Rodlike bismuth oxide and preparation method thereof

A technology of bismuth oxide and bismuth trioxide, which is applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., achieves the effects of low production cost, wide application prospect and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 4 grams of bismuth oxycarbonate to 2 milliliters of concentrated nitric acid, add 35 milliliters of deionized water after initial stirring, and continue stirring for dissolution and dilution. Then, the above solution was added to 110 ml of ammonia solution with a mass fraction of 15%, and stirred rapidly while adding to form a uniform suspension. Then the suspension was put into a 200 ml Teflon-lined stainless steel autoclave and reacted at a temperature of 383K for 48 hours. After the reaction is finished, the precipitated product is washed with deionized water and dried to obtain a rod-shaped bismuth oxide product.

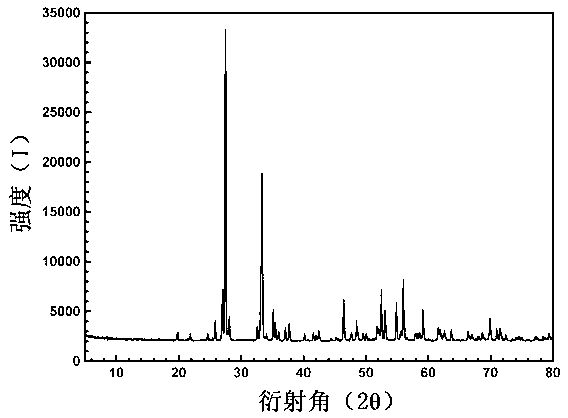

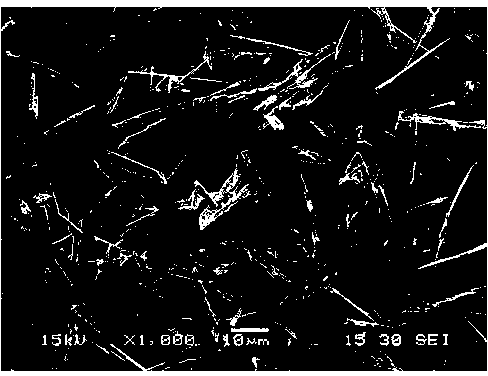

[0024] Bismuth oxide (Bi 2 o 3 ) crystal form is consistent with the standard powder diffraction card (JCPDS: 76-1730), the shape is rod-shaped, the diameter is between 2-3 microns, the length is between 30-50 microns, the aspect ratio is greater than 10, and the purity is between More than 99%.

Embodiment 2

[0026] Add 1.5 grams of bismuth nitrate pentahydrate into 1 ml of concentrated nitric acid, add 20 ml of deionized water after initial stirring, and continue stirring for dissolution and dilution. Then, the above solution was added to 50 ml of ammonia solution with a mass fraction of 20%, and stirred rapidly while adding dropwise to form a uniform suspension. Then the suspension was put into a 100 ml Teflon-lined stainless steel autoclave and reacted at a temperature of 393K for 24 hours. After the reaction is finished, the precipitated product is washed with deionized water and dried to obtain a rod-shaped bismuth oxide product.

[0027] Bismuth oxide (Bi 2 o 3 ) is consistent with the standard powder diffraction card (JCPDS: 76-1730). More than 99%.

Embodiment 3

[0029] Add 1 gram of bismuth oxycarbonate to 0.5 milliliters of concentrated nitric acid, add 10 milliliters of deionized water after initial stirring, and continue stirring for dissolution and dilution. Then, the above solution was added to 30 milliliters of sodium hydroxide solution with a substance concentration of 3 mol / liter, and was stirred rapidly while adding dropwise to form a uniform suspension. Then the suspension was put into a 50 ml Teflon-lined stainless steel autoclave and reacted at a temperature of 423 K for 12 hours. After the reaction is finished, the precipitated product is washed with deionized water and dried to obtain a rod-shaped bismuth oxide product.

[0030] Bismuth oxide (Bi 2 o 3 ) crystal form is consistent with the standard powder diffraction card (JCPDS: 76-1730). More than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com