Patents

Literature

190results about How to "Realize visual management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

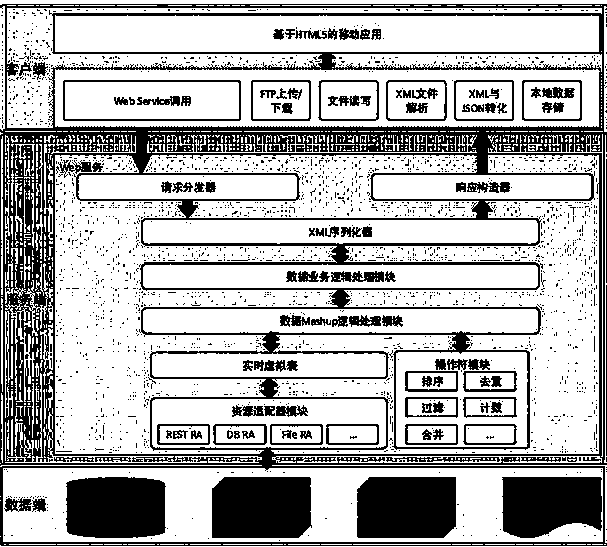

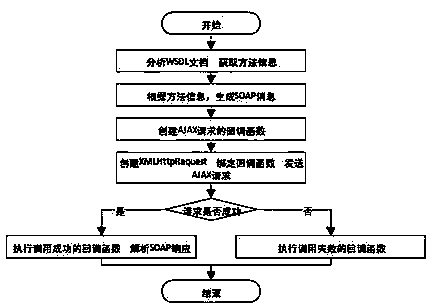

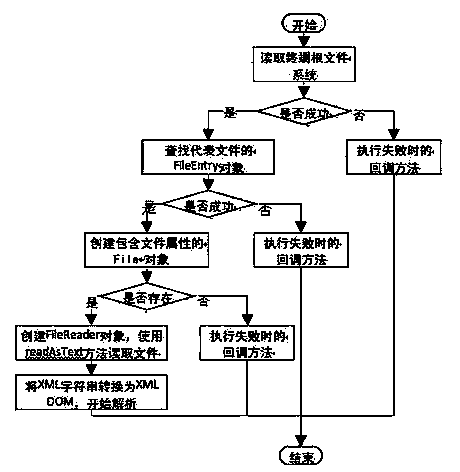

Cross-platform mobile data management system and method

InactiveCN103645951ARealize mobile managementRealize visual managementProgram initiation/switchingTransmissionHTML5Web service

The invention discloses a cross-platform mobile data management system and method. The system comprises a client, a server side and a data side, wherein the client is used for providing a mobile operating entry, namely, an interface intersection window, for the mobile data management system, and the form of the client is based on HTML5 local mobile application; the server side is used for providing data service for the client of the mobile data management system, and the form of the data service mainly comprises Web service and FTP (file transfer protocol) service; and the data side is used for providing a data source for the mobile data management system, and the form of the data source comprises a database resource, a sensor Restful resource, a Web service resource and a file resource. With the adoption of the cross-platform mobile data management system and method, a system can use various smart mobile terminal platforms in a compatible manner, so that the effect that the business logic of a mobile application is compiled once and can operate on the various smart mobile terminal platforms is realized.

Owner:BEIJING UNIV OF POSTS & TELECOMM

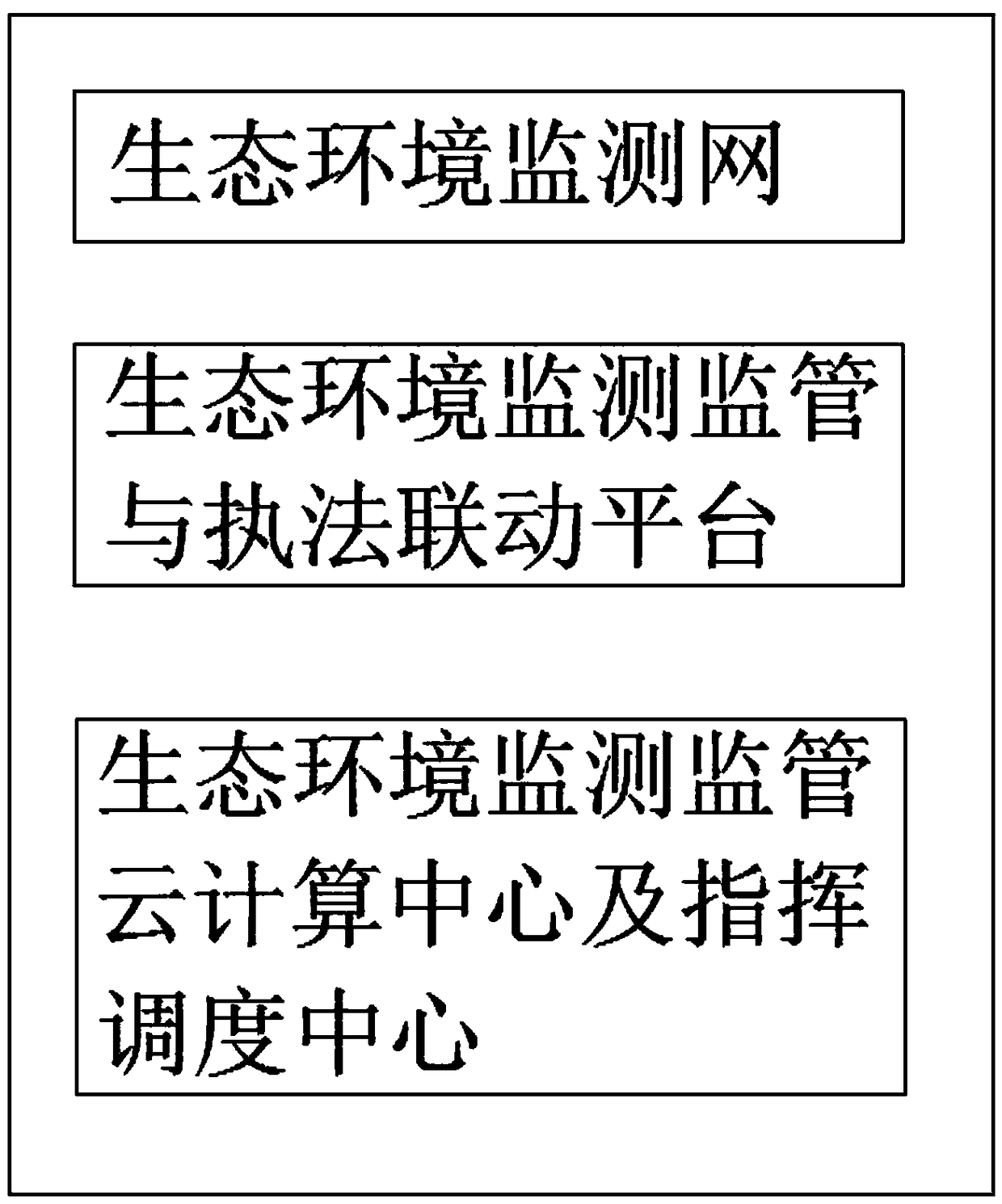

Ecological environment monitoring and supervising system

InactiveCN108982792ARealize linkageAchieve precise positioningEarth material testingTesting waterNatural disasterEcological environment

The invention provides an ecological environment monitoring and supervising system. The system comprises an ecological environment monitoring network, an ecological environment monitoring law-enforcement platform and an ecological environment monitoring and supervising command and dispatch center, wherein the ecological environment monitoring network comprises a mineral resource anti-illegal mining monitoring module, an illegal water-intake automatic monitoring module, a surface water environment monitoring module, a soil environment monitoring data collection module, a forest resource anti-illegal-tree-felling anti-flame monitoring module, a natural disaster automatic monitoring module, an ecological environment protection mass prevention data reporting module, an environment monitoring data collection module, a universal unmanned aerial vehicle monitoring module and an intelligent law-enforcement bayonet blocking module; the ecological environment monitoring law-enforcement platformcomprises an ecological environment supervising law-enforcement module, a monitoring data analysis and prewarning management module, a river chief comprehensive management module, an ecological environment dynamic supervising module and an intelligent law-enforcement linking module; and the ecological environment monitoring cloud operation center module, a command and dispatch center module and anemergency command and dispatch system platform module.

Owner:BEIJING LANZUN TECH

Electric power operation intelligent safety supervision system and supervision method thereof

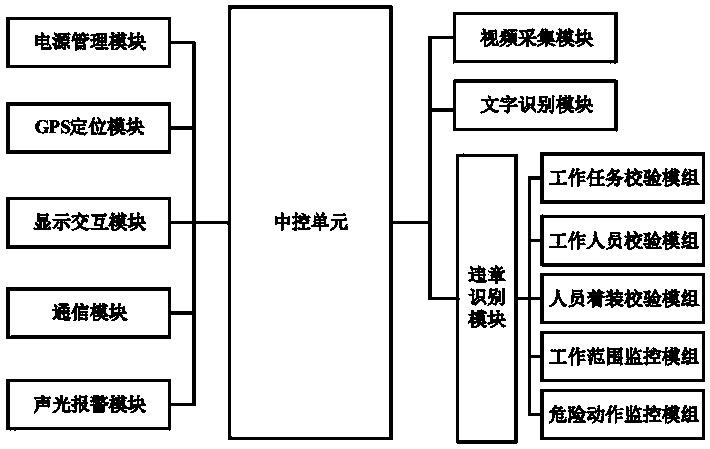

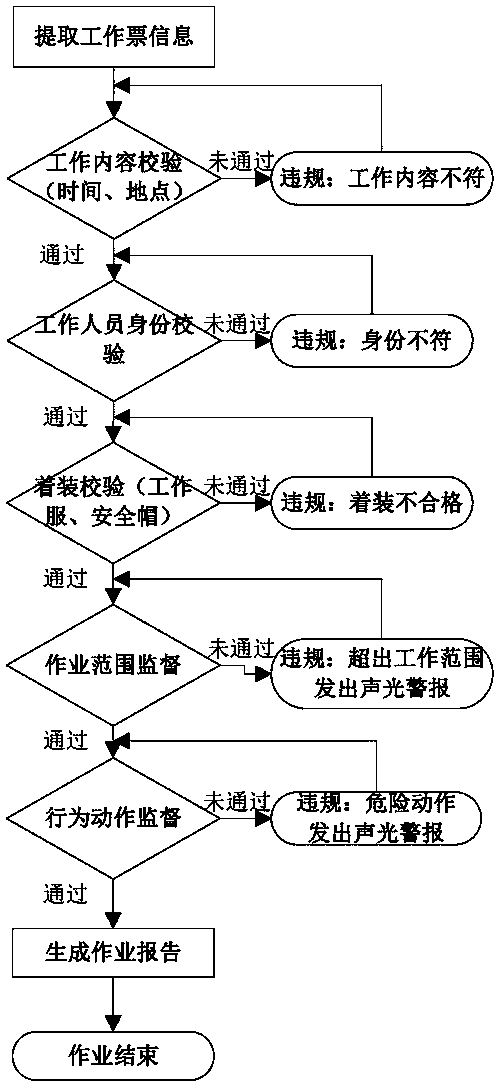

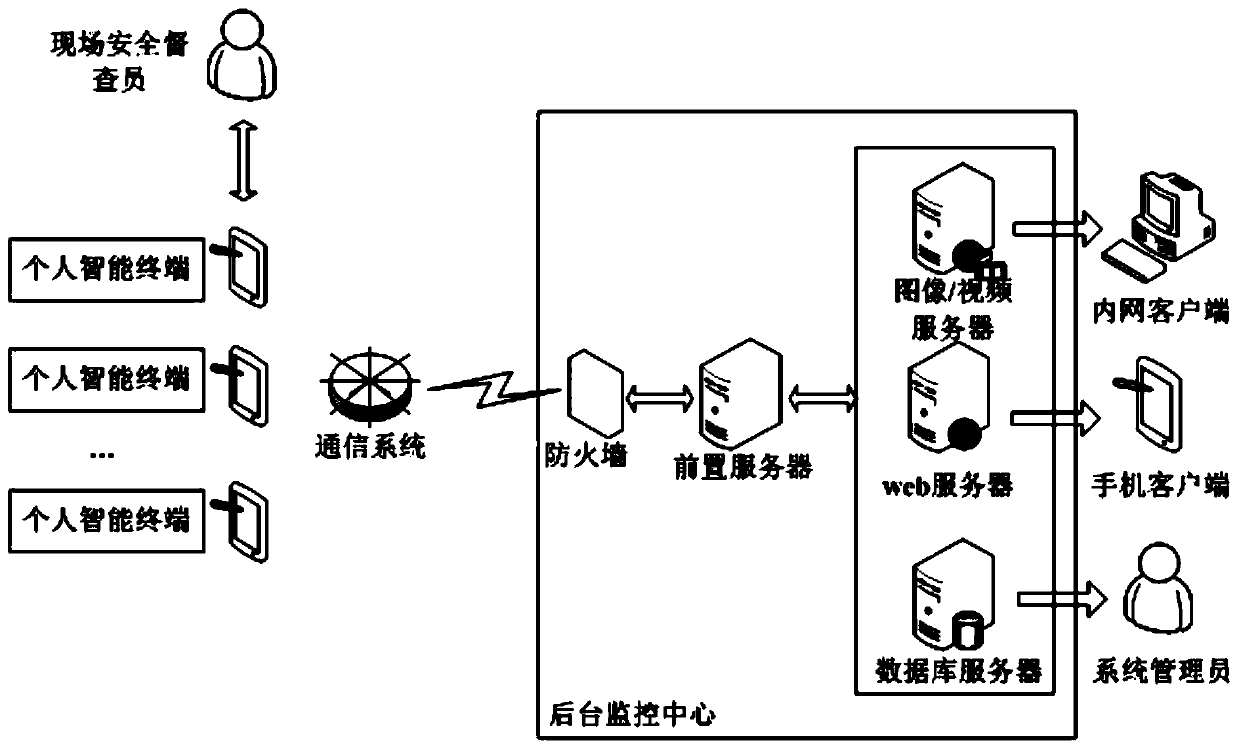

PendingCN110795989ACentralizationRealize visual managementBiometric pattern recognitionResourcesWireless transmissionSupply management

The invention provides an electric power operation intelligent safety supervision system and a supervision method thereof. The system comprises a personal intelligent terminal, a communication systemand a background monitoring center. The personal intelligent terminal comprises a video acquisition module, a GPS positioning module, a power supply management module, a display interaction module, acharacter recognition module, a violation recognition module and a sound-light alarm module, all the modules are electrically connected with the central processing unit, information acquisition and analysis are achieved, and when violation is found, the information is reported to supervise and manage personnel and sound-light alarm is given out. The communication system realizes two-way communication between the personal intelligent terminal and the background monitoring center and comprises video return and control instruction transmission. The communication system is composed of an industrial router and a 4G wireless network card, 4G wireless transmission is adopted, and the personal intelligent terminal transmits data to the background monitoring center through 4G wireless transmission.The background monitoring center calls, archives and manages the operation information.

Owner:GUANGDONG POWER GRID CO LTD +1

Automated welding machining system for non-standard components based on structural light vision

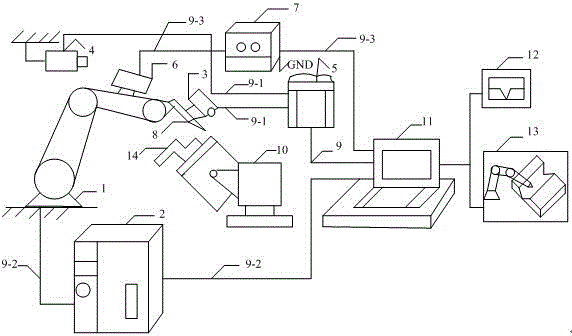

PendingCN106238969AShorten processing timeImprove labor productivityWelding/cutting auxillary devicesAuxillary welding devicesSix degrees of freedomStructure based

The invention provides an automated welding machining system for non-standard components based on structural light vision. The automated welding machining system comprises a weld joint visual detection system, a welding executing system, a communication and control system, a robot controller and a welder controller, wherein the weld joint visual detection system is used for recognizing weld joints, detecting positions, monitoring progress and transmitting images to the communication and control system; the welding executing system is used for executing welding action, and comprises a six-degree-of-freedom industrial robot, a welder and a welding gun; the communication and control system is used for realizing communication and process control, uses an industrial control computer as main control equipment and finishes the functions of displaying a welding process, processing the images, carrying out data operation and sending instructions; the robot controller receives instruction signals from the industrial control computer and controls the joint movement of the six-degree-of-freedom industrial robot so as to adjust the pose of the welding gun; and the welder controller receives the instruction signals from the industrial control computer and controls welding parameters, such as welding current and wire feed speed. The automated welding machining system can accurately detect and recognize features, such as weld joint types, positions and shapes, stably improve the welding machining quality of the non-standard components and greatly increase the production efficiency.

Owner:NANJING CHINA CONSTR CHEM EQUIP MFG +3

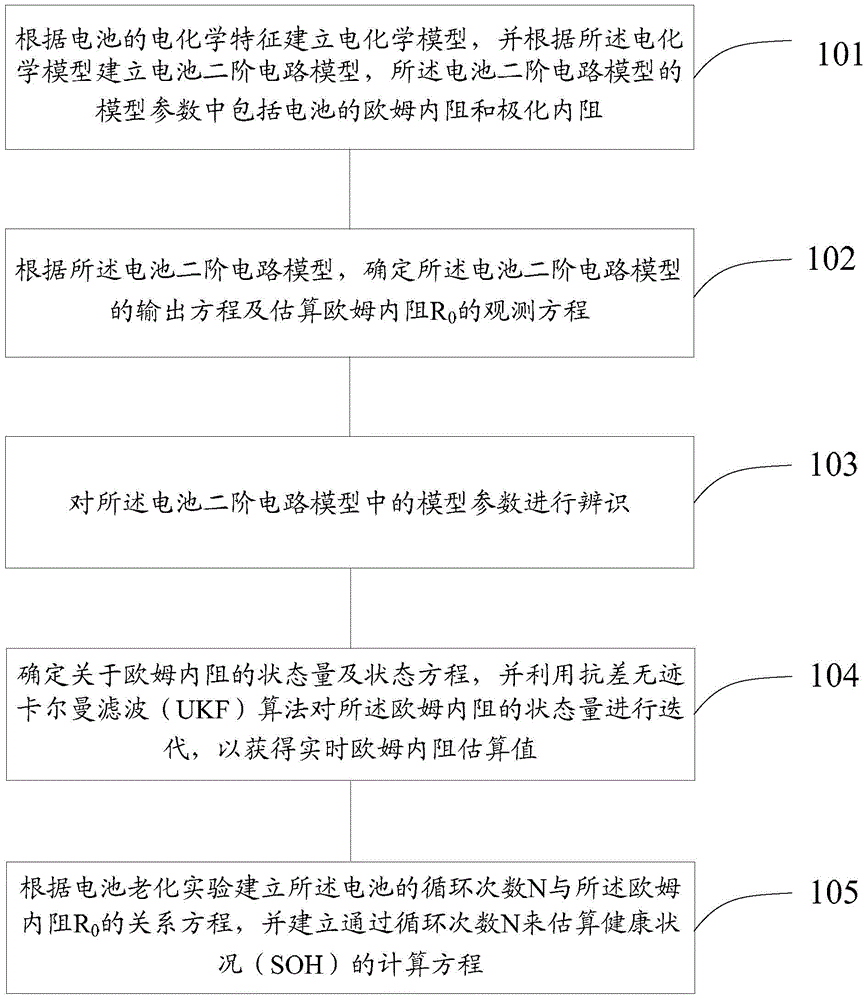

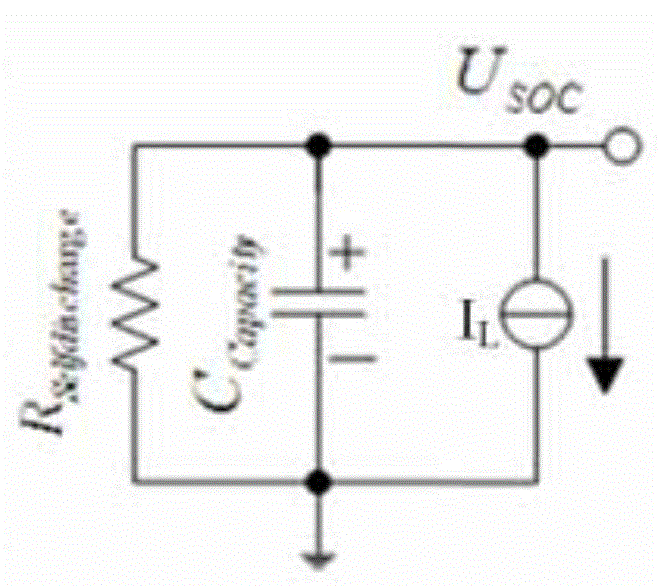

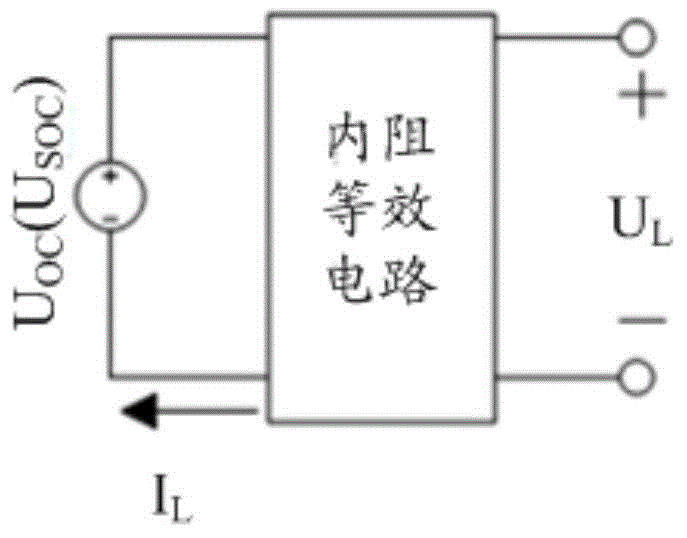

Online estimation method for battery capacity loss

ActiveCN105334462AHigh precisionEasy remote controlElectrical testingSpecial data processing applicationsInternal resistanceState of health

The invention discloses an online estimation method for the battery capacity loss. The method at least comprises the following steps that an electrochemical model is established according to electrochemical features of a battery, a battery second-order circuit model is established according to the electrochemical model, and parameters of the battery second-order circuit model comprise ohmic internal resistance and polarized internal resistance of the battery; according to the battery second-order circuit model, an output equation of the battery second-order circuit model and an observation equation for estimating the ohmic internal resistance R0 are determined; the parameters of the battery second-order circuit model are identified; the state quantity and state equation of the ohmic internal resistance are determined, and a robust UKF algorithm is used to carry out iteration o the state quality of the ohimic internal resistance to obtain the real-time estimation value of the ohmic internal resistance; and a relation equation between the circulation times N of the battery and the ohmic internal resistance R0 is established according to aging test of the battery, and a calculation equation for estimating the state of health (SOH) of the battery via the circulation times N is established.

Owner:HUAWEI TECH CO LTD +1

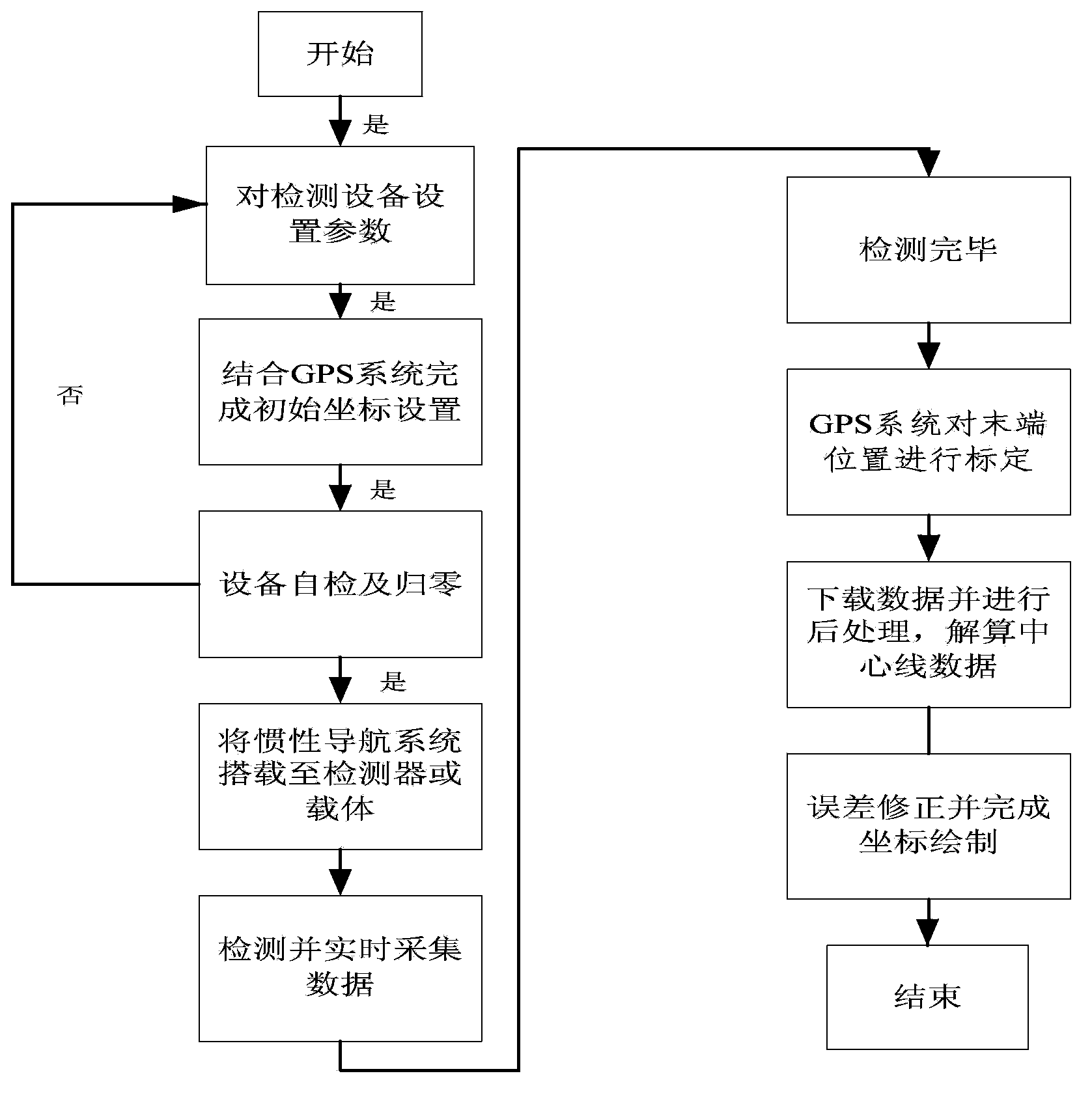

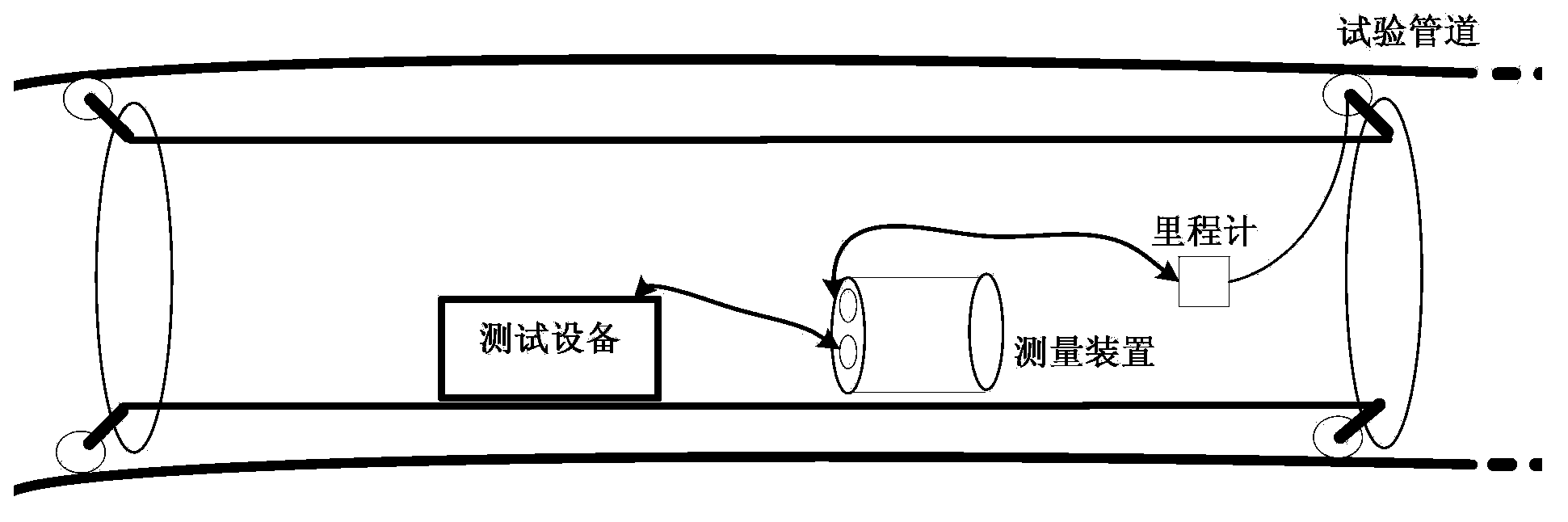

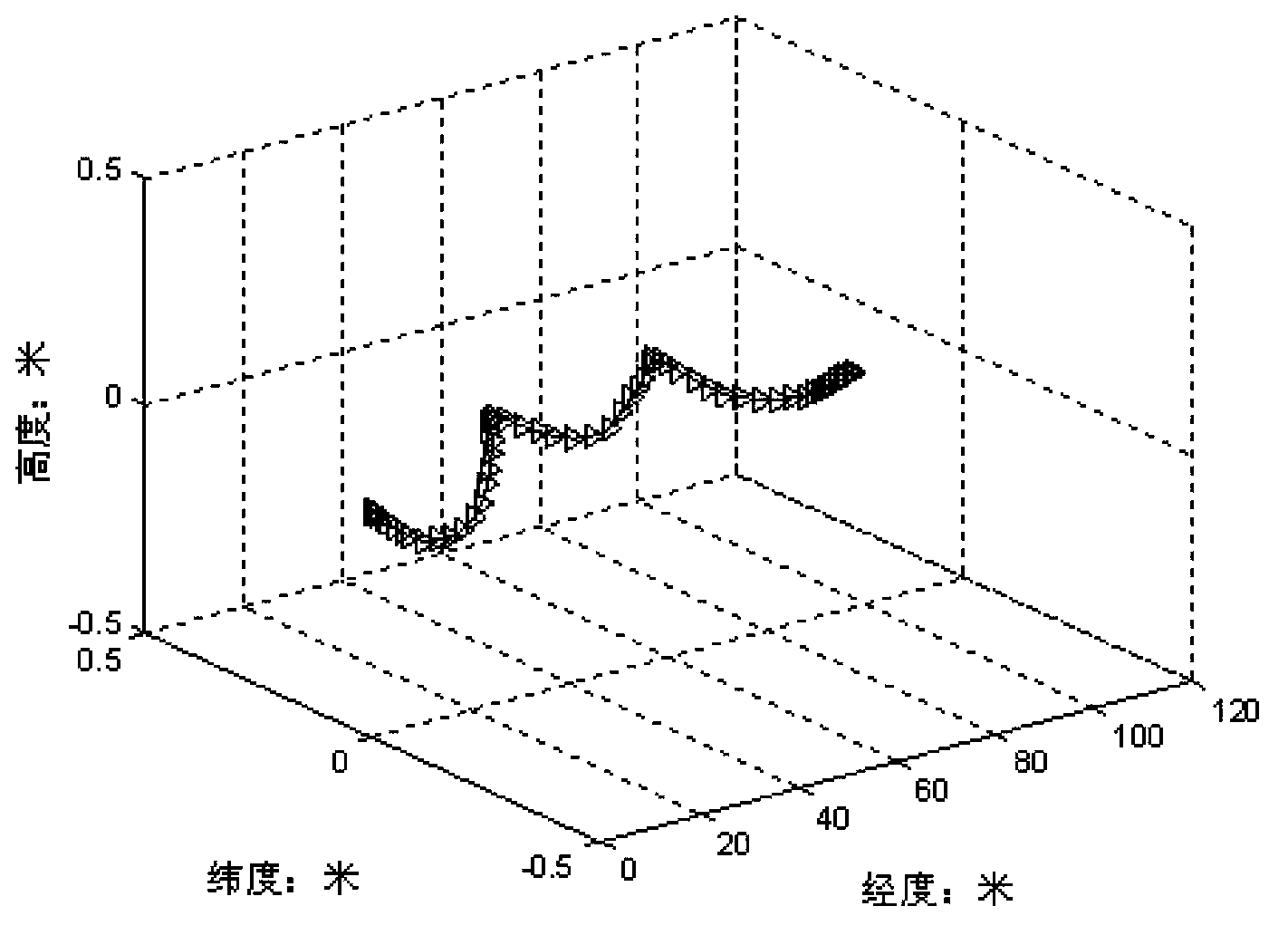

Inertial navigation measurement method for pipeline center line

InactiveCN103697886AImprove maintenance efficiencyReduce maintenance costsNavigation by speed/acceleration measurementsUsing wave/particle radiation meansInertial measurement unitTesting equipment

The invention provides an inertial navigation measurement method for a pipeline center line of a buried pipeline. An inertial navigation detection positioner is adopted for measurement, and is composed of a mobile carrier unit, an inertial measurement unit, an odometer wheel, a data storage unit, a data downloading and processing unit, a speed control unit, and a ground tracking positioning and power management unit. The method comprises the procedures: firstly setting parameters of a detection device; combining with a GPS system to complete initial coordinate setting; carrying out self-inspection of the device, and returning to zero; if being not completed, going back to set the parameters of the detection device; if being completed, mounting an inertial navigation system on a detector or other carriers; detecting and carrying out real-time data acquisition; completing the detection; calibrating a terminal position by the GPS system; downloading data, carrying out post treatment, and resolving center line data; carrying out error correction, and completing drawing of coordinates; and ending. The method can accurately draw out the three-dimensional coordinates, moving directions and displacement of the pipeline center line and even pipeline deformation.

Owner:PETROCHINA CO LTD

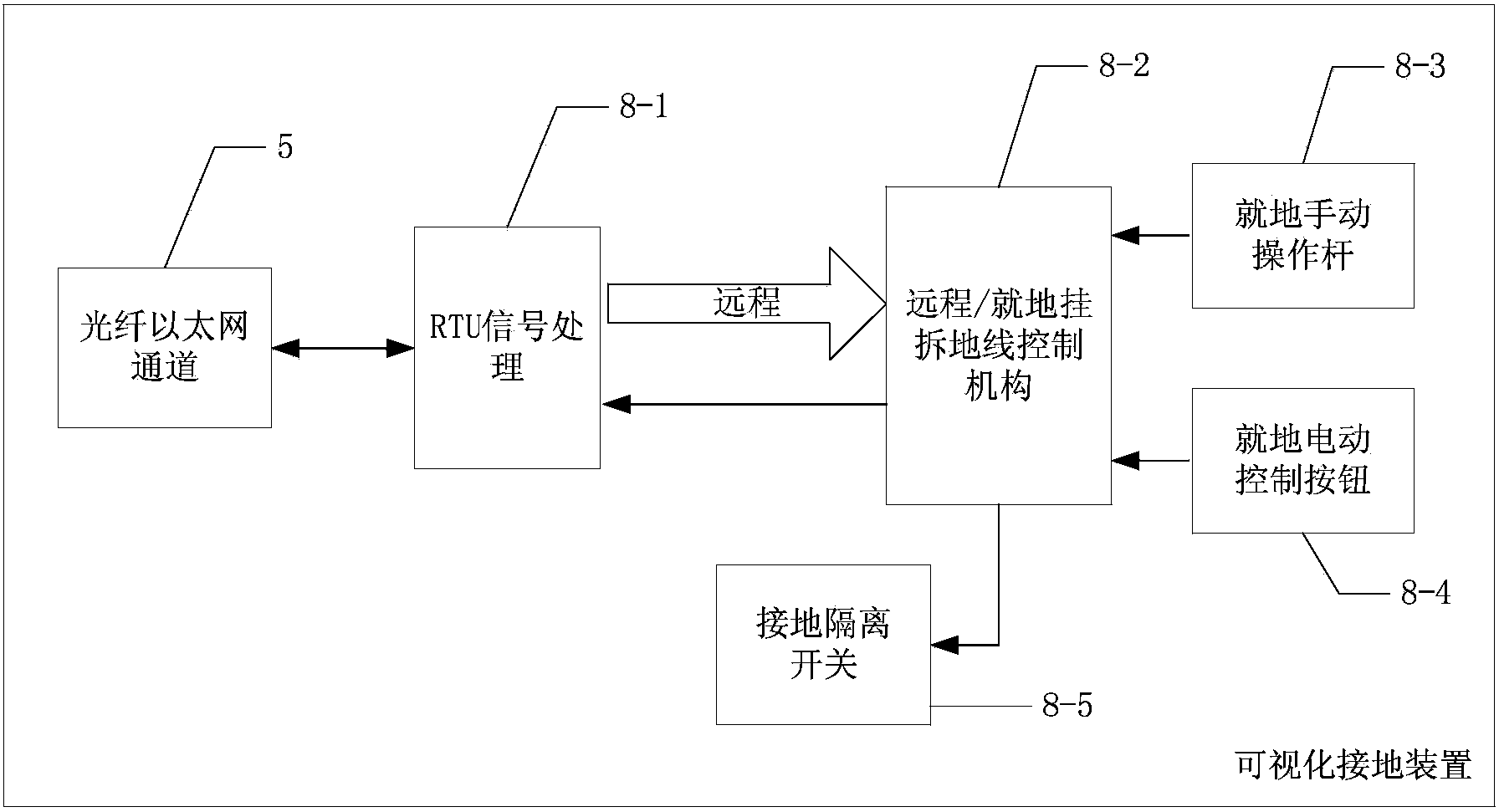

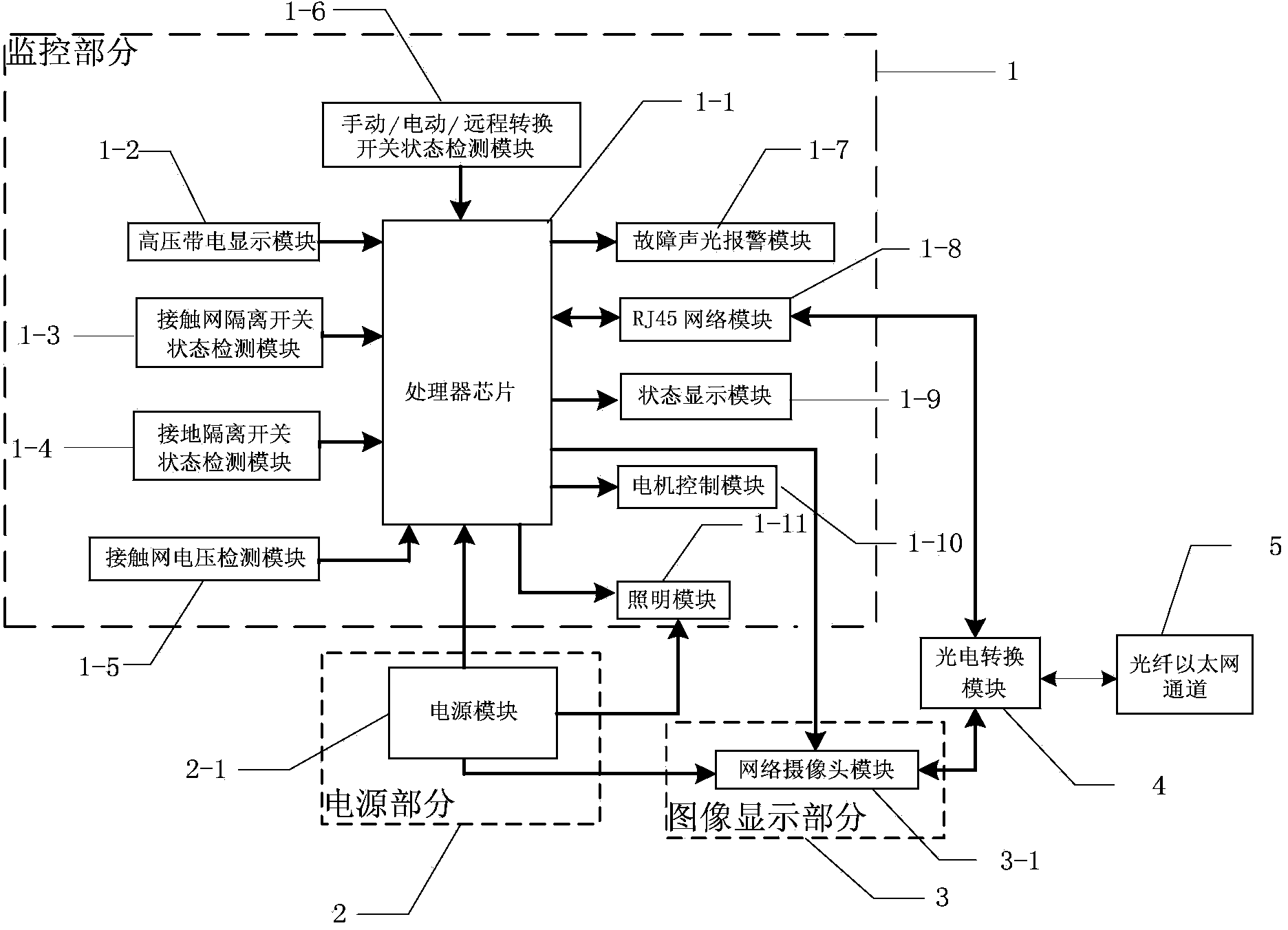

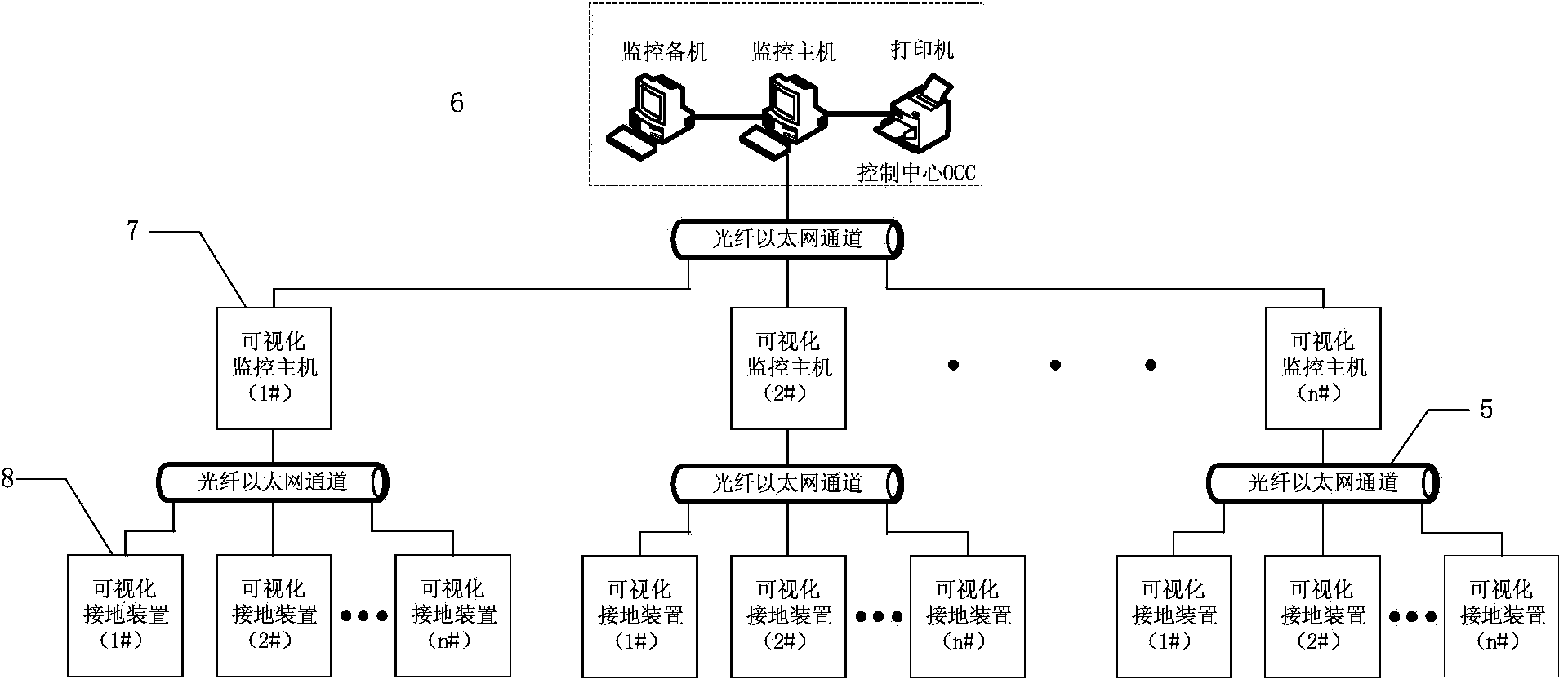

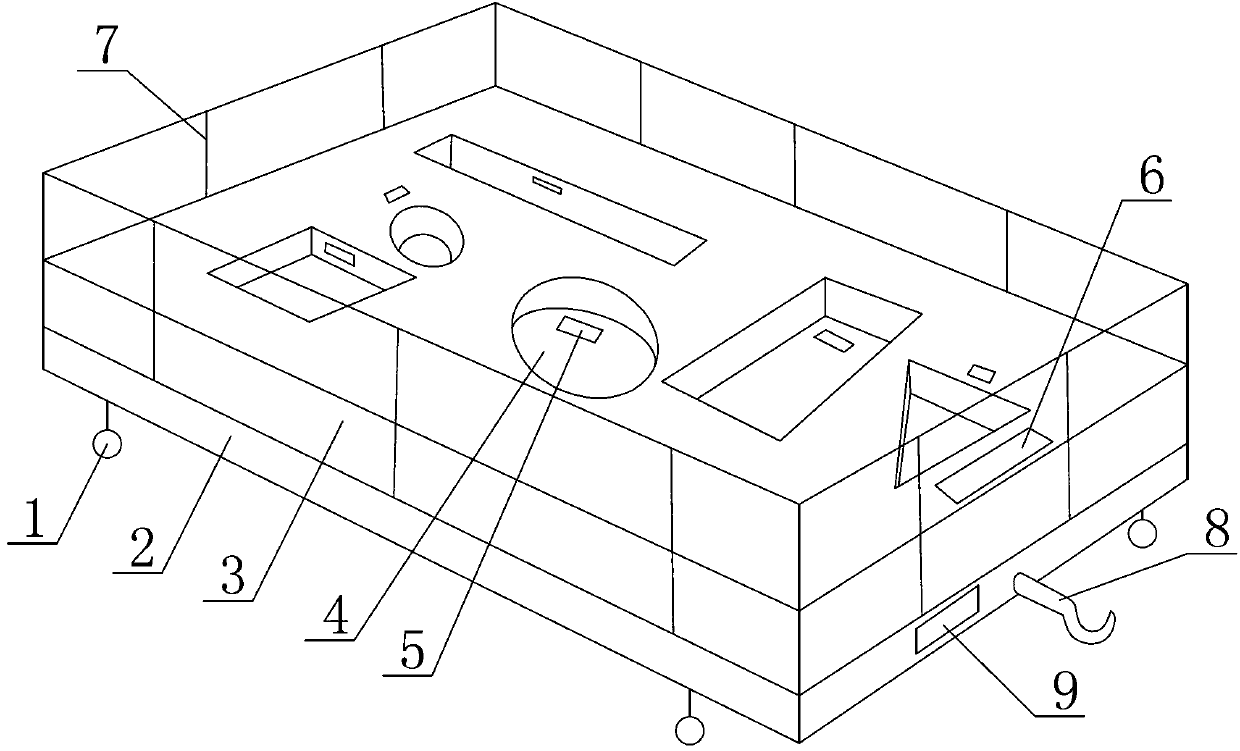

Visualization direct current supply grounding device based on video image, and monitor method

ActiveCN103616859AEnsure personal safetySolve the problem of manually going to the site to hang and remove the ground wireClosed circuit television systemsProgramme total factory controlVideo imageFirst aid

The invention discloses a visualization direct current supply grounding device based on a video image, and a monitor method. The visualization direct current supply grounding device based on the video image comprises an RTU signal processing part and a grounding transmission control mechanism connected with the RTU signal processing part. The RTU signal processing part comprises a monitor part, an image display part, a power source part, a photovoltaic conversion module and a fiber optic Ethernet channel. The monitor part can transmit measurement signals to a monitor host in real time, wherein the measurement signals comprise ground wire hanging and detaching information, the electrified state of a contact net and the like when maintenance and first-aid repair are carried out; meanwhile, the image display part is started, and the turn-on and turn-off states of a grounding separation switch are collected in real time so that working personnel in a dispatching center can determine the accuracy of the information; meanwhile, the ground wire hanging and detaching position is located, and the purpose of the reliable on-line monitor and visualization monitor is achieved. The problems that in the maintenance and first-aid repair operation of an existing rail traffic power supply system, the ground wire still needs to be mutually hung and detached, actual image information of a spot cannot be visually obtained, the spot cannot be accurately mastered, error judgments are made and error power transmission is caused can be solved.

Owner:XUZHOU ZHONGKUANG TRANSMISSION TRACK SCI & TECH

Material delivery transfer device

The invention relates to a material delivery transfer device, and the device comprises a storage and delivery trolley with wheels, wherein a buffering cushion is arranged on the storage and delivery trolley; the buffering cushion is provided with a plurality of delivery containers which are in one-to-one correspondence with materials prepared for stations of produced or repaired products; the delivery containers are counter bores formed in the upper surface of the buffering cushion and matched with the corresponding materials in appearance; the inner wall of each counter bore or the buffering cushion near to the counter hole is adhered with a first label matched with the type of the corresponding material; the first labels can be managed by color codes; a plurality of colors can be configured to respectively represent a plurality of models of the products. The material delivery transfer device disclosed by the invention is designed according to standardization, modularization, flexibility and visualization; the delivery containers have constant volume and are fixed according to the characteristics of the materials needed by stations of the produced or repaired products, and are designed by using the station as unit; the buffering cushion can protect the materials; the materials need not to be packed and no dismounting of the packing is needed, so waste of the resources is reduced and the work efficiency is improved as well.

Owner:NANJING NANCHE PUZHEN IND LOGISTICS CO LTD

An assembled construction method of electromechanical pipelines based on the BIM technology

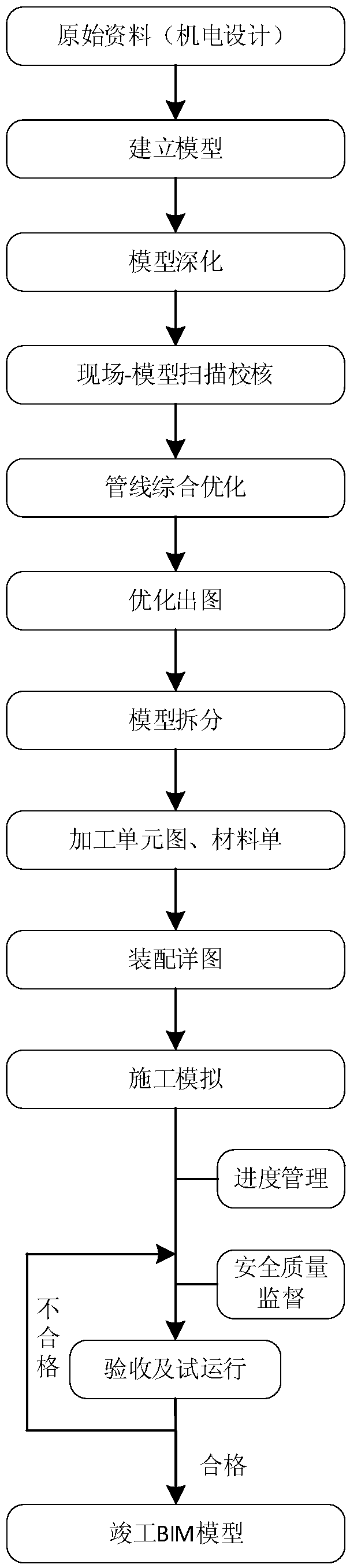

PendingCN109543233AType of reductionReduce in quantityGeometric CADBuilding material handlingDigitizationTraceability

The invention relates to an assembled construction method of electromechanical pipelines based on the BIM technology, which comprises the steps of partitioning a S1 prefabricated processing model; S2model creation; S3 model processing; S4 Prefabricated machining drawing and prefabricated material list are issued; S5 machining components; S6 Assembly details; S74D construction simulation; S8 On-site assembly installation, acceptance and commissioning; S9 Completion of the BIM model. The invention can increase the quantity, the kind and the specification of the BIM virtual component, reduce thetype and the quantity of the prefabricated component, realize the cooperation and the docking with the prefabricated factory, help the workers to understand the design intention better through the visual and visual expression, help the workers to improve the accuracy and the quality efficiency of the production, improve the construction efficiency, and reduce the cost. Realize the digitization, refinement and visualization management of project schedule, construction scheme, quality, safety and other aspects, so that the project data can be traceable.

Owner:CCCC FIRST HARBOR ENG +1

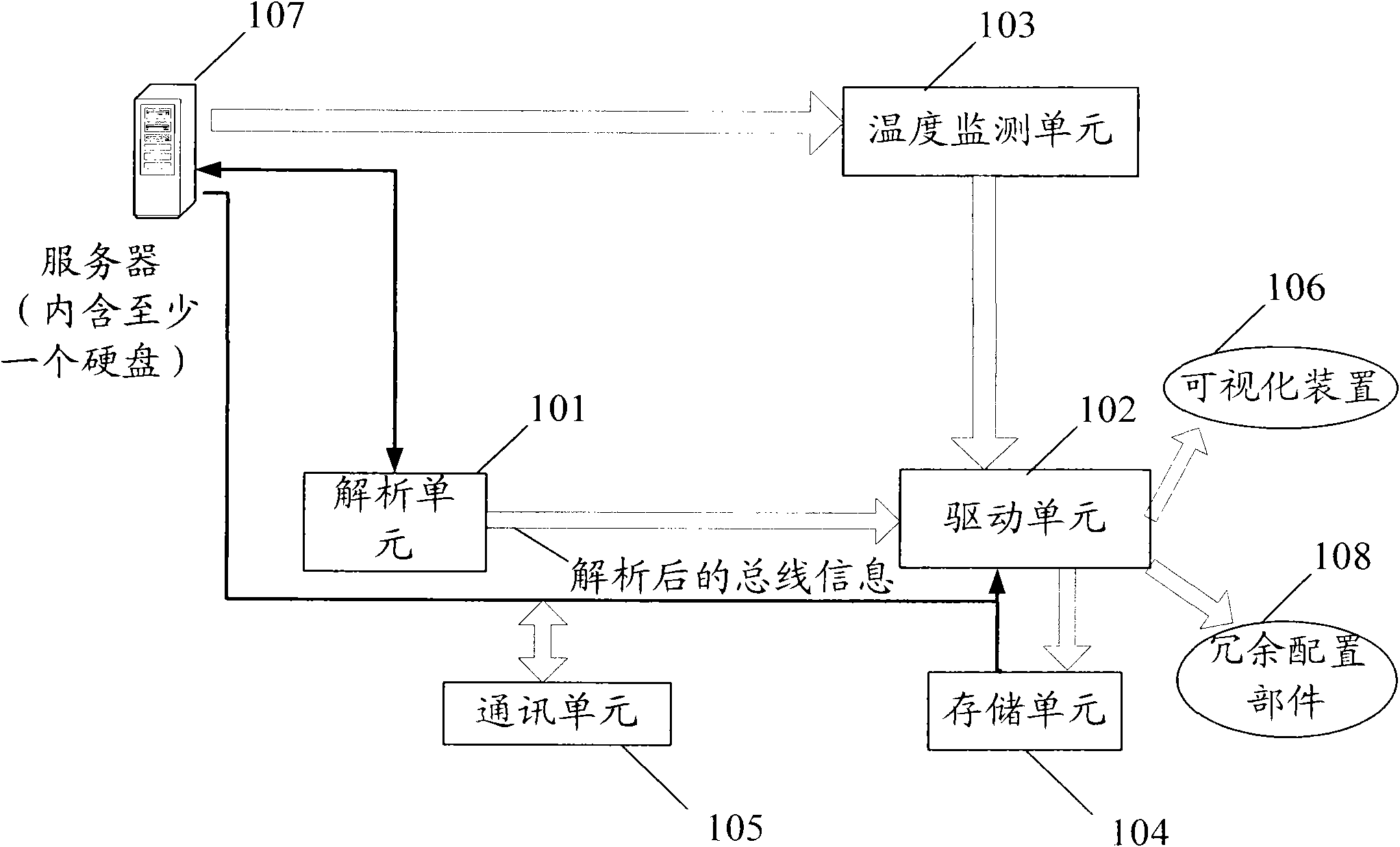

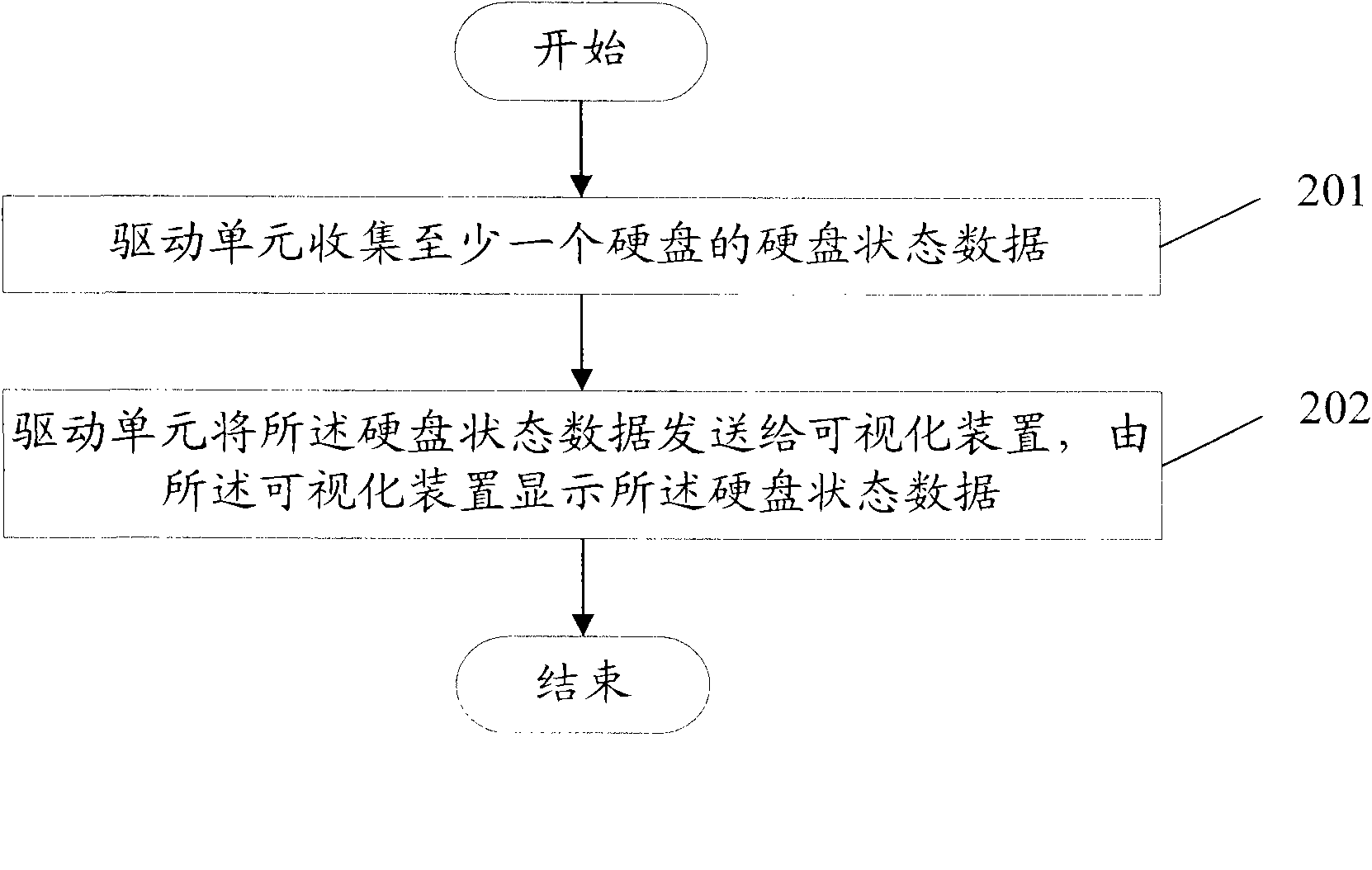

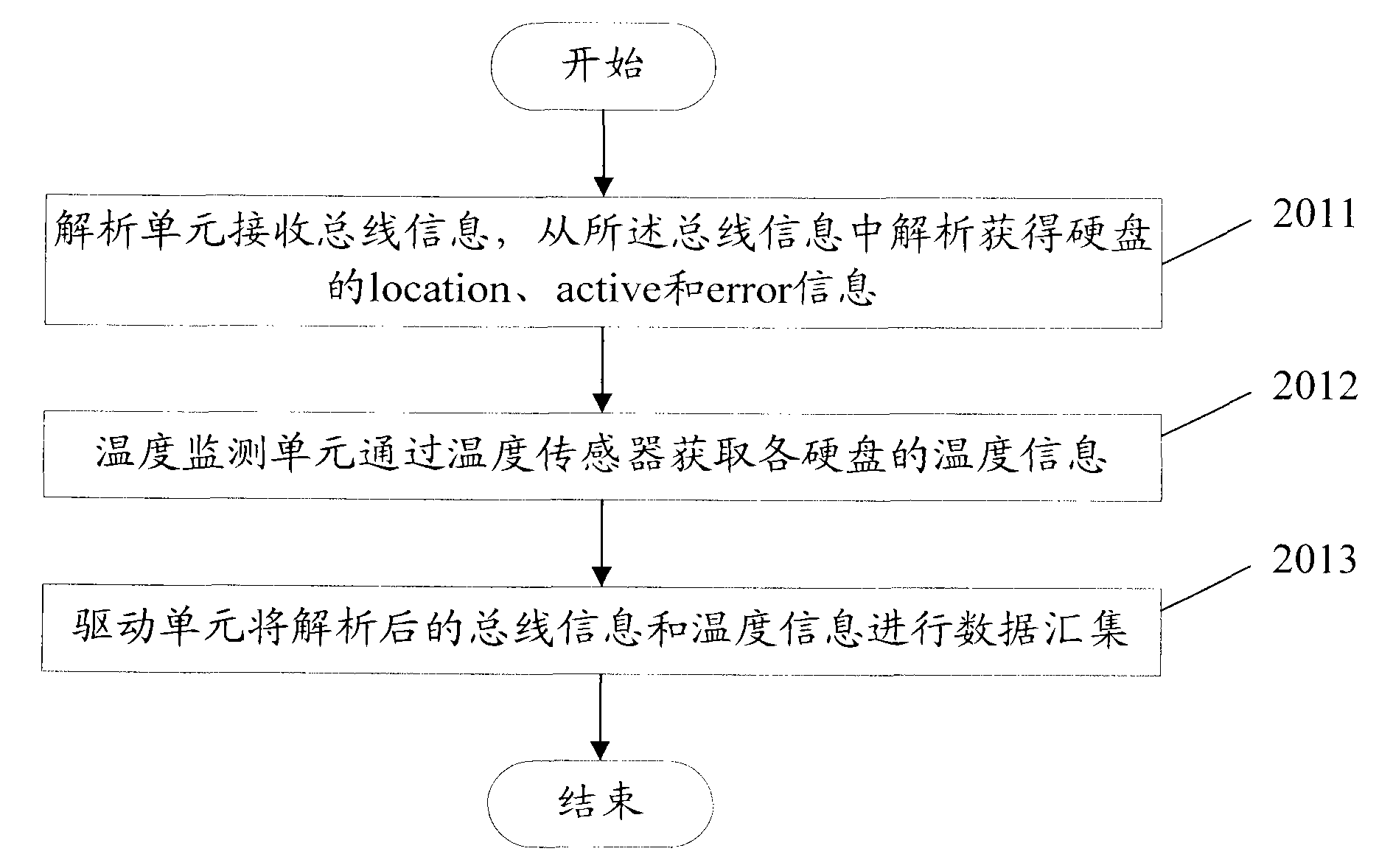

Method and system for monitoring hard-disk status

InactiveCN101901181ARich running status informationRealize visual managementHardware monitoringMonitoring methodsReal-time computing

The invention provides a method and a system for monitoring hard-disk status, relates to the field of computer communication, and solves the problem that management cannot be performed conveniently if detailed hard-disk status cannot be acquired. The method comprises the following steps of: collecting data of the hard-disk status of at least one hard-disk; transmitting the data of the hard-disk status to a visual device; and displaying the data of the hard-disk status by using the visual device. The technical scheme of the invention is suitable for hard-disk monitoring.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

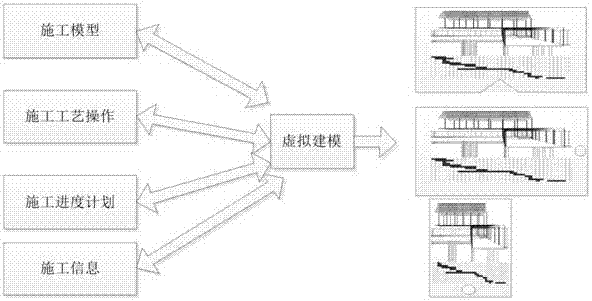

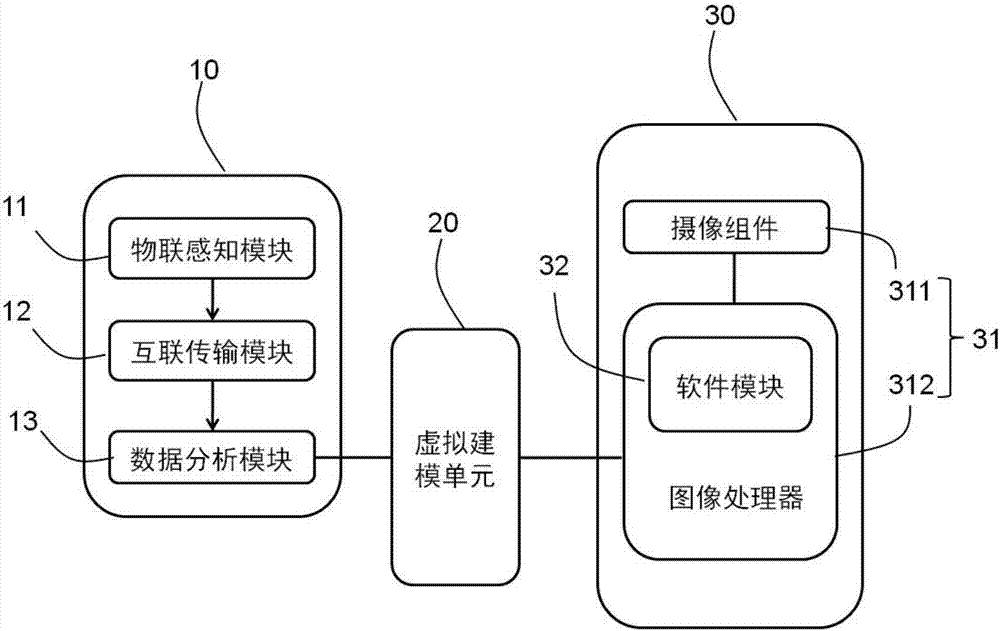

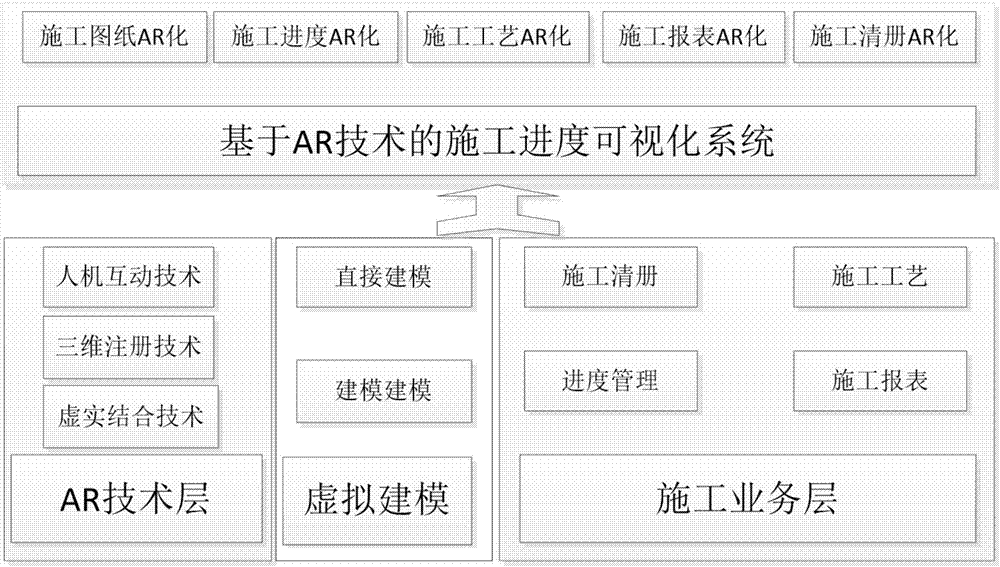

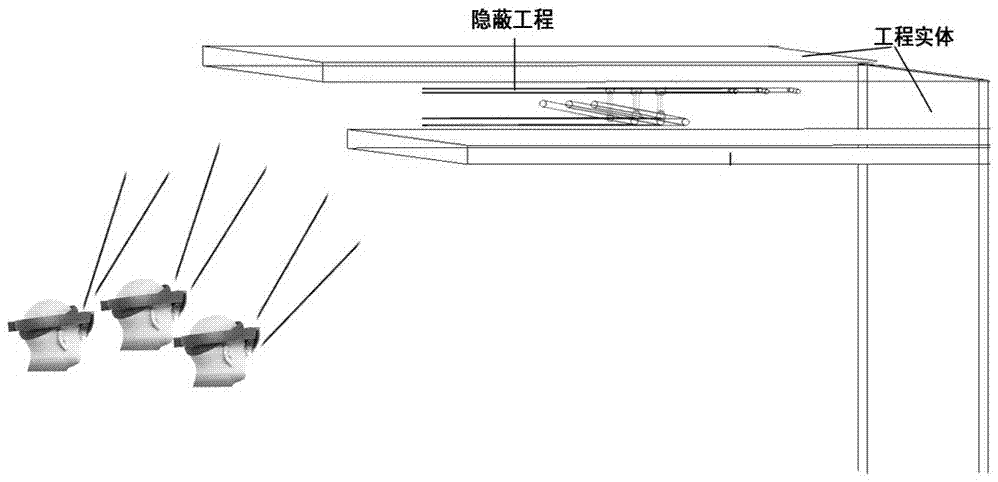

Augmented reality-based construction progress visual management system and method

InactiveCN106897817ARealize visualizationRealize visual managementResourcesSensing dataProgram planning

The invention provides a construction progress visualization management system based on augmented reality. The augmented reality-based construction progress visualization management system includes: a construction management and control unit, which is used to automatically collect IoT sensing data and manual input information on the construction site, classify, summarize and organize the collected data, and combine the WBS to organize the on-site construction The process is decomposed into a number of progress nodes, compiled into a construction schedule for management; the virtual modeling unit, based on the data provided by the construction control unit, constructs a construction-related virtual model; the augmented reality unit is used to scan the real scene and Identify, and superimpose the virtual model provided by the virtual modeling unit on the identified real scene, so as to present or display the augmented reality effect of the construction progress. The invention also provides a method of a construction progress visualization management system based on augmented reality.

Owner:朗坤智慧科技股份有限公司

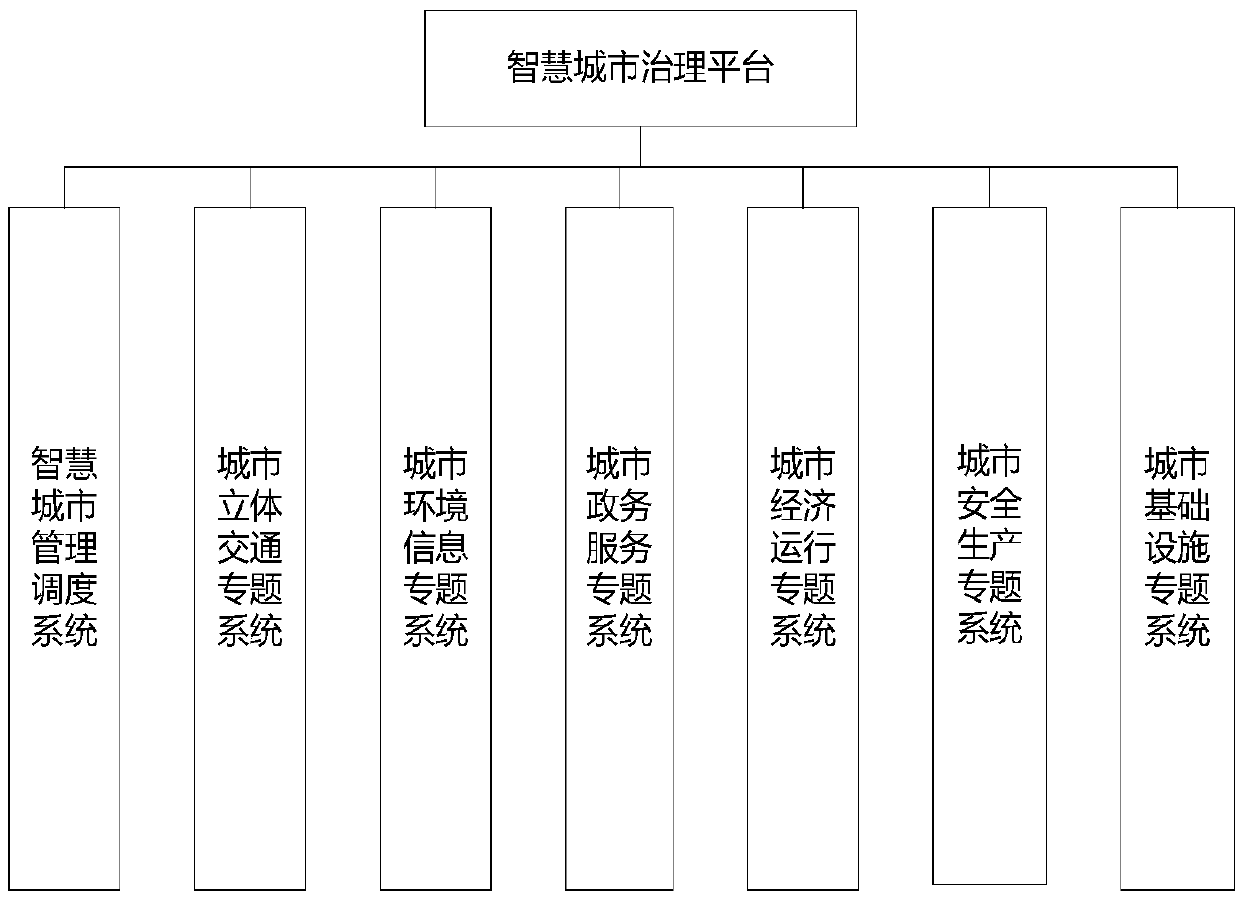

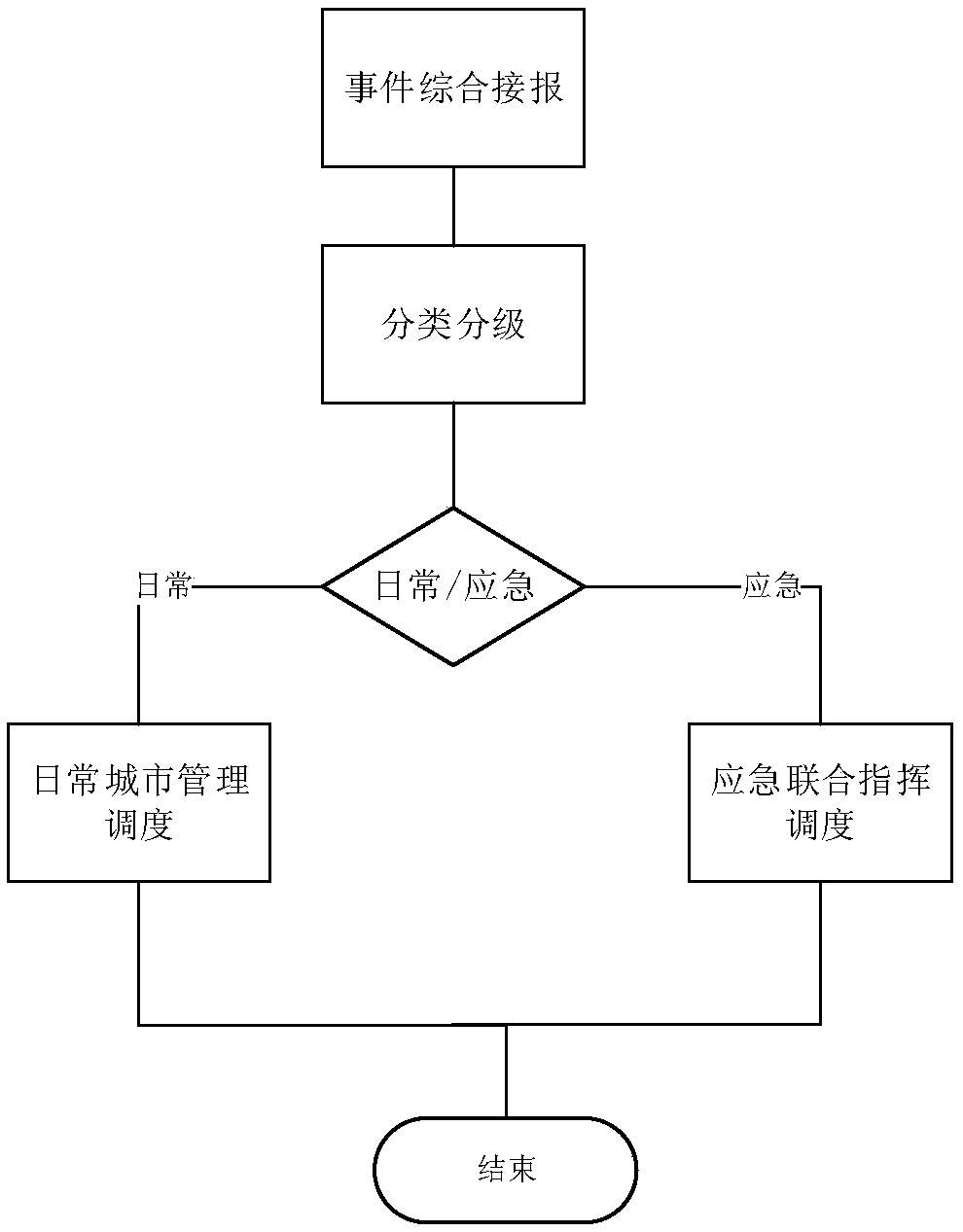

A smart city platform for urban governance

PendingCN109544428AOptimize the allocation of public resourcesInnovative social managementData processing applicationsClimate change adaptationLivelihoodInternet of Things

The invention provides a smart city platform for urban governance, which includes establishing a city CIM early warning model, a Urban three-dimensional transportation thematic system, a urban environmental information thematic system, a urban government affairs service thematic system, a urban economic operation thematic system, a urban safety production thematic system, a urban infrastructure thematic system based on 3D GIS model and AI intelligent early warning , to achieve the monitoring, processing and operation of the overall intelligence of the city. Through the integration ability of urban thematic application to information and urban Internet of Things perceptual resources, it plays a universal role in the three-dimensional transportation, economic operation, safety in production,infrastructure, government services and other important livelihood services. The application in urban governance and public services is conducive to promoting the coverage of basic public services indifferent levels, different regions and different groups, effectively improving the level of public services and their equal coverage, assisting government decision-making, crisis management, and enhancing government governance capacity.

Owner:NANJING LES INFORMATION TECH

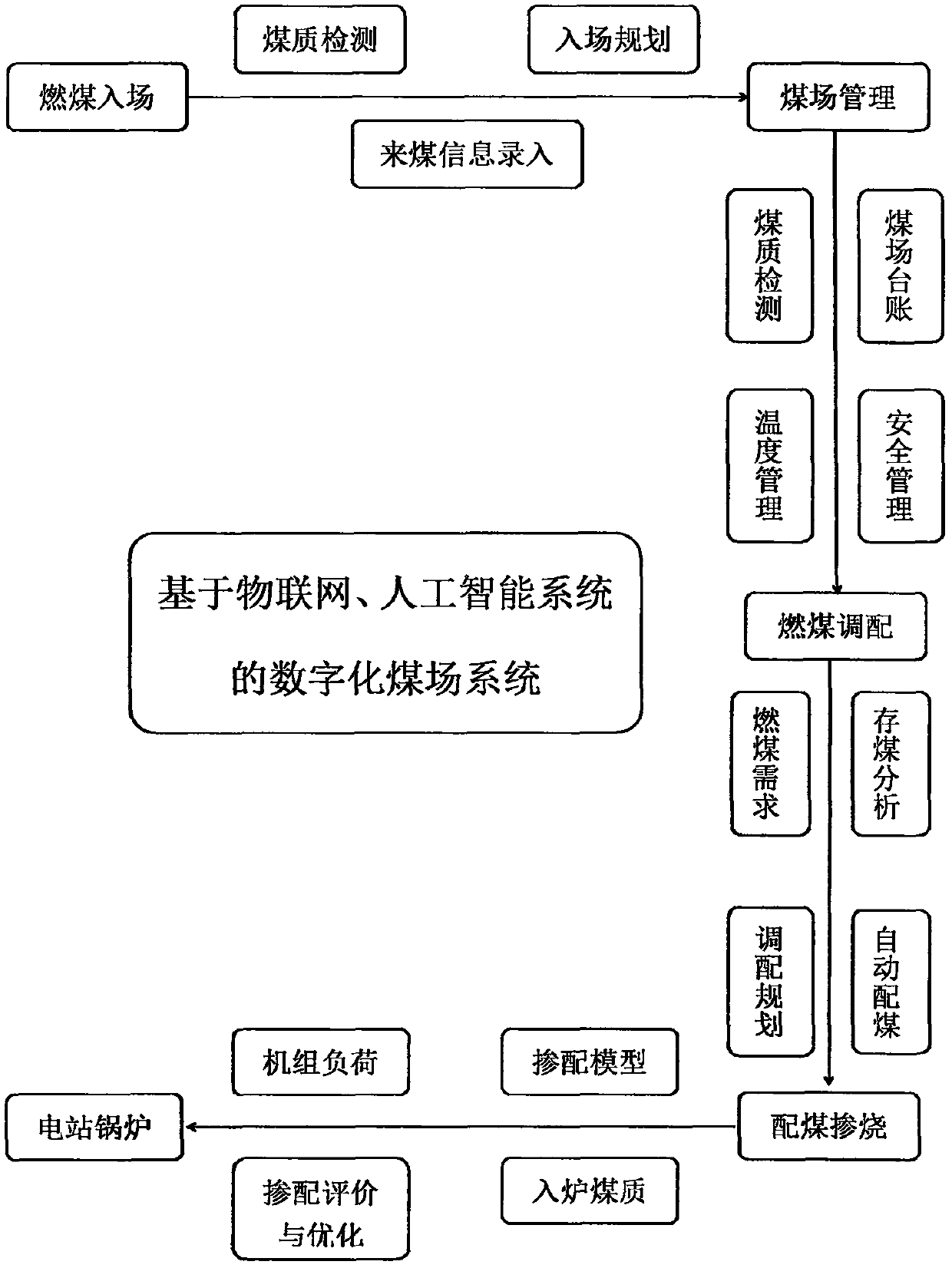

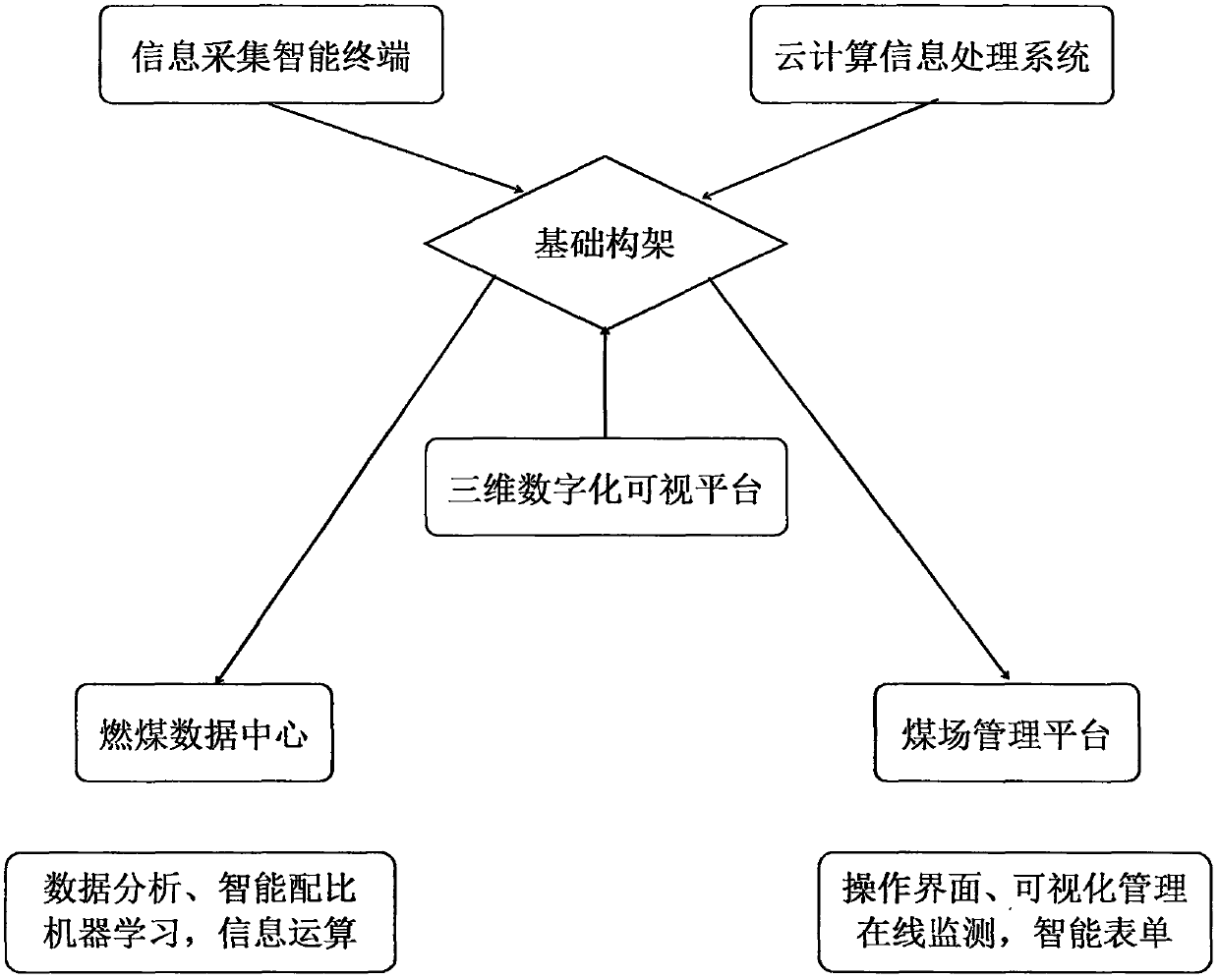

Digitized coal yard system based on Internet of Things and artificial intelligence system

PendingCN109583699AHigh degree of digitizationEasy to deployOffice automationResourcesData centerClosed loop

The invention provides a digitalized coal yard system based on Internet of Things and an artificial intelligence system, relates to the technical field of fuel management, digitalized factories and power generation, and particularly relates to a digitalized management system of a coal yard. The method is based on the Internet of Things. The invention discloses a digital coal yard system of an artificial intelligence system. Digitization and intelligentization of coal yard and fire coal data are achieved by means of an artificial intelligence system, coal quality test equipment and entrance detection equipment are combined by means of coal yard related equipment and an information acquisition intelligent terminal, fire coal digital management is achieved, a data reference basis is providedfor coal blending combustion and fire coal planning, and actual economic benefits are brought to enterprises. According to the invention, a management chain from entry to evaluation is required to beestablished, and closed-loop management of fuel is realized, so that a coal yard management platform and a coal-fired data center are provided on the basis of an overall scheme architecture, and digitalization, visualization and intelligentization of coal yard management of power generation enterprises are realized through construction of the coal yard management platform and the coal-fired data center.

Owner:天津市容创智行节能科技有限公司

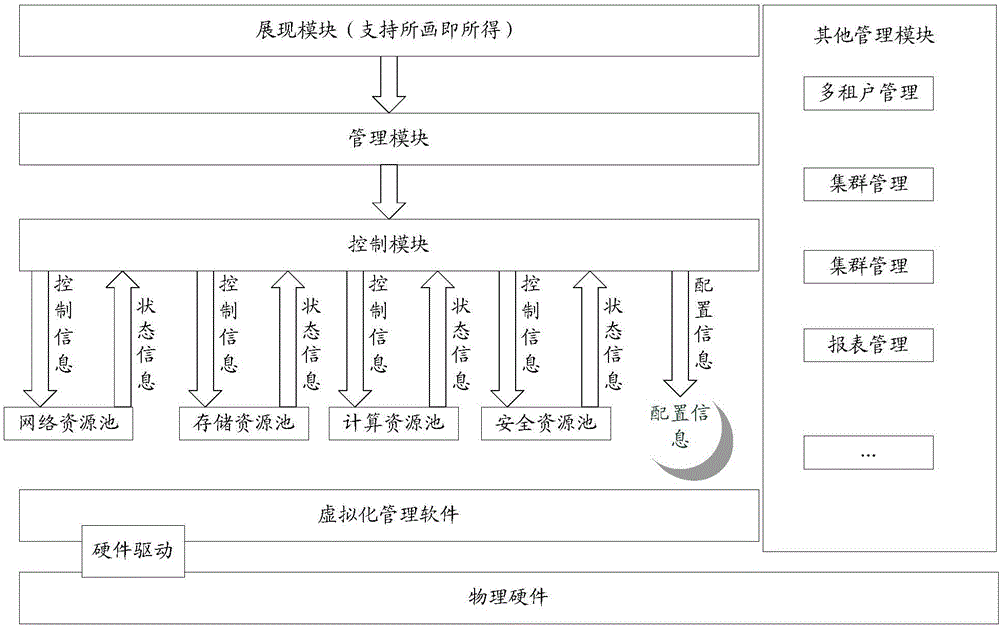

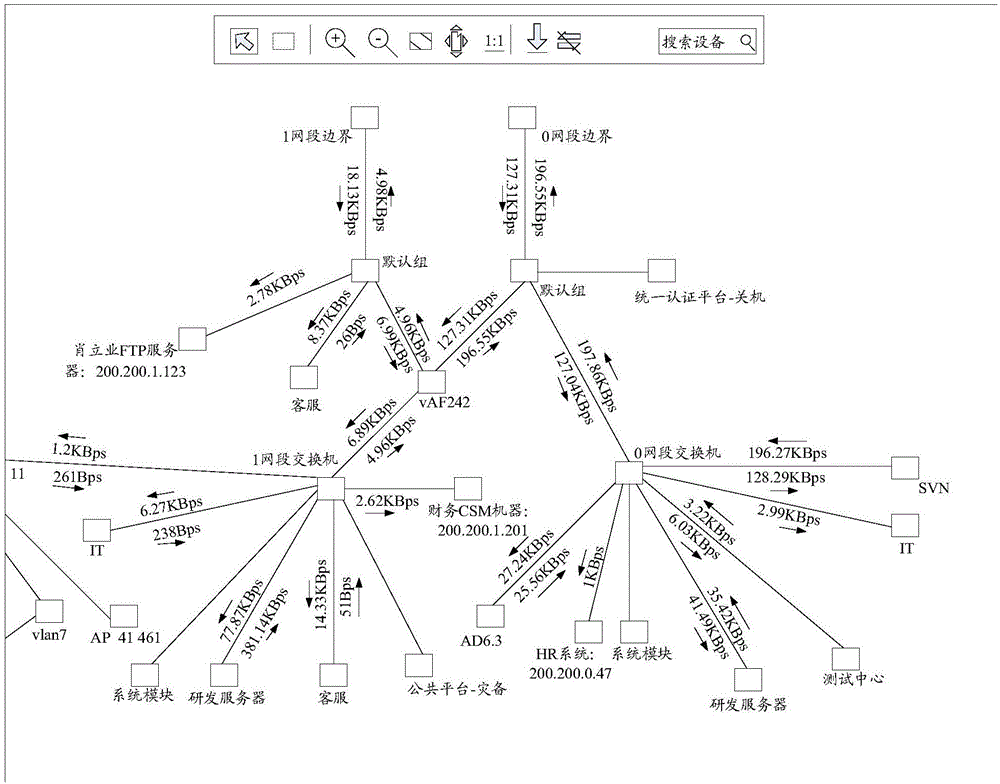

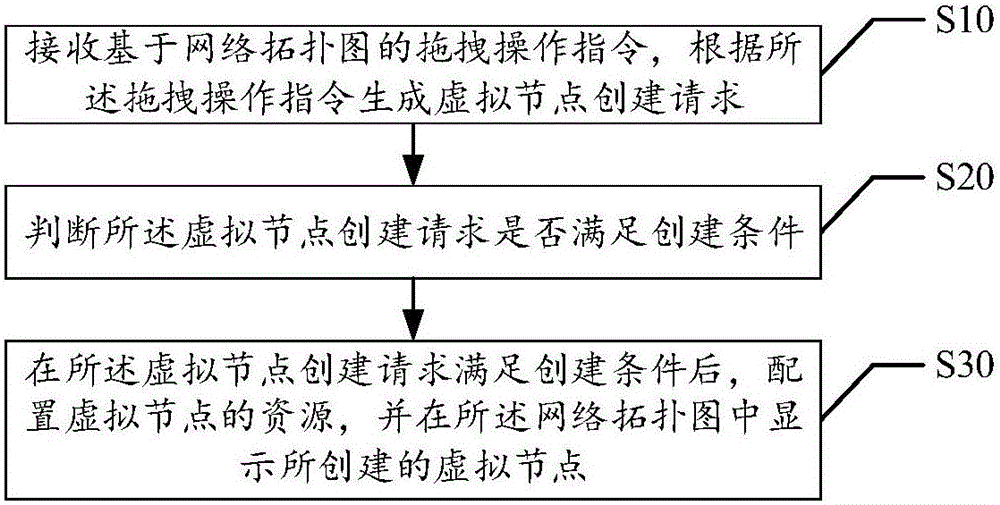

Virtual node creating method and apparatus based on network topological diagram

ActiveCN106713003ARealize visual managementReduce management difficultyData switching networksVirtualizationTopological graph

The invention discloses a virtual node creating method based on a network topological diagram. The method comprises the following steps: receiving a drag operation instruction based on the network topological diagram, and according to the drag operation instruction, generating a virtual node creating request; determining whether the virtual node creating request satisfies a creating condition; and after the virtual node creating request satisfies the creating condition, configuring resources of virtual nodes; and displaying the created virtual nodes on the network topological diagram. The invention further discloses an apparatus based on a network topological diagram. According to the invention, configuration operation of the virtual nodes is reduced, the configuration efficiency of the virtual nodes is improved, and the management difficulty of a virtual platform is greatly reduced.

Owner:SANGFOR TECH INC

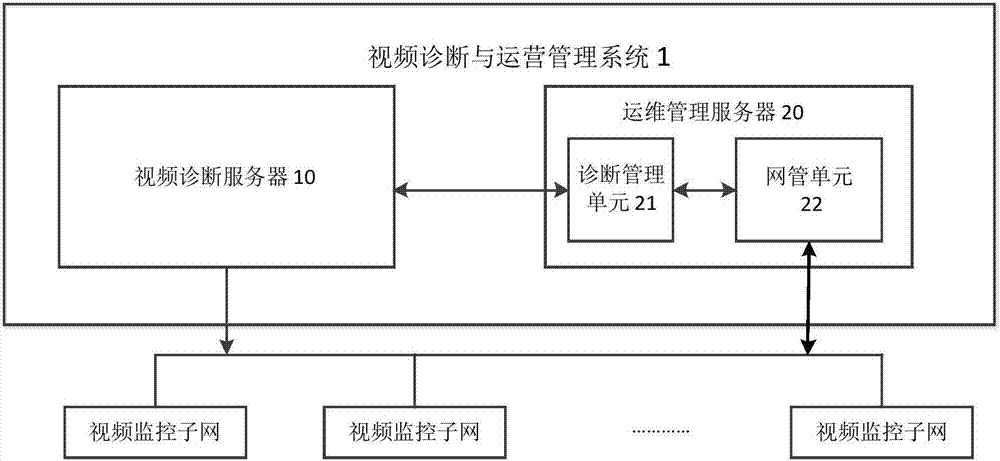

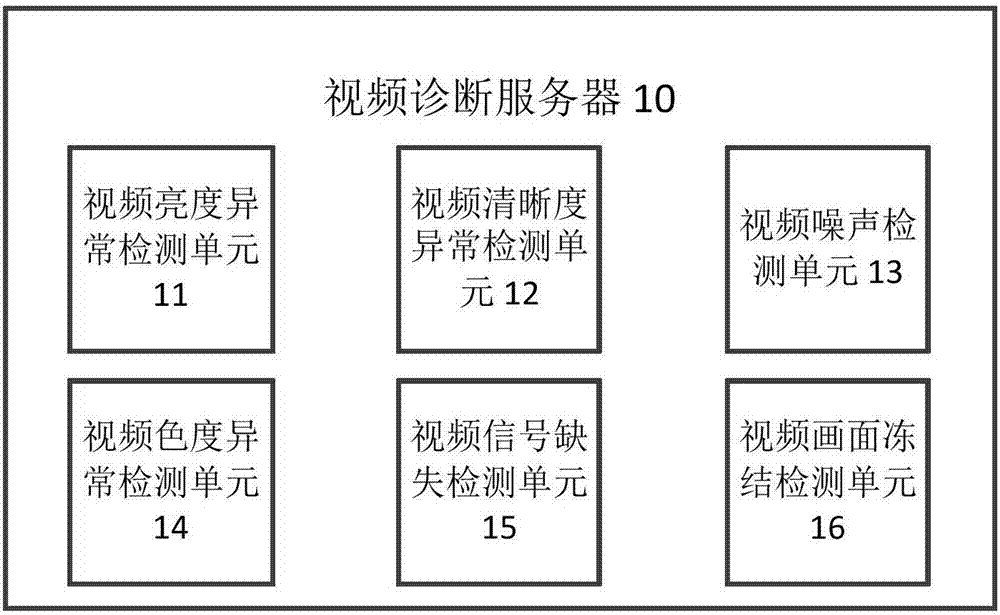

Video diagnosis and operation and maintenance management system and method of video monitoring network

ActiveCN107959847AReal-time monitoring of running statusRealize automatic monitoringTelevision systemsAlarmsVideo monitoringStatistical analysis

The invention provides a video diagnosis and operation and maintenance management system and method of a video monitoring network. The system comprises a video diagnosis server used for performing video quality diagnosis analysis, and transmitting a detection result to an operation and maintenance management server; and the operation and maintenance management server obtains the states of all kinds of devices of a video monitor sub network by using the SNMP protocol, locates a video fault device, performs running state inspection and monitoring, state statistical analysis, device fault alarm push, device fault maintenance management and asset management on all kinds of devices. The video diagnosis and operation and maintenance management system can monitor the running state conditions of the server, the devices and the like in the system in real time, can automatically perform inspection and can directly locate the source of the problem once finding the problem and push the source of the problem to operation and maintenance personnel, and perform alarm of different levels according to the order of severity of the problem, so that the operation and maintenance personnel can find theproblem point and solve the same at the first time; and statistical analysis can be performed on various operation and maintenance problems, the weaknesses in the system are discovered, and the subsequent system upgrades and maintenance are guided.

Owner:王磊

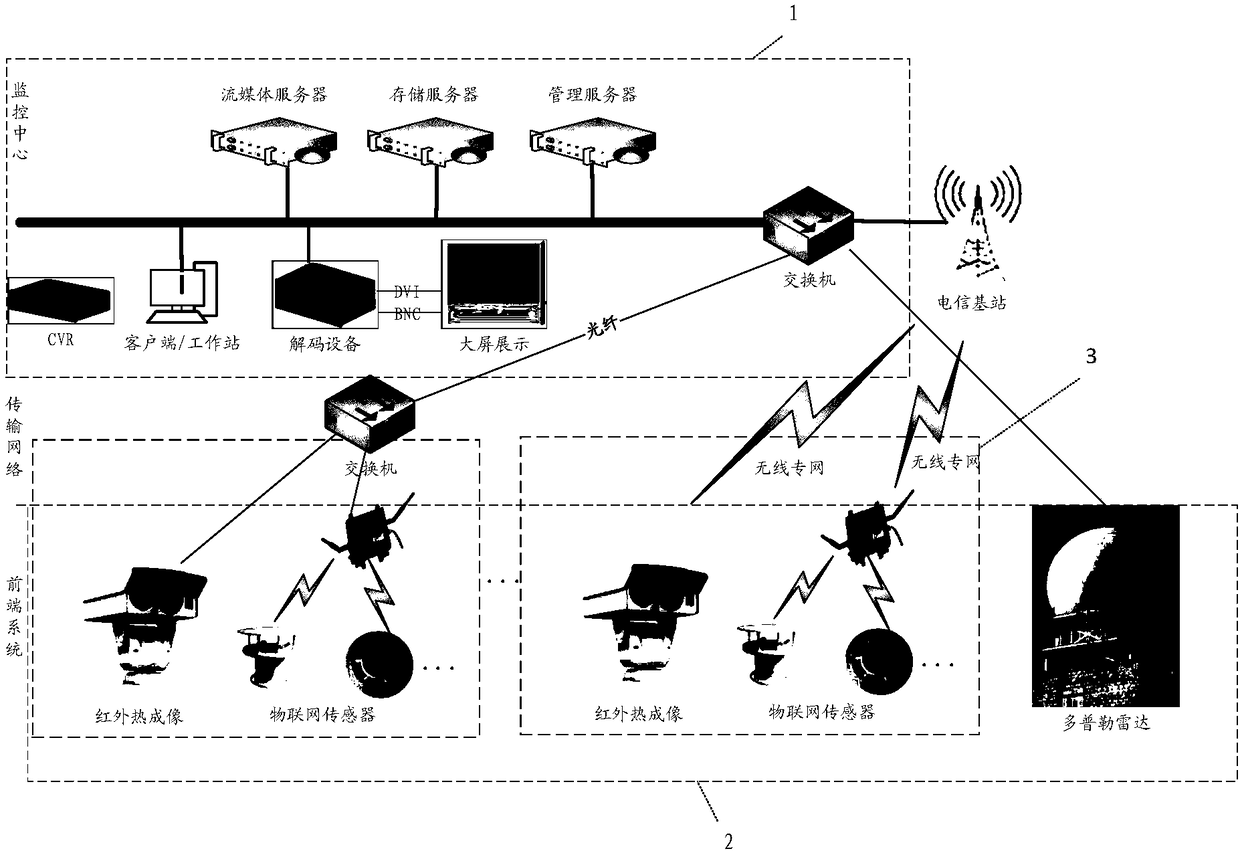

Transmission line mountain fire protection system

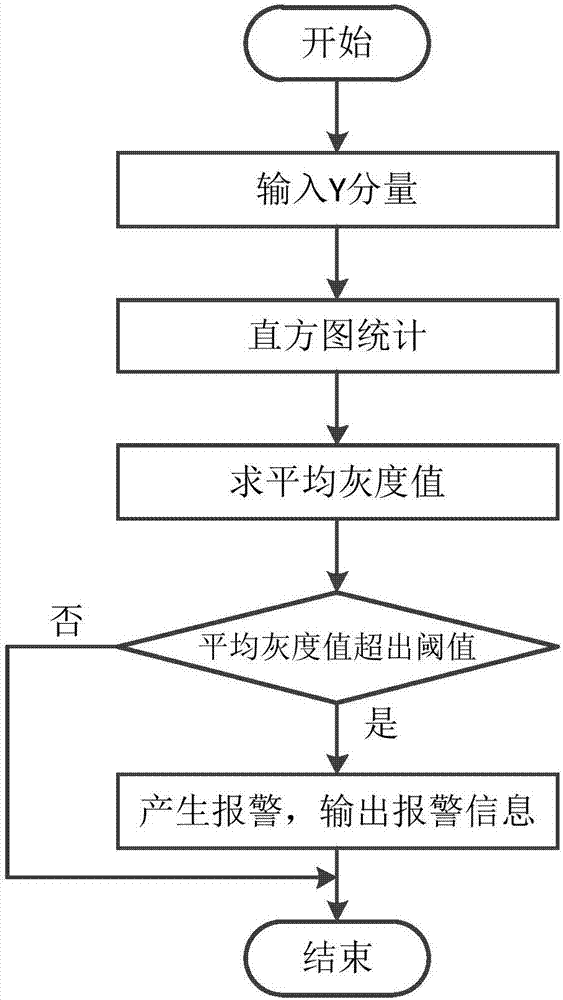

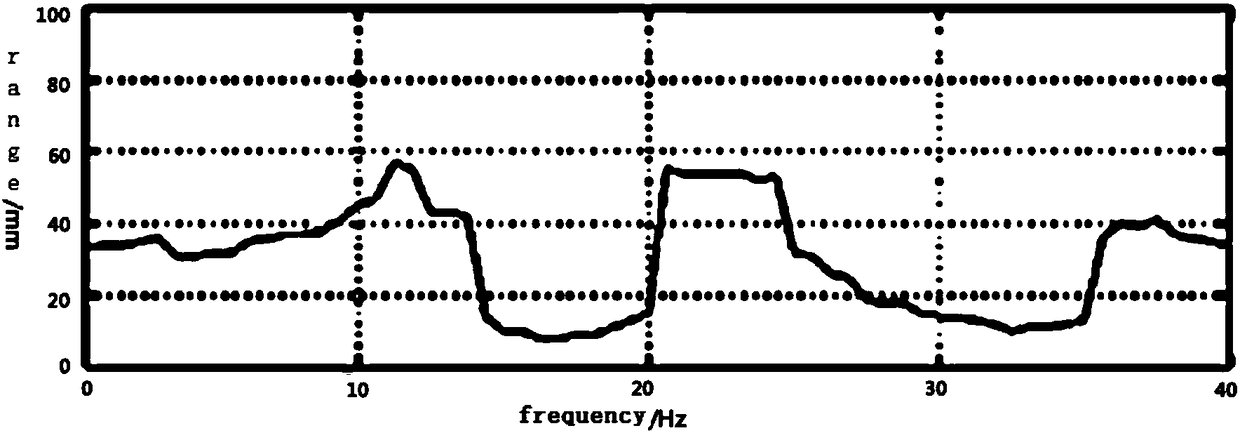

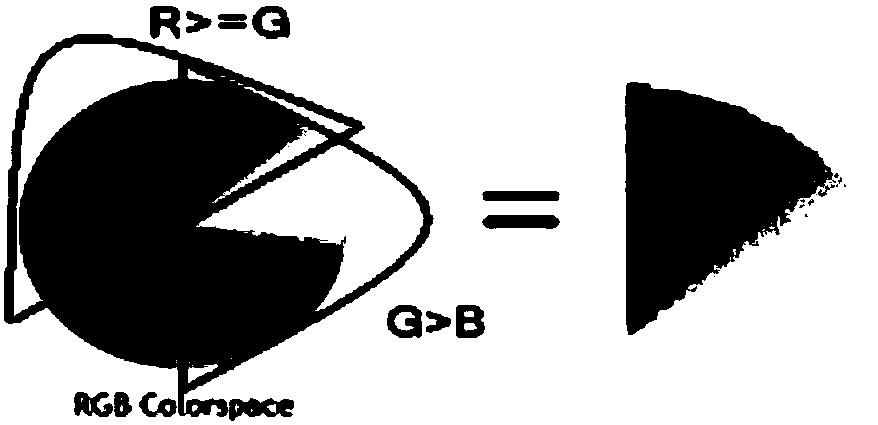

InactiveCN108205862ARealize visual managementReal-time monitoring of the monitoring rangeFire alarmsEngineeringForest resource

The invention provides a transmission line mountain fire protection system comprising a background power GIS monitoring center and a front end system connected thereto through a transmission network.The front end system comprises an infrared video detection system for sending alarm information including location information and video data, an Internet of Things sensor for monitoring monitory point meteorological information including wind power, wind direction, temperature and humidity and smoke, and a Doppler radar for determining mountain fire information and fire location. The background power GIS monitoring center is used for determining, according to detection results, whether to start the Doppler radar to determine the mountain fire information and the fire location, analyzing and processing the received information, and then marking and making a prompt at the corresponding position of a power transmission line map. The transmission line mountain fire protection system is provided with the front end system with an integrated monitoring function. By combination with a power GIS, visual management of forest resource information can be achieved.

Owner:XIAMEN GREAT POWER GEO INFORMATION TECH +3

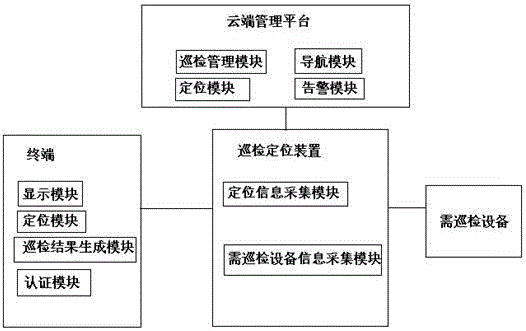

System for realizing intelligent tour inspection of transformer station and personnel positioning as well as method thereof

InactiveCN106092084AAchieve seamless connectionImprove accuracyNavigation instrumentsSwitchgearEngineeringTransformer

The invention discloses a system for realizing intelligent tour inspection of a transformer station and personnel positioning. The system comprises a terminal, a tour inspection positioner and a cloud management platform; the terminal enables communicating connection with the tour inspection positioner, the tour inspection positioner is arranged in a transformer station work zone, equipment required for tour inspection is externally connected with the tour inspection positioner, and the tour inspection positioner enables communicating connection with the cloud management platform though a tour inspection positioning gateway. The invention also discloses a method for realizing intelligent tour inspection of transformer station and personnel positioning. The system and the method realize visual management of intelligent tour inspection, safe tour inspection, and daily tour inspection, seamless connection from the terminal to the cloud is realized, the pertinency, reliability and accuracy of the tour inspection of the transformer station are higher, and the work efficiency of the tour inspection staff of the transformer station can be effectively increased.

Owner:NANJING INST OF TECH

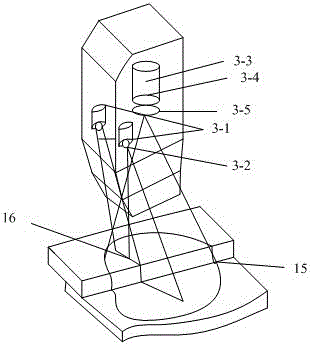

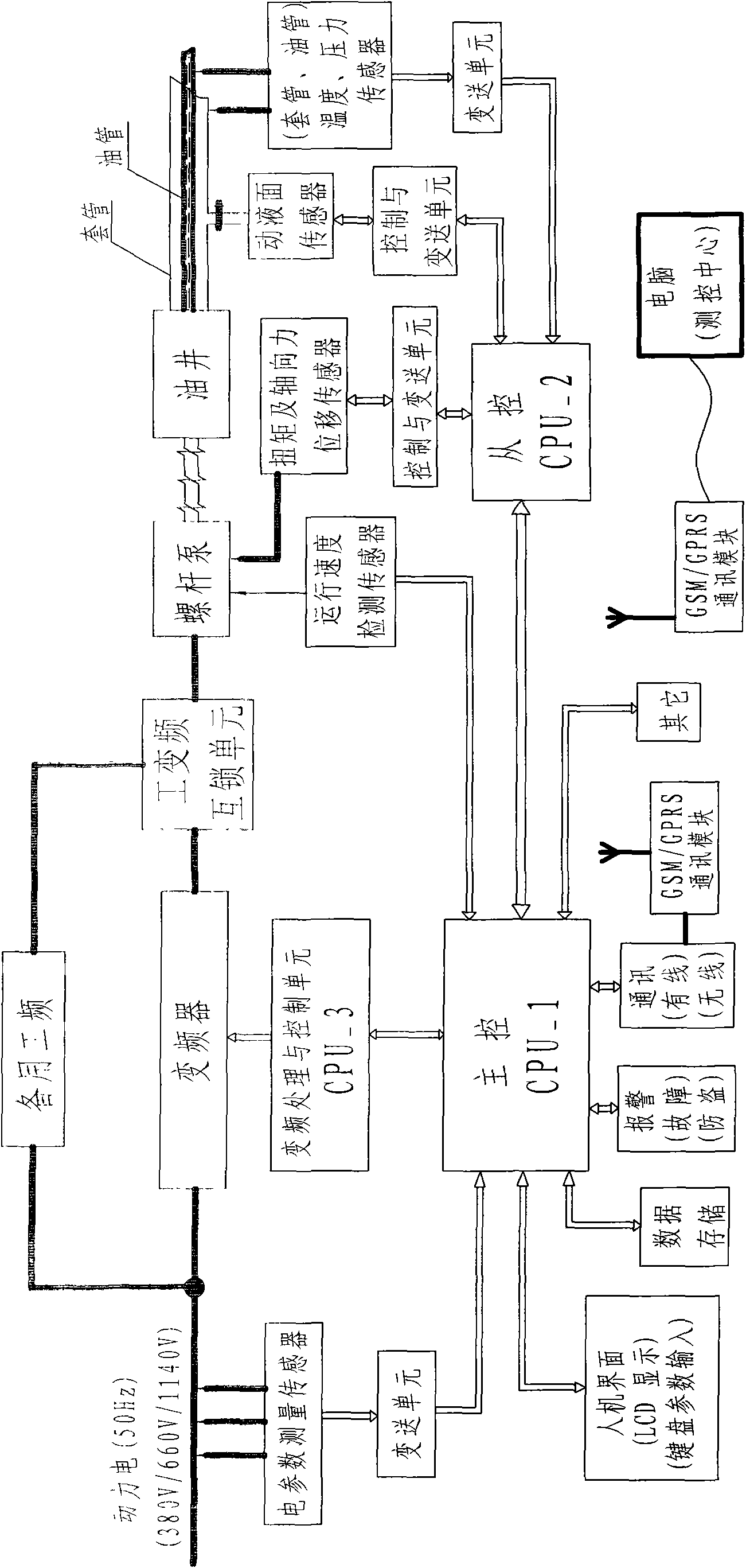

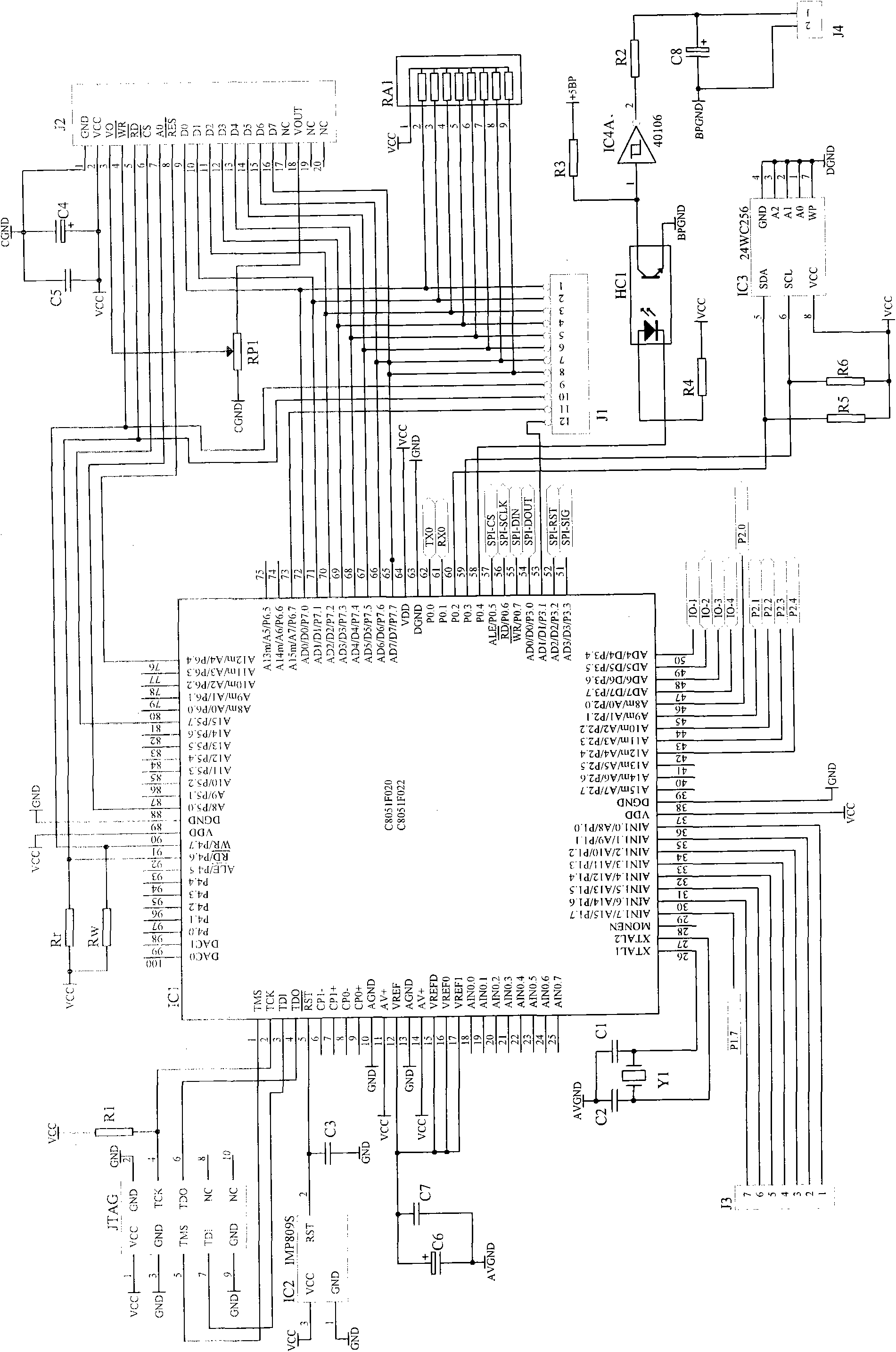

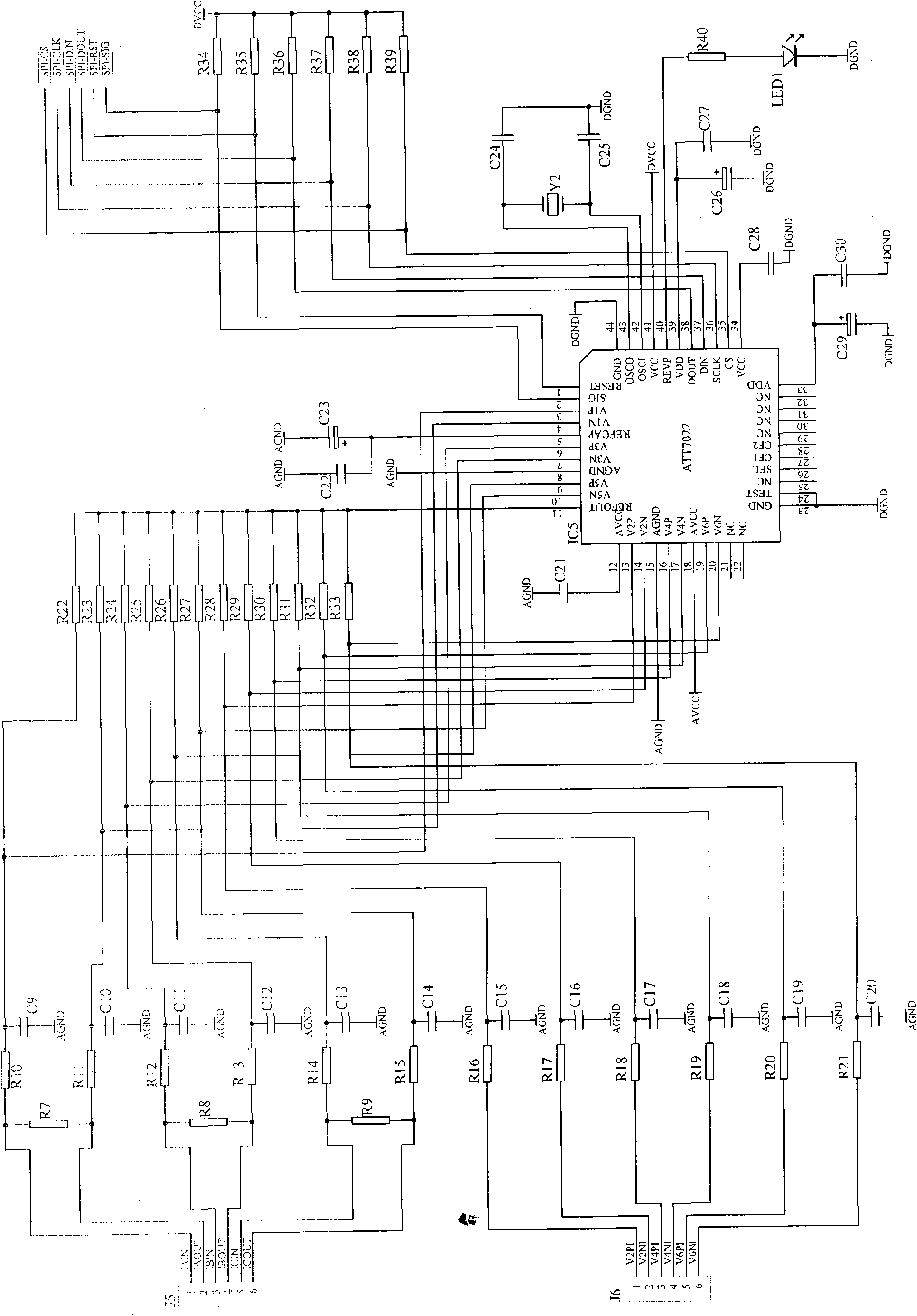

Intelligent monitoring device for screw pump well

InactiveCN101539135AMonitor work dataExtended service lifeFlexible member pumpsElectric controllersClosed loopEngineering

The invention relates to an intelligent monitoring device for a screw pump well, which is a high-performance industrial control device combined with optical, mechanical and electronic integration and electronic information and communication technology, and is mainly used for intelligently monitoring oil extraction of the screw pump well in oil field. The intelligent monitoring device mainly comprises a light current part and a strong current part, and is characterized in that the intelligent monitoring device takes connection of parts such as a sensor capable of measuring dynamic liquid level of the screw pump well on line, a sensor capable of measuring the torque and axial force of the screw pump well on line, a sensor capable of measuring electricity using parameters such as running current constantly and a remote wireless communication device and the like with a CPU as a core to realize the effective measurement and intelligent closed-loop control of the screw pump well. The intelligent monitoring device can avoid pump burning phenomenon of a screw pump caused by evacuation through accurate measurement and effective monitoring and dispatching, scientifically make a hot washing system according to wax deposition cause and the like to avoid phenomena such as rod breakage and the like, find eccentric wear problem in time to prolong pump detection cycle, and optimize design of the screw pump well to reasonably determine working parameters and reduce potential safety hazard and the like.

Owner:王洪亮 +1

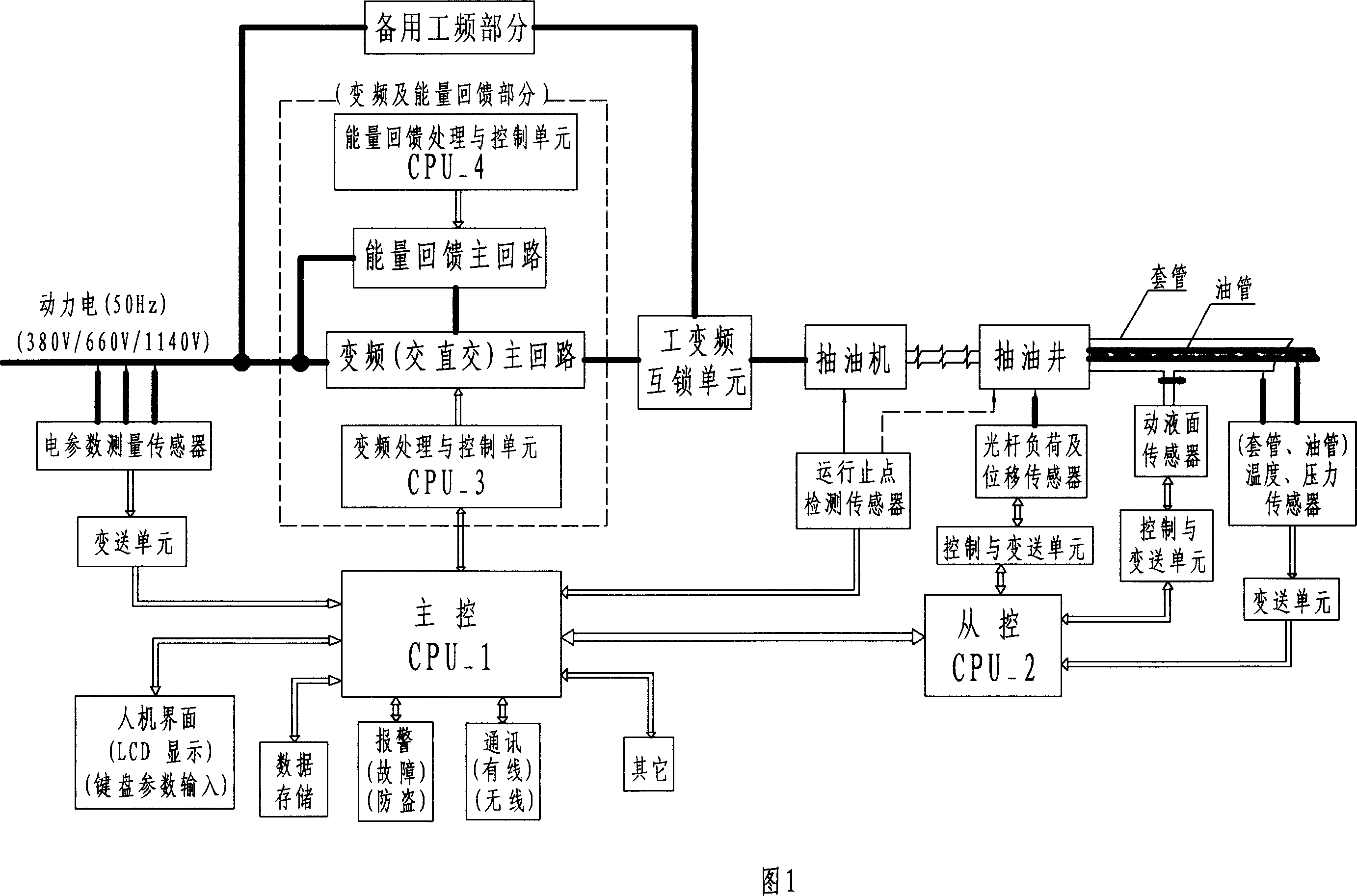

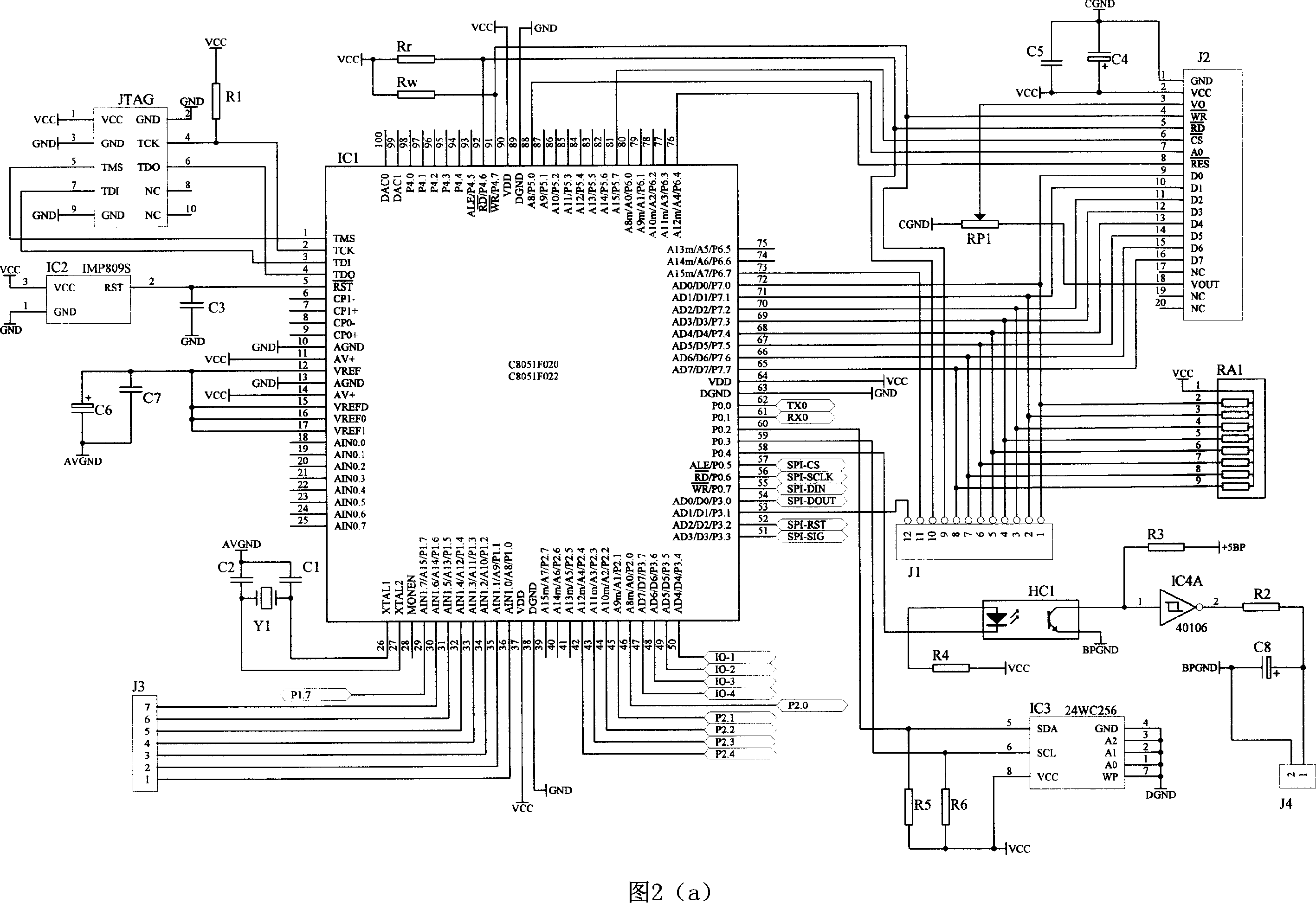

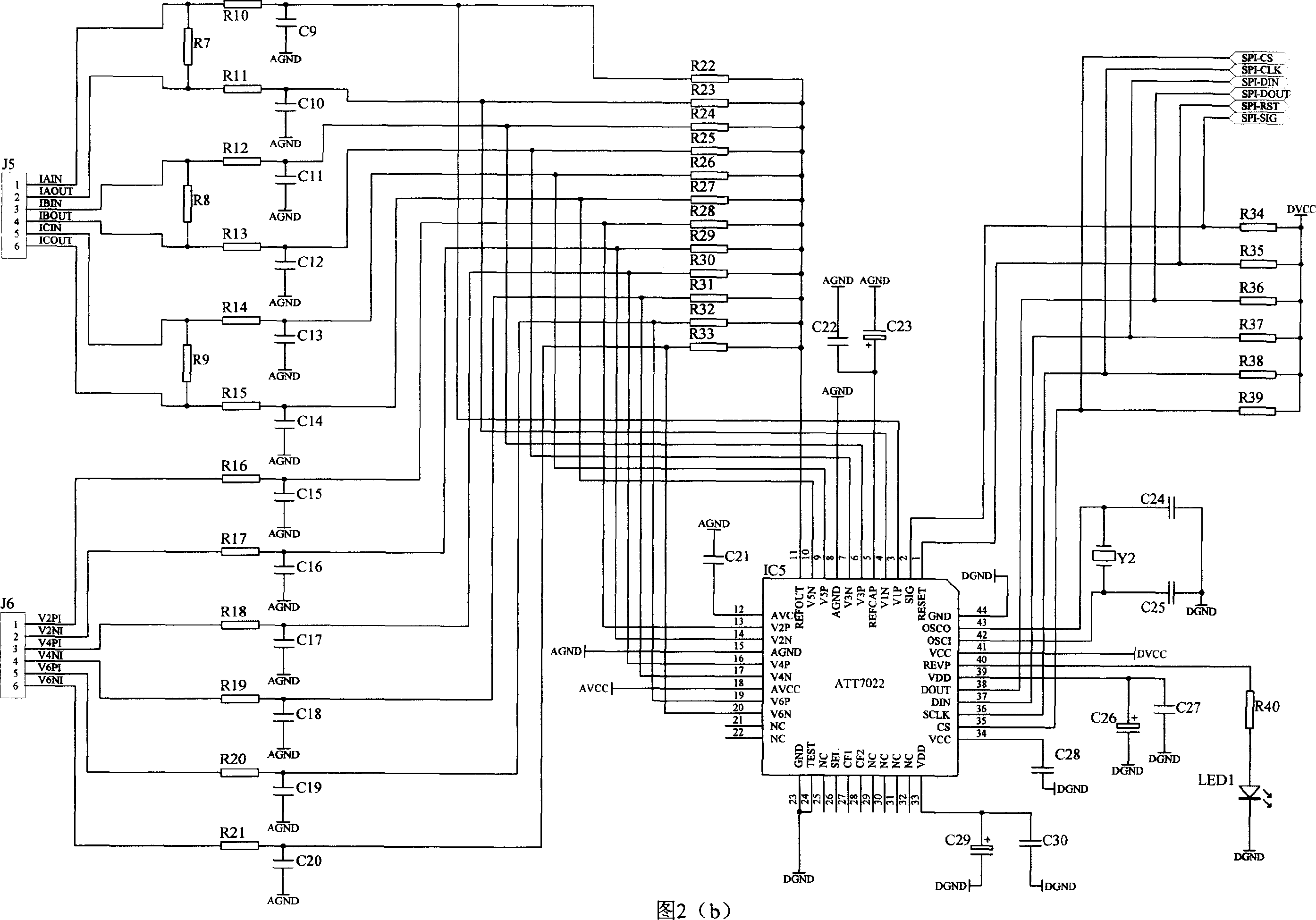

Smart synergetic controller for oil pump

InactiveCN1978865ARealize artificial intelligenceRealize automatic controlComputer controlFluid removalClosed loopPower grid

The invention relates to pumping unit intelligent multiplier controller. It mainly includes light and strong current parts. Its feature is that dynamic liquid level transducer and polished rod load and displacement transducer are connected with the CPU to realize exact closed-loop control for the pumping well. The light current part includes main control CUP and controlled CPU; the strong current part includes energy feedback, stand by power frequency, and power frequency conversion interlocking parts. The invention can increase pumping well system efficiency, realize its energy saving and consumption reducing, increase both production and income, input-output ratio, and economic benefit, can be suited for oil field electric network specificity and pumping well variability.

Owner:王洪亮 +1

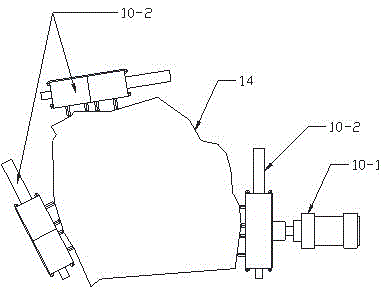

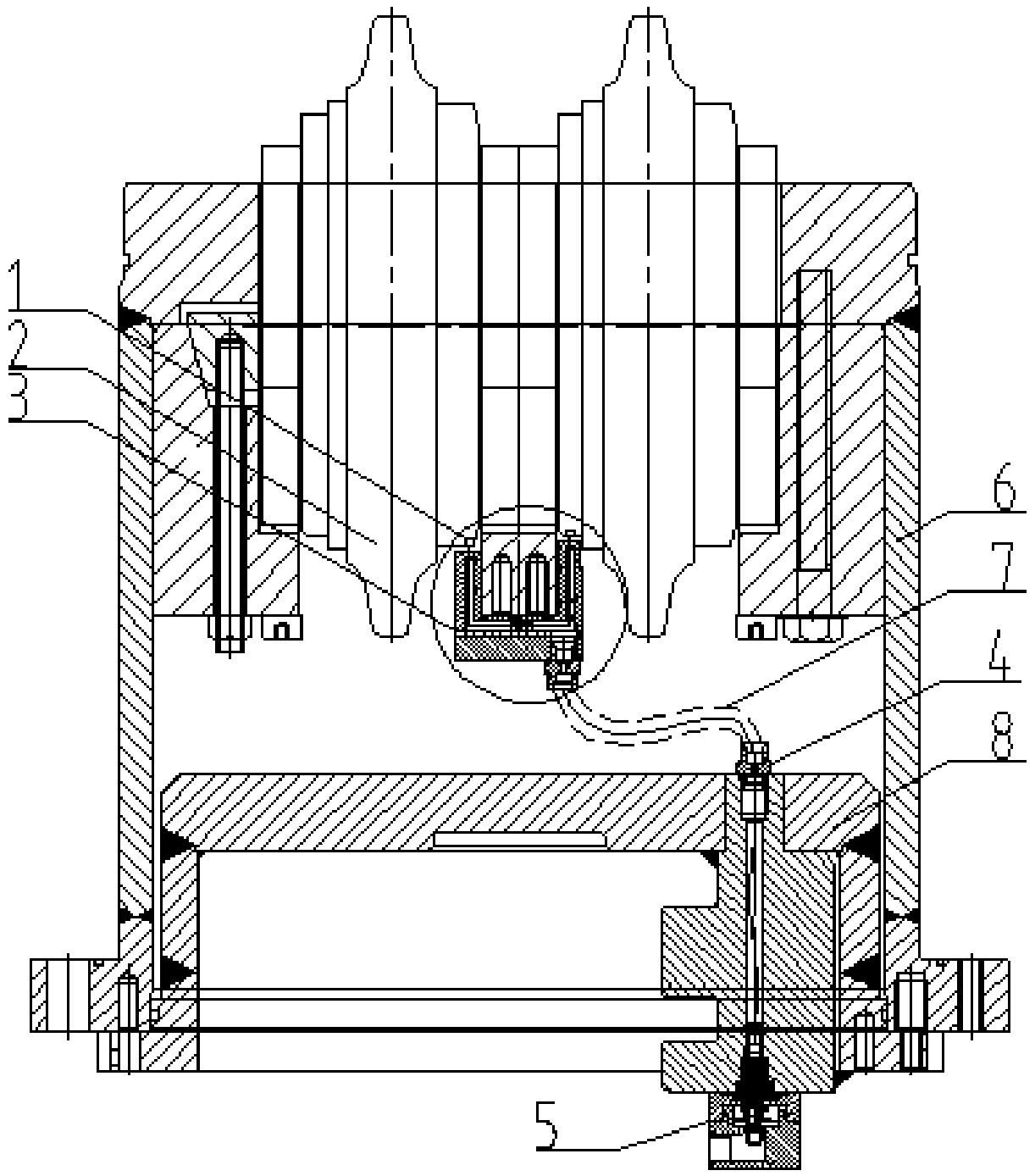

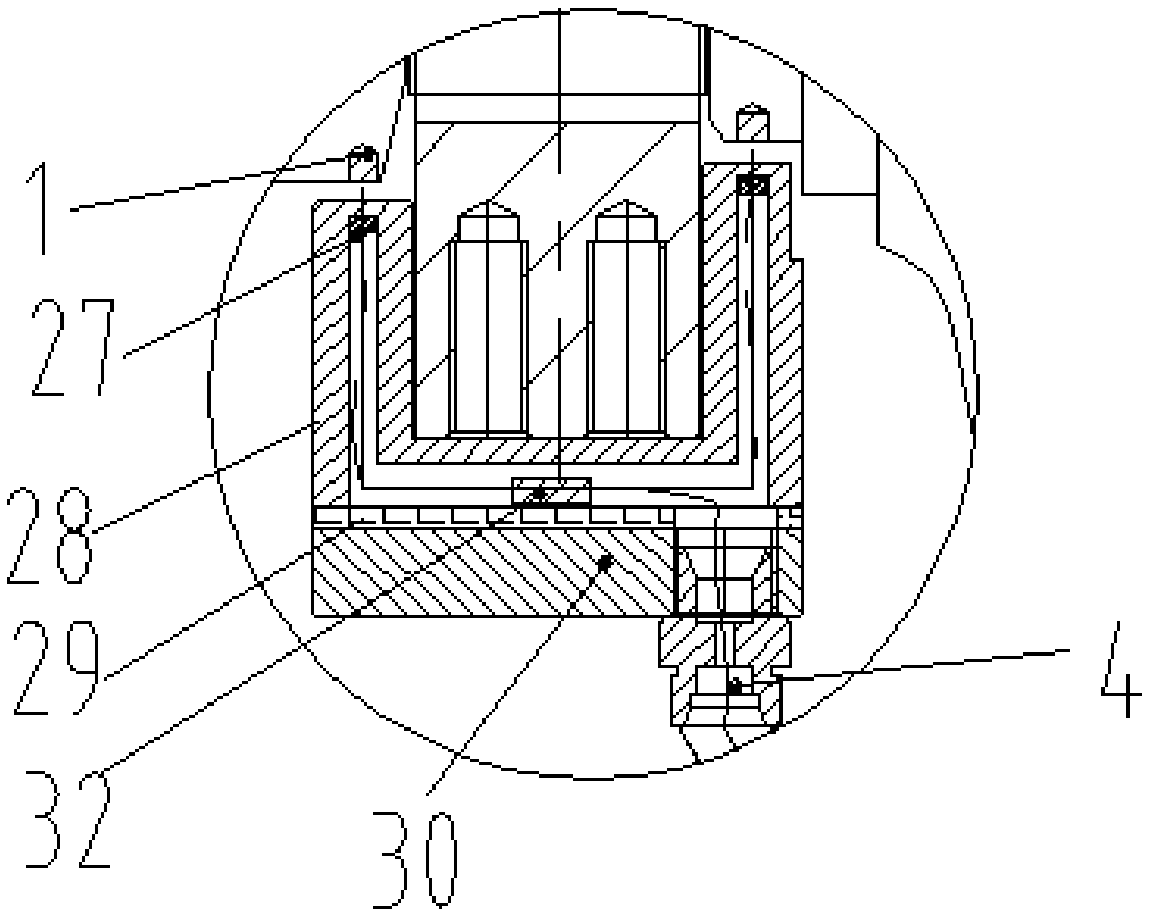

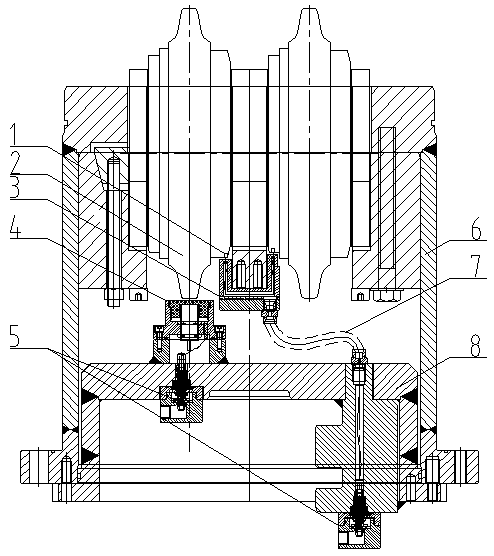

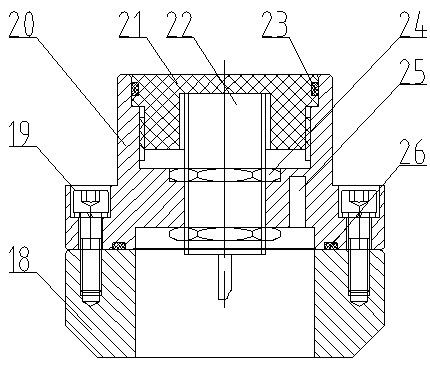

Normal pressure cutterhead hob rotating speed and temperature measurement device and wear extent measurement method

ActiveCN108181484AAchieve connectionRealize visual managementThermometer detailsTemperature measurement of moving solidsFour quadrantsEngineering

The present invention provides a normal pressure cutterhead hob rotating speed and temperature measurement device and a wear extent measurement method which solve the problem that the state monitoringof the wear extent of a hob in a normal pressure cutter cannot be carried out. Four induction magnets are arranged on a cutter ring of the hob uniformly, and a rotating speed sensor is arranged rightbelow the hob and measures the actual rotating speed of the hob. The four induction magnets separate the cutter ring of the hob into four quadrants uniformly, according to the current actual rotatingspeed of the hob, the time that the hob rotates 1 / 4 circle is calculated, the wear value of the cutter ring when the hob rotates is calculated, and according to the wear value of the cutter ring, andby utilizing a third-order Bezier curve, a hob contour wear curve is fitted, thereby obtaining the hob contour wear extent. The normal pressure cutterhead hob rotating speed and temperature measurement device and the wear extent measurement method of the present invention realize the visual management of all hob wear extents and the rotating speed on a cutterhead, at the same time, help a shielddriver to determine whether the cutterhead cutter needs to be replaced or maintained, also can help the driver to correct the tunneling parameters better to improve the tunneling efficiency, help to reduce the manpower consumption and the working risk, and also enable the tunneling efficiency to be improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

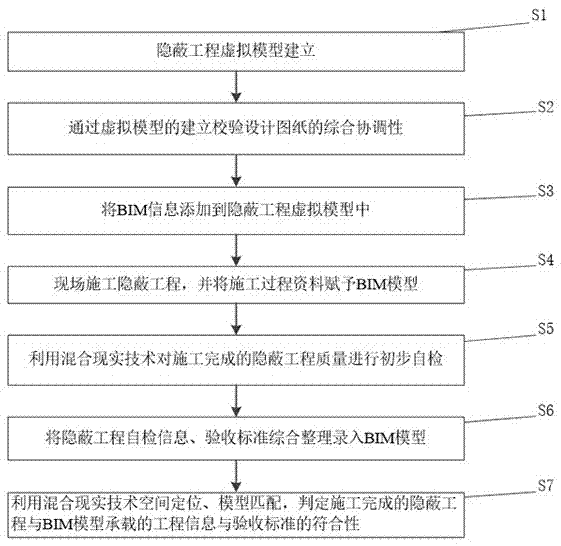

Hidden project acceptance method based on mixed reality technology

InactiveCN107229777AImprove efficiencyLow comprehensive costGeometric CADOffice automationBuilding information modelingMixed reality

The invention discloses a hidden project acceptance method based on a mixed reality technology. The method comprises the steps of S1, establishing a hidden project virtual model; S2, verifying comprehensive coordination of a design drawing through establishment of the virtual model; S3, adding BIM (Building Information Modeling) information into the hidden project virtual model; S4, constructing a hidden project on the site, and endowing a BIM model with a construction process document; S5, carrying out preliminary self-inspection on the quality of the constructed hidden project by use of the mixed reality technology; S6, comprehensively arranging and inputting the self-inspection information and an acceptance standard of the hidden project into the BIM model; and S7, determining the conformity between the constructed hidden project and the project information and the acceptance standard which are borne by the BIM model by use of the mixed reality technology. The hidden project acceptance method based on the mixed reality technology which is provided by the invention is reasonable in procedure and convenient to operate; and the mixed reality technology and the BIM technology are combined, the acceptance efficiency of the hidden project is improved, the comprehensive cost is reduced, and thus the method has broad market prospects and promotional values.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

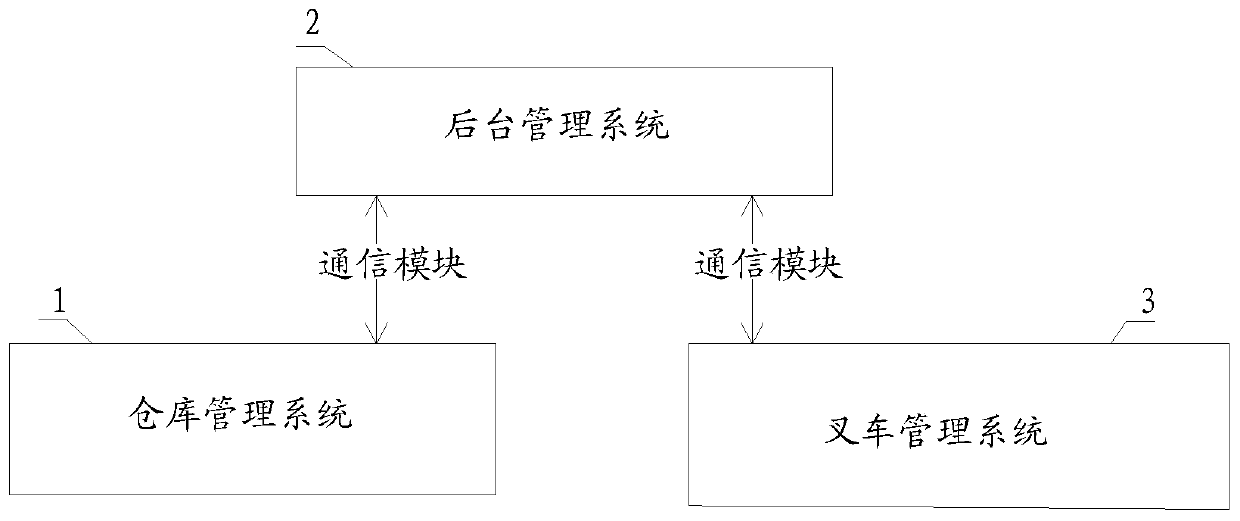

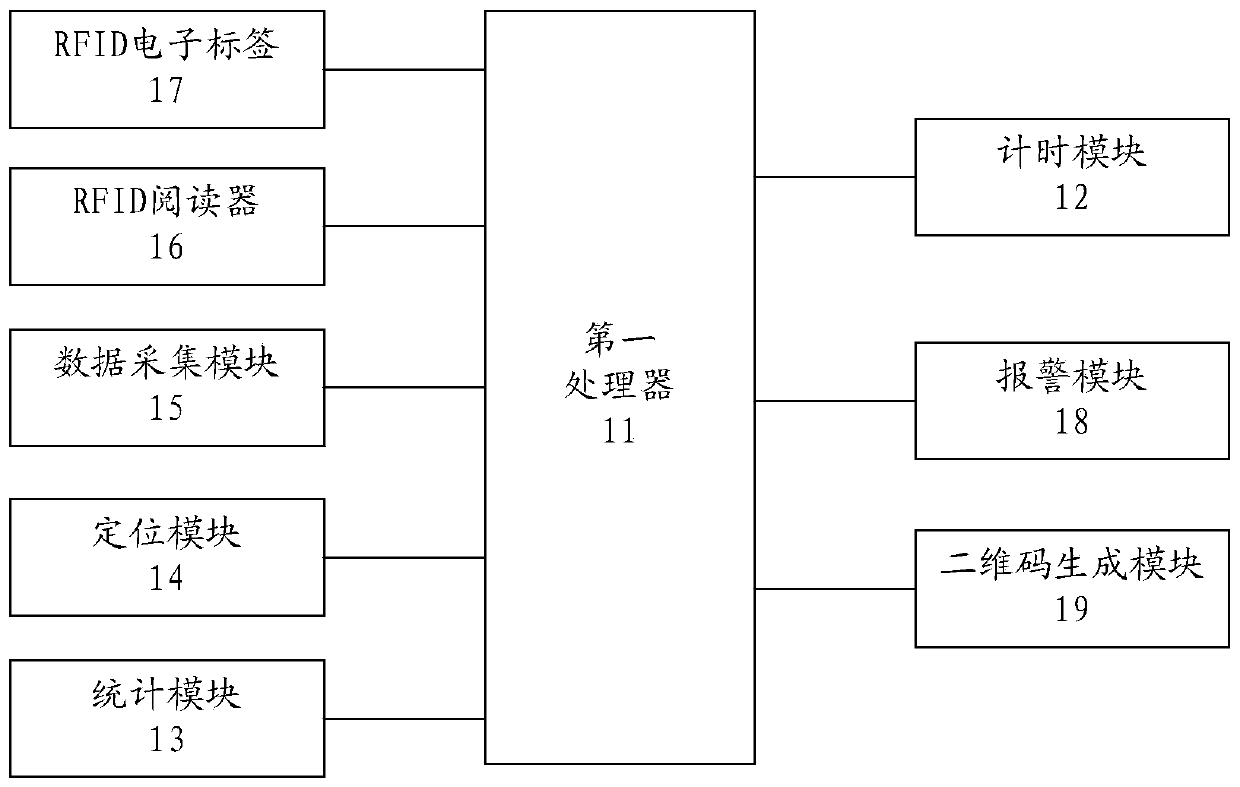

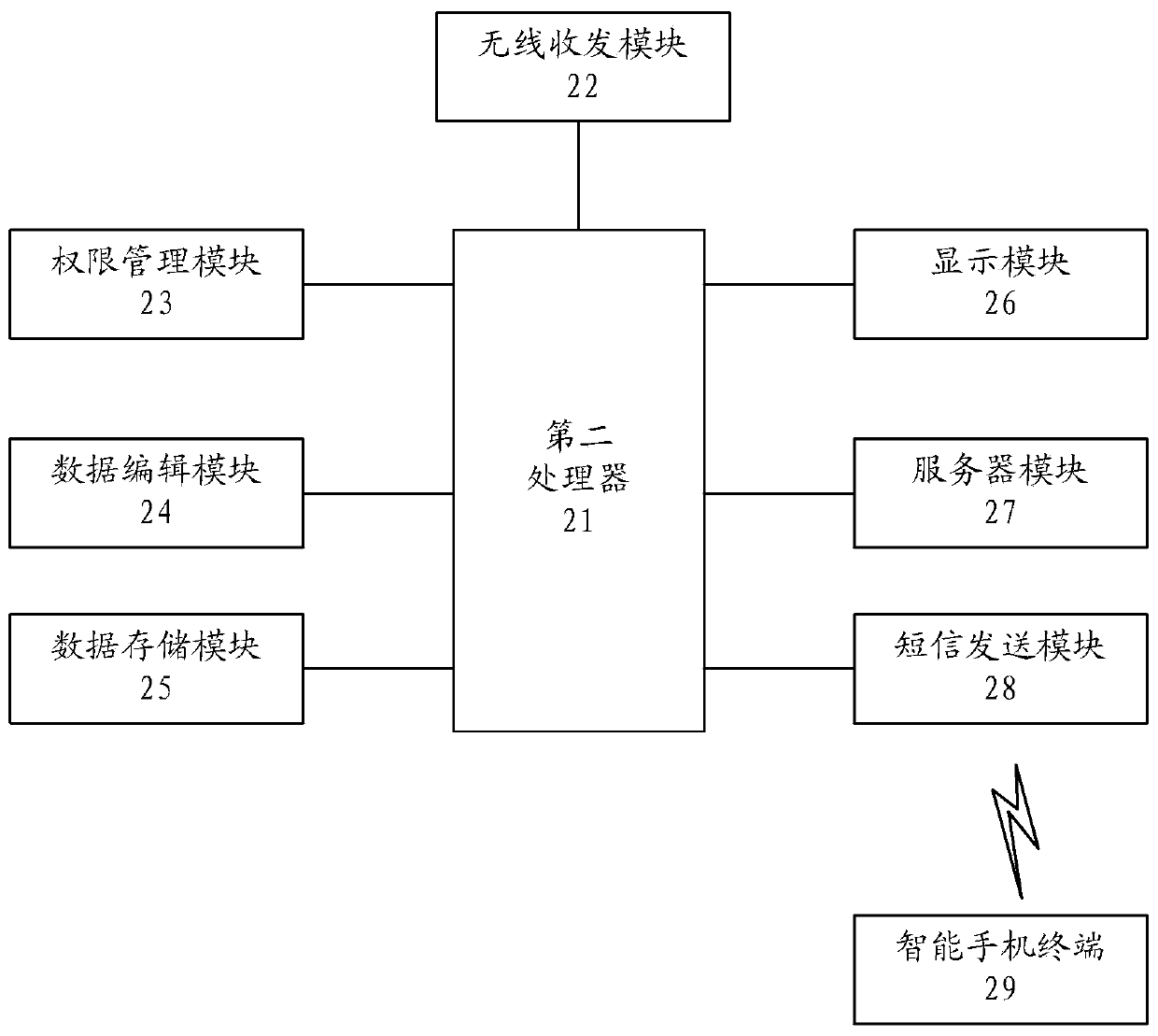

Warehousing system based on radio frequency technology, and control method

PendingCN111539668AEasy to viewSafe and quick placementCo-operative working arrangementsLogisticsManagement systemOperations research

The invention discloses a warehousing system based on a radio frequency technology, and a control method. The system is applied to a warehouse comprising a plurality of goods allocations and a plurality of transportation paths, and comprises a background management system, a warehousing management system and a forklift management system. The background management system is used for receiving and storing commodity warehouse-in and warehouse-out information, storing the commodity allocation information and judging whether the quantity data and the size data of the commodity allocation information meet the requirements of the commodity warehouse-in and warehouse-out information on commodity allocations or not; the warehouse management system is used for collecting the number of warehouse-in commodity allocations, warehouse-in time and commodity allocation information. The forklift management system is used for reading the navigation information of the forklift path navigation module arranged on the transportation path, planning the path according to the commodity information stored in radio frequency tags in the carried commodities, and sending out a navigation prompt according to theplanned path and the navigation information. According to the technical scheme, inherent defects of personnel management can be avoided, so that commodities can be safely and quickly placed in correct commodity allocations, and the commodity allocations are prevented from being moved by mistake.

Owner:GUANGDONG POWER GRID CO LTD +1

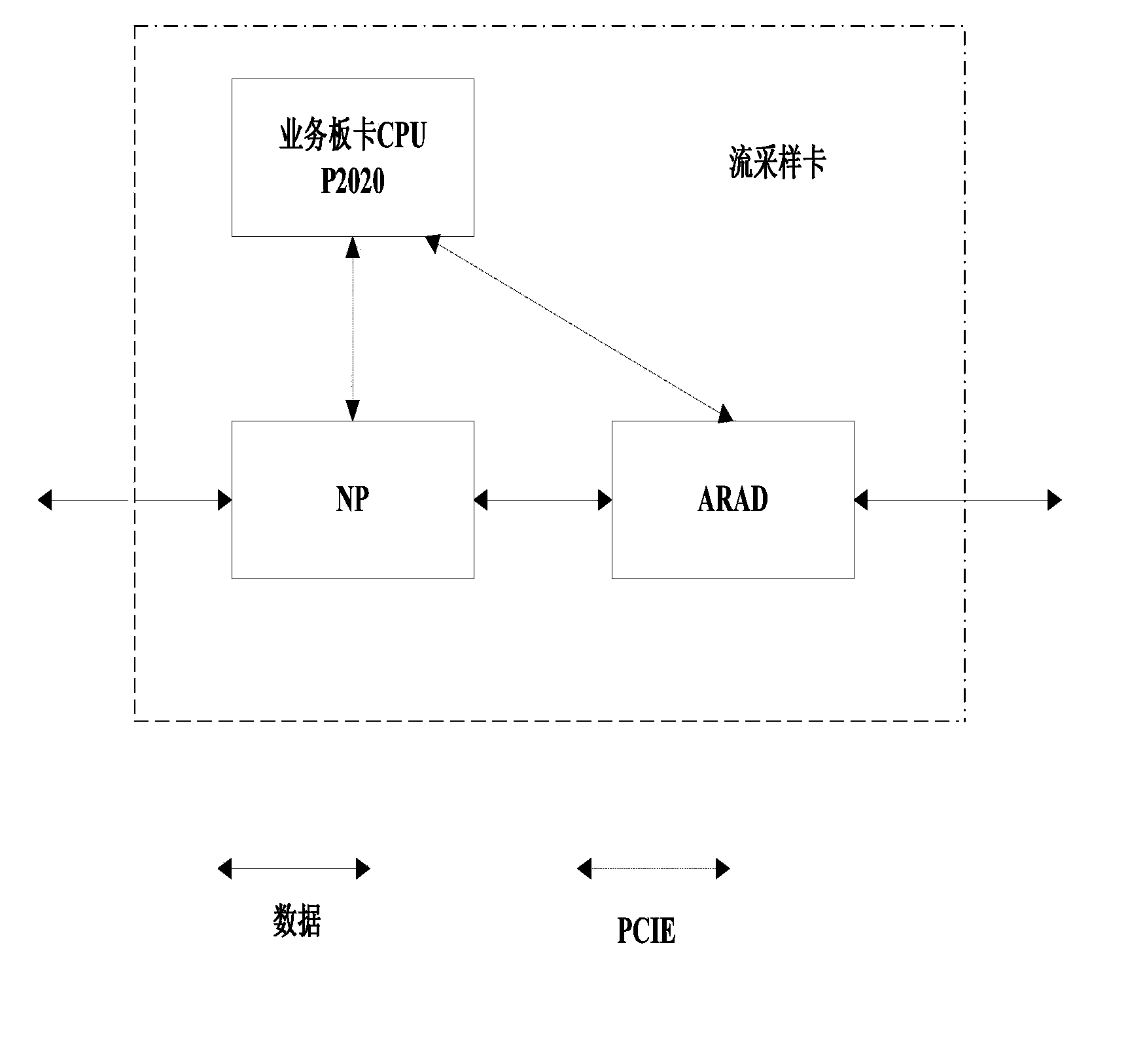

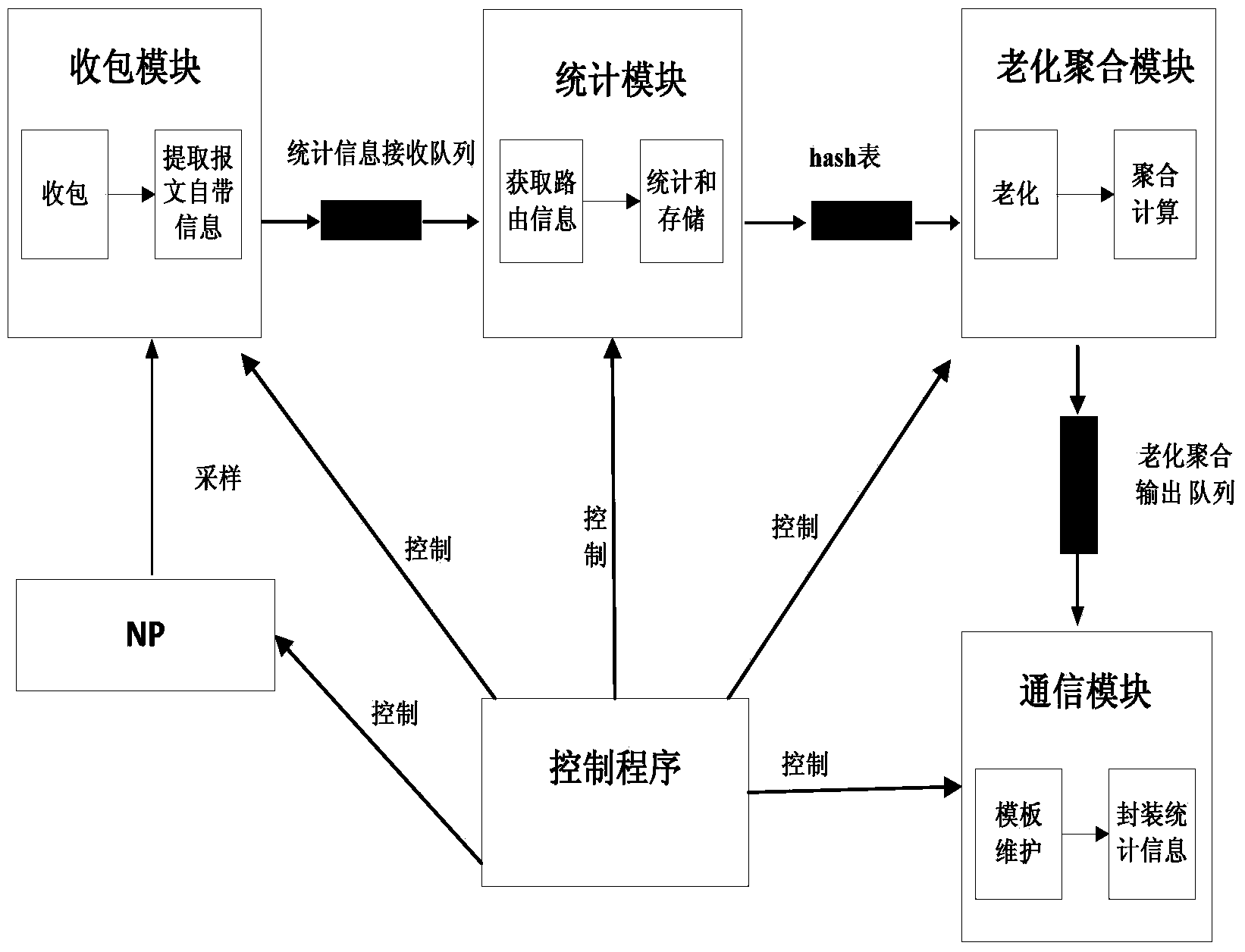

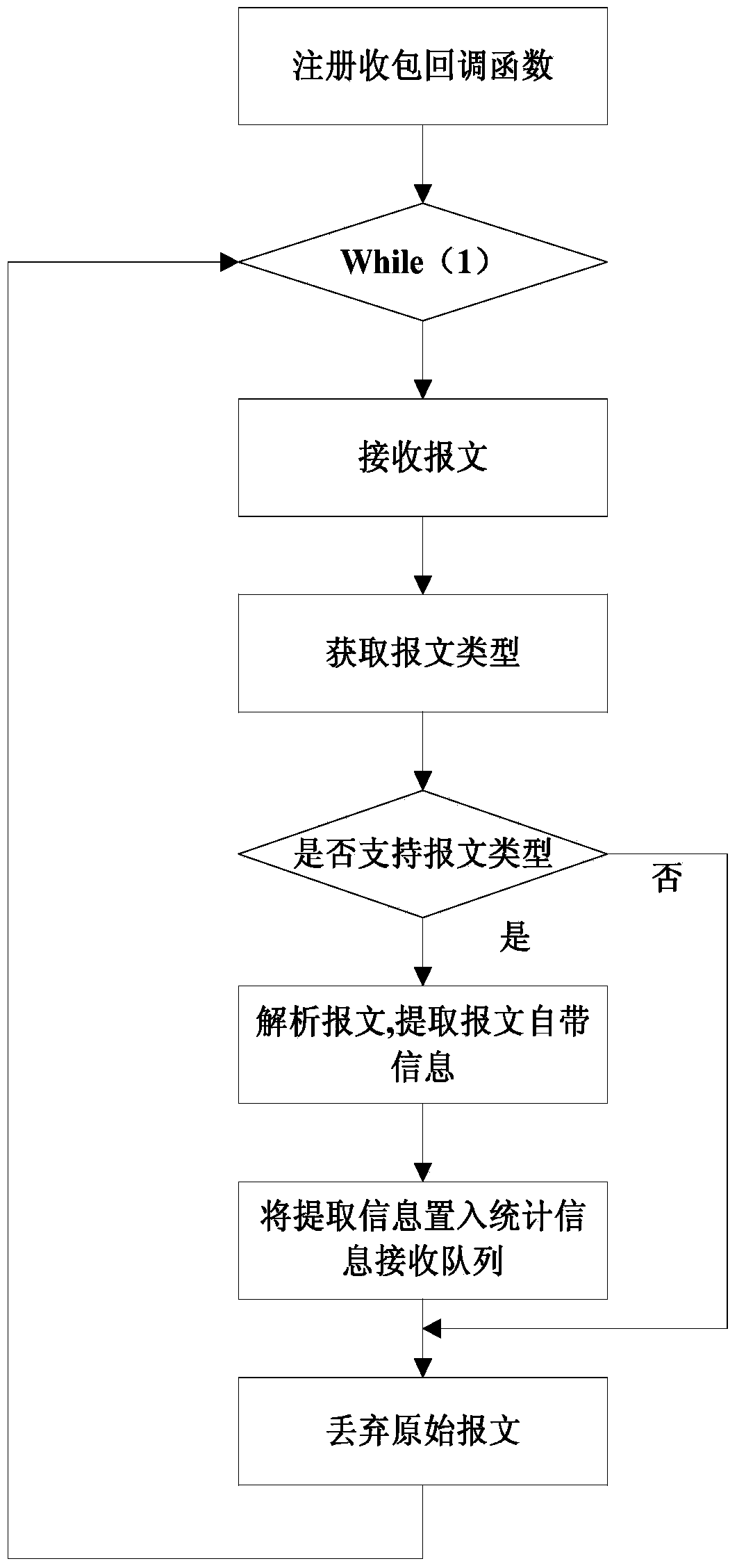

IP stream information statistical method for charging and monitoring

InactiveCN103414594AAccurately grasp the running statusDetect anomalies in real timeData switching networksTraffic capacityData stream

The invention relates to an IP stream information statistical method for charging and monitoring. Flow statistical analysis is carried out on an IP data packet through a stream sampling module to obtain original, detailed and basic IP data streams flowing through a port, and the flow statistical analysis comprises message analysis, message information statistics, statistical information aging and collection and statistical information output. The stream sampling module is arranged in a common service board card, and comprises four submodules, namely, a packet collecting module, a statistical module, an aging and collection module and a communication module. The IP stream information statistical method can accurately grasp a network operating state, provides the accurate information of network flow in real time, can find and process network abnormal conditions in real time, can allow management and the charging for service application, helps network administers to carry out network planning, network monitoring and flow trend analysis, and achieves network visualization management.

Owner:FENGHUO COMM SCI & TECH CO LTD

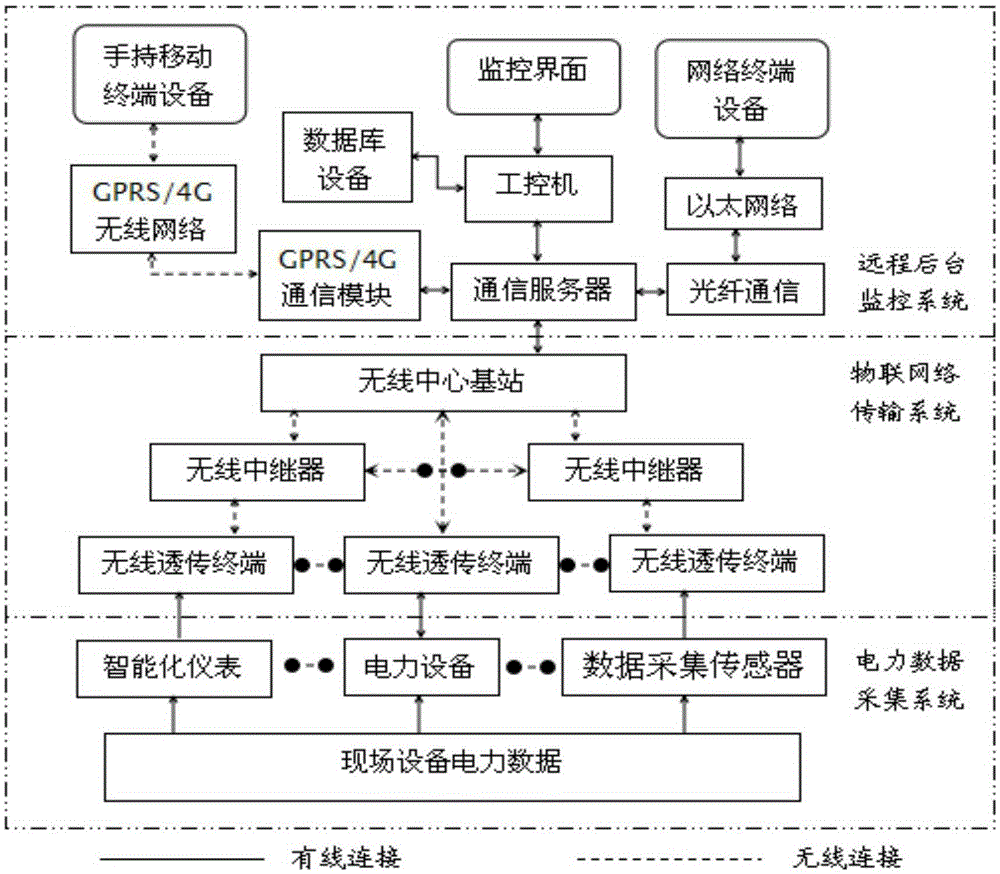

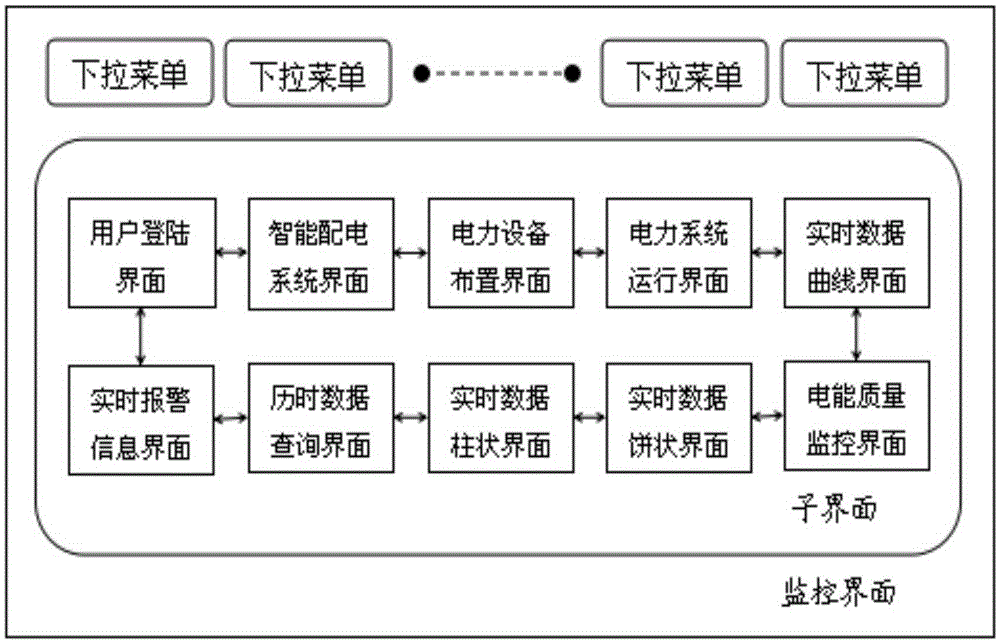

Intelligent power supply and distribution management system based on Internet of things

InactiveCN105337422AImprove efficiencyLow costCircuit arrangementsNetwork terminationDistribution power system

The invention discloses an intelligent power supply and distribution management system based on the Internet of things, and aims at replacing a traditional power supply and distribution system to achieve wirelessness, networking and intellectualization of power supply and distribution management. The intelligent power supply and distribution management system based on the Internet of things comprises three subsystems of a power data collection system, an Internet of things transmission system and a remote background monitoring system. The power data collection system is composed of power equipment, an intelligentized instrument and a data collection sensor, the Internet of things transmission system is composed of wireless passthrough terminals, wireless repeaters and a wireless center base station, and the remote background monitoring system is composed of an industrial personal computer monitor, a mobile terminal monitor and an Ethernet network monitor. The industrial personal computer monitor is composed of an industrial personal computer, a monitoring interface, a communication server and a database device, the mobile terminal monitor is composed of a GPRS / 4G communication module, a GPRS / 4G wireless network and a hand-held mobile terminal device, and the Ethernet network monitor is composed of optical fiber communications, an Ethernet network and a network terminal device.

Owner:王亲武

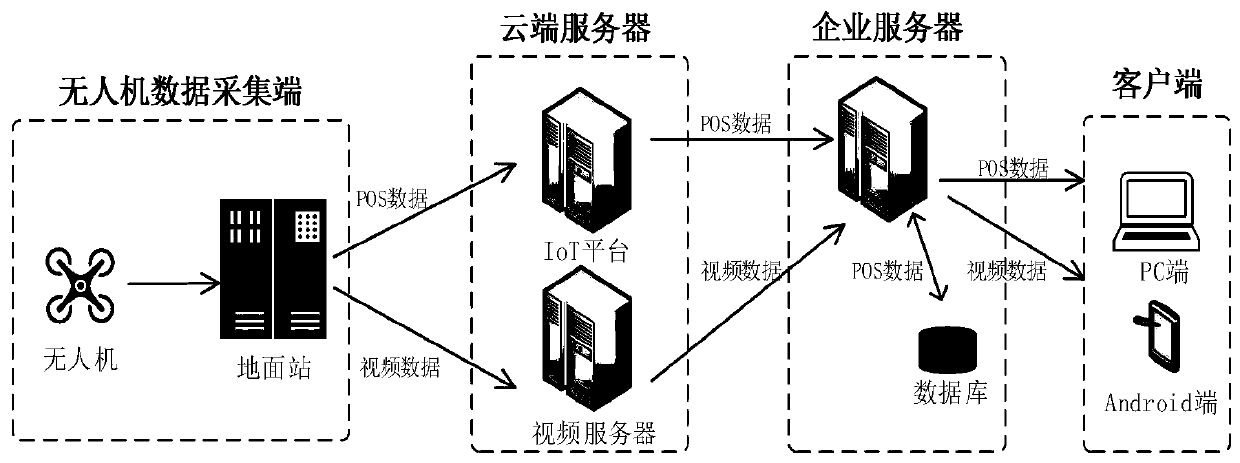

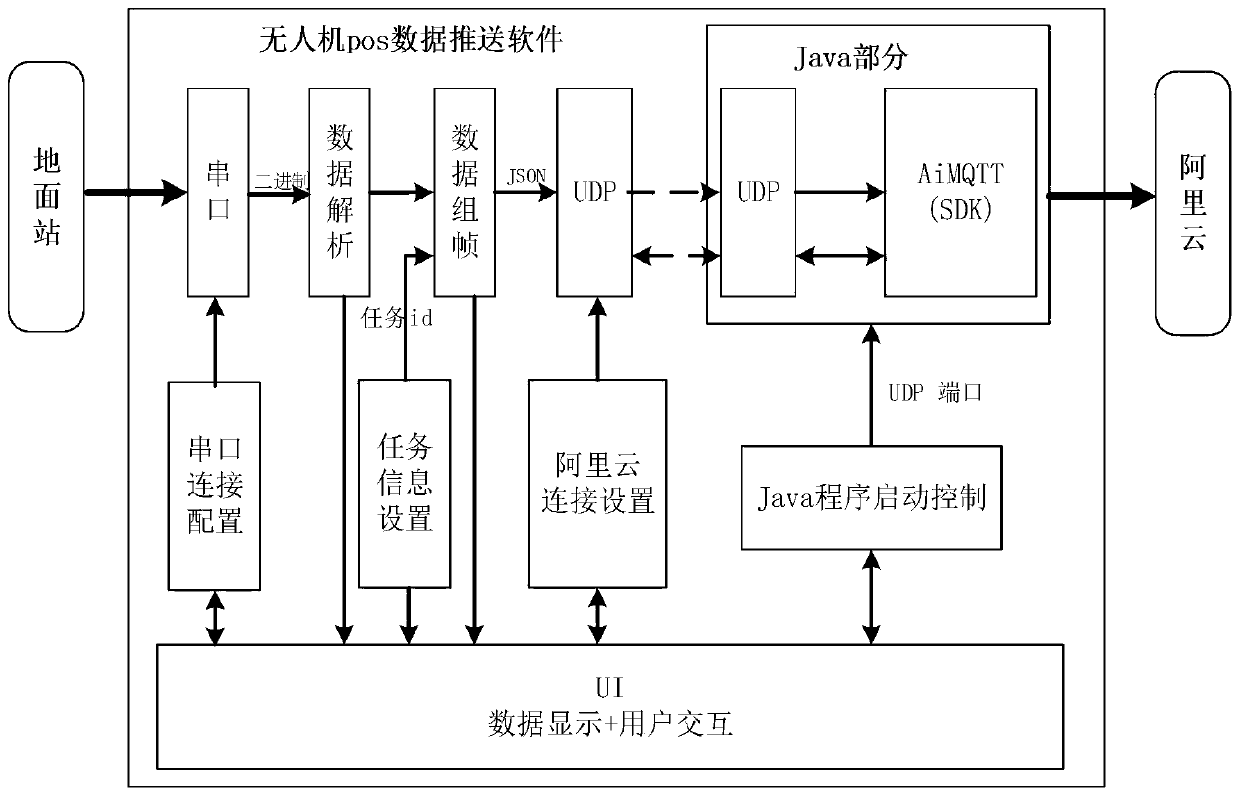

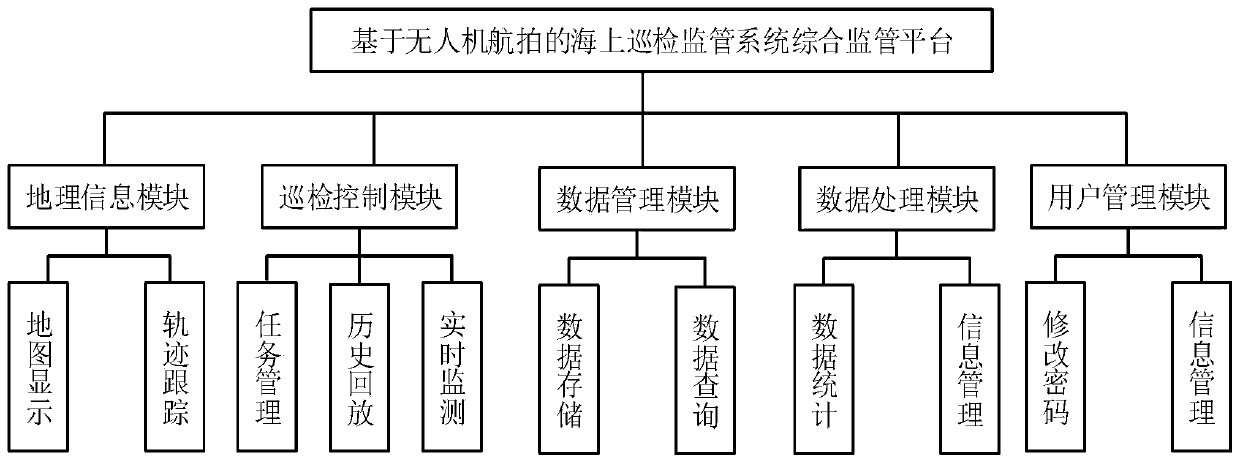

Offshore inspection supervision system based on unmanned aerial vehicle aerial photography

InactiveCN110866991AImprove practicalityFunction increaseChecking time patrolsClosed circuit television systemsData acquisitionInformation management

The invention discloses an offshore inspection supervision system based on unmanned aerial vehicle aerial photography. The system is composed of four main parts: an unmanned aerial vehicle data acquisition terminal, a cloud server, an enterprise server and a client. A PC client and an Android client form an unmanned aerial vehicle marine inspection comprehensive supervision platform. The functionsof data real-time access forwarding, geographic information management, trajectory tracking, aerial video live broadcasting, historical trajectory and video playback, data statistical analysis and emergency management, Android APP real-time supervision and the like of the marine inspection unmanned aerial vehicle can be achieved. The marine environment is supervised in real time through the unmanned aerial vehicle aerial photography, so the supervision range is wide, the inspection efficiency is high, the cost loss is small, and the problems that a traditional inspection system is short in inspection visual range, slow in response, poor in small ship supervision capacity, low in efficiency, not timely in dispatching and commanding and the like are solved.

Owner:BEIJING UNIV OF TECH

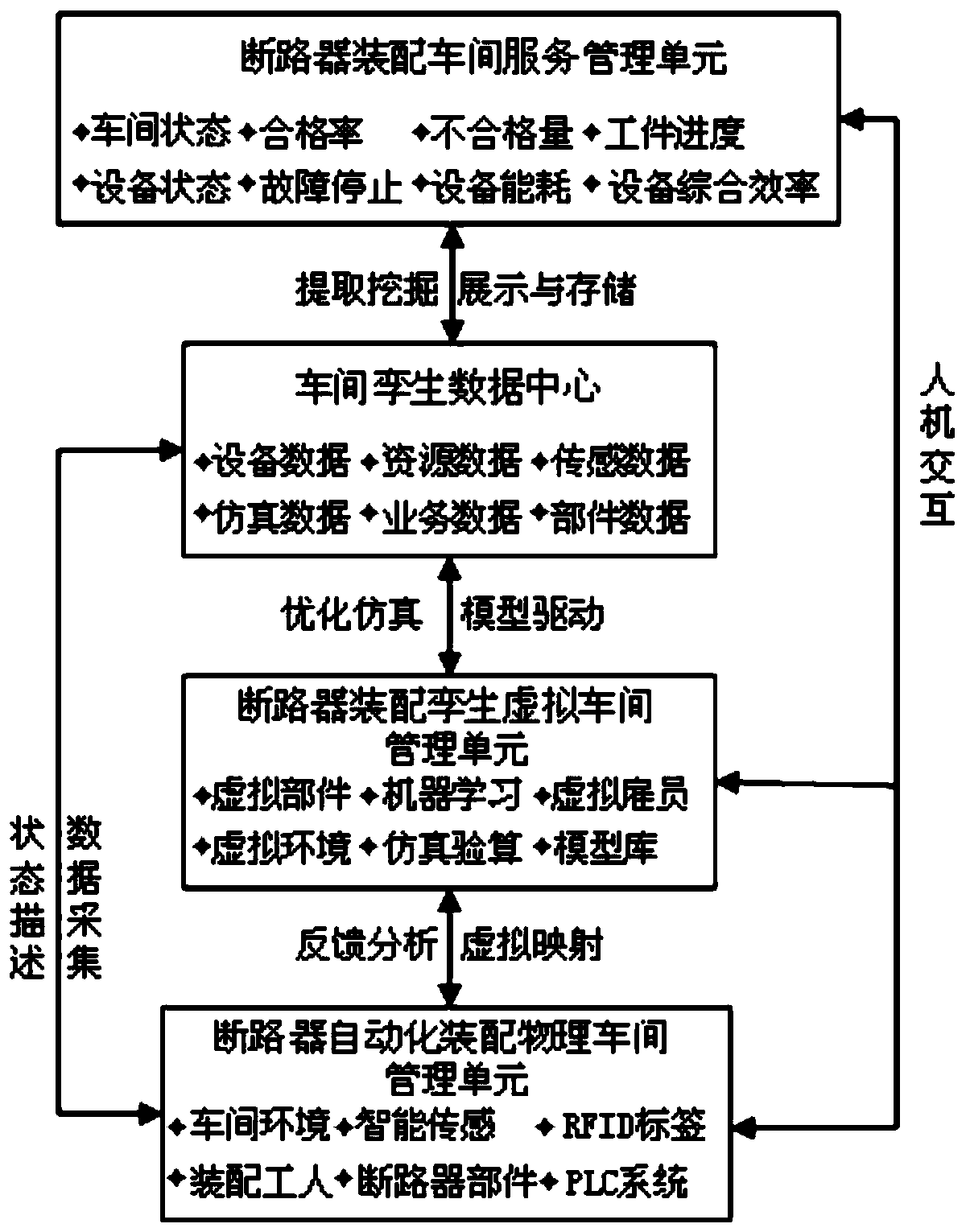

Management platform of circuit breaker automatic assembly digital twinning workshop

InactiveCN110989506AImprove production management levelRealize automatic controlTotal factory controlProgramme total factory controlAutomatic controlVirtual vehicle

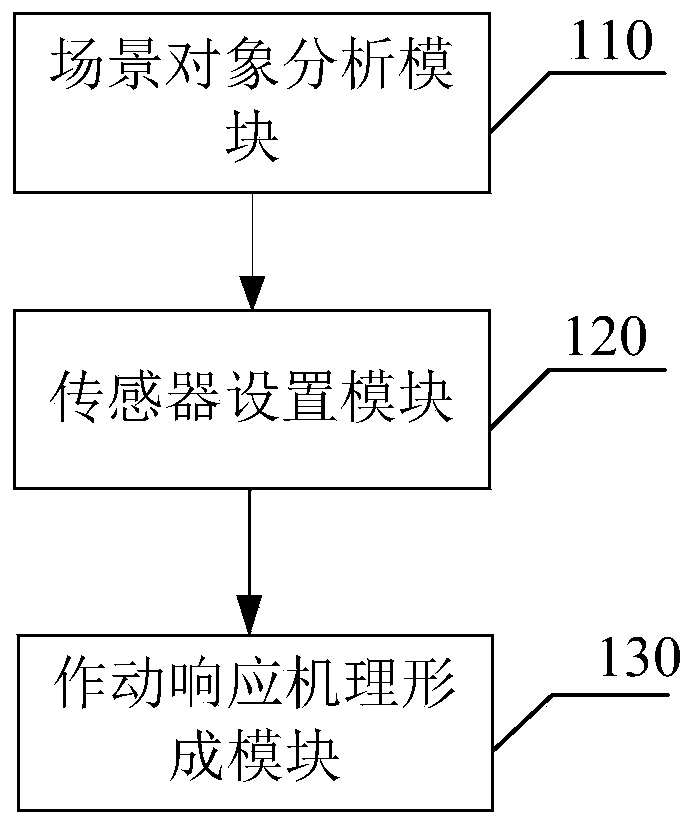

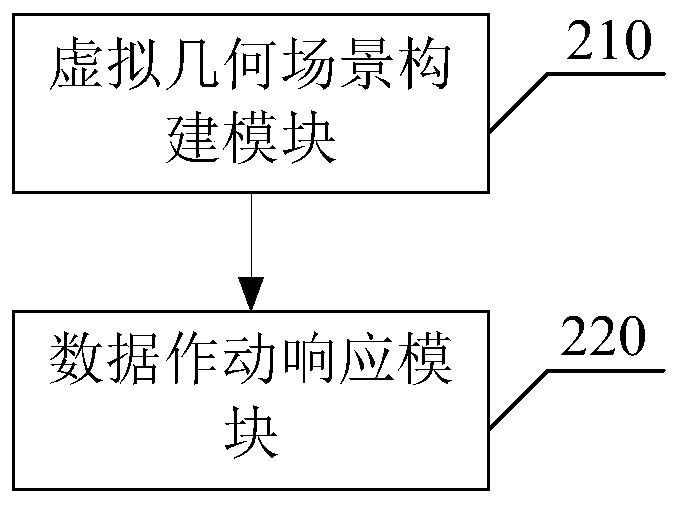

The invention provides a management platform of a circuit breaker automatic assembly digital twinning workshop. The management platform comprises a circuit breaker automatic assembly physical workshopmanagement unit, a circuit breaker assembly twinning virtual workshop management unit, a workshop twinning data center and a circuit breaker assembly workshop service management unit. The circuit breaker automatic assembly physical workshop management unit performs scene object analysis, sensor network configuration and actuation response. The circuit breaker assembly twin virtual workshop management unit performs virtual geometric scene construction and data action response control. The workshop twin data center stores twin data. The circuit breaker assembly workshop service management unitperforms networking communication, twinning data construction and physical workshop management unit management and monitoring. According to the invention, intelligent and visual management of production elements, workshop activity plans, workshop production processes and other elements of the circuit breaker automatic assembly workshop is realized, and automatic control, parameter visualization and real-time state monitoring of a physical entity workshop are realized.

Owner:WENZHOU UNIV

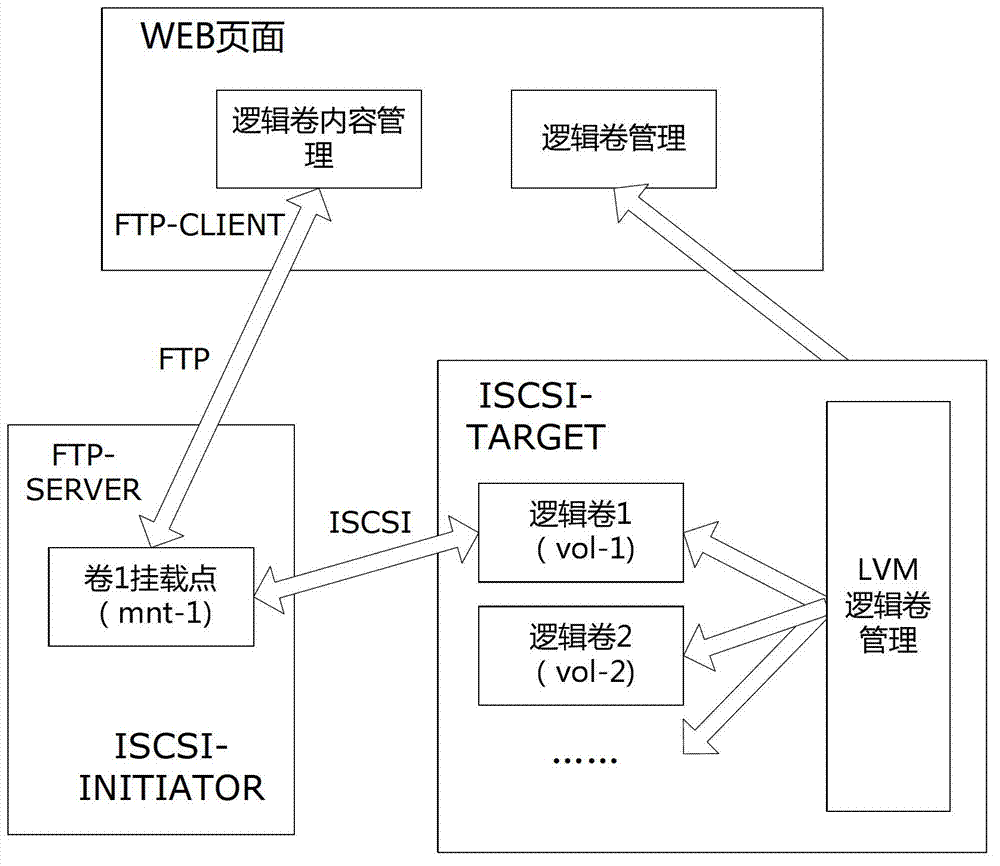

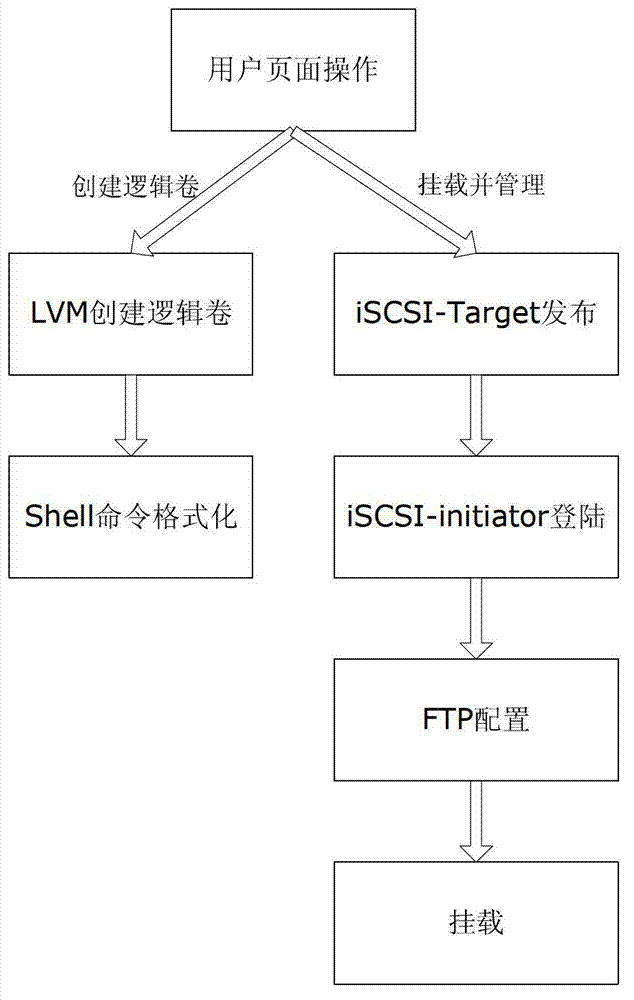

Logical volume management method

InactiveCN102833334AEfficient managementRealize visual managementTransmissionSoftware simulation/interpretation/emulationWeb serviceStorage management

The invention relates to the technical field of virtual disk management, in particular to a logical volume management method. According to the invention, a logical volume can be managed by means of a Web server, an LVM (Logical Volume Manager) functional module, an iSCSI (Internet Small Computer System Interface) functional module and an FTP (File Transfer Protocol) functional module; a user accesses the web server through a network; and the web server calls the LVM functional module, the iSCSI functional module or the FTP functional module to realize corresponding functions according to user operation. According to the logical volume management method disclosed by the invention, files in the logical volume are directly managed by using an FTP server, the problems of complexity and troublesomeness of managing the logical volume by executing a shell command are solved, and a user can operate self files more intuitionally. The logical volume management method disclosed by the invention can be widely applied to storage management of a cloud computing system.

Owner:GUANGDONG ELECTRONICS IND INST

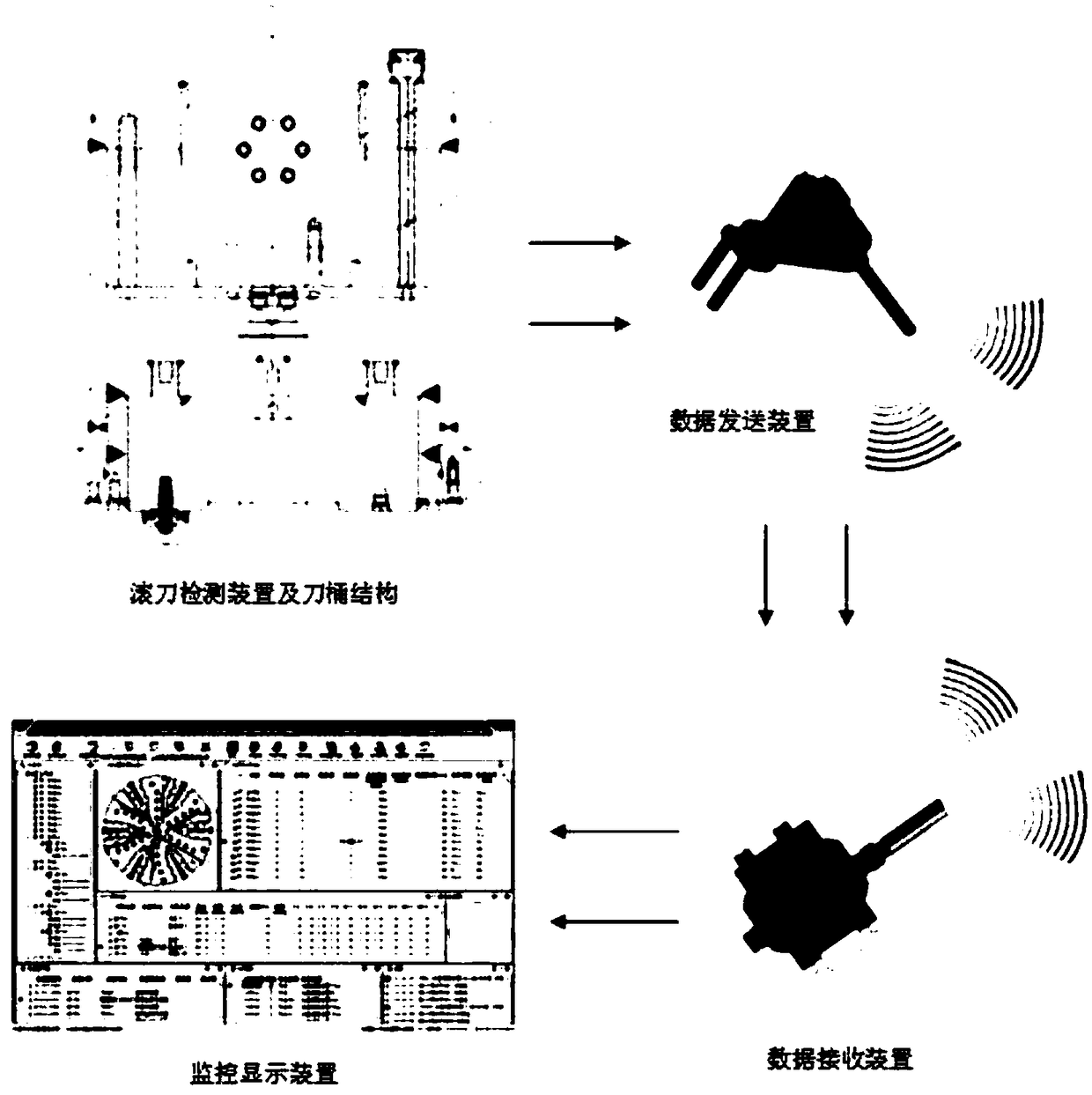

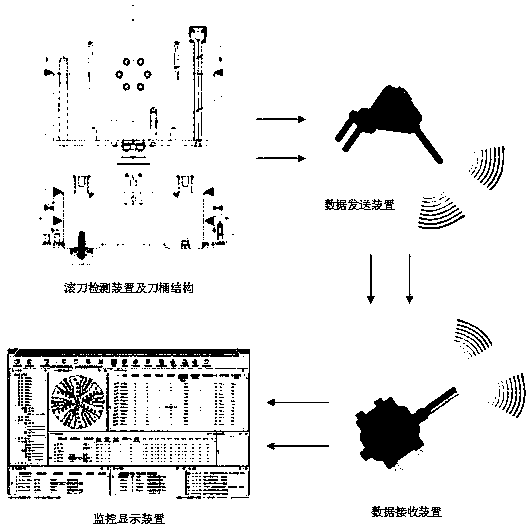

Cutter real-time monitoring system for normal pressure cutter replacement

PendingCN108387261AReliable tool change basisGood tunneling parametersMeasurement devicesTunnelsCondition monitoringEngineering

The invention provides a cutter real-time monitoring system for normal pressure cutter replacement to solve the problem that state monitoring cannot be carried out on a cutter in a normal pressure cutter replacement device. The system comprises a hobbing cutter detection device, a data sending device, a data reception device and a monitoring display device. The hobbing cutter detection device is arranged in a cutter cylinder of the hobbing cutter; the hobbing cutter detection device is connected with the data sending device; the data sending device is wirelessly connected with the data reception device; and the data reception device is connected with the monitoring display device. The system realizes visual management of wear extent and rotation speed of all hobbing cutters on a cutterhead, and helps a tunnel shield driver to judge whether the cutterhead and tool need replacing or maintaining, can also help the driver to better modify tunneling parameters to improve tunneling efficiency, helps to reduce manpower consumption and work risk and can also help to improve tunneling efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

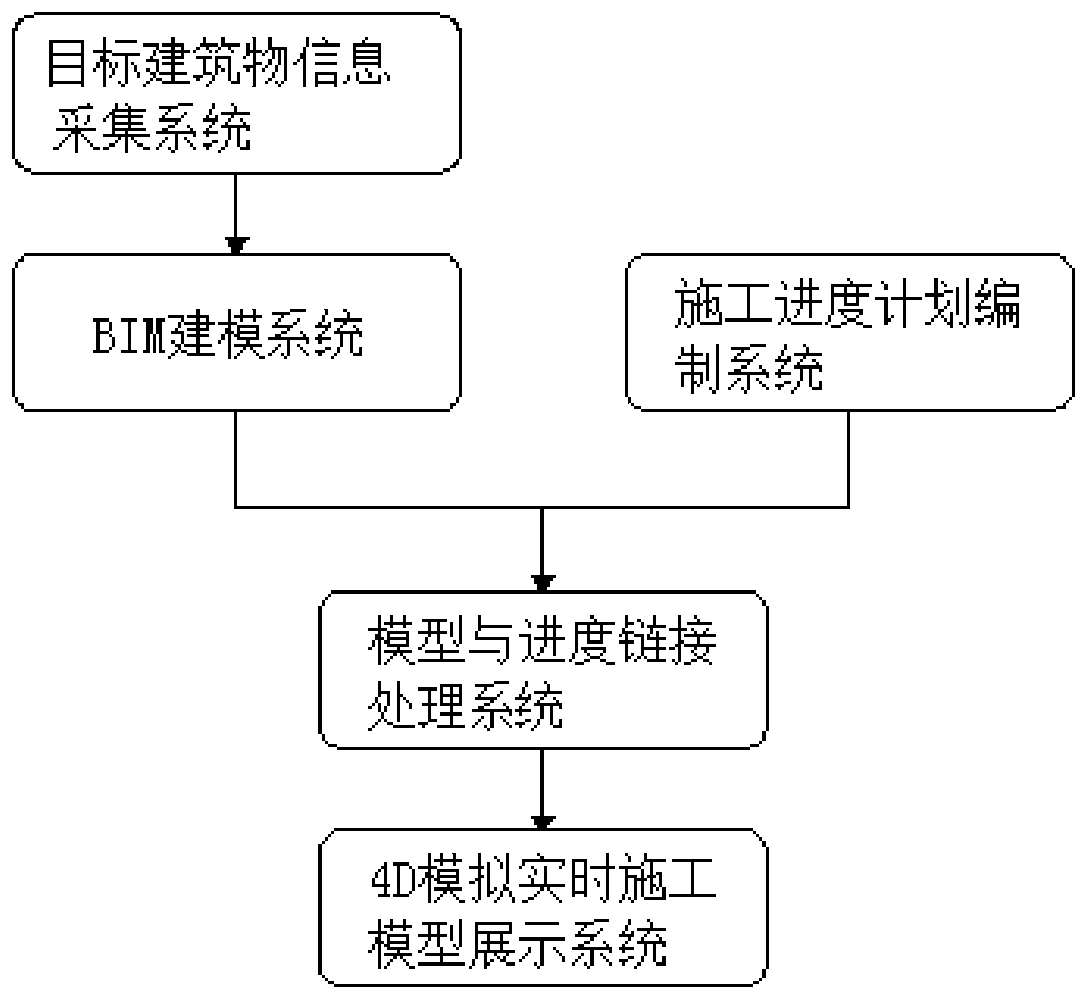

4D simulation system based on BIM real-time construction model

PendingCN110362904AAchieve integrationRealize visual managementGeometric CADResourcesInformatizationProgram planning

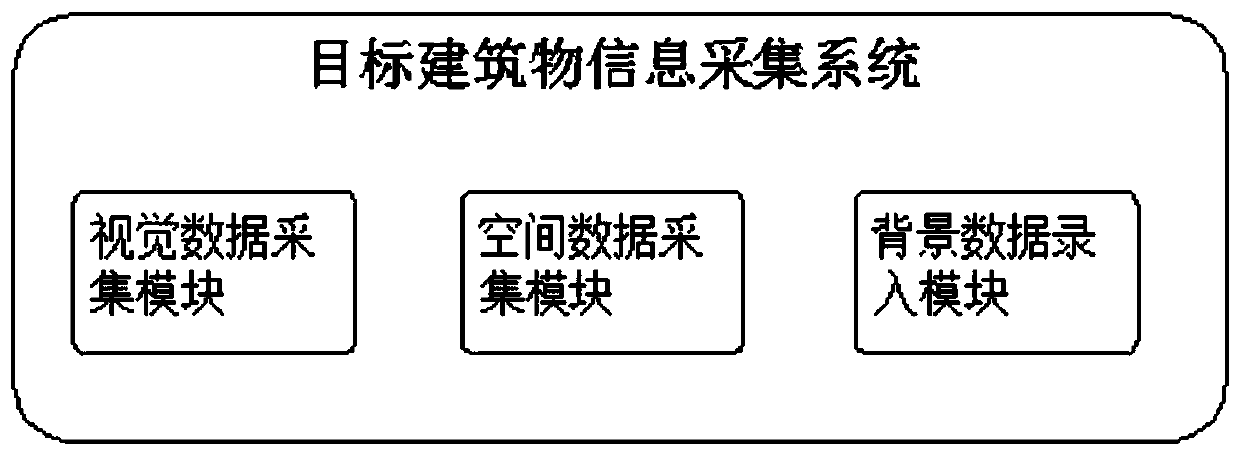

The invention discloses a 4D simulation system based on a BIM real-time construction model. The 4D simulation system comprises a target building information acquisition system, a BIN modeling system,a construction progress planning system, a model and progress link processing system and a 4D simulation real-time construction model display system. In the present invention, information collection is carried out on the actual construction progress of a target building; meanwhile, construction progress plan data is collected; the construction progress plan data is updated to the BIM model of thetarget building; three-dimensional display of construction cleaning of the target building is dynamically achieved, the actual state of the target building is accurately reflected, informatization, integration and visualization management of the construction progress, resources, cost and site of the target building are achieved, the construction efficiency is improved, the construction period is shortened, and the cost is saved.

Owner:死海旅游度假有限公司

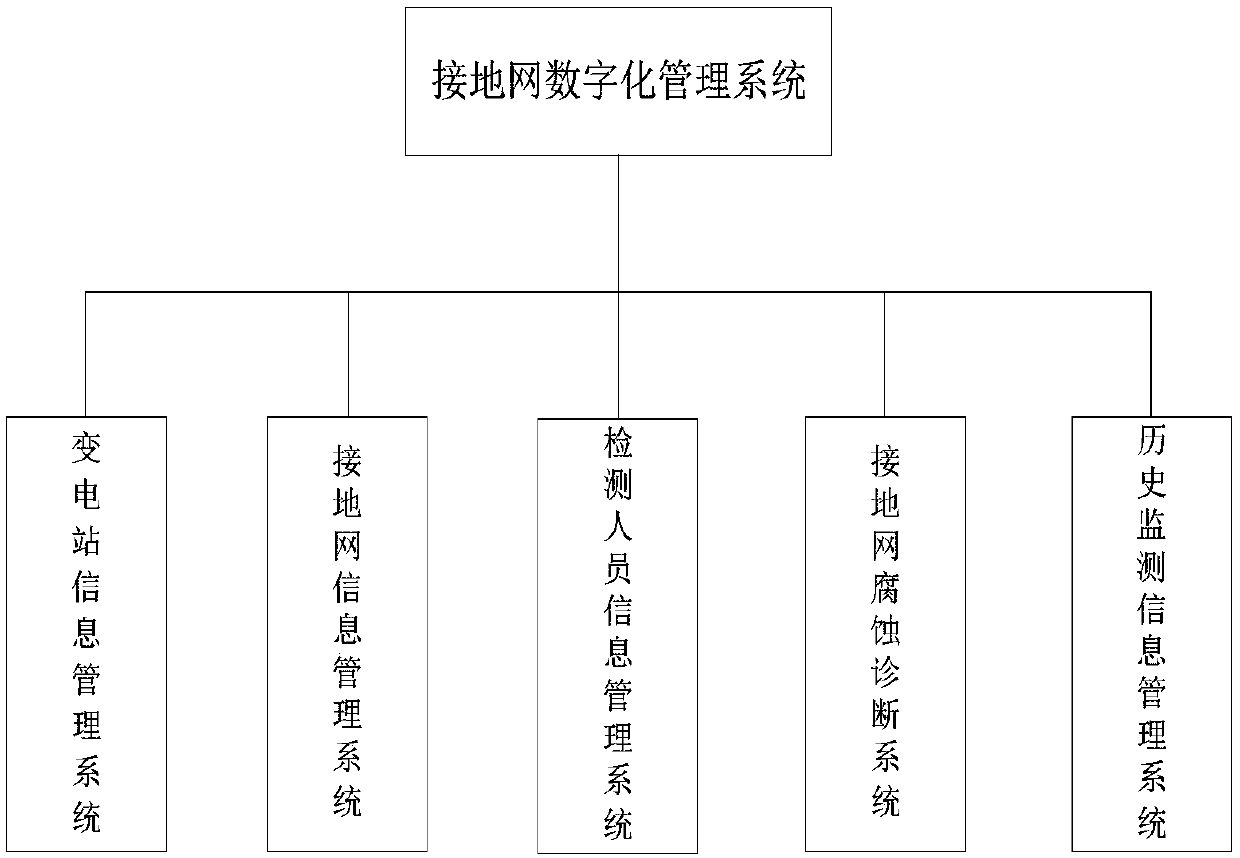

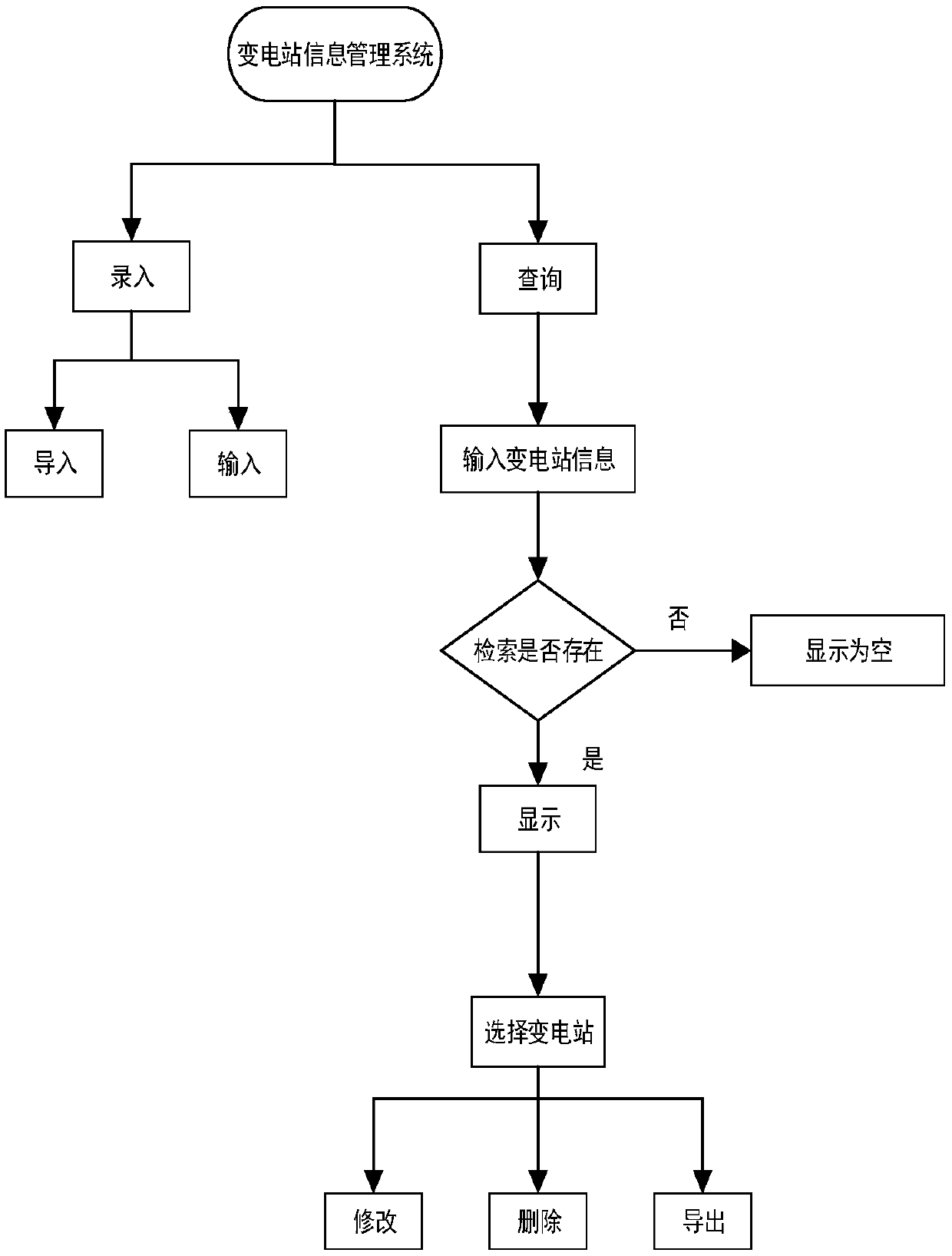

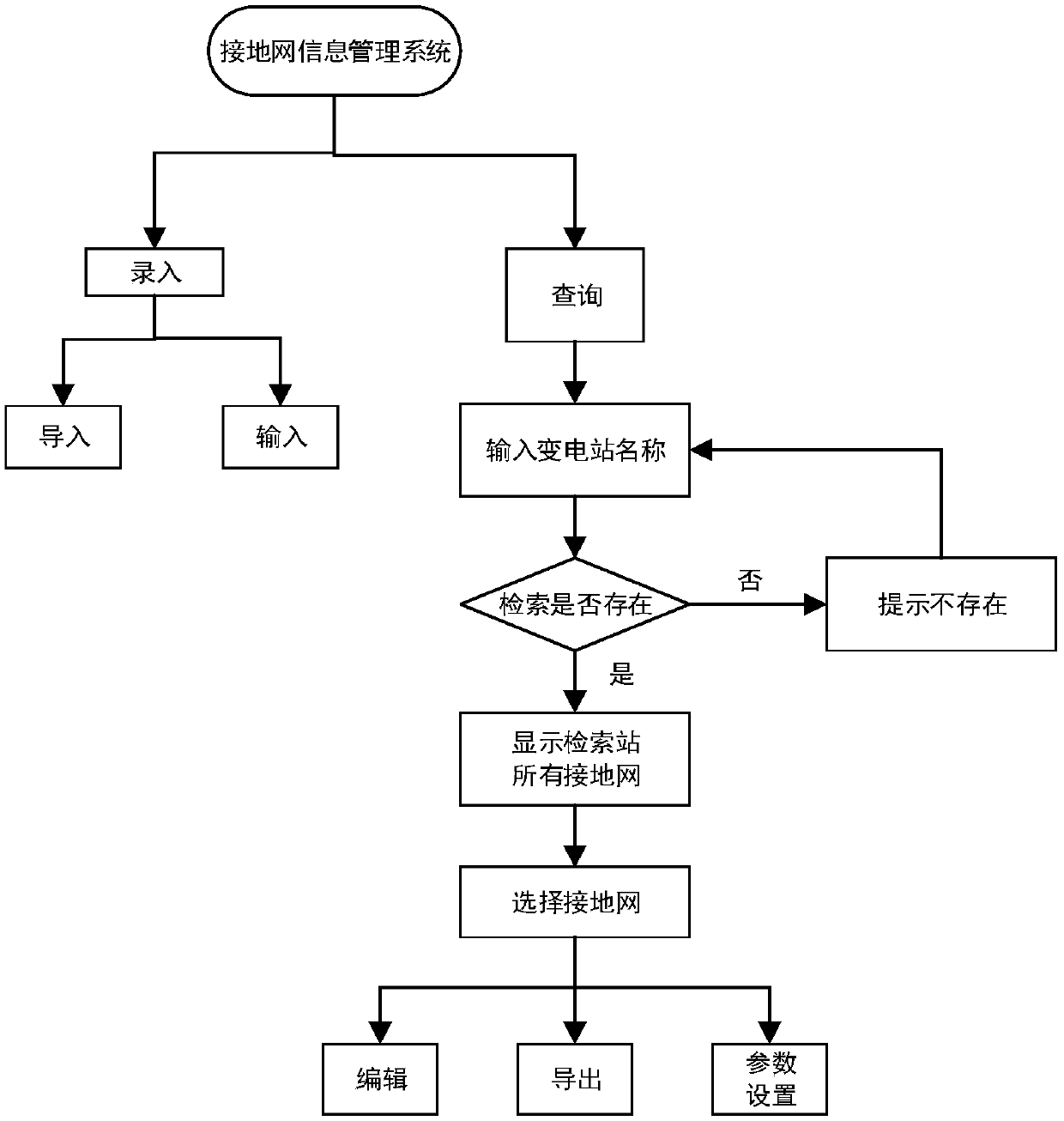

Substation grounding grid digital management system

The invention discloses a transformer substation grounding grid digital management system. The system comprises a transformer substation information management system. The system comprises five subsystems, namely a grounding grid information management system, a detection personnel information management system, a grounding grid corrosion diagnosis system and a historical monitoring information management system, the subsystems are all connected with a remote database server, an appointed page is accessed through a browser to upload measurement data, and rapid calculation of corrosion diagnosis is completed through a remote calculation server; Through combination of a client and a server, a user can carry out transformer substation operation. information management of a grounding grid anddetection personnel; Corrosion diagnosis and historical data analysis of the grounding grid are achieved, finally informatization management, digital management and visual management of the transformer substation and the grounding grid are achieved, the operation state of the grounding grid is comprehensively mastered, continuous tracking and prediction of the corrosion state of the grounding gridare achieved, and critical data support and decision basis are provided for life prediction of the grounding grid.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com