Manufacturing execution system

A manufacturing execution system and ERP system technology, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as rarely seen domestic MES products and lack of mature products, and achieve the effect of quickly and efficiently solving production abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

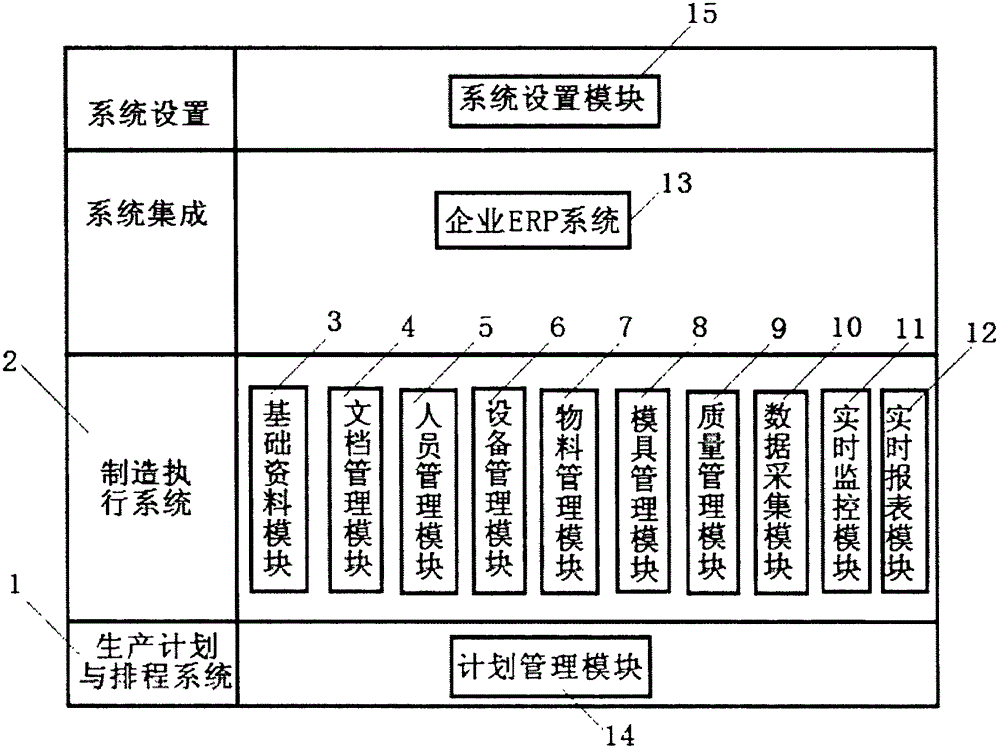

[0029] see figure 1 As shown, the manufacturing execution system includes a production planning and scheduling system 1, and a manufacturing execution system 2 is integrated on the basis of the production planning and scheduling system 1. The manufacturing execution system 2 includes a basic data module 3, a document Management module 4, personnel management module 5, equipment management module 6, material management module 7, mold management module 8, quality management module 9, data acquisition module 10, real-time monitoring module 11 and real-time reporting module 12, the manufacturing execution system 2 The upper layer is integrated with the enterprise ERP system 13, and the bottom layer of the manufacturing execution system 2 is connected with the data collector 16 and the human-computer interaction terminal interface 17 at the production site.

[0030] Further, the production planning and scheduling system 1 includes a planning management module 14 .

[0031] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com