Precision forging plastic molding process for internal toothed rings of planetary speed reducers

A planetary reducer and plastic forming technology, applied in metal processing equipment, wheels, transportation and packaging, etc., can solve the problems of large accumulated error in tooth profile processing, large investment in machine tools and low labor production efficiency, and shorten the production cycle , Saving raw materials, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A precision forging plastic forming process for the inner gear ring of a planetary reducer with a weight of 10Kg:

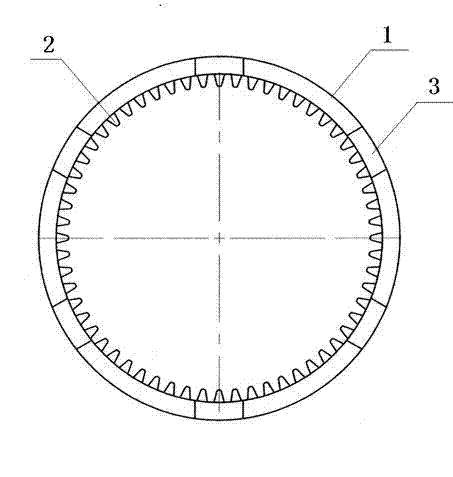

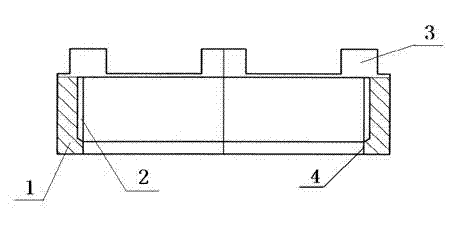

[0018] see figure 1 , figure 2 As shown, a precise forging of an inner gear ring of a planetary reducer, including a metal ring 1 and a metal tooth 2, the metal tooth 2 is arranged on the inner wall of the metal ring 1, and the metal tooth 2 is involute tooth shape , the number of teeth of the metal teeth 2 is forty-one teeth, the one side end surface of the metal ring is provided with a positioning block 3, and the six positioning blocks 3 are evenly distributed on one side end surface of the metal ring 1 Above, the metal ring 1 , the metal teeth 2 and the positioning block 3 are integral structures, and a toothless section 4 is arranged between the other inner wall of the metal ring 1 and the metal teeth 2 . Its plastic forming includes the following steps: a. Material cutting: the metal bar is cut by the CNC sawing machine; b. Billet sh...

Embodiment 2

[0019] Embodiment 2: A precision forging plastic forming process for the inner gear ring of a planetary reducer with a weight of 6Kg. The production steps are the same as in Embodiment 1, except that after the cold forging plastic forming step, annealing and cold pushing are further carried out Extrusion and finishing step, the cold push and finishing forming is to use a finishing die to cold finish the annealed part into a forging without subsequent processing on the tooth profile.

[0020] Using the above-mentioned temperature-cooling compound precision forging plastic forming technology, the product quality is stable, the accumulated error between tooth shapes is small, the yield is high, the strength is high, the density is high, impact resistance, the production efficiency is improved, the production cycle is shortened, raw materials are saved, and the cost is reduced. The production cost also protects the production environment, replaces the traditional processing method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com