Shrink ratio test stand for testing performance of brake material for railway train

A technology for braking materials and rail trains, which is applied in the fields of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems of inability to meet the urgent needs of new materials, difficult product testing, slow progress, etc., to promote rapid development, complete functions, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

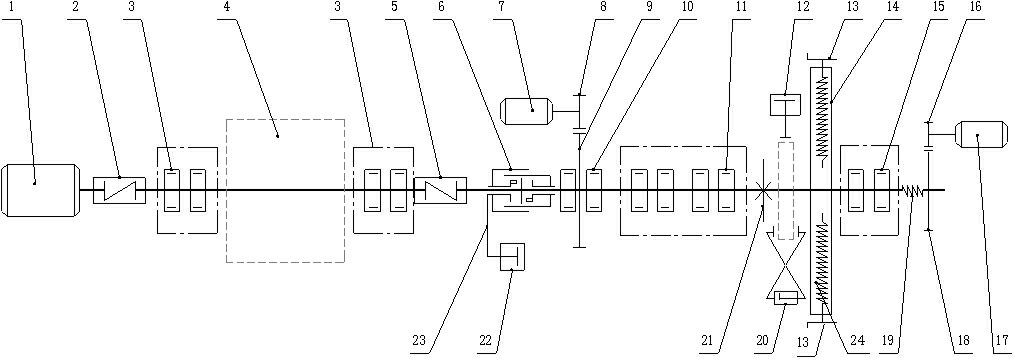

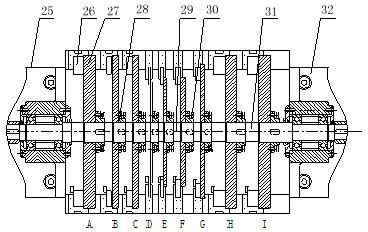

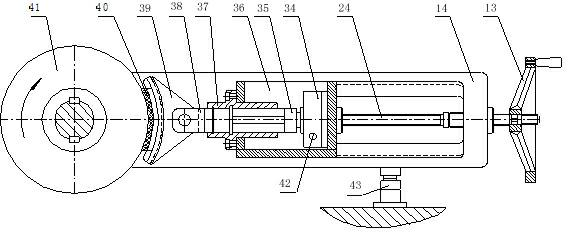

[0030] With the development of the high-speed rail business, the demand for new materials and new products for brakes such as bullet trains, high-speed trains, subways, etc. requires to speed up the pace of research on new materials and new products, but the research and development of materials is inseparable from testing equipment, including The international market is judged by the expensive 1:1 train bench test. There is no other alternative, which greatly lengthens the research cycle and cannot meet our urgent needs for new material development-production-application. At this stage, the braking materials and products of aircraft, trains, ships, automobiles and construction machinery in our country are guaranteed by friction material performance testing machines, especially the brakes and materials of aircraft wheels - C / C carbon discs , that is, the use of a small-sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com