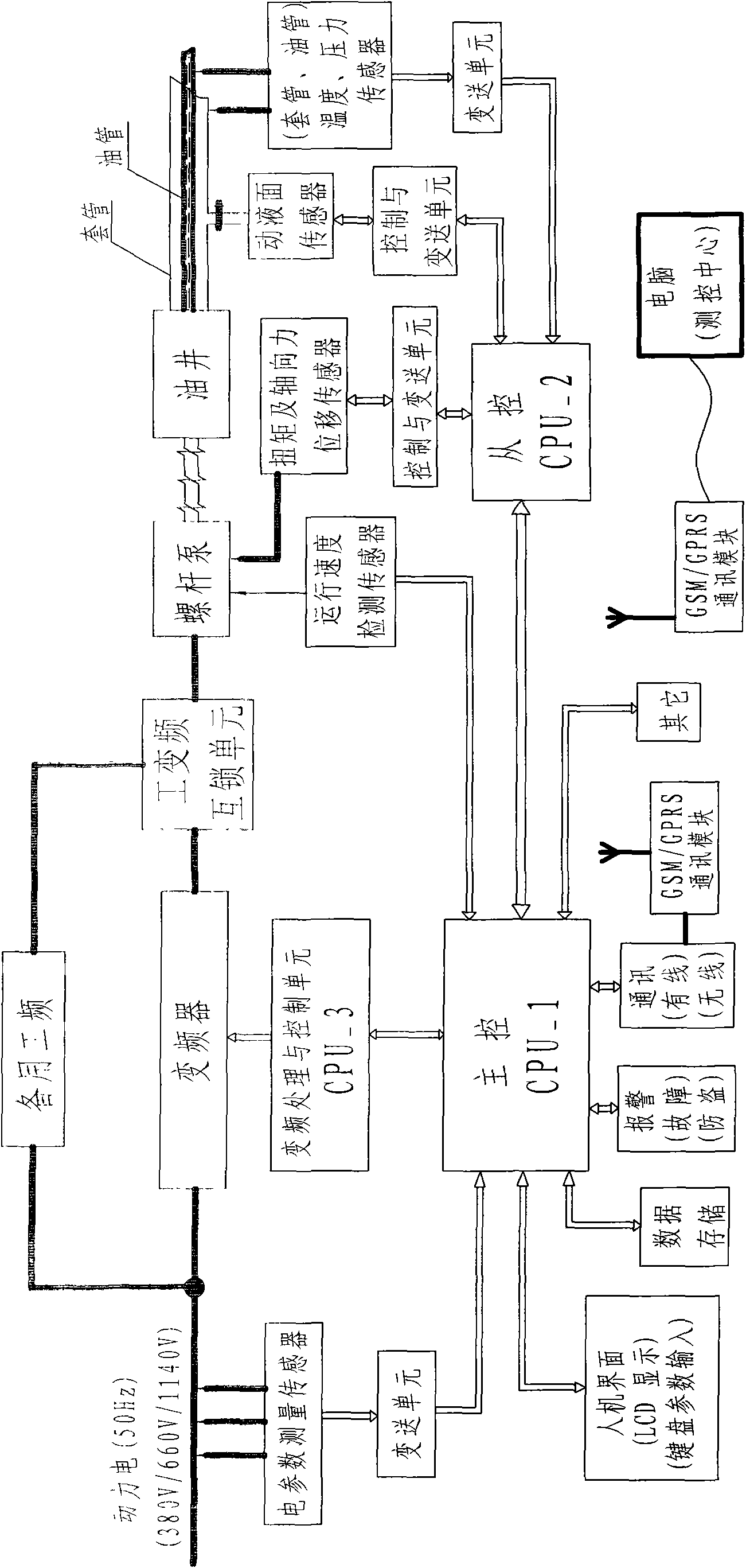

Intelligent monitoring device for screw pump well

An intelligent monitoring and screw pump technology, applied in pump control, mechanical equipment, pumps, etc., can solve the problems of no electrical design structure, unstable performance, and only emphasizing power saving, etc., to achieve automatic processing of system failures and extended inspection of pumps Cycle, the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

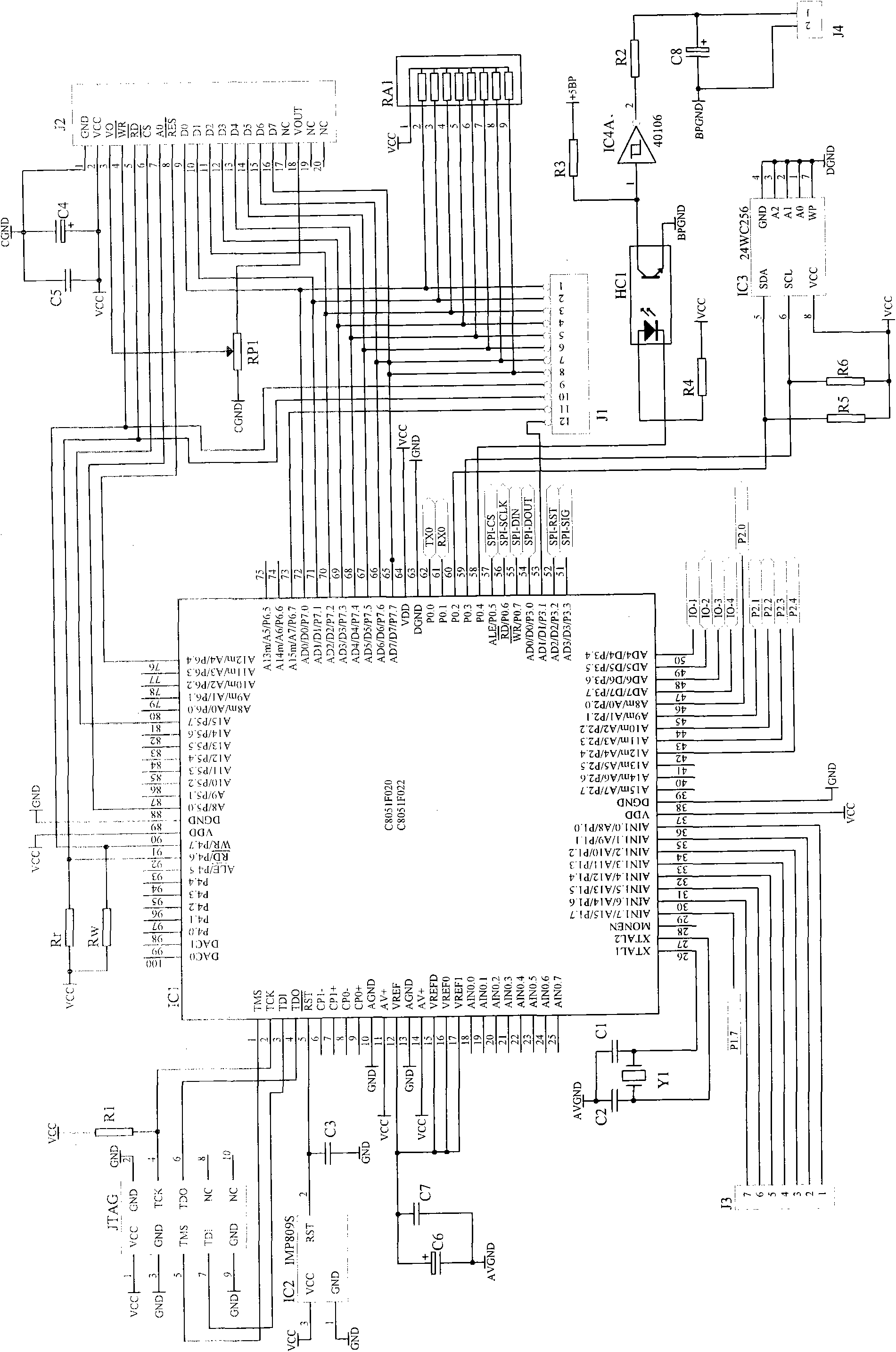

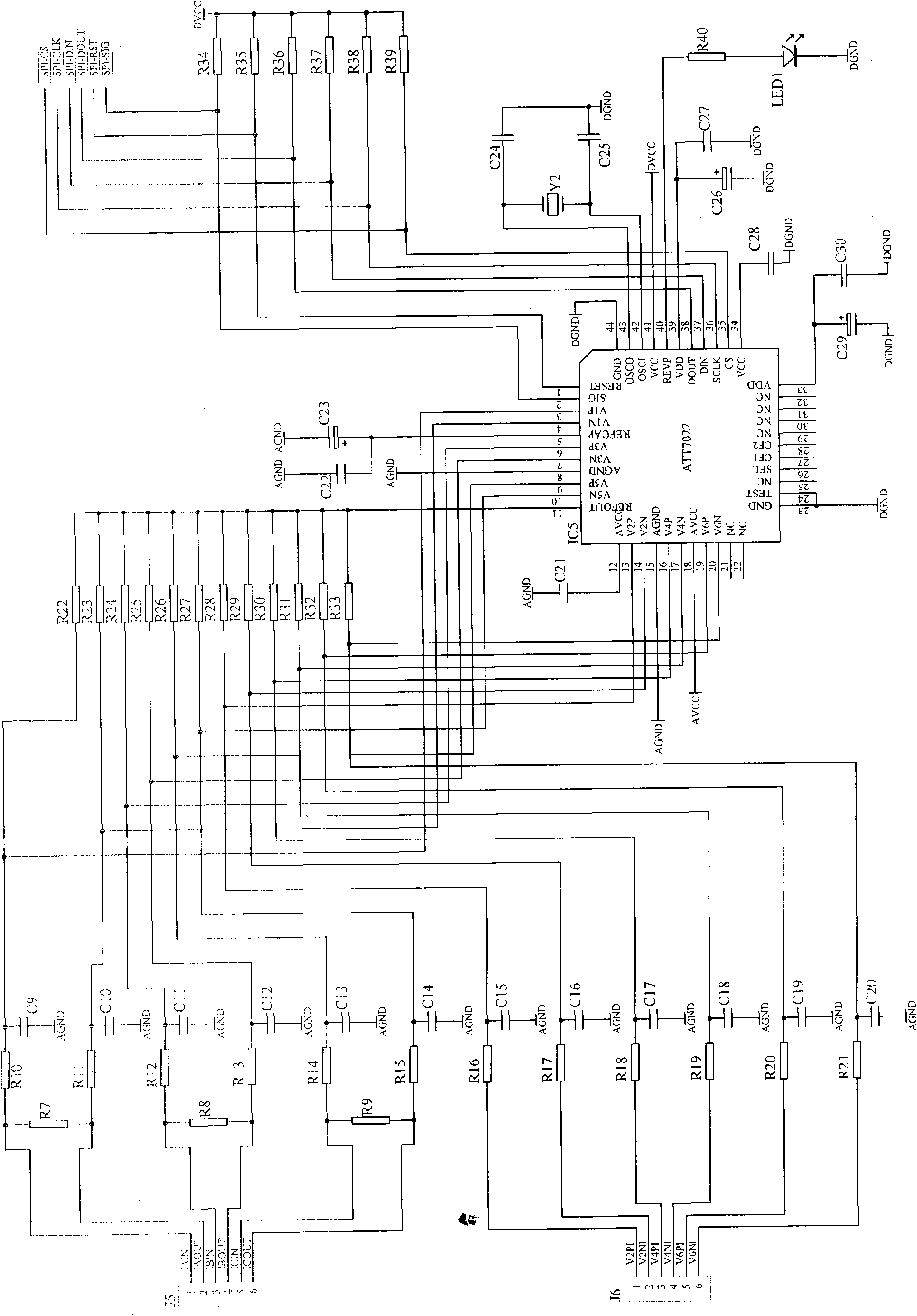

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0044] Figure 2(a) ~ Figure 2(f)It is an exploded view of the circuit principle diagram of the main control CPU part of the present invention. In Figure 2(a), IC1 is the main control CPU, that is, single-chip microcomputer C8051F020 or C8051F022. These two single-chip microcomputers are produced by Cygnal Company in the United States. The core is 16 bits, the data bus is 8 bits, and integrated AD, DA, PWM, 6 IO port, 4K RAM, 64K ROM, I 2 C bus, watchdog and other functions, rich internal resources, stable and reliable, good anti-interference performance, IC2 is the CPU reset chip, completed by IMP809S, J1 is the parallel data bus and control interface connected with the slave CPU, J2 is 320 ×240 Chinese character dot matrix liquid crystal display interface, RA1 is the pull-up resistance of the parallel data bus, IC3 is the data storage chip 24WC256, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com