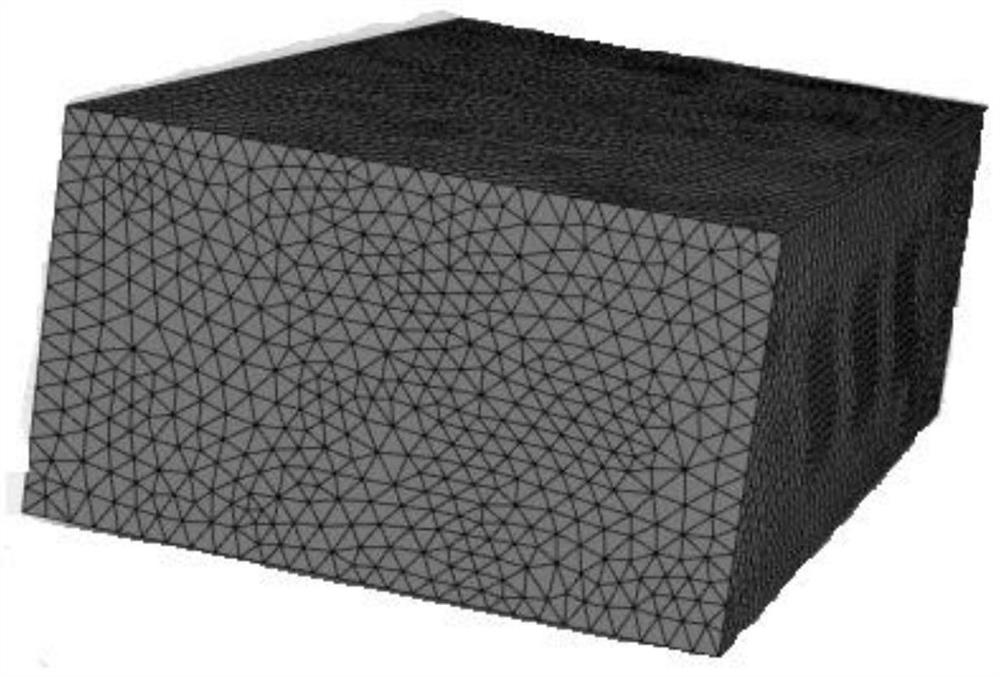

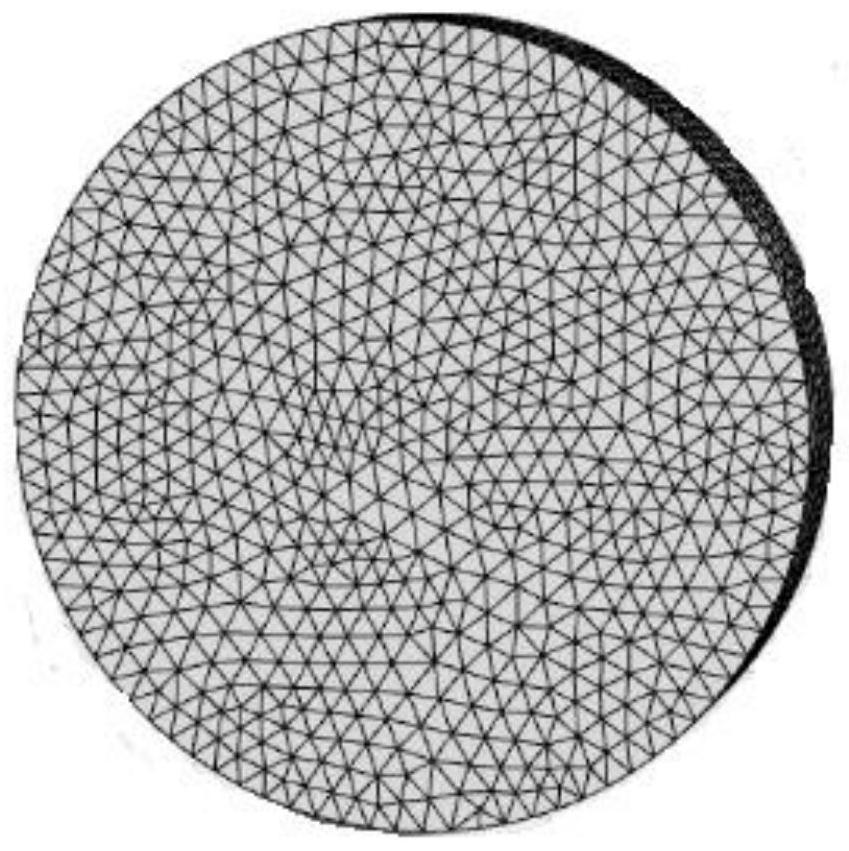

Overall active power prediction method for regional wind power plant

InactiveCN112182996AGood adaptability to geometric simulationImprove accuracyDesign optimisation/simulationAnalogue computationGeometric modeling

The invention discloses an overall active power prediction method for a regional wind power plant, and the method comprises a flow field numerical model and comprises the following steps: S1, grid division, S2, boundary condition setting, S3, solving parameter setting, S4, calculation by an SSTk-omega turbulence model, and adoption of an SIMPLEC algorithm as a pressure and speed coupling algorithmand S5, analysis of numerical simulation results. Prediction performance of each wind power plant in the region is considered, ICEM software is utilized in the CFD simulation calculation system to generate the structured grid by creating the Block, and by means of the advantage of good geometric simulation adaptability of the structured grid, unstructured grid division is carried out on the complex geometric model. The power prediction value of the wind power plant with poor prediction performance is calculated according to the change trend of the wind power plant with excellent prediction performance through a certain weight, an SSTk- omega turbulence model is adopted for solving and calculating, the SIMPLEC algorithm is adopted as the pressure and speed coupling algorithm, and the method can improve the overall generated power prediction accuracy of the regional wind power plant.

Owner:DALI BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION CO CHINA SOUTHERN POWER GRID CO LTD

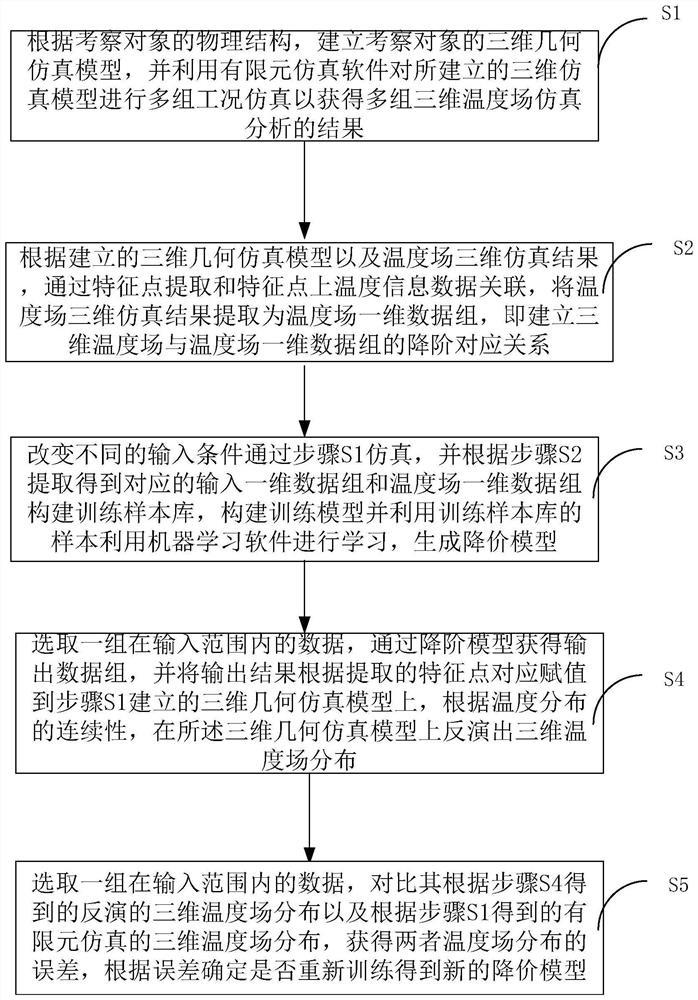

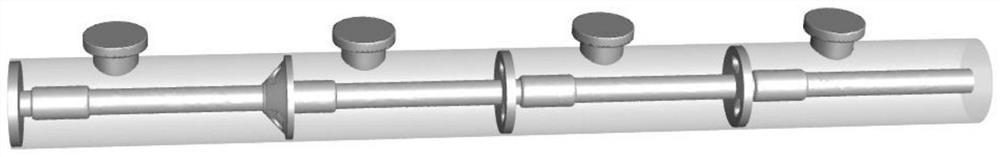

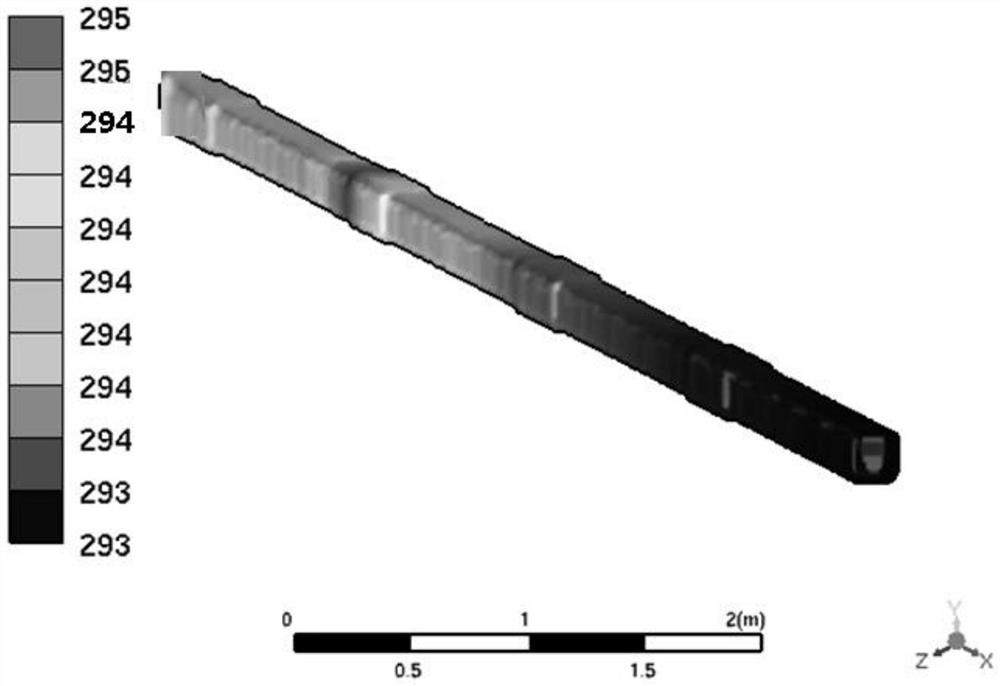

GIS equipment temperature field reduced-order rapid simulation method

PendingCN114239346ADesign optimisation/simulationMachine learningEquipment temperatureDimensional simulation

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

The adjustment method of the environment adjustment system of power distribution room based on the optimal arrangement of sensors

ActiveCN109412050BEffective controlImprove accuracySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsAmbient monitoringEnergy conservation

The invention discloses a distribution room environment adjusting system adjusting method based on sensor optimization arrangement. The adjusting method comprises a sensor optimization arrangement method and an adjusting system adjusting method; the sensor optimization arrangement method comprises the following steps of establishing a three-dimensional geometric simulation model of a transformer substation distribution room by utilizing Ansys, performing distribution room temperature field and humidity field simulation analysis on the simulation model by means of Ansys, obtaining temperature field and humidity field distribution simulation graphs at different heights, and selecting temperature and humidity sensors for distribution through the simulation graphs. The problem of accidents caused by that the indoor temperature and humidity monitoring points are small in distribution and unreasonable in distribution is solved; and 2, on the aspect of a control strategy, once it is monitoredthat the environment has certain unqualified point, all equipment are started, and the whole environment can be adjusted together; and consequently, the method is not accurate enough, while unnecessary equipment is started, so that the working time of equipment is prolonged, the energy consumption is increased, and the purposes of energy conservation and emission reduction cannot be achieved.

Owner:GUIZHOU POWER GRID CO LTD

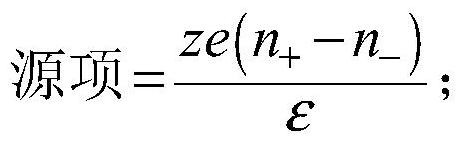

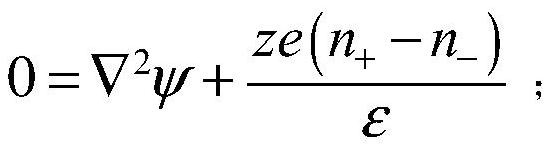

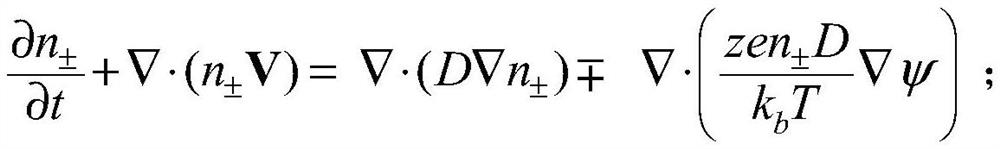

A method for simulating fluid flow inside a porous medium solid-phase converter

ActiveCN109509220BImprove performanceRapid modelingImage enhancementImage analysisConvertersImaging processing

The invention discloses a method for simulating the internal fluid flow of a porous medium solid-phase converter. A geometric simulation area of a porous medium is established by sintering a solid-phase converter sample made of glass beads; Slice image sequences are processed and three-dimensionally reconstructed, the 3D reconstruction model of the porous medium solid-phase converter is meshed, the fluid flow inside the porous medium converter is studied, and the solid-phase skeleton and fluid in the porous medium are analyzed based on the electric double layer theory The potential distribution of the contact surface and its neighborhood; the image processing method of 3D volume pixels is adopted, and the continuity of the solid-phase converter in porous media is considered in different directions, which improves the accuracy of the 3D reconstructed geometric model, thereby improving the simulation accuracy of the fluid distribution At the same time, it has the advantages of fast modeling, good convergence, and high portability, which can speed up the modeling of the signal conversion process involved in the fluid flow inside the porous medium solid-phase converter, and help to improve the overall performance of the liquid ring angular accelerometer.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

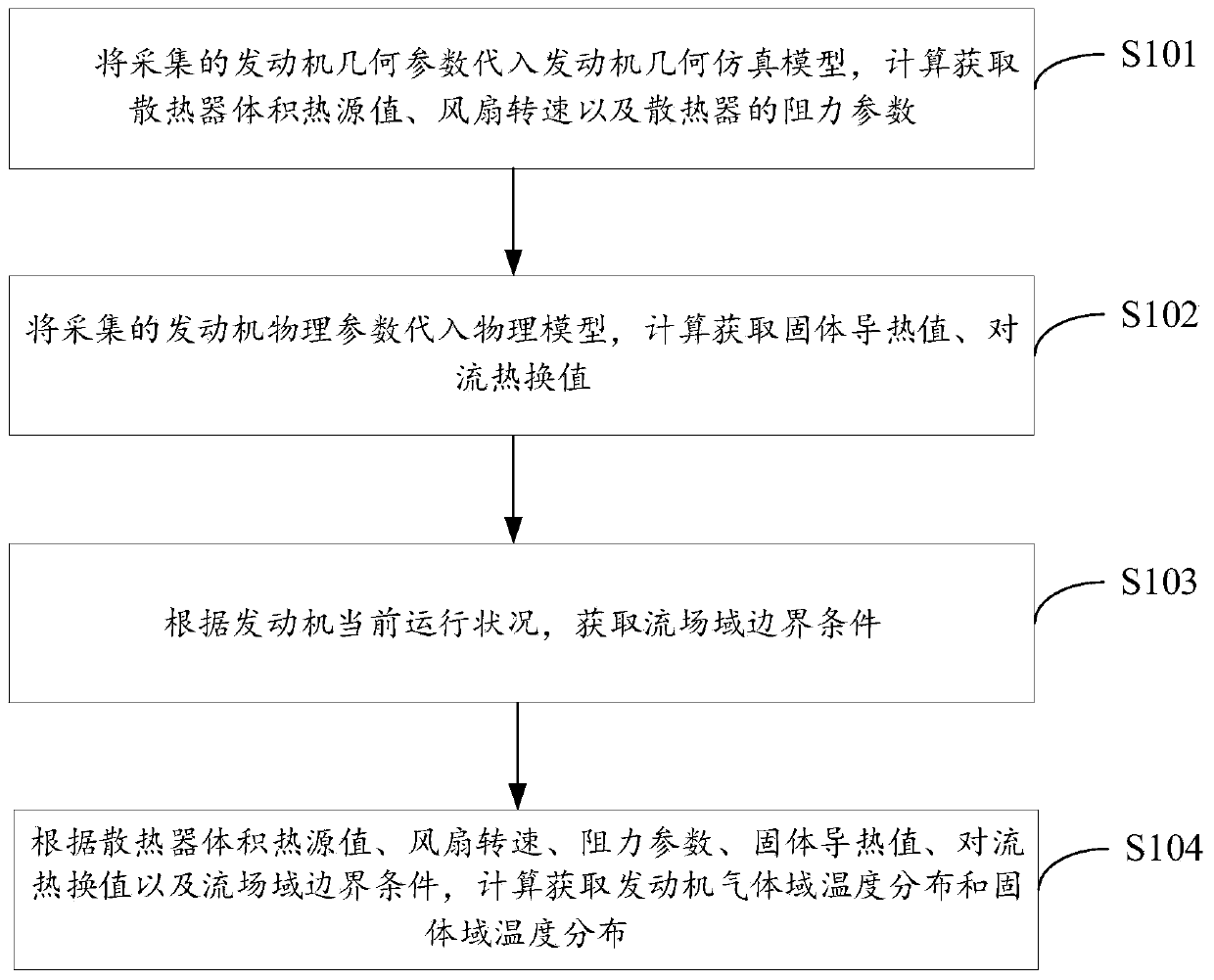

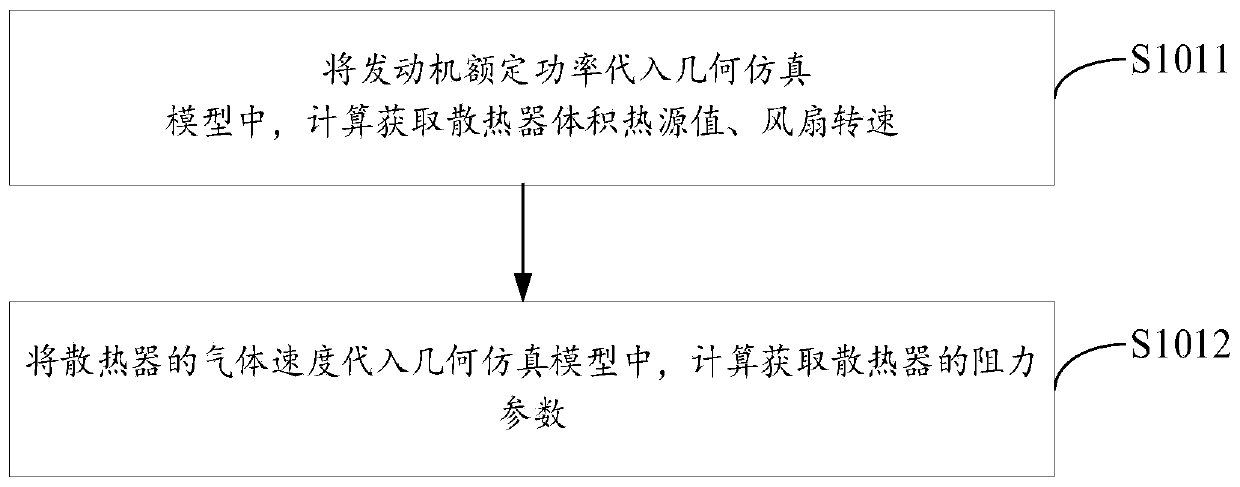

Engine temperature distribution calculation method and device and storage medium

PendingCN111460581AAccurate temperature distributionAccurate assessmentGeometric CADDesign optimisation/simulationPhysical modelEngineering

The invention provides an engine temperature distribution calculation method and device and a storage medium, and relates to the technical field of software simulation. The method comprises the following steps of substituting collected geometric parameters of the engine into a geometric simulation model of an engine, calculating to obtain a radiator volume heat source value, a fan rotating speed and resistance parameters of a radiator, substituting the collected physical parameters of the engine into a physical model, calculating to obtain a solid heat conduction value and a convective heat exchange value, and obtaining a flow field domain boundary condition according to the current operation condition of the engine; and calculating to obtain engine gas domain temperature distribution andsolid domain temperature distribution according to the radiator volume heat source value, the fan rotating speed, the resistance parameter, the solid heat conduction value, the convective heat exchange value and the flow field domain boundary condition. By calculating the mutual heat transfer effect of the gas domain and the solid domain and the solid heat transfer property of the solid domain atthe same time, accurate temperature distribution of all parts of the engine compartment can be calculated, and accurate evaluation of the positions of heat damage points of important components in anengine is achieved.

Owner:SANY HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com