Patents

Literature

86results about How to "Improve production management level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Implementing method of integrated power grid dispatching operation intelligent mistaken-early-warning preventing system

InactiveCN103761624AReduce the impactStable supportResourcesSystems intergating technologiesPower gridOperation model

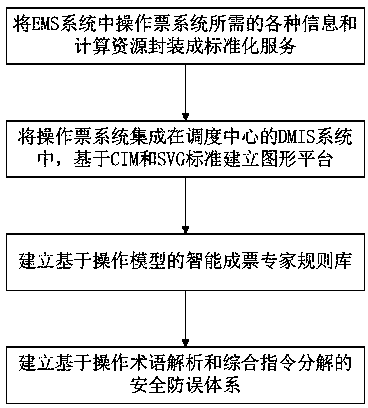

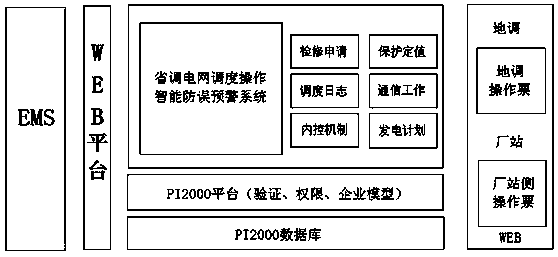

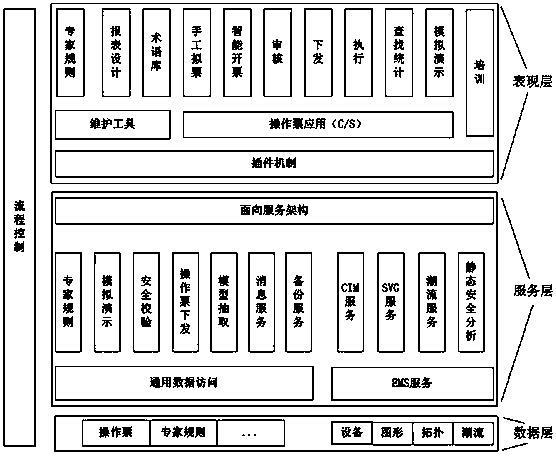

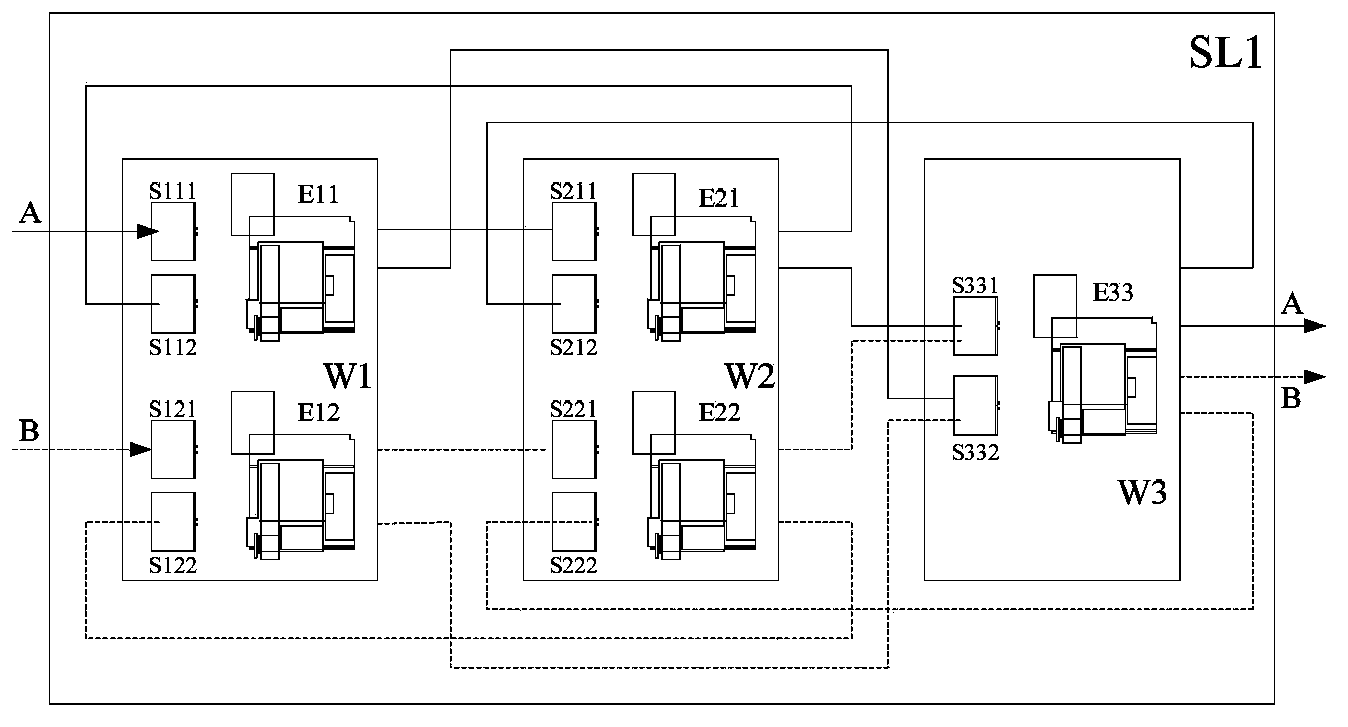

The invention provides an implementing method of an integrated power grid dispatching operation intelligent mistaken-early-warning preventing system. The implementing method comprises the following steps that various information and computing resources required by an operation ticket system in an EMS system of a dispatching center are packaged into standardized service; the operation ticket system is integrated a DMIS system of the dispatching center, and a graphic platform is built according to the CIM and SVG standard; an intelligent ticket-making expert rule base based on an operation model is built, and a safe mistake preventing system based on operation term analysis and comprehensive instruction analysis is built. The implementing method has the advantages of having little influence on the EMS system, being beneficial for popularization and the like, and can improve billing efficiency and circulation speed of dispatching operation tickets. During equipment maintaining peaks in spring and autumn, equipment operation safety is guaranteed, rapidness of equipment operation is guaranteed, work efficiency and the production and management level of the power grid are improved, prevention of large-area power outage accidents is facilitated, and safe production of an electric power company is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER

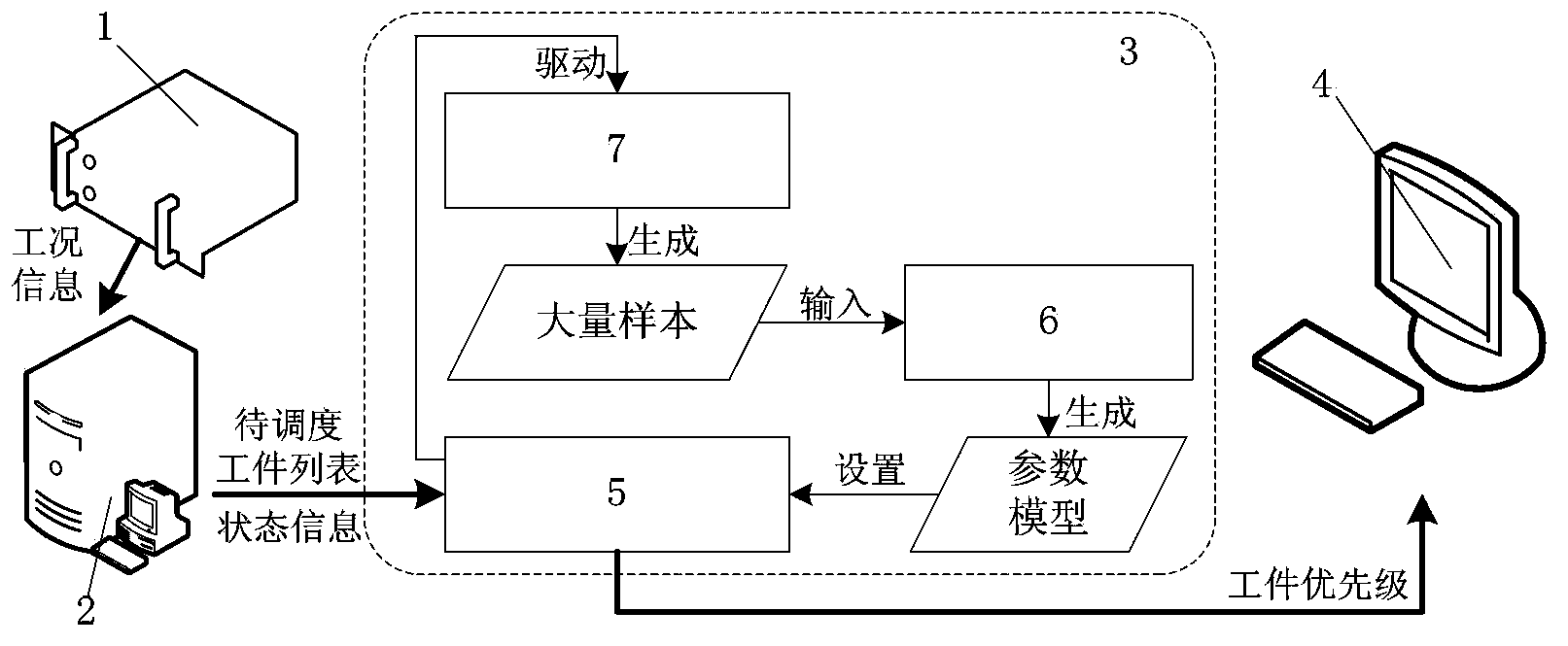

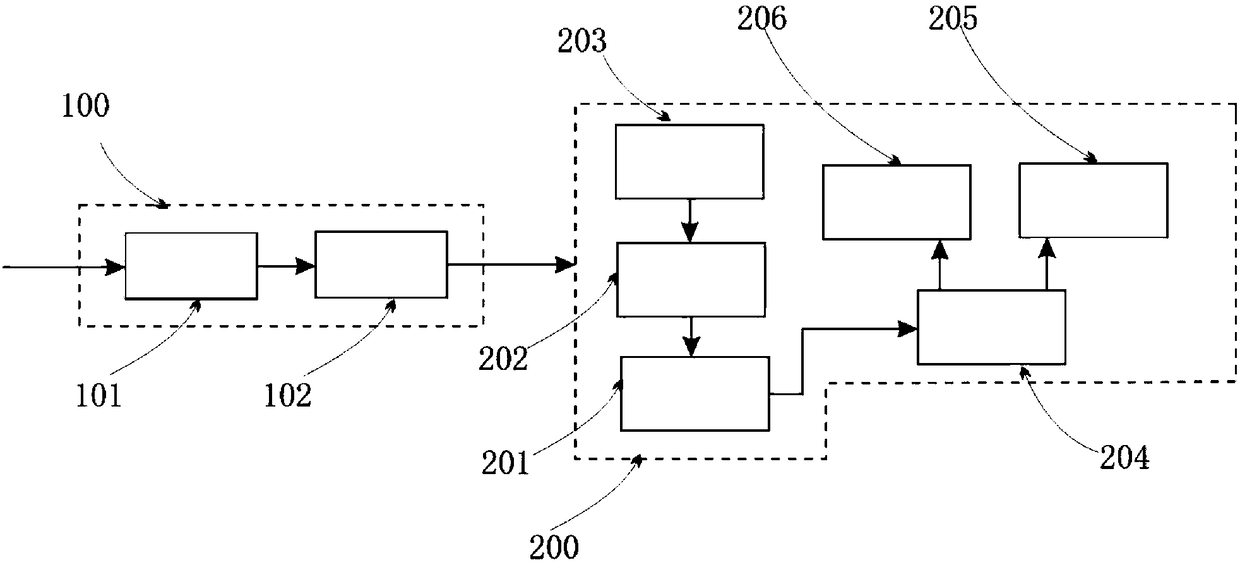

Semiconductor production line self-adaptation dynamic dispatching device

InactiveCN103439886AIncrease profitOn-Time Delivery ImprovementAdaptive controlDisplay deviceManufacturing execution system

The invention relates to a semiconductor production line self-adaptation dynamic dispatching device which is connected with a manufacturing execution system. The dispatching device comprises a dispatching management device, a learning device and a display device. The dispatching management device is connected with the manufacturing execution system, and the dispatching management device, the learning device and the display device are connected in sequence. The dispatching management device acquires a list of current workpieces to be dispatched through the manufacturing execution system and transmits the list of the current workpieces to be dispatched to the learning device, the learning device calculates machining priorities of the current workpieces to be dispatched according to a dispatching rule stored in the learning device and transmits the priorities of the current workpieces to be dispatched to the display device, and the display device displays the priorities of the current workpieces to be dispatched. Compared with the prior art, the semiconductor production line self-adaptation dynamic dispatching device has the advantages of being capable of improving workpiece machining efficiency and bottleneck equipment use ratios, good in dynamic regulation performance, and the like.

Owner:TONGJI UNIV

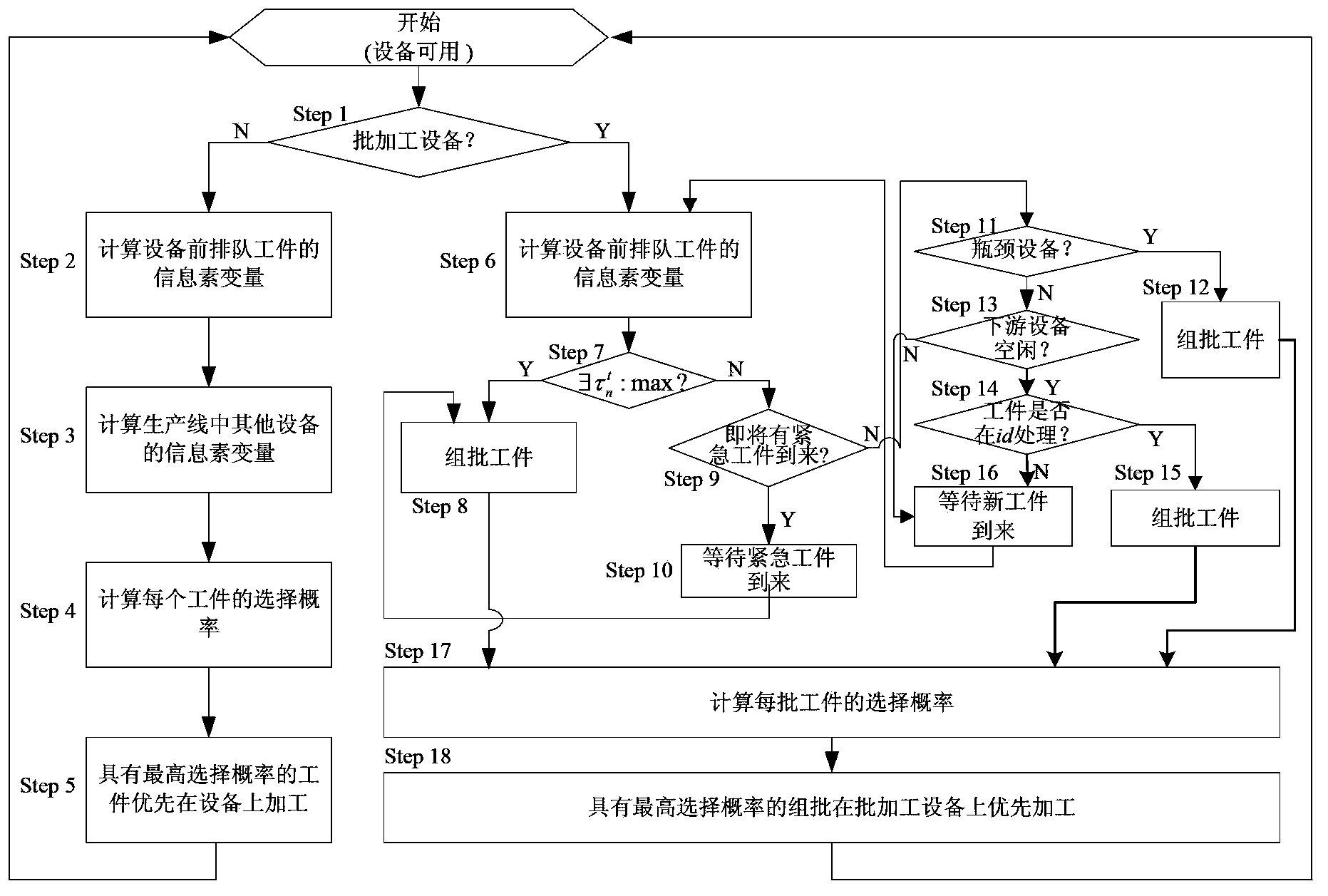

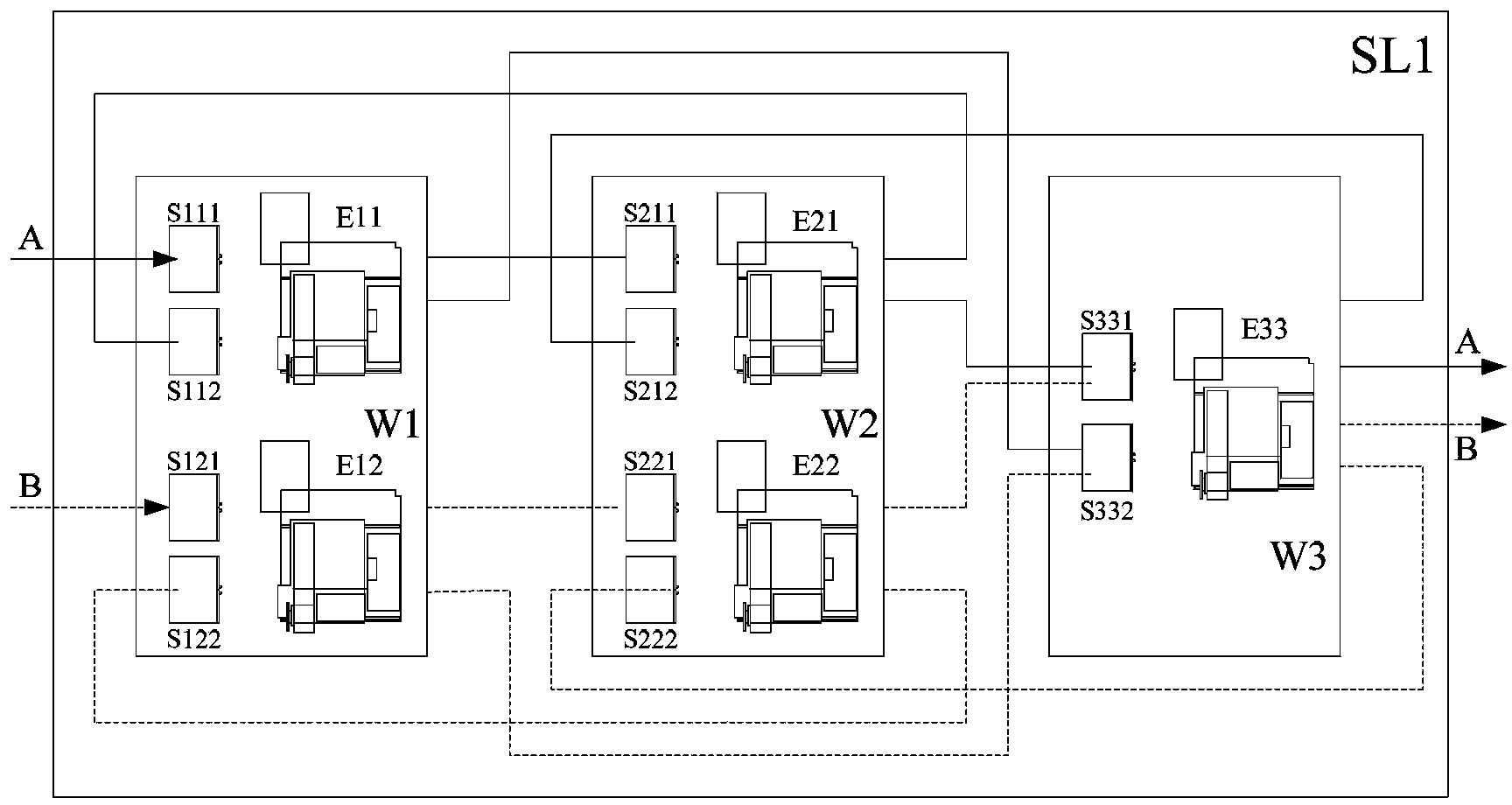

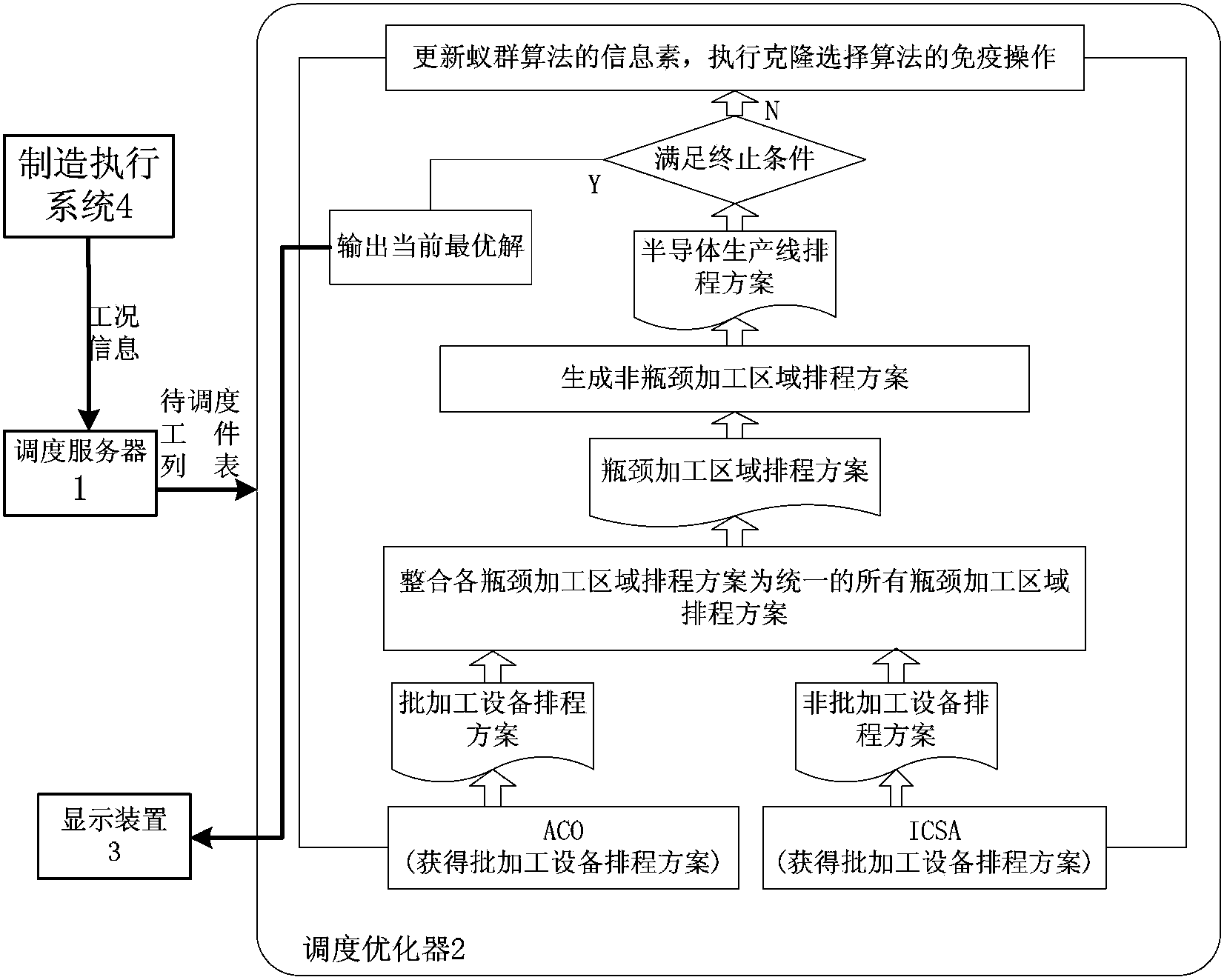

Semiconductor production line optimized dispatching device

InactiveCN103439885AIncrease profitOn-Time Delivery ImprovementBiological modelsAdaptive controlManufacturing execution systemAnt colony

The invention relates to a semiconductor production line optimized dispatching device which comprises a dispatching server, a dispatching optimizer and a display device. The dispatching server, the dispatching optimizer and the display device are sequentially connected. The dispatching server obtains the current production situation and the list of workpieces to be dispatched by timing updating through a manufacturing execution system of an enterprise, the dispatching optimizer transmits a dispatching request to the dispatching server and receives the list of the workpieces to be dispatched from the dispatching server, and an ant colony immune fusion algorithm is applied to obtain the optimized dispatching schemes. The display device displays the optimized dispatching schemes on stations, and assists production management personnel in dispatching decisions. Compared with the prior art, the semiconductor production line optimized dispatching device has the advantages of solving the difficult problem of semiconductor production line optimized dispatching, having important practical value, having important guiding significance in improving the production management level of the semiconductor enterprises in China and the like.

Owner:TONGJI UNIV

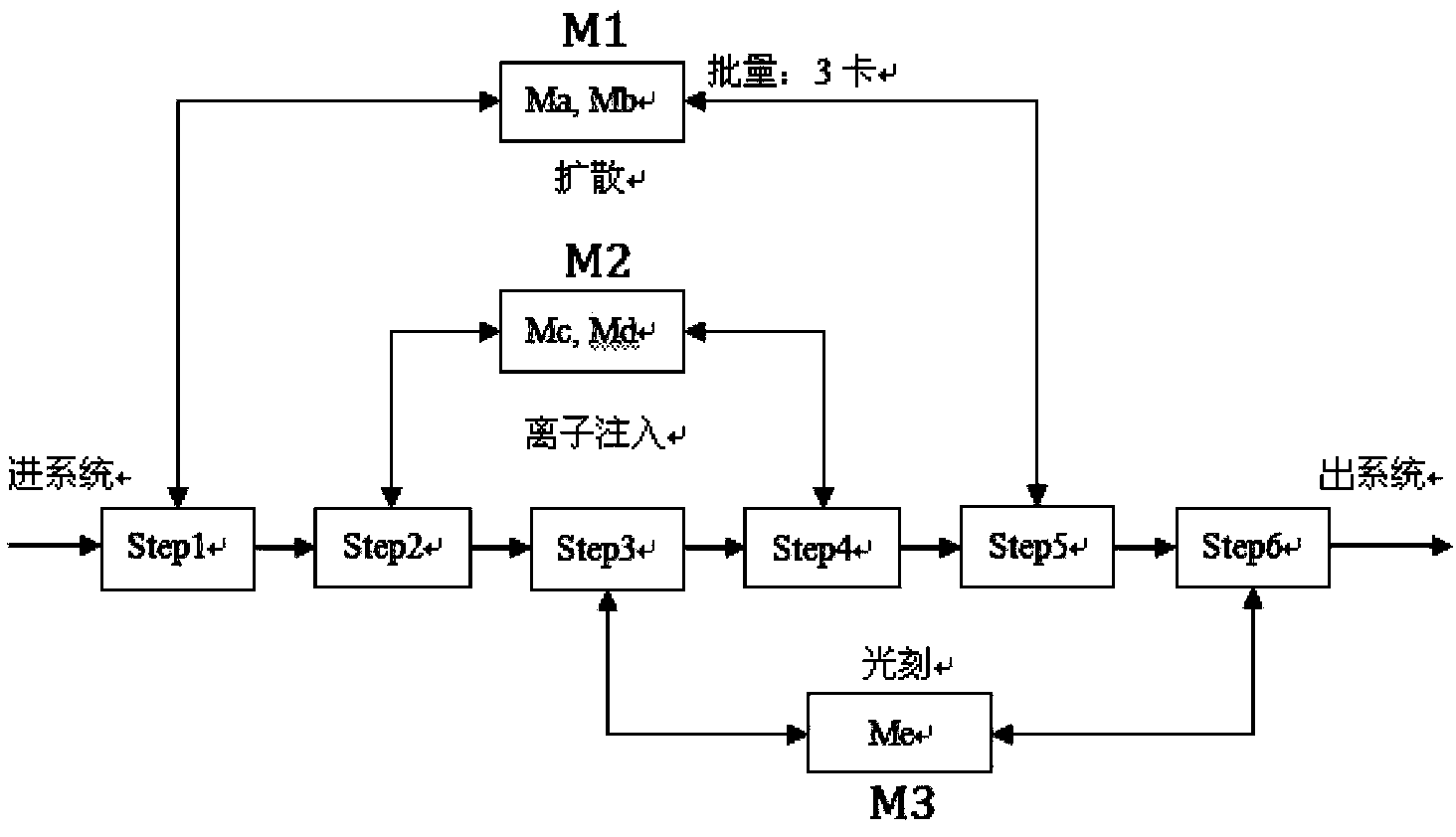

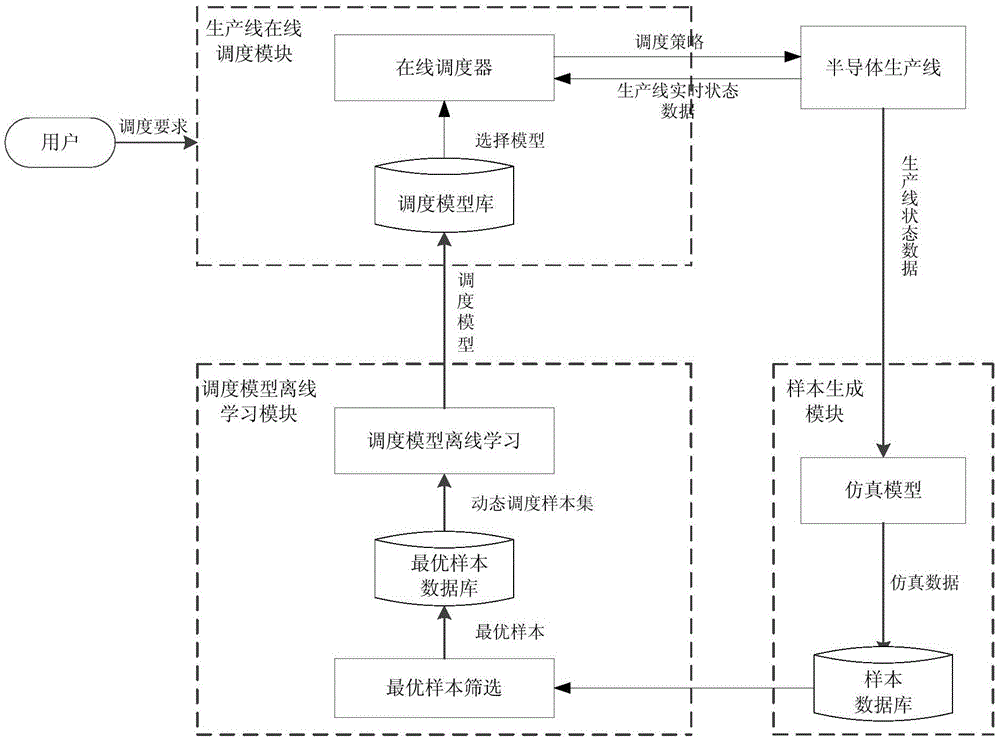

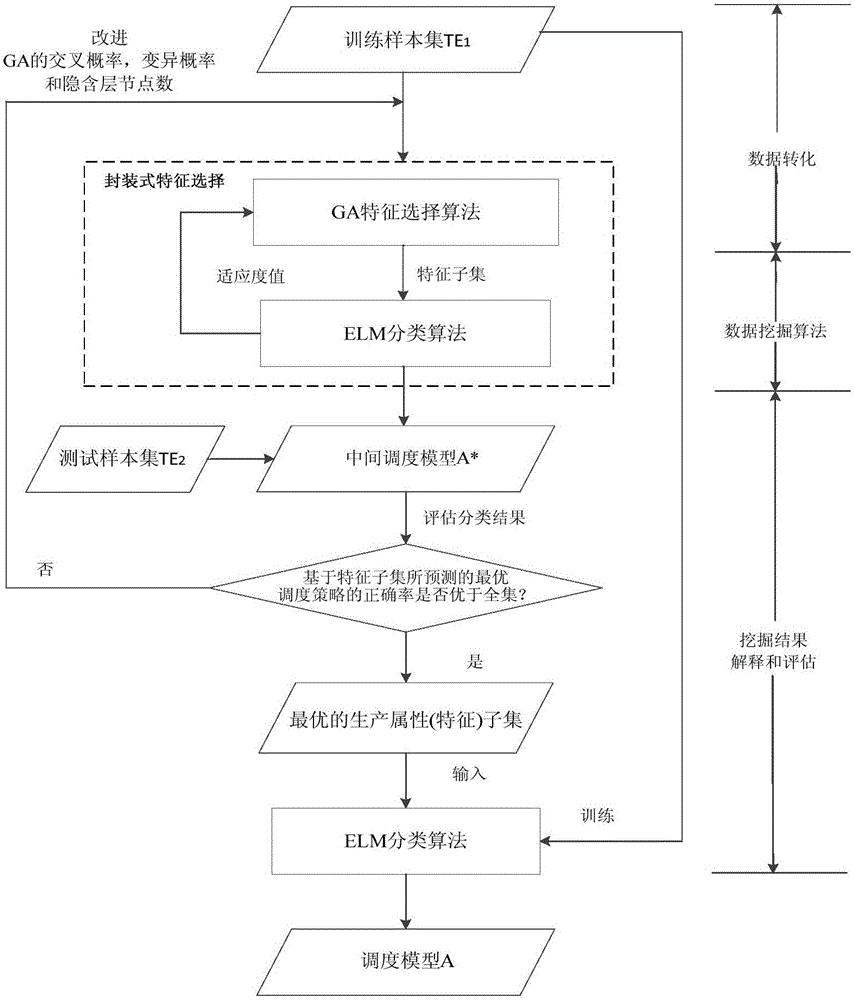

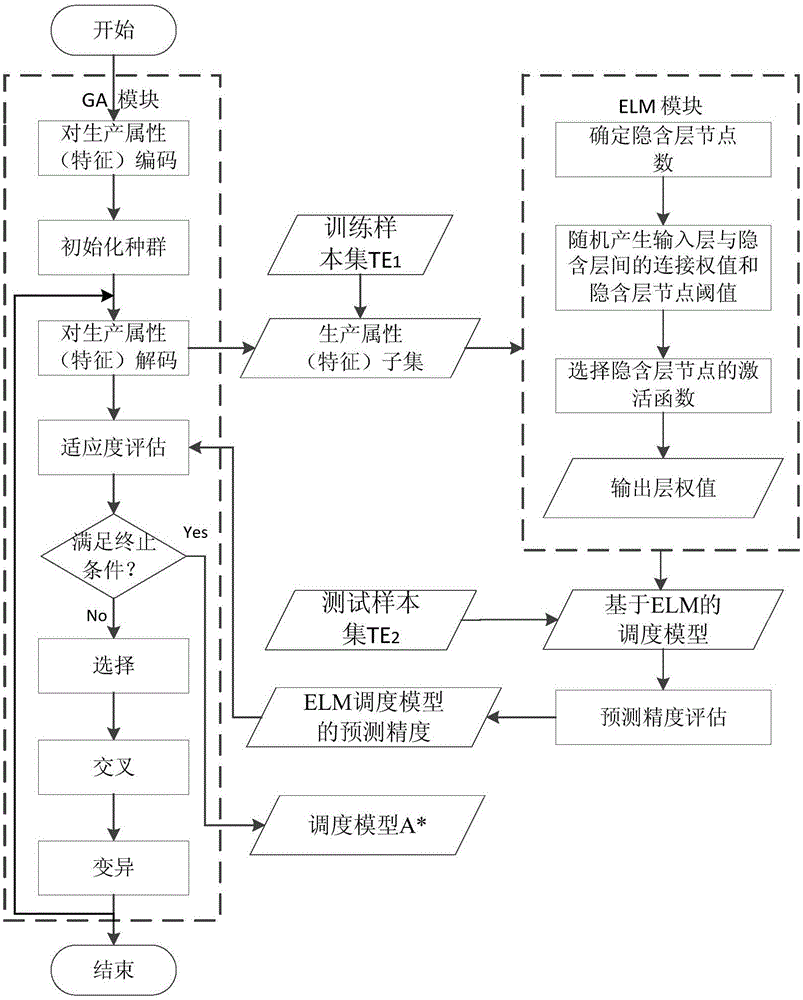

Semiconductor production line dynamic scheduling device

InactiveCN105045243AFast Optimal Scheduling StrategyQuickly provide the optimal scheduling strategyTotal factory controlProgramme total factory controlOptimal schedulingApplication scheduling

The invention relates to a semiconductor production line dynamic scheduling device, comprising a sample generation module for generating data samples, a scheduling model off-line learning module for building a scheduling module according to the data sample, and a production online scheduling module used for generating a real-time scheduling strategy according to the user scheduling target and the scheduling model to perform online scheduling of the semiconductor production line. A matched scheduling model is chosen from a scheduling model database according to the user requirements; the system state information of the semiconductor production line is inputted; and the application scheduling model chooses an optimal or a close-to-optimal scheduling strategy from the candidate scheduling strategies to be applied to the operation of the production line. Compared with the prior art, the semiconductor production line dynamic scheduling device achieves the real-time performance and optimization of the scheduling, satisfies the effectiveness of the scheduling and improves the overall performance of the production line.

Owner:TONGJI UNIV

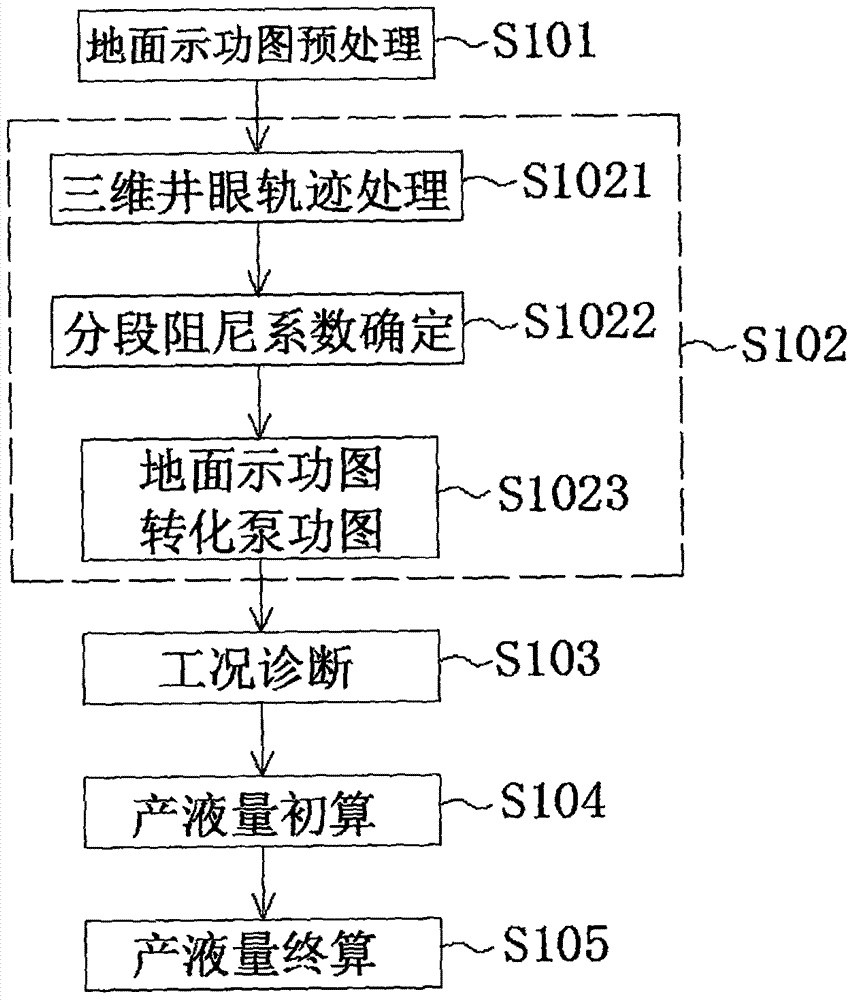

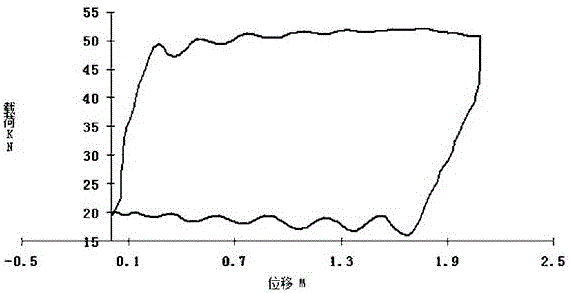

Method and system for improving oil pumping well indicator diagram oil gauging precision

ActiveCN107288617AHigh precisionAccurately grasp the dynamic changes of productionSurveyConstructionsIndicator diagramOil well

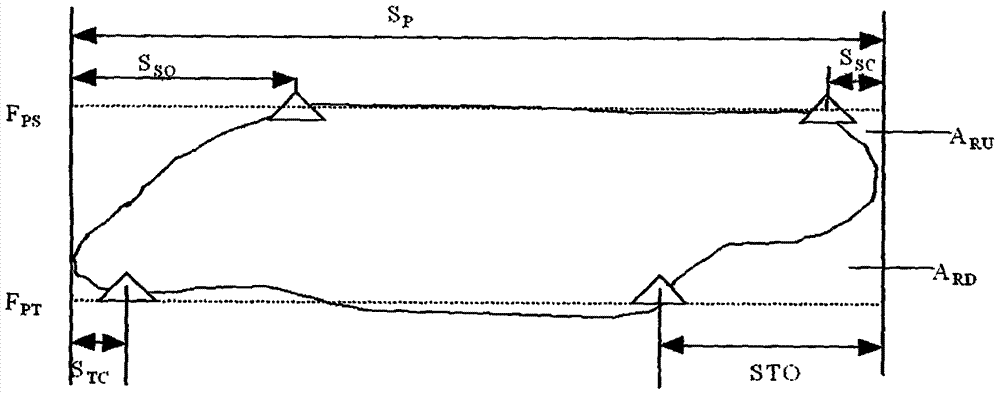

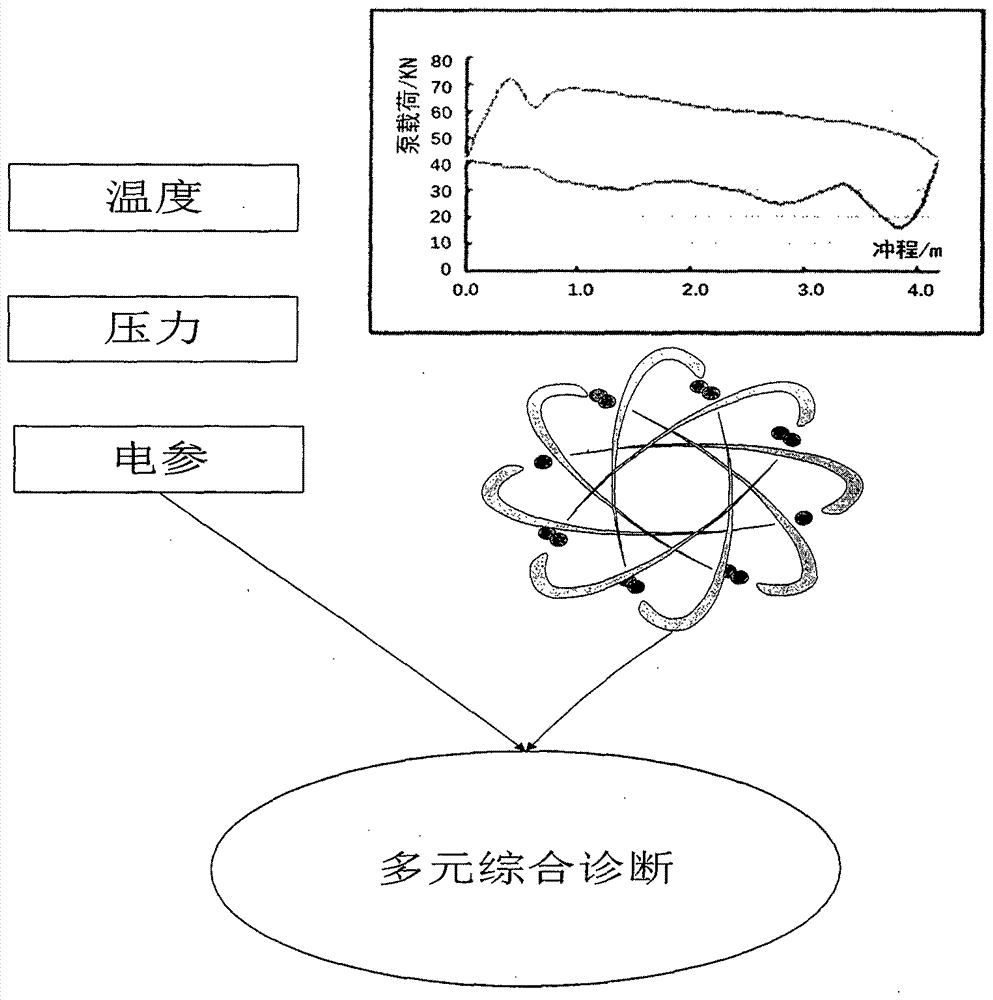

The invention relates to the technical field of pumping units, in particular to a method for improving oil pumping well indicator diagram oil gauging precision. The method comprises the following steps of 101, ground indicator diagram pretreatment, 102, ground indicator diagram transformation, 103, working condition diagnosis, 104, liquid production capacity preliminary calculation, and 105, liquid production capacity final calculation. The invention further comprises a system for improving the oil pumping well indicator diagram oil gauging precision, the system comprises an indicator diagram treatment module, a working condition diagnosis and classification module, a liquid production capacity calculation module and a liquid production capacity correction module which are connected in sequence. By means of the method and the system, analysis diagnosis optimization is conducted on indicator diagram data of an oil pumping well which are collected and transmitted to a real-time database, the precision of liquid production capacity measurement of the oil pumping well can be improved greatly, production dynamic change of the oil well is commanded accurately, and production management level of the oil well is improved effectively.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

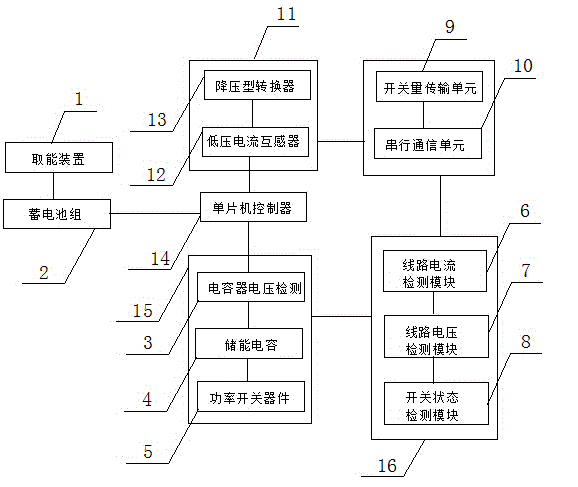

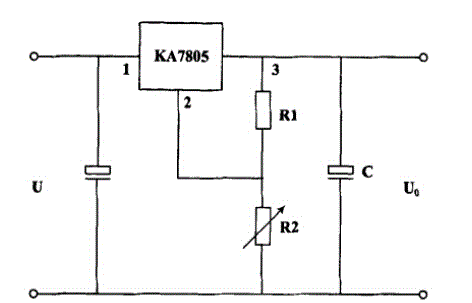

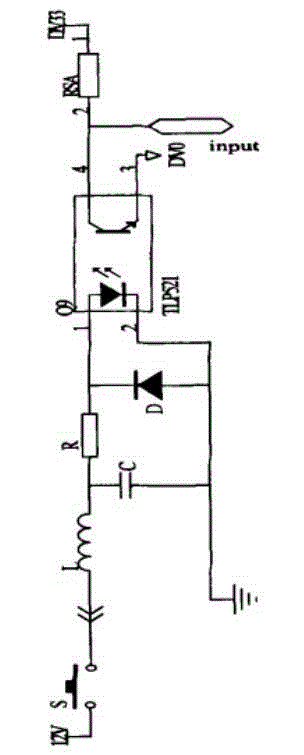

Intelligent power distribution network outdoor broken circuit monitoring device

InactiveCN106300655AReduced risk of errorReduce volumeCircuit arrangementsMicrocontrollerData acquisition

The invention discloses an intelligent power distribution network outdoor broken circuit monitoring device. The intelligent power distribution network outdoor broken circuit monitoring device comprises a breaker main body; the breaker main body is provided with a power supply module, a control module and a sampling module; the control module and the sampling module are respectively connected to the power supply module; the control module comprises a single-chip microcomputer controller, a signal processing module and an intelligent driving controller; and the control module and the sampling module are connected through a transmission module. The intelligent power distribution network outdoor broken circuit monitoring device can realize a function of switching on and off a circuit load and isolating a fault, realizes an on-site control operation and realizes a remote control operation through a front end collection device receiving a system order. The intelligent power distribution network outdoor broken circuit monitoring device not only finishes data collection, wherein the data includes data of three-phase current, voltage, a breaker state, etc, but also realizes remote fault alarm, and can detect an interphase short circuit fault of the circuit, a single-phase grounding fault and transmits fault information to an automation main station.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

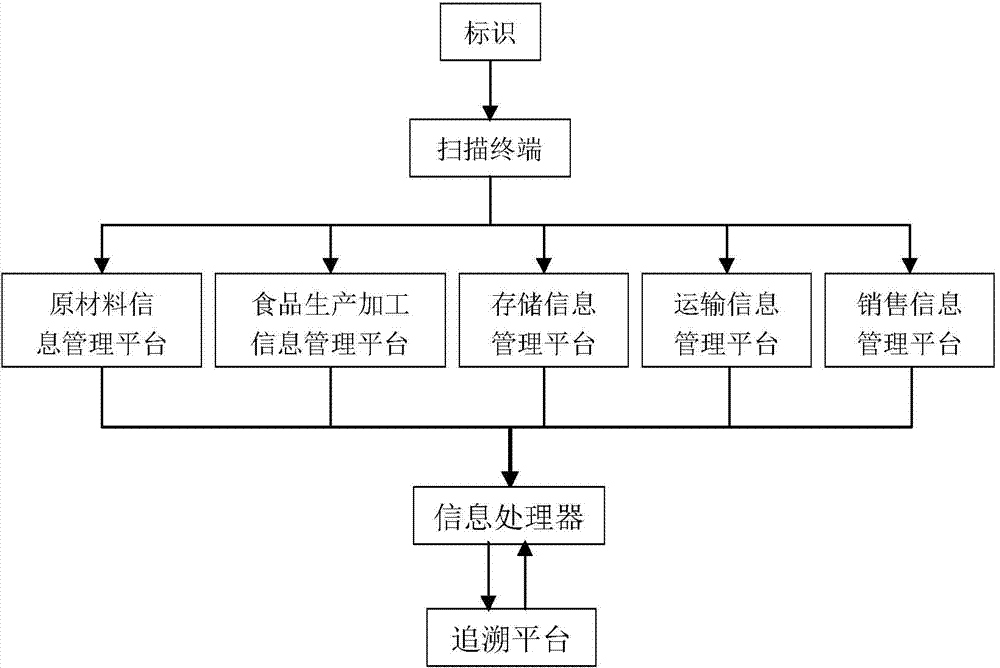

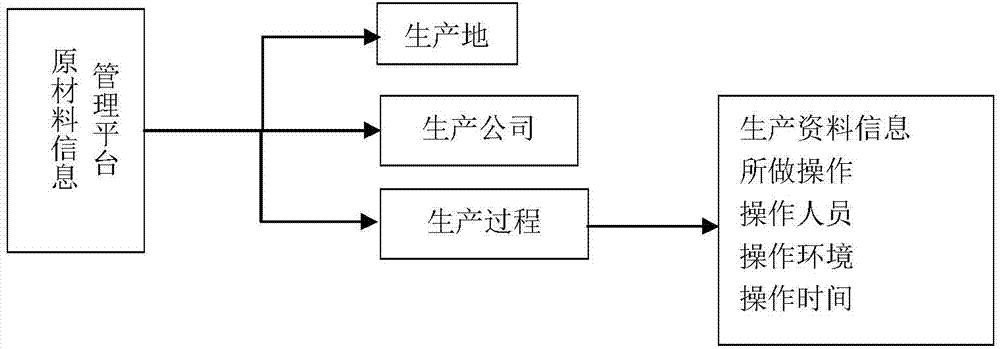

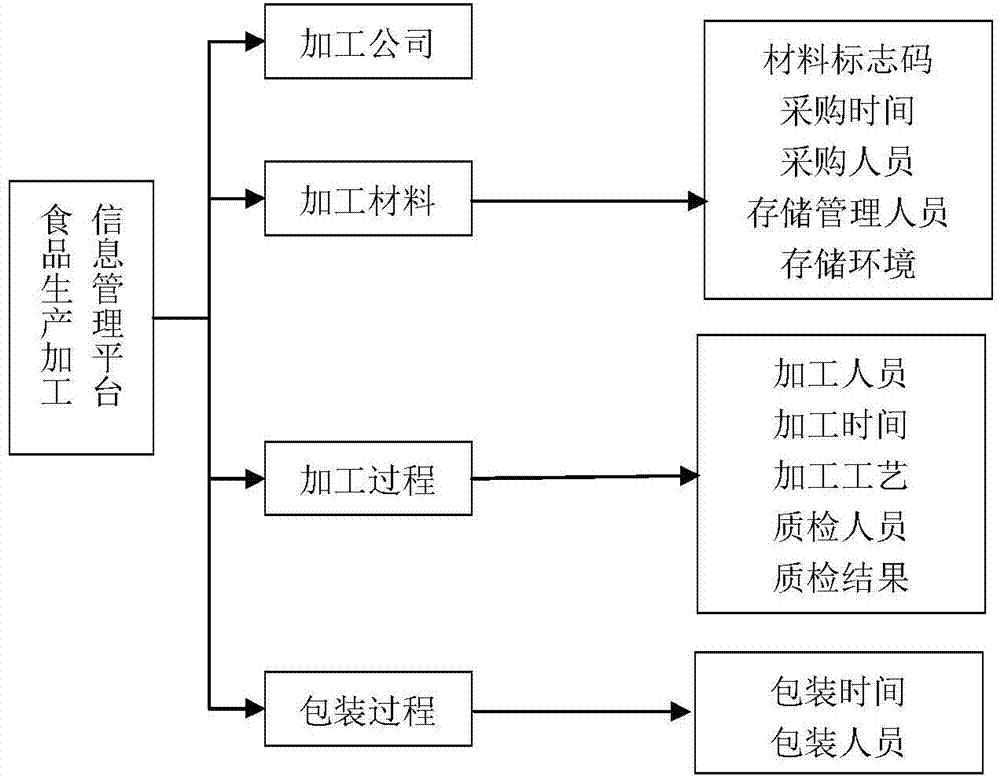

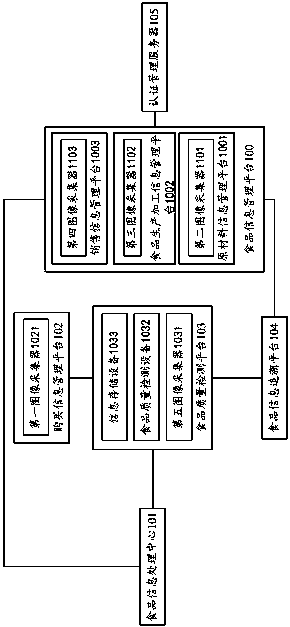

Food traceability system

InactiveCN104331768AImprove production management levelConvenient queryCo-operative working arrangementsResourcesFood safetySecurity question

The invention discloses a food traceability system. The food traceability system comprises a food label, a scanning terminal, an information processor, a raw material information management platform, a food production processing information management platform, a stored information management platform, a transportation information management platform, a sales information management platform and a traceability platform. The food traceability system records the key point information of all links from raw material cultivation to processing, packaging, storage, transportation and sales of food, even to the responsible people, and therefore, the whole process management from field to dining-table is truly realized, and in case of a food safety problem, the source of the problem can be found out according to the information chain as soon as possible. Besides, the food traceability system is helpful for an enterprise to promote the production management level, and provides basis for consumers to buy.

Owner:WUXI ASCEND MEDICAL EQUIP

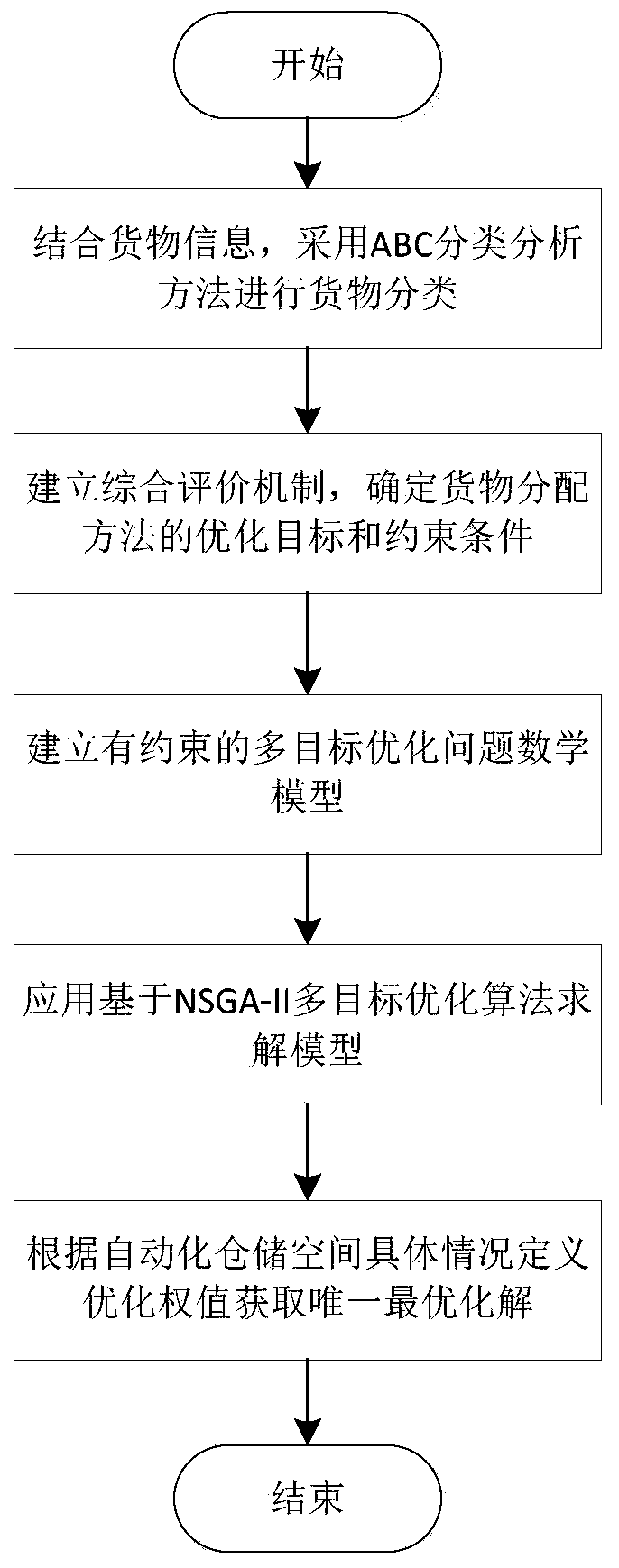

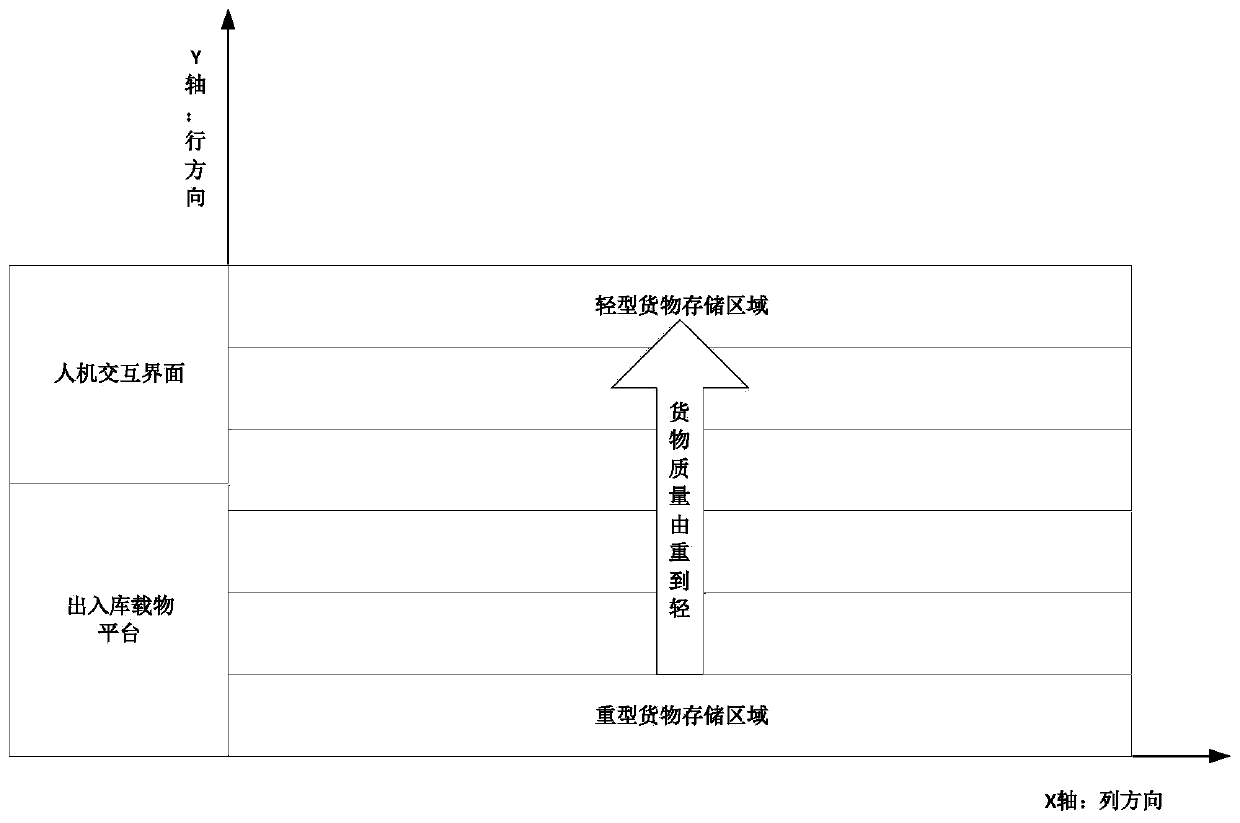

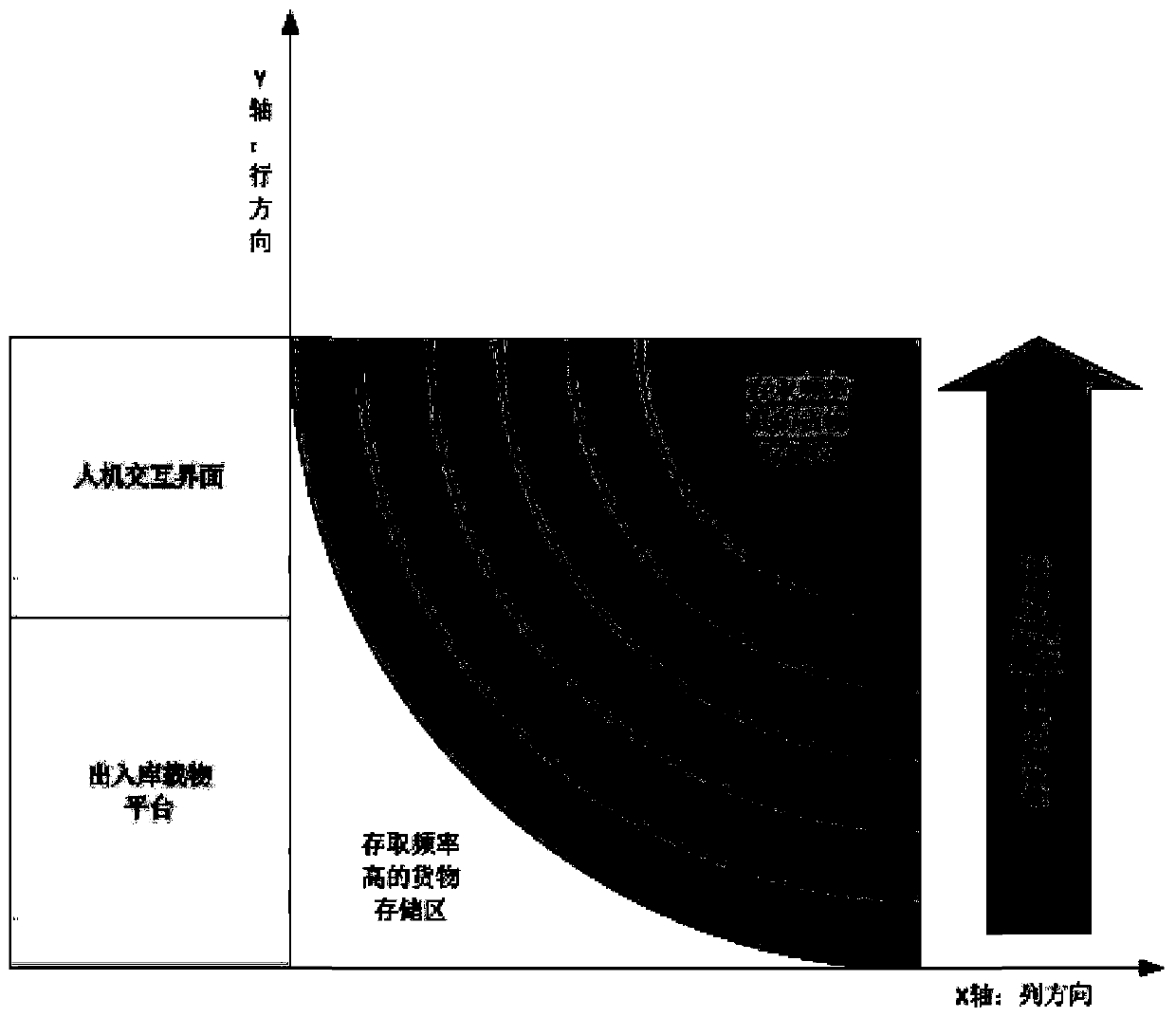

NSGA-II-based automatic storage goods allocation optimization method

ActiveCN111178606AImprove global convergenceGood search abilityInternal combustion piston enginesForecastingOptimization problemOperations research

The invention discloses an NSGA-II-based automatic storage goods allocation optimization method, and the method comprises the steps: carrying out the goods classification through an ABC classificationanalysis method in combination with the goods information; determining an optimization target and a constraint condition of the automatic storage goods allocation method; establishing a constrained multi-objective optimization problem mathematical model; and solving the model by adopting an NSGA-II-based optimization algorithm to obtain an optimal Pareto solution set, and distributing optimization weights according to the actual specific situation of the automatic storage space to obtain a unique non-dominated solution as an optimal solution. The method can be suitable for small and medium-sized automatic storage such as intelligent express cabinets, intelligent vending machines and self-service storing and taking cabinets; the automatic storage space utilization rate and the goods storing and taking execution efficiency can be effectively improved, the working intensity of workers is relieved, the labor cost and the device maintenance cost are greatly reduced, the safety and reliability of automatic storage are improved, and the good practical value and the wide application value are achieved.

Owner:NANJING UNIV OF SCI & TECH

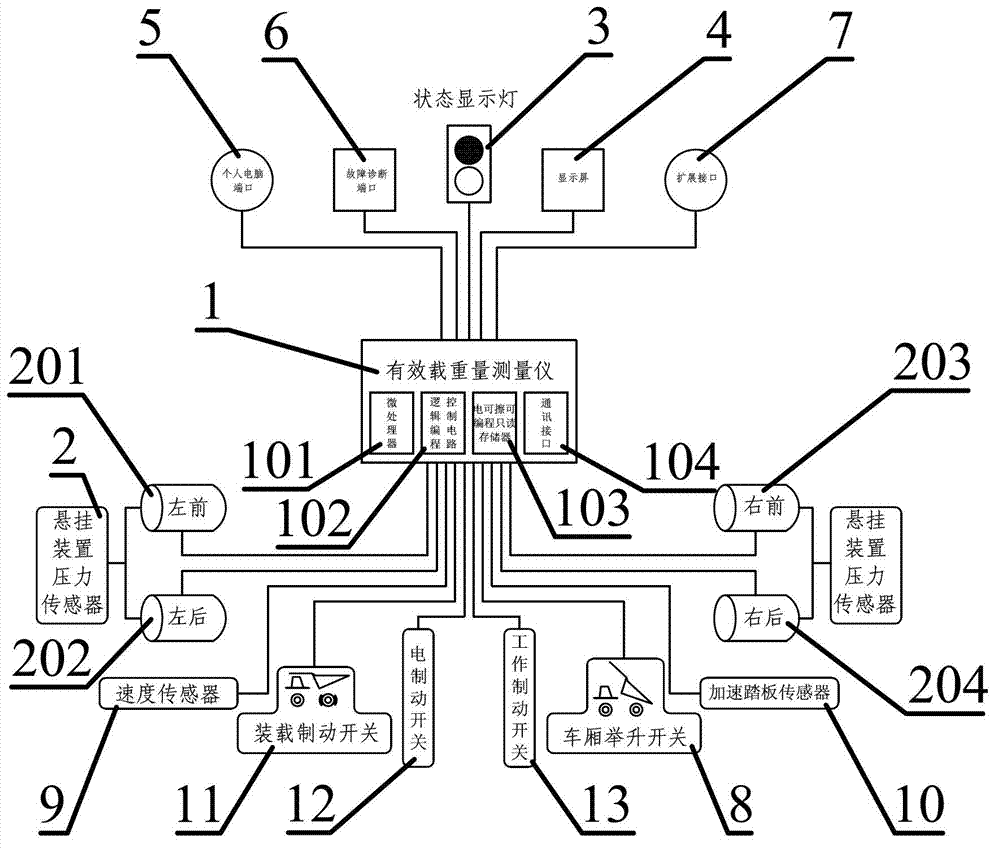

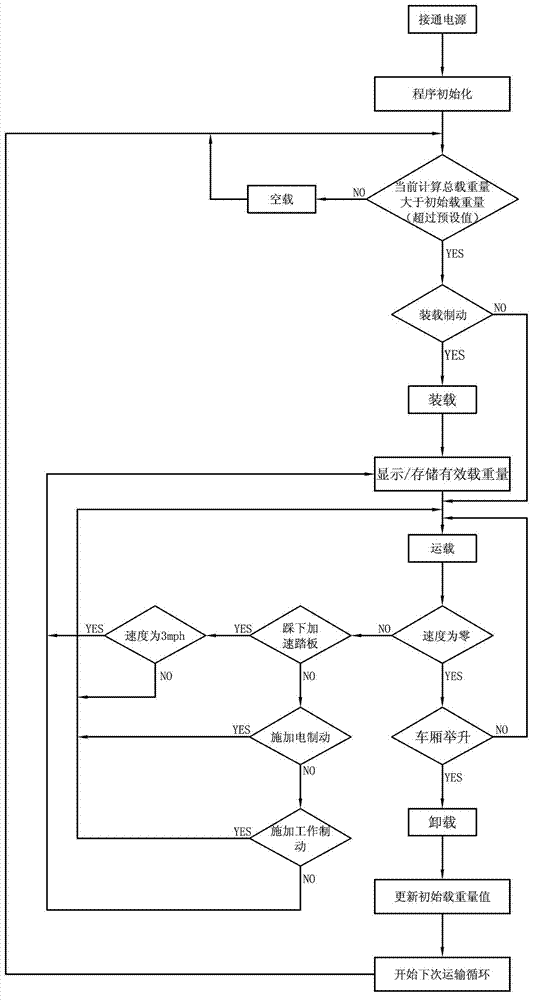

Weighting device and working method for mining self-discharging vehicle

InactiveCN103033244AAccurate weighingAvoid OverloadingProgramme controlComputer controlProgrammable read-only memoryReal-time communication

The invention discloses a weighting device and a working method for mining self-discharging vehicle. The device comprises an effective load capacity gauge, a hanging device pressure sensor, a display screen, a state display lamp and a signal input device. The signal input device comprises a compartment lifting switch, a speed sensor, an accelerating pedal sensor, a loading braking switch, an electric braking switch and a working braking switch. The effective load capacity gauge comprises a micro processor, a logic programming controlling circuit, an electric erasable programmable reading-only memory and a communication port. The effective load capacity gauge has the functions of real-time computing, controlling, storing, communicating, displaying and the like. The effective load capacity of the self-discharging vehicle under various conditions is recorded. Accurate weighting is achieved and overloading is avoided. Vehicle operating data are recorded and data real time communication and transmission are conducted with outer equipment or an outer system. The weighting device and the working method for mining self-discharging vehicle is provided with the ability of autonomously recognizing operating state. And accuracy of the measured effective load capacity is guaranteed.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

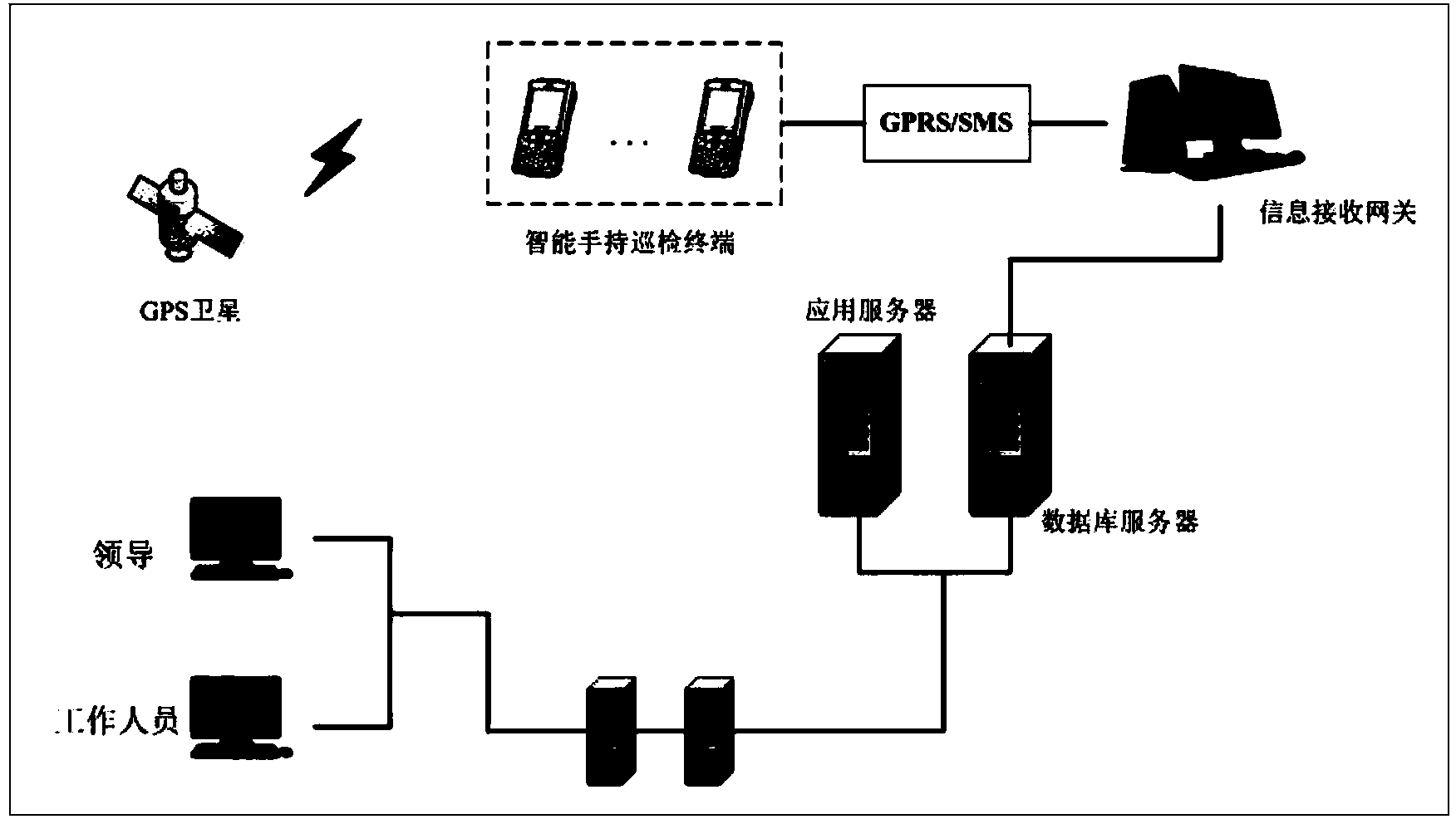

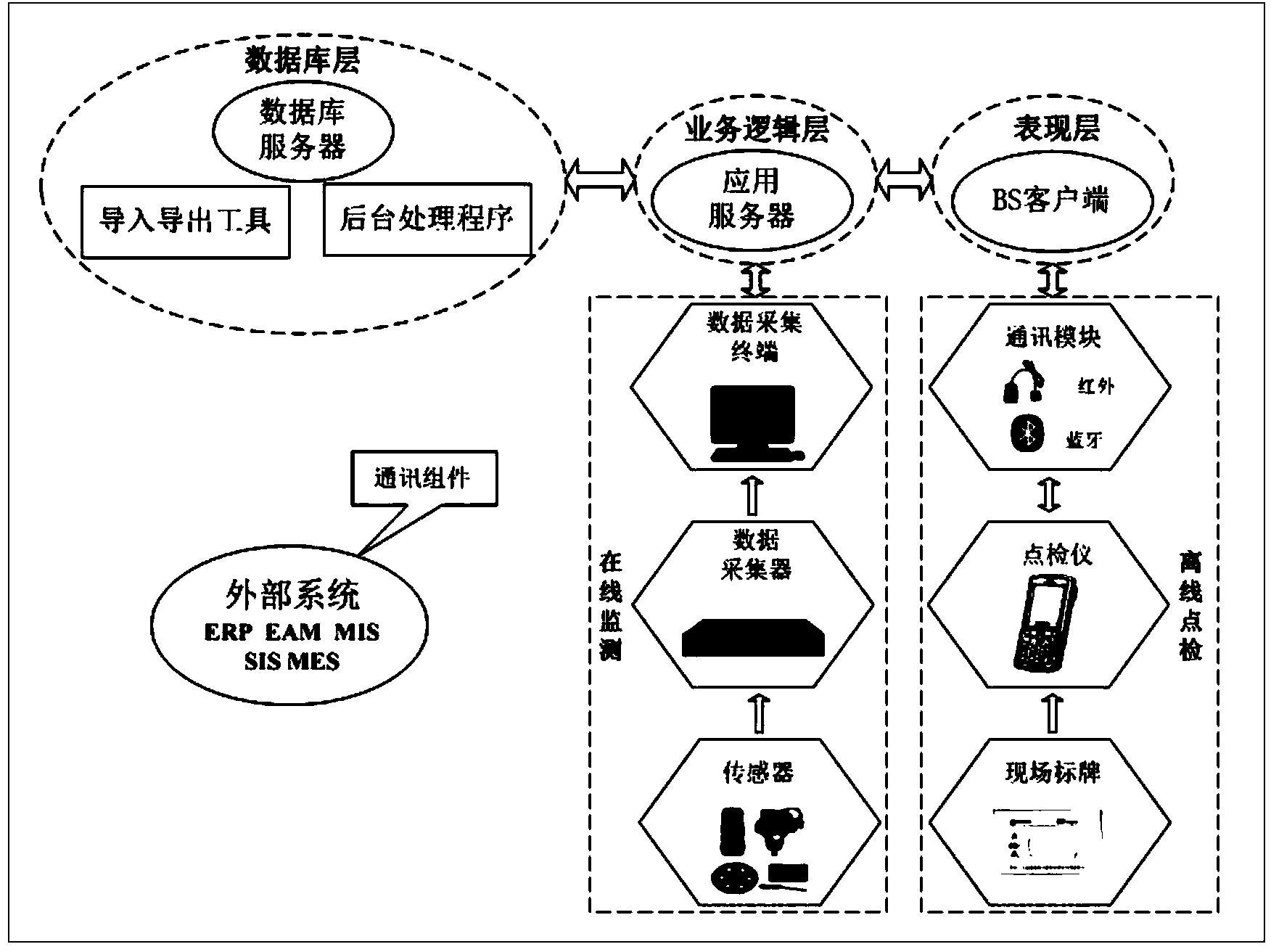

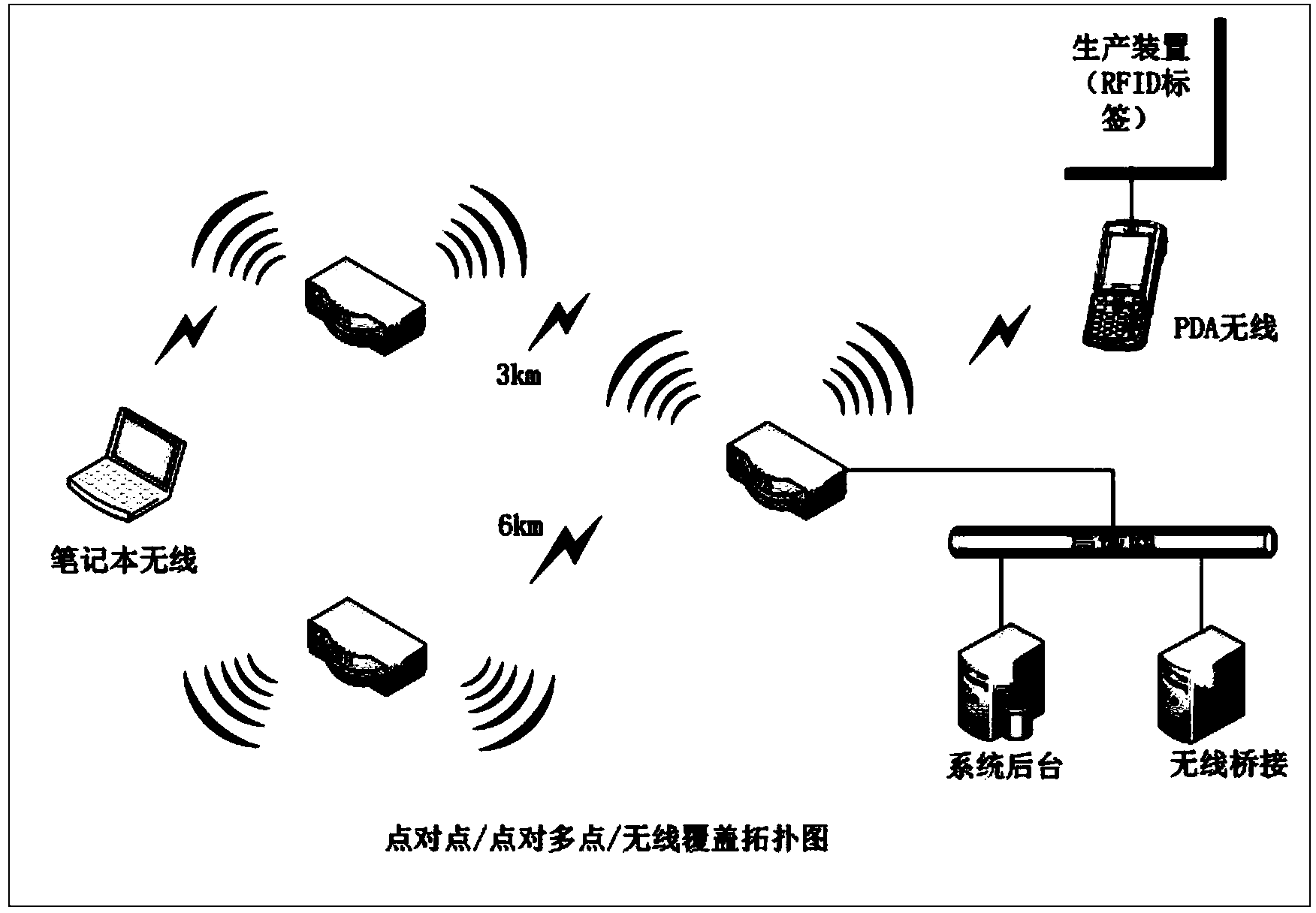

Chemical industry production site patrol system based on internet of things technology

InactiveCN103714434AChange uncontrollableImprove production management levelChecking time patrolsTechnology managementChemical industryThe Internet

The invention discloses a mechanical industry production site patrol system based on the internet of things technology. An MVC mode is adopted for the system. The system comprises a presentation layer, a service logic layer and a database layer, wherein the presentation layer is used for presenting functions of the system and interacting with a user, and the presentation layer of the system includes two forms, namely, a user browser end and a handheld patrol instrument. The service logic layer is used for data exchange between the database layer and the presentation layer, dispatching requests of the user, selecting an appropriate presentation method for display, explaining input of the user, and mapping the input of the user to the executable operation of the database layer. The database layer is composed of all levels of database resources.

Owner:SHANGHAI HUAYI INFORMATION TECH

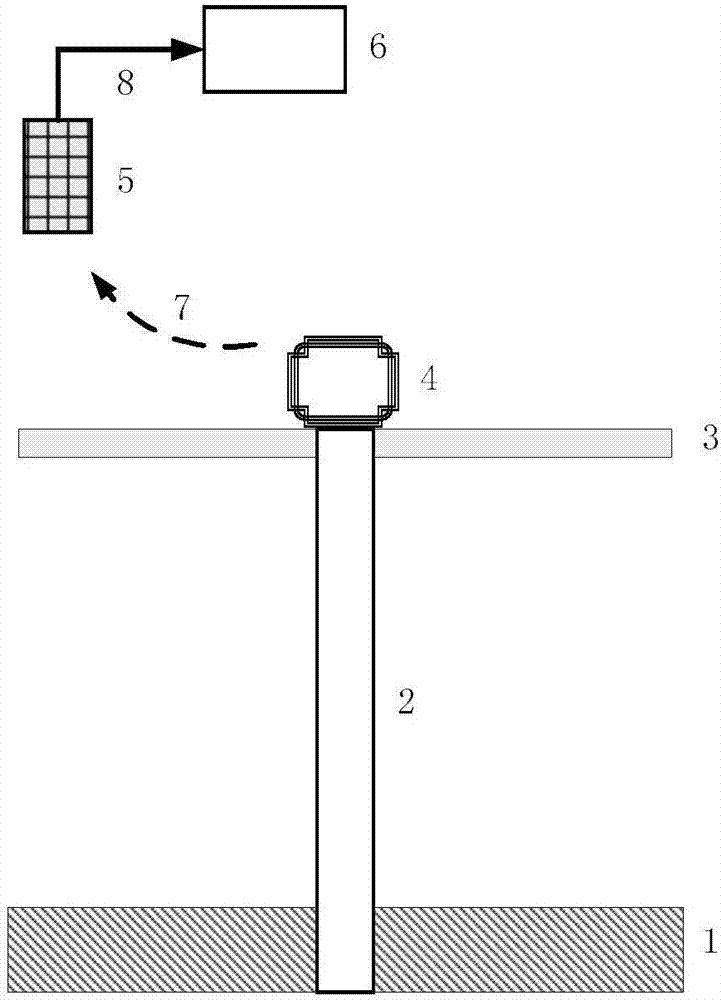

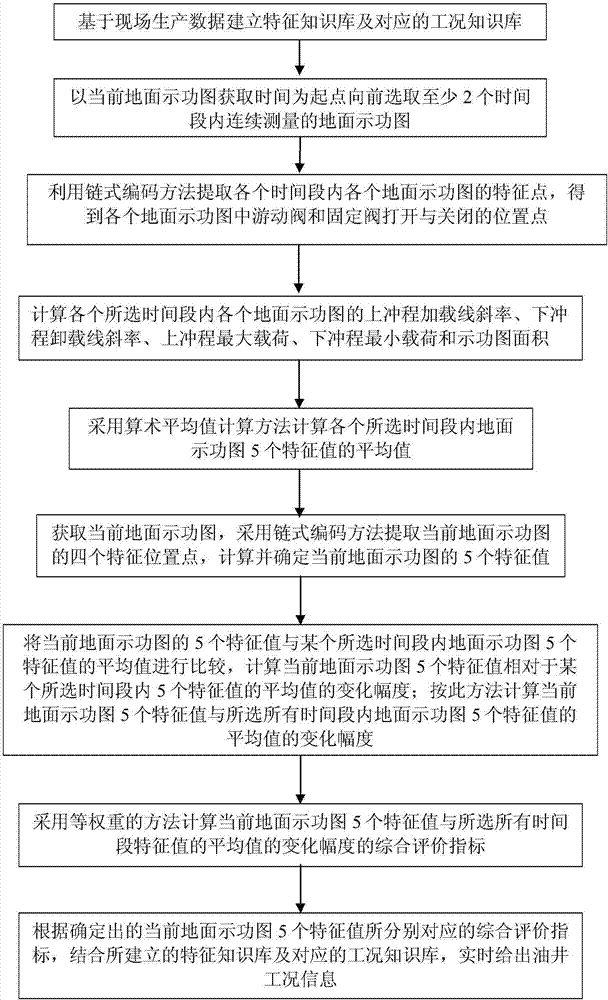

Rod pumped well real-time work condition diagnosing method based on time sequence surface dynamometer cards

The invention discloses a rod pumped well real-time work condition diagnosing method based on time sequence surface dynamometer cards. The rod pumped well real-time work condition diagnosing method comprises the following steps: establishing a characteristic knowledge base and a corresponding work condition knowledge base based on site production data; continuously measuring the surface dynamometer cards in each time quantum before the current surface dynamometer card is selected; using a chained encoding method to extract characteristic points of each surface dynamometer card in each time quantum, and obtaining the turning-on and turning-off positions of traveling valves and fixed valves in each surface dynamometer card; calculating the characteristics values of each surface dynamometer card in each selected time quantum, including upstroke loaded line slope, down stroke unloaded line slope, upstroke maximum load, down stroke minimum load and dynamometer card area; then, adopting an equal weight method to calculate the comprehensive evaluation index of variation amplitude of the average value of the characteristic value of the current surface dynamometer card and the selected characteristic value of all time quantum; and finally giving out oil well work condition information in combination with the characteristic knowledge base and a corresponding work condition knowledge base according to the comprehensive evaluation index.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

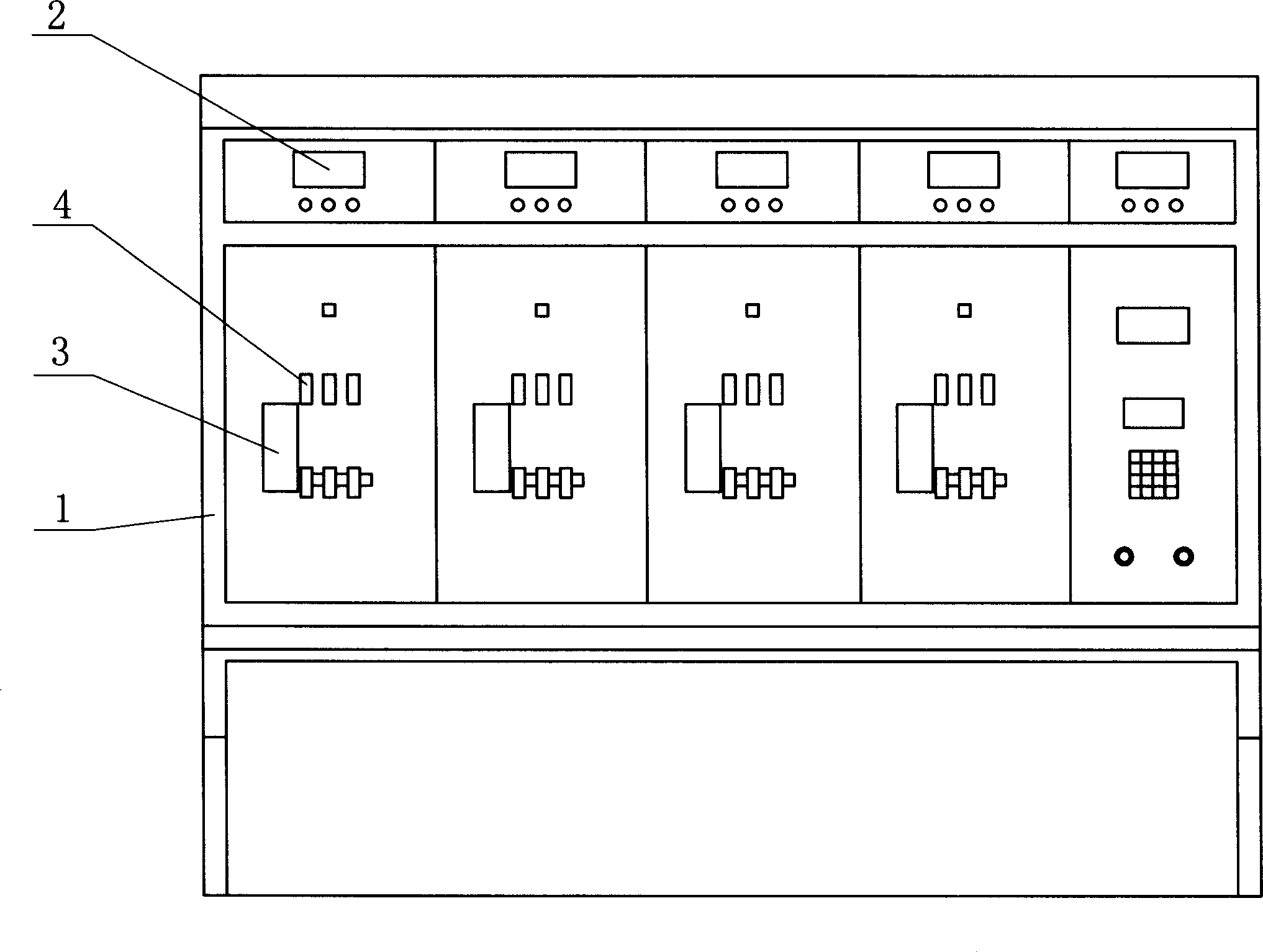

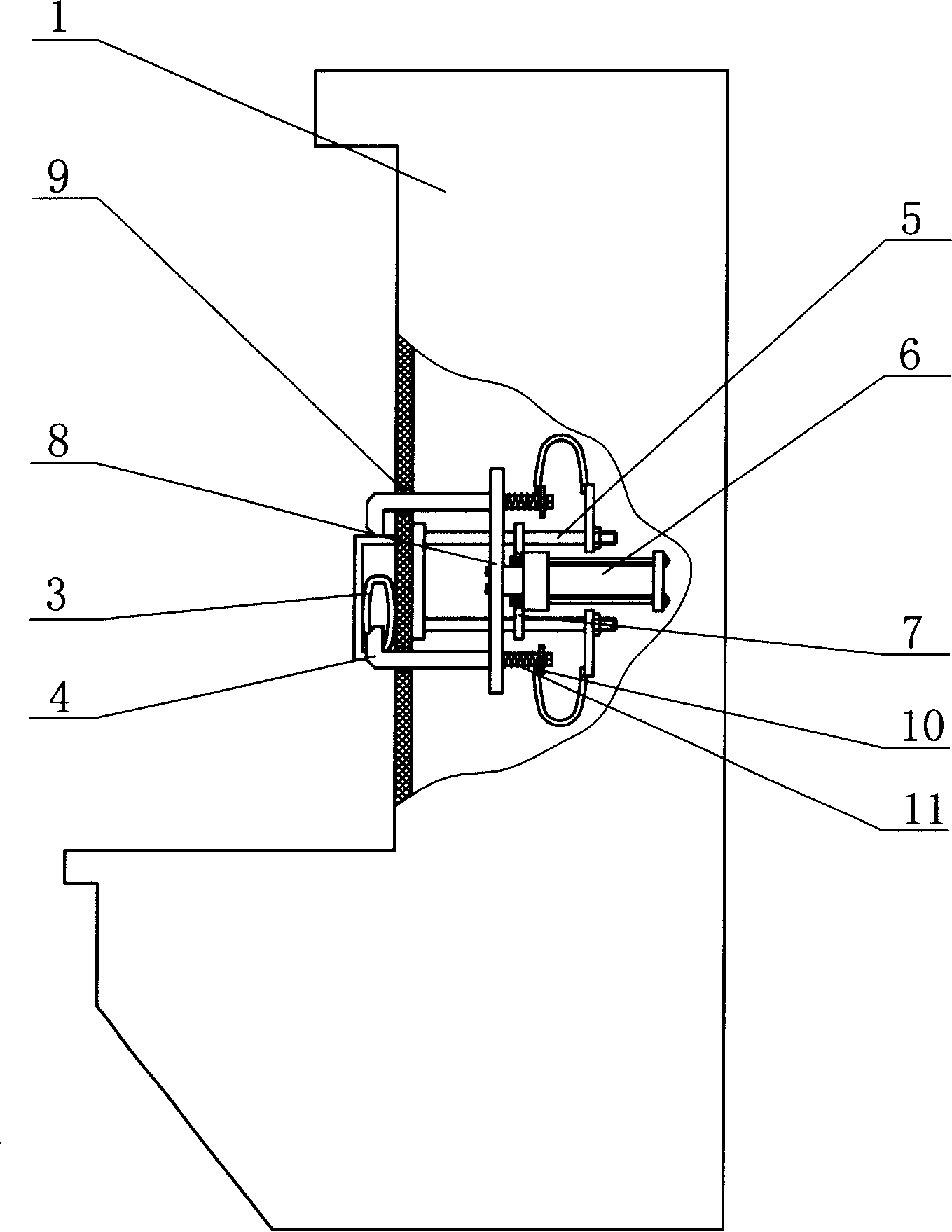

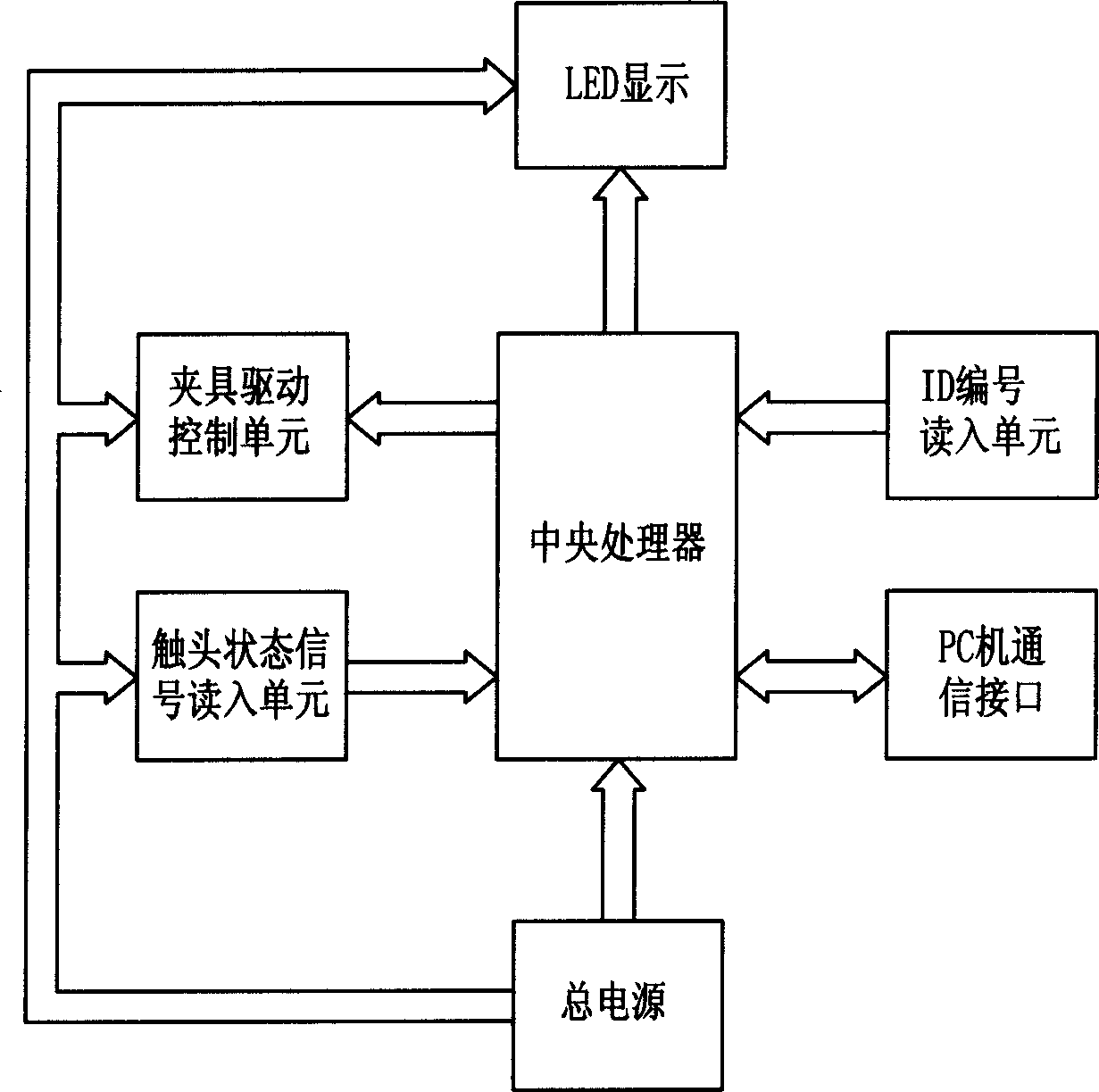

On-line intelligent checking table for low voltage breaker protective property

InactiveCN1716493AAvoid opportunitiesReduce the influence of human factorsCalibrating/seeting protective devicesLow voltageDisplay device

The on-line intelligent checking table for the protection property of low voltage breaker includes work table, fixture, display device, main detection loop and power circuit. The on-line intelligent checking table features that it includes also product ID distinguishing device, main control circuit and fixture drive executing mechanism. Owing to the product ID distinguishing device, the main control circuit and the fixture drive executing mechanism, the present invention reads in the product code, establishes product quality inspecting database, and stores and manages the database in PC during inspection, and this is favorable to raising product managing level and improving production process by means of the user's feedback information, raising product quality and preventing phony.

Owner:WENZHOU JUCHUANG ELECTRICAL TECH CO LTD

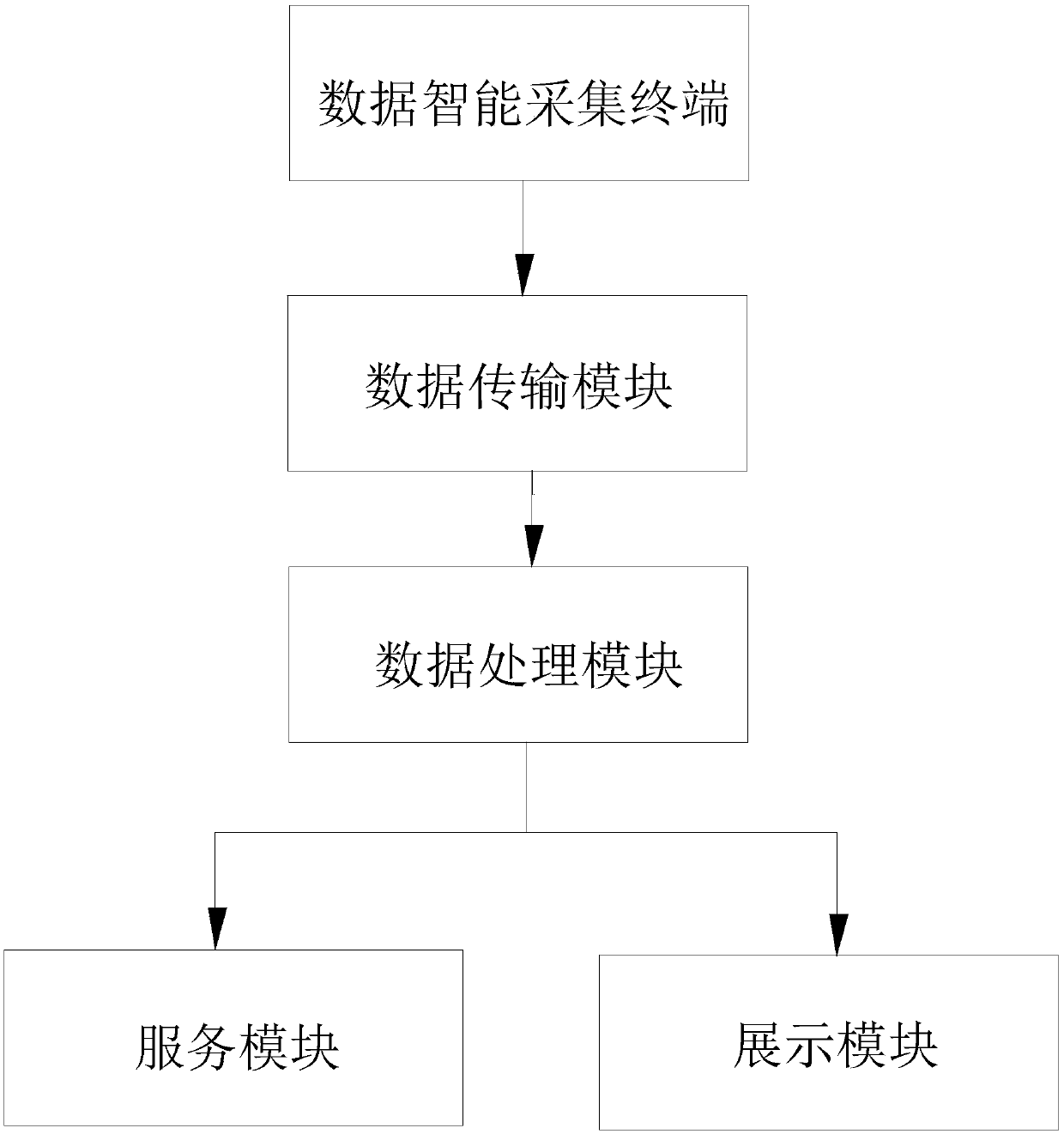

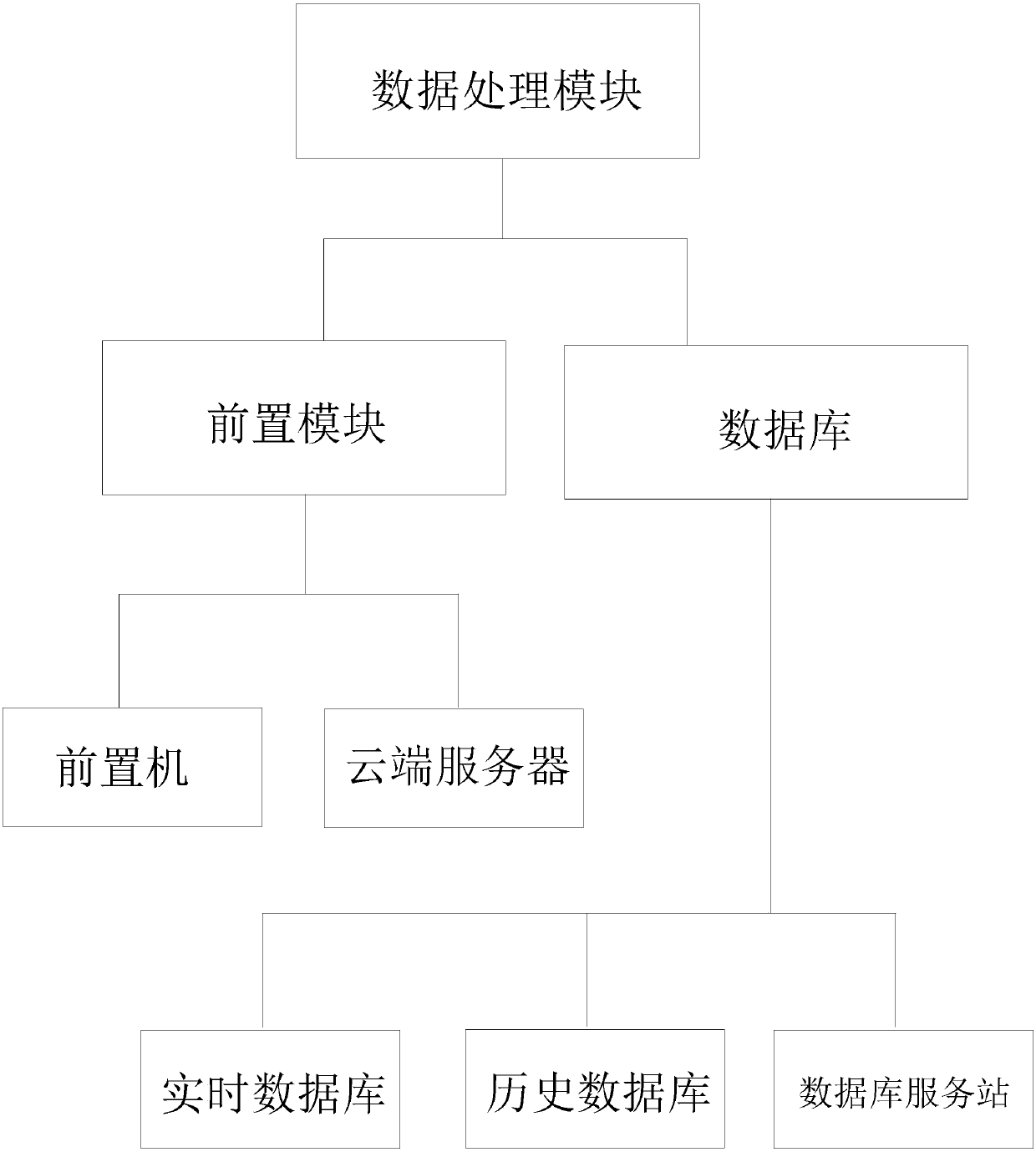

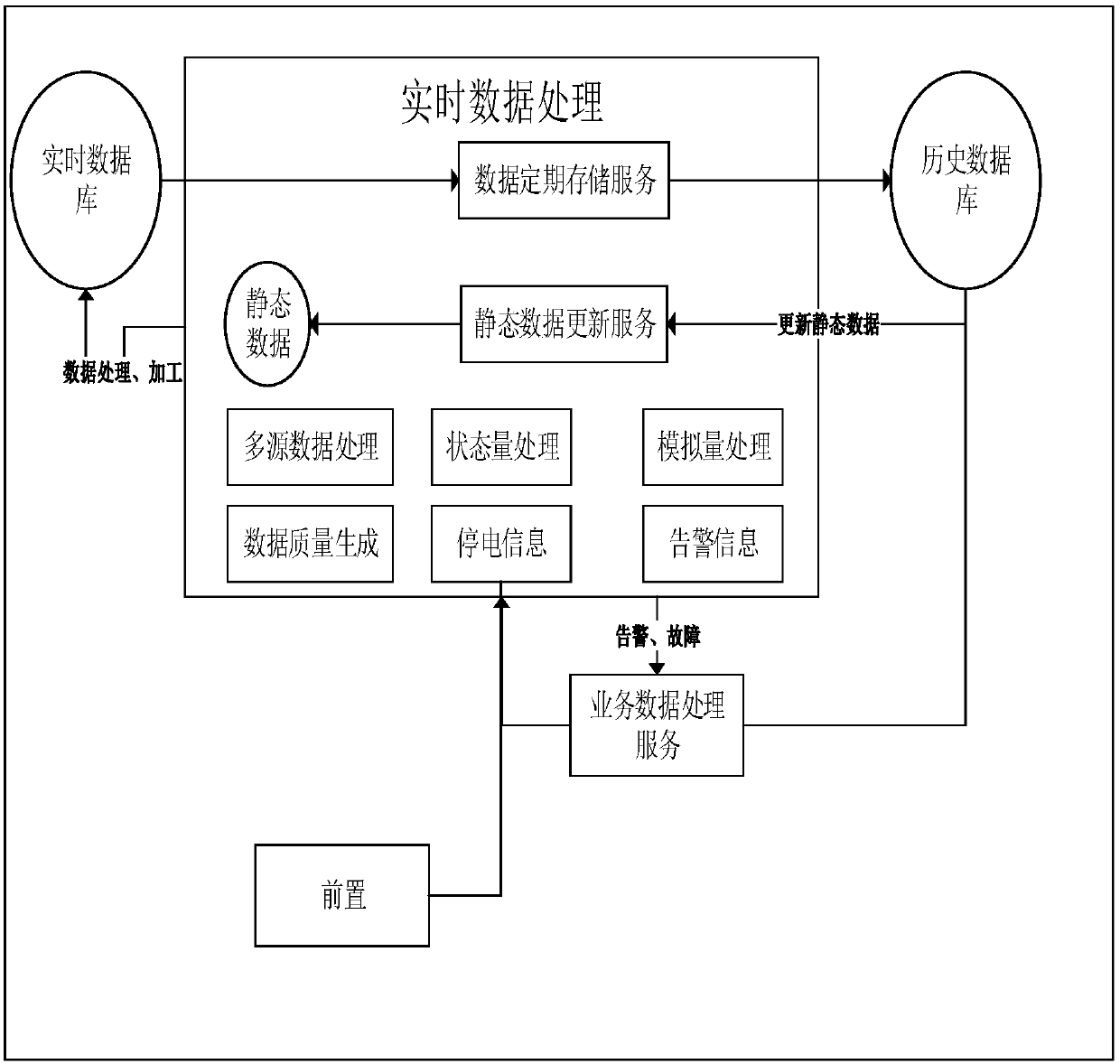

Integrated monitoring and managing system for middle and low voltage distribution network

ActiveCN107707029AMaster the operationRealize monitoringCircuit arrangementsInformation technology support systemLow voltageSmart grid

The invention discloses an integrated monitoring and managing system for a middle and low voltage distribution network. The integrated monitoring and managing system comprises an intelligent data collection terminal, a data transmission module, a data processing module, a service module and a display module, wherein the intelligent data collection terminal transmits initial data to the data processing module through the data transmission module; the data processing module carries out real-time processing on the obtained data, generates cooked data capable of being recognized by the system andstores the cooked data into a real-time database; the service module provides the cooked data to the outside world and generates a real-time state of the distribution network and a real-time alarm oran event record according to the cooked data; and the display module displays the cooked data in a form of an image or a video and provides a user with human-computer interaction with a managing function. The management level and the service quality of a middle and low voltage distribution network system can be improved, complaints from the user are reduced, informationalized, automated and interactive development of related business of the middle and low voltage distribution network is achieved and a foundation is laid for construction of a smart power grid.

Owner:ZHUHAI XUJIZHI ELECTRIFIED WIRE NETING AUTOMATIONCO +1

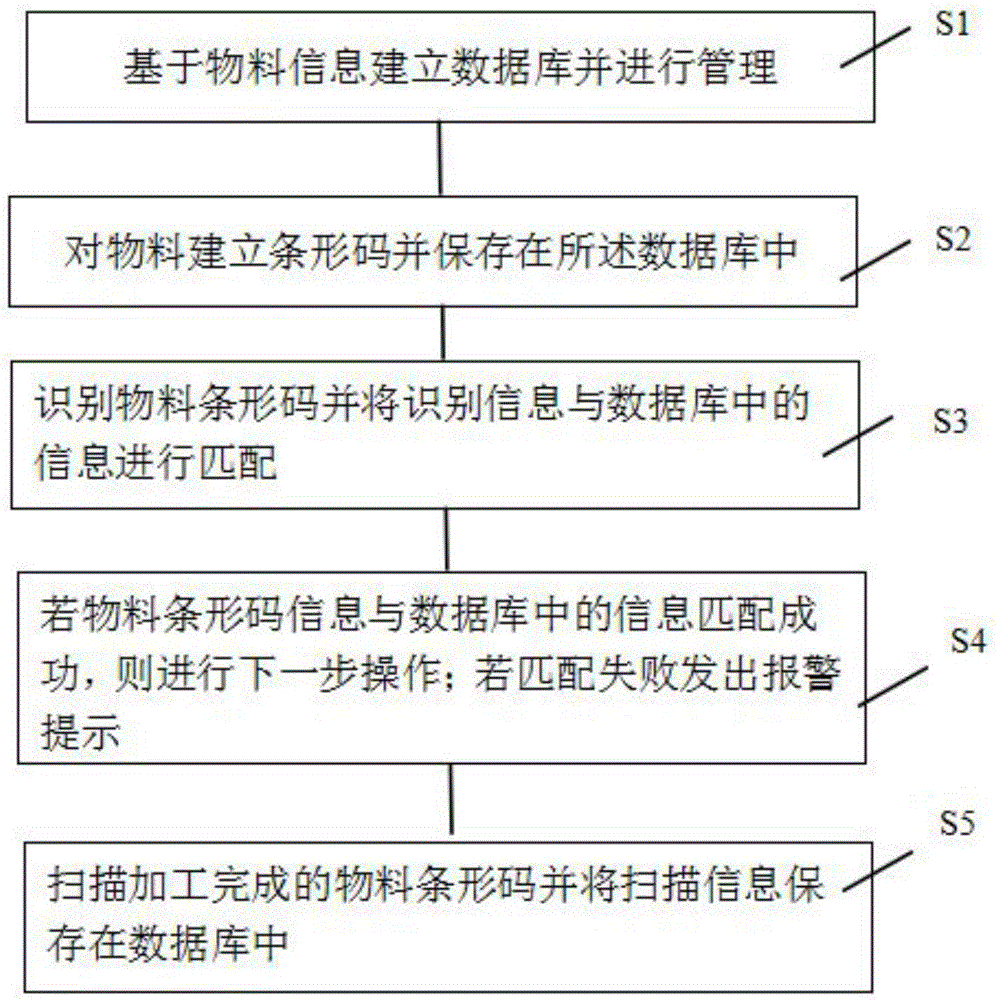

SMT material mistake preventing and tracing method and system

The invention provides an SMT material mistake preventing and tracing method and system. The method comprises the following steps that a database is established based on material information, and management is conducted; bar codes are established for materials and stored in the database; the material bar codes are recognized, and matching is conducted on the recognized information and the information in the database; if the material bar code information is matched with the information in the database successfully, the next step is conducted; if the material bar code information is failed to be matched with the information in the database, an alarm is sent out; and the bar codes of the materials which are processed completely are scanned, the scanning information is stored in the database, and the purpose of extracting production line data in real time can be achieved. It is not required to make feeding tables, feeding is carried out according to programs, material mistaking is prevented, and paper-free operation is achieved. Manual checking is not required, the efficiency is high, and no mistake will be made. The materials are sought quickly, the line exchanging efficiency is improved, and the employee pressure is lowered.

Owner:COMING INTELLIGENCE TECH CO LTD

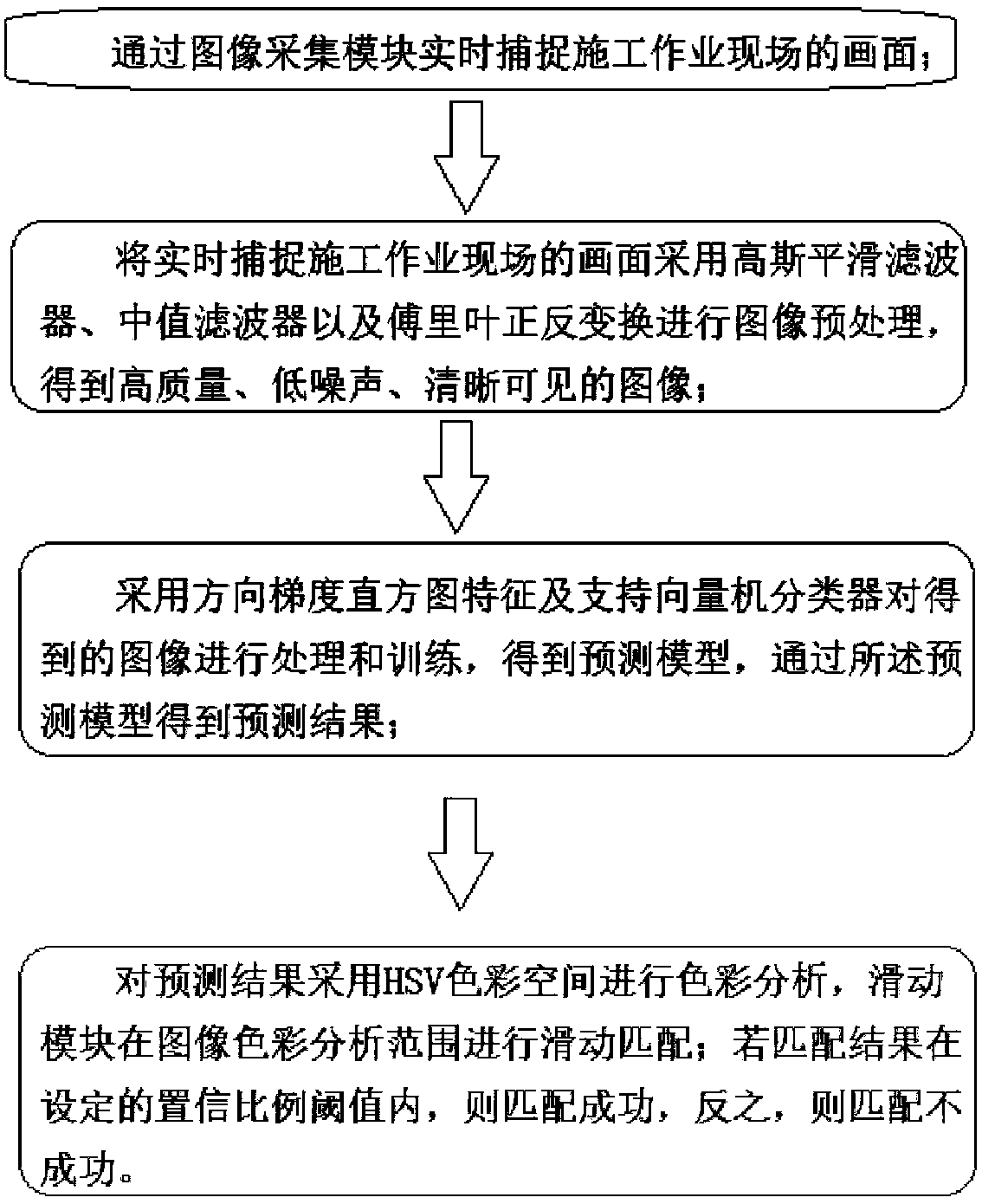

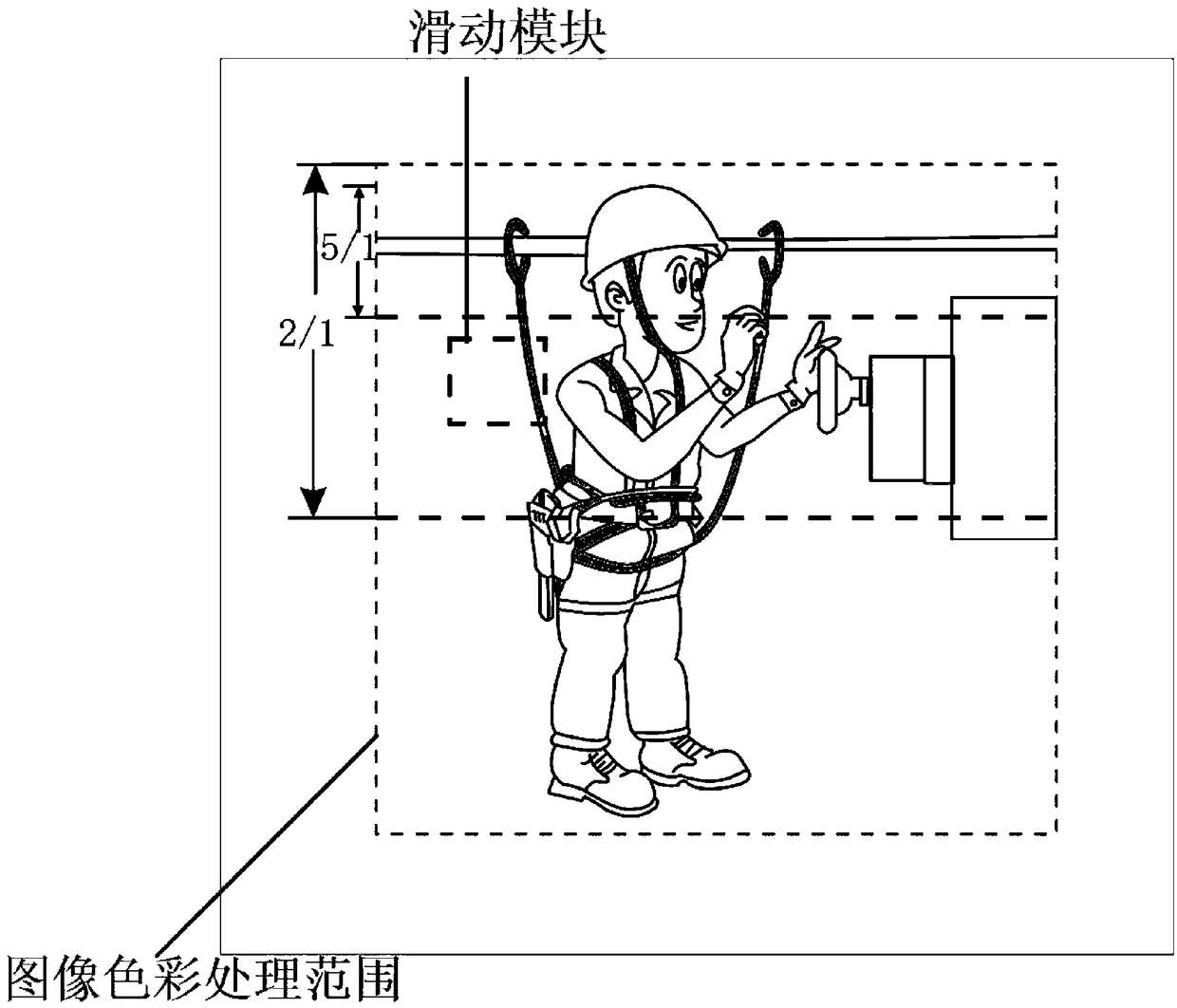

Safety belt wearing detecting device and detecting early-warning method for workman working high above the ground

InactiveCN108416289AReduce or even eliminate seat belt failureGuarantee personal safetyCharacter and pattern recognitionImaging processingHistogram of oriented gradients

The invention provides a safety belt wearing detecting device and detecting method for a workman working high above the ground. The detecting device is composed of an image collecting device and an image processing and identifying device. In addition, the detecting method comprises: step one, capturing a picture of a construction work site in real time by an image acquisition module; step two, carrying out image preprocessing on the picture, captured in real time, of the construction work site by using an image preprocessing module; step three, processing and training the obtained image by using directional gradient histogram features and a support vector machine classifier to obtain a prediction model and acquiring a prediction result by the prediction model; and step four, carrying out acolor analysis on the prediction result by using HSV color space, carrying out sliding matching in an image color analysis range by a sliding module, determining a matching success on the condition of determining a matching result to be in a set confidence ratio threshold, and otherwise, determining unsuccessful matching.

Owner:陕西中联电科电子有限公司

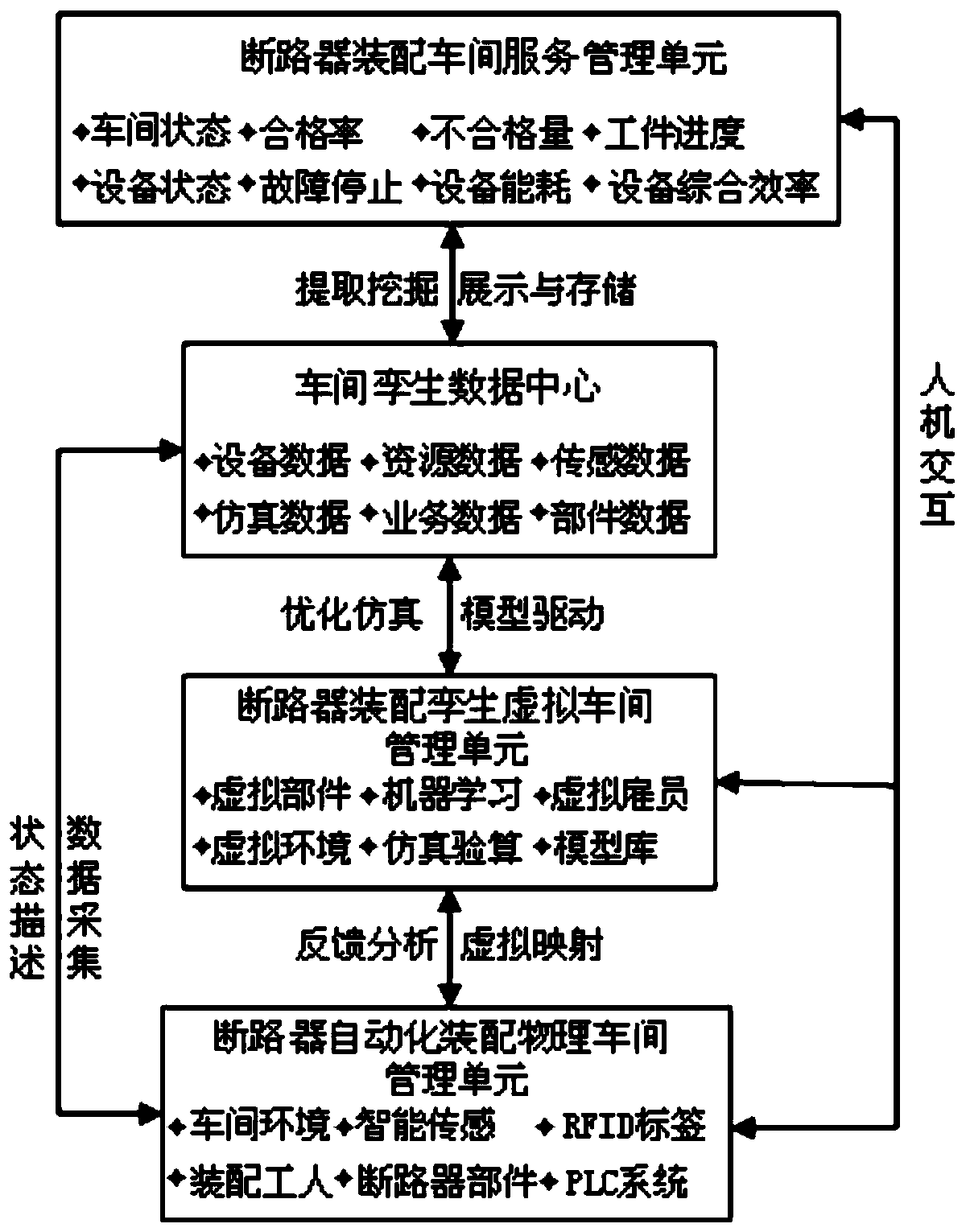

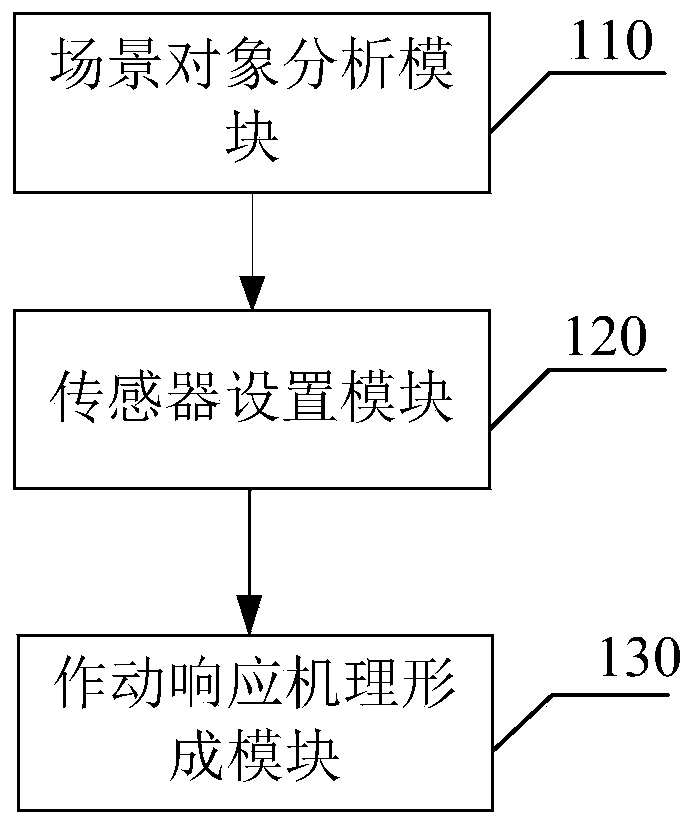

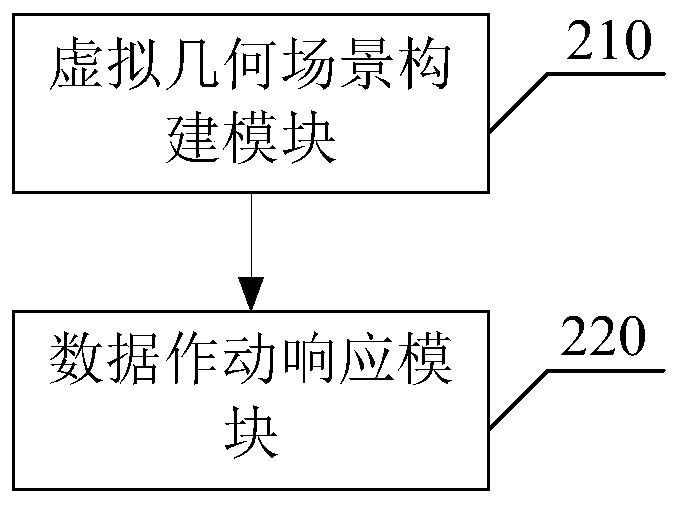

Management platform of circuit breaker automatic assembly digital twinning workshop

InactiveCN110989506AImprove production management levelRealize automatic controlTotal factory controlProgramme total factory controlAutomatic controlVirtual vehicle

The invention provides a management platform of a circuit breaker automatic assembly digital twinning workshop. The management platform comprises a circuit breaker automatic assembly physical workshopmanagement unit, a circuit breaker assembly twinning virtual workshop management unit, a workshop twinning data center and a circuit breaker assembly workshop service management unit. The circuit breaker automatic assembly physical workshop management unit performs scene object analysis, sensor network configuration and actuation response. The circuit breaker assembly twin virtual workshop management unit performs virtual geometric scene construction and data action response control. The workshop twin data center stores twin data. The circuit breaker assembly workshop service management unitperforms networking communication, twinning data construction and physical workshop management unit management and monitoring. According to the invention, intelligent and visual management of production elements, workshop activity plans, workshop production processes and other elements of the circuit breaker automatic assembly workshop is realized, and automatic control, parameter visualization and real-time state monitoring of a physical entity workshop are realized.

Owner:WENZHOU UNIV

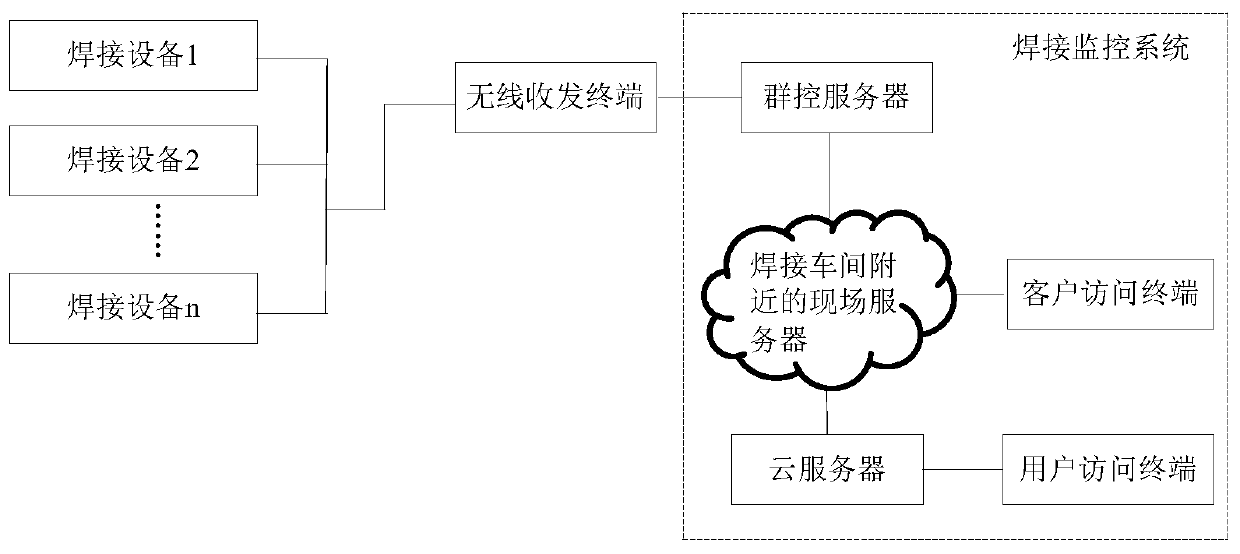

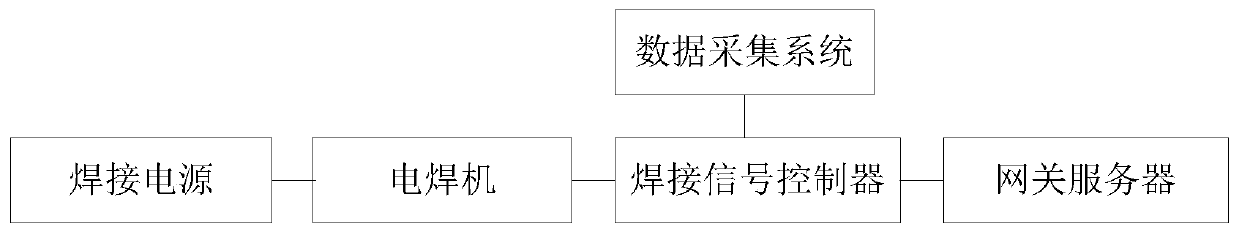

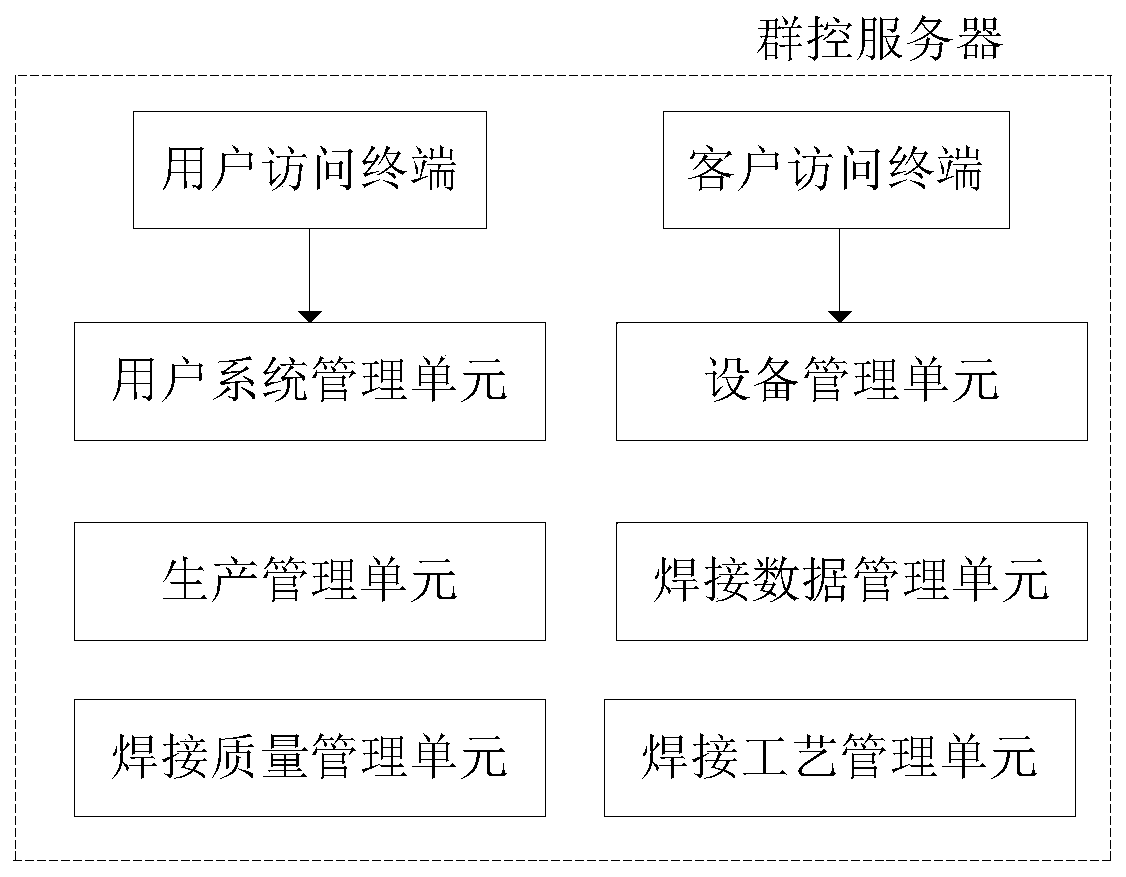

Informationized welding management control system and control method

PendingCN110193686AReal-time monitoring of welding operationsSimple networkingWelding/cutting auxillary devicesAuxillary welding devicesControl systemControl engineering

The invention discloses an informationized welding management control system and control method. The welding management control system involves one or more welding device arranged in a welding workshop and a welding monitoring system in communication connection with the welding device; the welding device comprises a welding machine power supply, a welding machine, a gateway server, a data acquisition system and a welding signal controller, wherein the data acquisition system and the welding signal controller are embedded in the welding machine, the welding machine power supply is electricallyconnected with the welding machine, the data acquisition system and the welding signal controller which are embedded in the welding machine, the gateway server and the data acquisition system are electrically connected with the welding signal controller, and the gateway server is in communication connection with the welding monitoring system so as to realize the management and control of the welding process information. According to the system and the method, the welding device can be controlled and managed, and the running state of the welding device can be monitored, so that the automation level and the management level of the welding workshop are improved, and the control of the product welding quality is improved.

Owner:南宁嘉昌机电设备有限责任公司

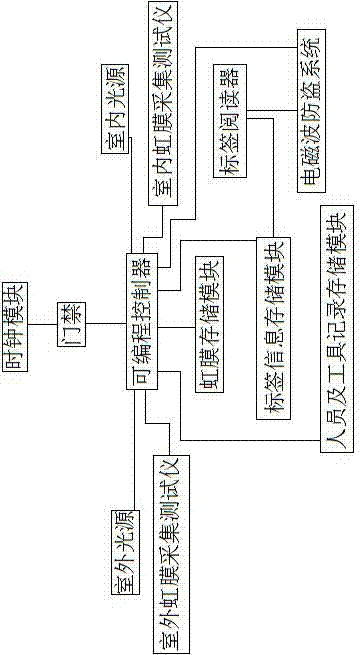

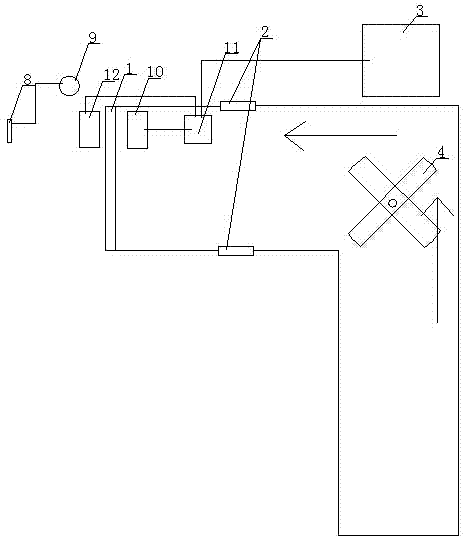

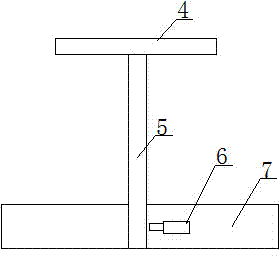

Intelligent electric power safety management system based on iris algorithm

InactiveCN104766069AImprove accuracyImprove securityCo-operative working arrangementsCharacter and pattern recognitionSafety management systemsProgrammable logic controller

The invention provides an intelligent electric power safety management system based on an iris algorithm. The intelligent electric power safety management system comprises a door control part, a programmable controller connected with the door control part, RFID labels bonded to tools, an outdoor iris testing instrument installed outside a tool room and connected with the programmable controller, and an indoor iris testing instrument installed inside the tool room and connected with the programmable controller, the programmable controller is connected with an iris storage module, a label information storage module and a personnel and tool record storage module, the label information storage module is connected with an RFID label reading module, and the door control part is connected with a clock module. Personnel information and equipment and tool data are accurately and rapidly collected and managed for the electric power department, articles gotten by each operation person each time are accurately registered, missing of the tools is prevented, and meanwhile the double-safety of personnel and equipment is achieved.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN

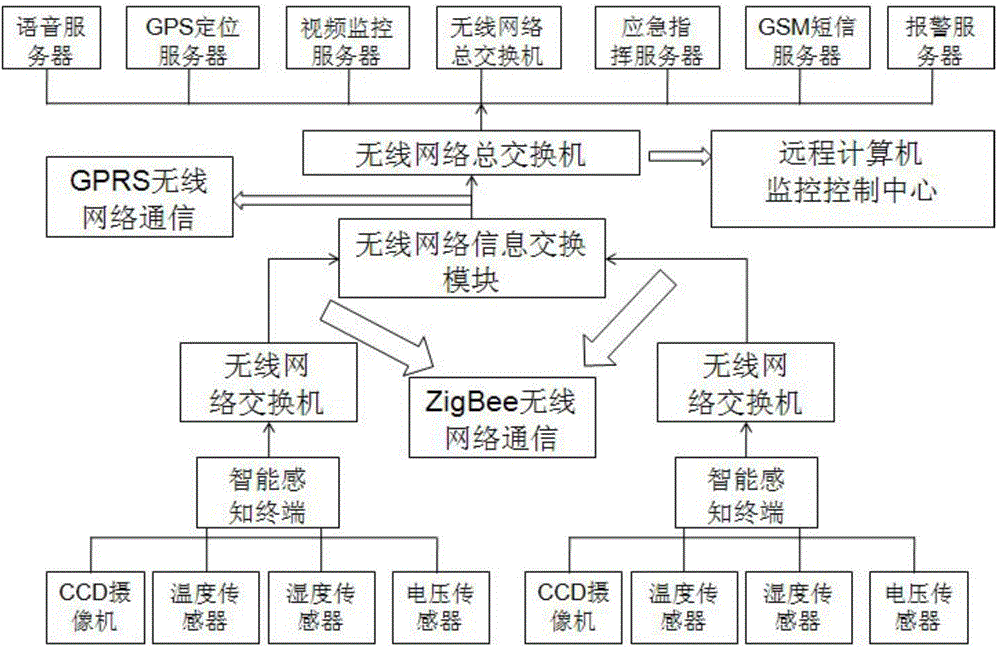

High-voltage power wireless network monitoring, alarming and positioning system

InactiveCN104820414ALearn about the operationReal-timeProgramme total factory controlHigh pressureRemote computing

The invention provides a high-voltage power wireless network monitoring, alarming and positioning system. An intelligent sensing terminal acquires the temperature, humidity, voltage and on-site video conditions of the high-voltage power, and transmits to a wireless network information exchange module by use of a wireless communication module. The wireless network information exchange module is interconnected with a remote computer monitoring and control center by use of a wireless network communication module so as to transmit the acquired information by the intelligent sensing terminal to the remote computer monitoring and control center and give out an alarm and perform positioning for abnormal cases occurring to the high-voltage power. According to the invention, remote wireless real-time monitoring and alarm are achieved, the operation of the high-voltage power can be known in real time through the arrangement of the intelligent sensing terminal, and the abnormal cases are alarmed and positioned.

Owner:STATE GRID CORP OF CHINA +1

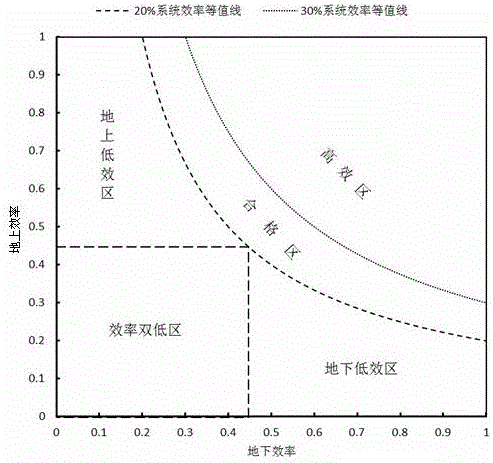

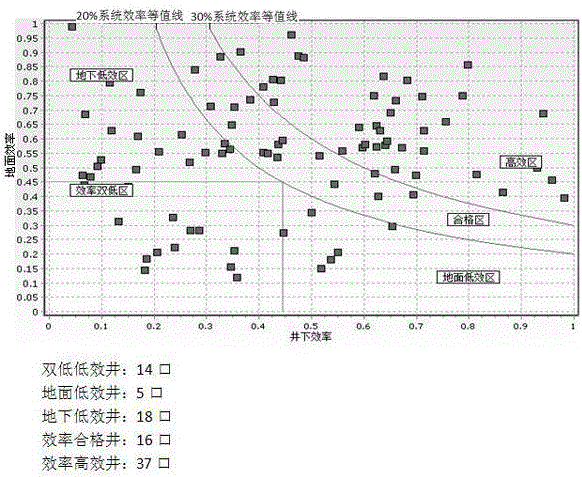

Evaluation and rectification method based on operation conditions of rod-pumped wells in whole block

ActiveCN105863607AImprove production management levelTo achieve the effect of economic intensificationSurveyConstructionsParallel computingIndicator diagram

The invention relates to an evaluation and rectification method based on operation conditions of rod-pumped wells in a whole block. Relevant data in an A2 database are extracted; the load rate, the torque load rate and the power load rate are worked out, and ground efficiency, underground efficiency and system efficiency are worked out through indicator diagram data; and evaluation criterions of key nodes such as the rod-pumped well system efficiency, the motor load rate, the reduction gearbox load rate, the polished rod load rate, the pump discharge coefficient and the submergence depth, and corresponding rectification measures are established. The operation conditions of the rod-pumped wells in the whole block are considered, the wells to be rectified are screened out according to the evaluation criterions, the numbers of the wells are listed, the specific rectification measures are proposed for the wells according to specific problems, and the reliable technological method is provided for efficient and economical management of the wells in the whole block.

Owner:NORTHEAST GASOLINEEUM UNIV

Food supply and quality supervision and tracing system

PendingCN107944719AGuarantee the safety of daily consumptionImprove production management levelClosed circuit television systemsResourcesInformation processingFood safety

The invention provides a food supply and quality supervision and tracing system comprising a food information management platform, a food information processing center, a purchasing information management platform, a food quality detection platform, a food information tracing platform, and an authentication management server. The food information management platform is used for recording relevantinformation of food in processes of production, transportation and sales; the food information processing center is connected to the food information management platform; the purchasing information management platform includes a first image collector; the food quality detection platform is connected to the food information processing center and the purchasing information management platform; the food information tracing platform is connected with the food information management platform and the food quality detection platform; and the authentication management server is connected to the food information management platform. Therefore, relevant information of all links of raw material cultivation, processing, packaging, storage, transportation and sales of the food is recorded truly and reliably by image collection. When a safety problem occurs at the food, traceability is realized quickly and the person in charge is found out quickly, so that the production and sales of food companiesare supervised effectively.

Owner:ZHENGZHOU BENNONG AGRI TECH CO LTD

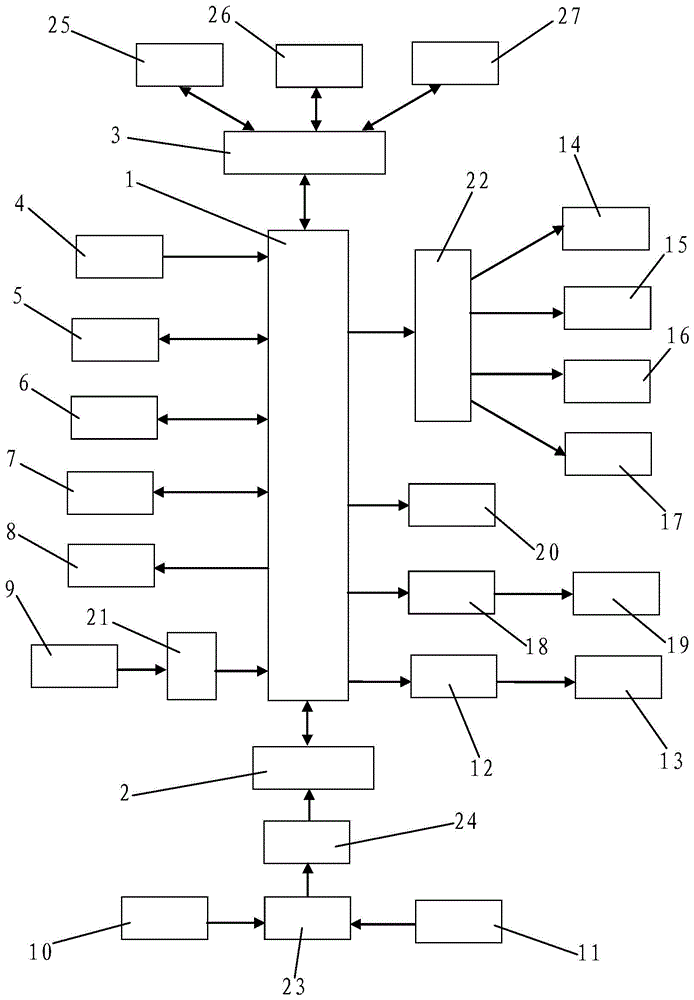

Concrete batching stirring control system

InactiveCN104552608AEasy and fast programmingLess nestingIngredients proportioning apparatusControl apparatusAutomatic controlControl system

The invention discloses a concrete batching stirring control system. The concrete batching stirring control system comprises an input signal device, an output signal device, a main controller, an auxiliary controller I, an auxiliary controller II, a storage, a watchdog circuit, a timer and an audible and visual alarm, wherein the main controller is used for receiving material batching information and controlling the whole concrete batching stirring process; the auxiliary controller I is used for acquiring field sensor signals; the auxiliary controller II is used for expanding functions of the concrete batching stirring control system so that the system can be in communication with an upper computer of a monitoring center; the storage is used for storing running parameters and the material batching information of the system; the watchdog circuit is used for preventing the main controller from being halted due to various interferences; the timer and the audible and visual alarm are respectively connected with the main controller. The concrete batching stirring control system is reasonable in design, comprehensive in function, and low in input cost; the automatic control of the whole process of batching, discharging and stirring at a concrete stirring station by operation can be realized; the contradict between the weighing precision and the weighing speed is solved; the production management level of the stirring station is improved; the equipment running fault rate is reduced.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

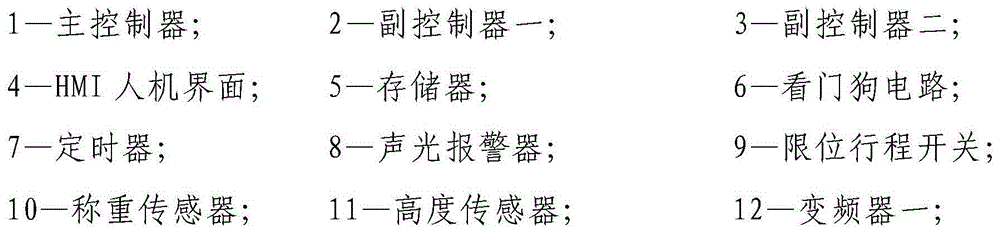

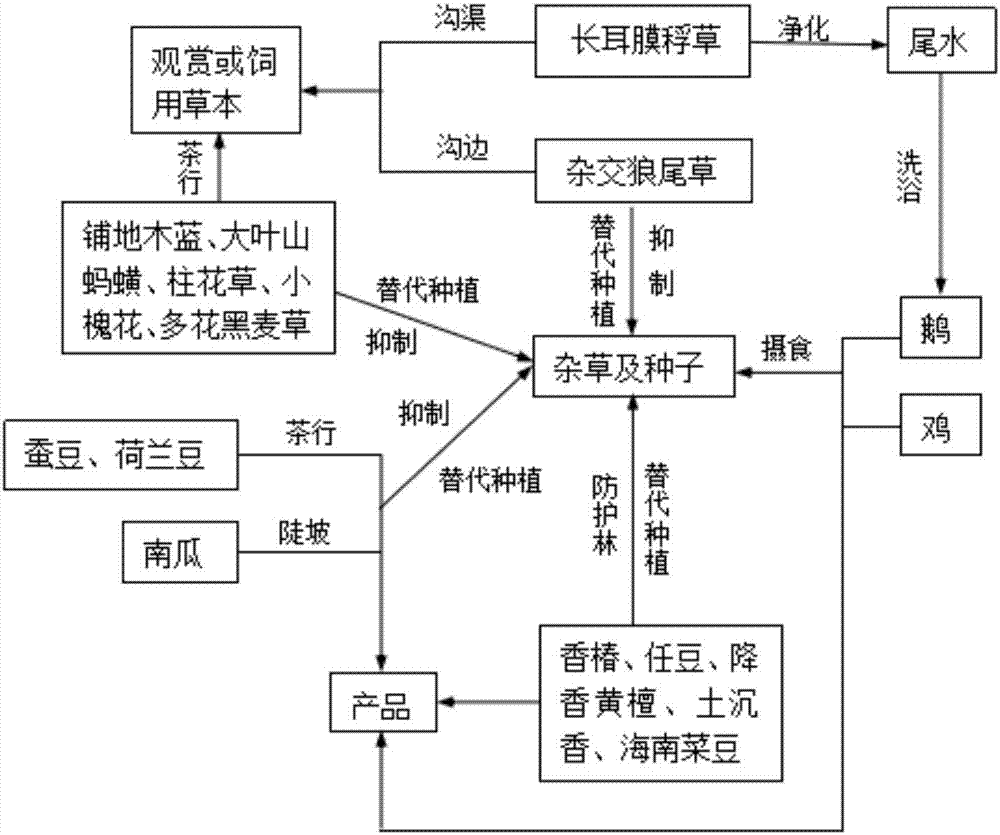

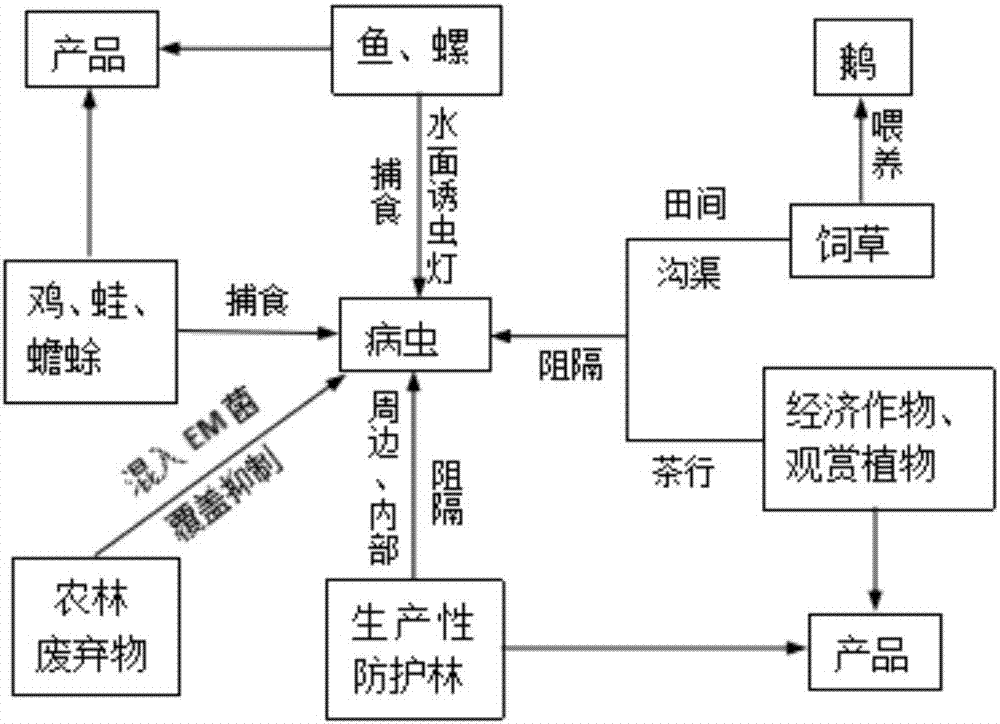

Ecological management and protection system of young tea plantation

InactiveCN107211807AImprove the landscape effectIncrease economic incomeClimate change adaptationPisciculture and aquariaTerrainDisease

The invention belongs to the field of tea plantation management and protection, and particularly relates to an ecological management and protection system of a young tea plantation. The system comprises an ecological prevention and control unit and a soil fertilizing unit, and the ecological prevention and control unit is in charge of weed prevention and control and disease and pest prevention and control; weed prevention and control includes intercropping economic crops and herbal ornamental or feed plants in the tea plantation, arranging ecological protection forest at highest terrain, on peripheral four sides around and at harmful air ports of the tea plantation, arranging water storing and draining ditches around the tea plantation, planting hybrid pennisetum beside the ditches and planting aquatic forage grass in the ditches; disease and pest prevention and control includes a pest inducing lamp in a pond and breeding chickens, fogs and toads in the tea plantation; the soil fertilizing unit comprises covering agricultural and forestry waste smashed raw material matrixes among ridges of the tea plantation for 5-10cm in thickness, planting green manure like green forage grass and leguminous plants or economic crops and breeding earthworms in the tea plantation. The ecological management and protection system is environment-friendly, simplified, efficient, easy to realize and wide in application range and can achieve operational objectives of ecologization, systematization and scientification.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

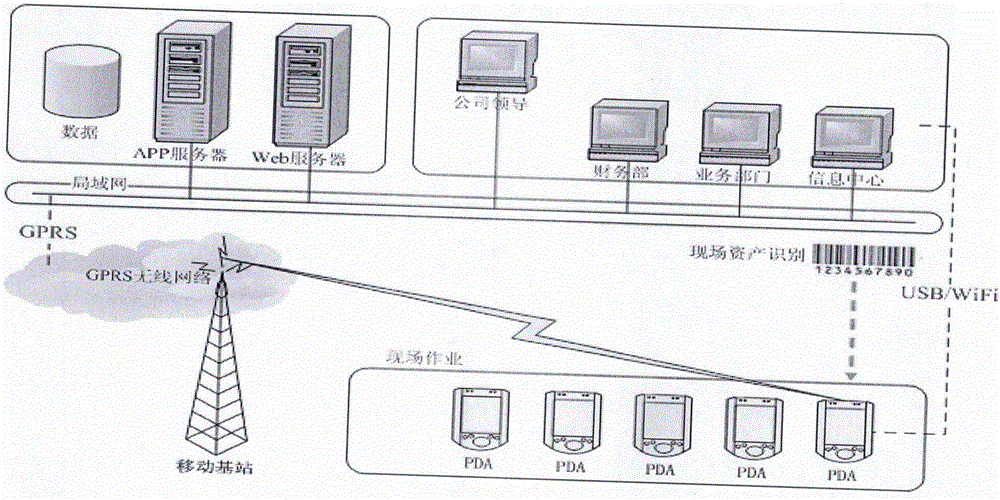

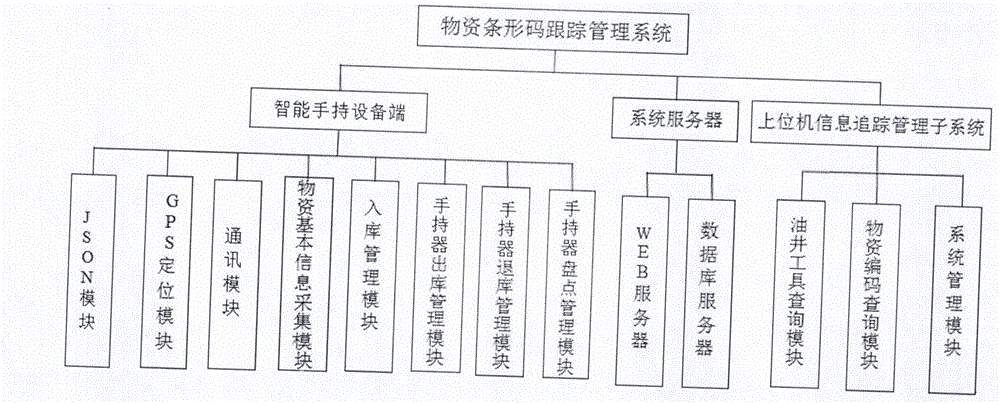

Material barcode tracking management system

InactiveCN106156982ARealize real-time monitoringKeep abreast of usageLogisticsWorkstationGlobal Positioning System

The invention discloses a material barcode tracking management system which comprises an intelligent handheld equipment terminal and a system server. The intelligent handheld equipment terminal uploads material data to the system server through a wireless network or downloads the same from the system server; the intelligent handheld equipment terminal comprises a JSON (JavaScript object notation) module, a communication module, a GPS (global positioning system) positioning module, a material basic information collection module, a handheld device warehousing-out management module and a handheld device warehouse-withdrawal module. Barcode management technology, mobile platform technology, geographic information technology and GPS positioning technology are applied in an oilfield material management system, so that management ways of the oilfield system are enriched, management level is improved, reliable material application information is provided to management personnel, and materials are ensured to be applied to specific workstations.

Owner:NORTHEAST GASOLINEEUM UNIV

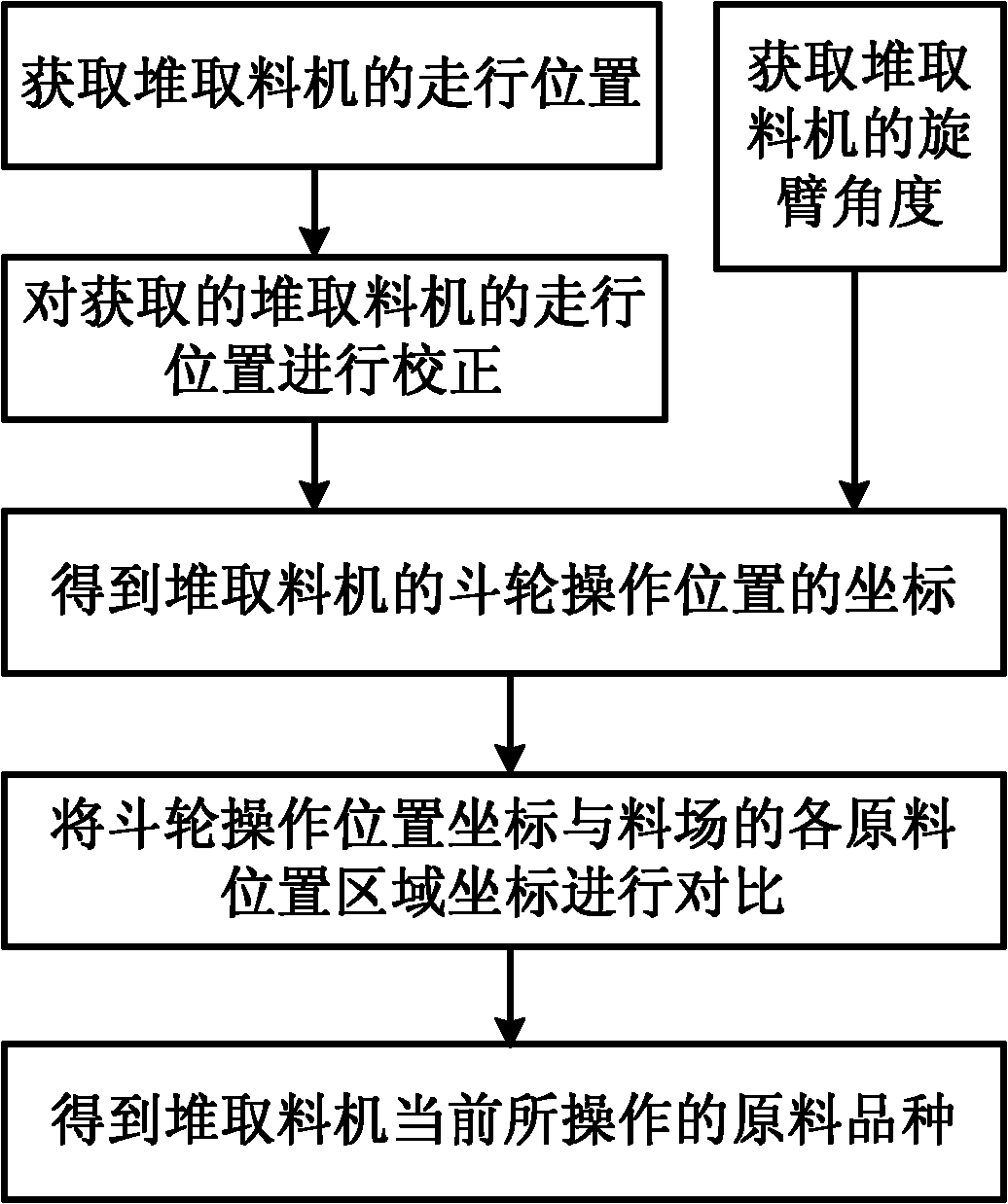

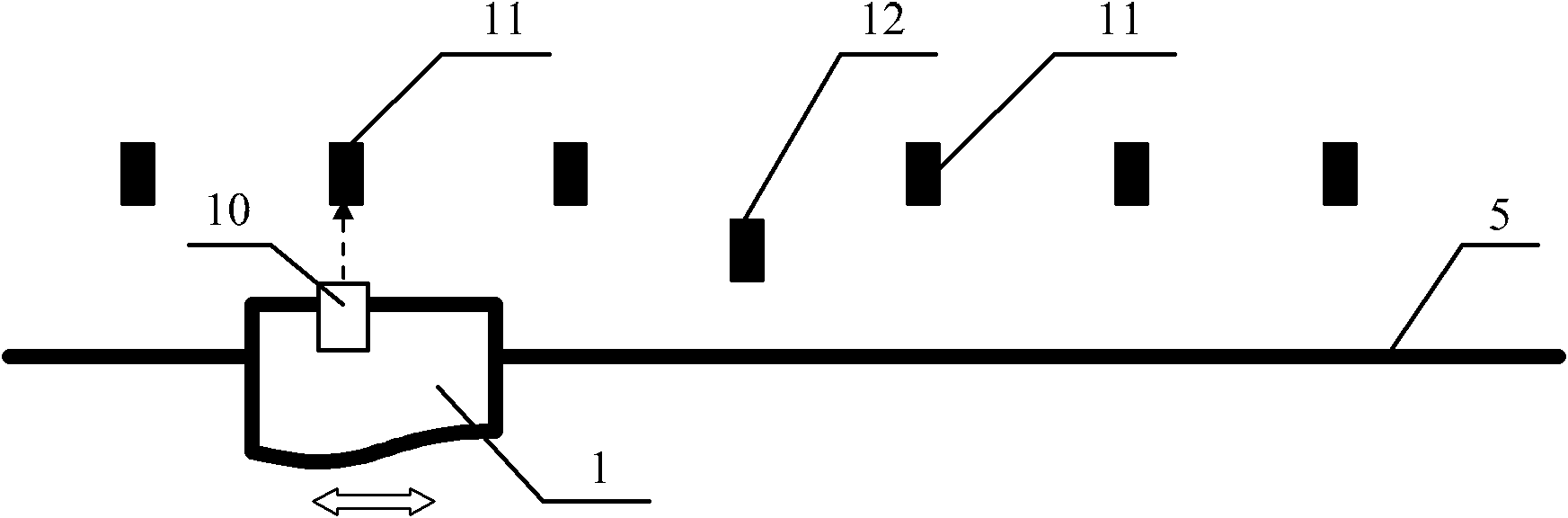

Method and system for identifying varieties of piled and taken raw materials in stockyard

ActiveCN102020118AAvoid mixing accidentsElimination of mixed accidentsLoading/unloadingEngineeringMechanical engineering

The invention relates to a method and a system for identifying the varieties of piled and taken raw materials in a stockyard. The method comprises the following steps of: acquiring the running position of a material piling and taking machine and the angle of a spiral arm of the material piling and taking machine; obtaining the operating position coordinates of a bucket wheel, positioned at the tail end of the spiral arm, of the material piling and taking machine according to the acquired running position of the material piling and taking machine, the angle of the spiral arm, the spiral arm length of the material piling and taking machine and the length of the stockyard; and comparing the operating position coordinates of the bucket wheel with the position area coordinates of each raw material in the stockyard to obtain the varieties of the raw materials currently operated by the material piling and taking machine. The identification method is not influenced by external factors; and inthe method and the system, the varieties of the raw materials operated by the material piling and taking machine can be accurately identified in various environments so as to avoid the occurrence of variety mixing accidents and improve the production efficiency.

Owner:中广核智能科技(深圳)有限责任公司

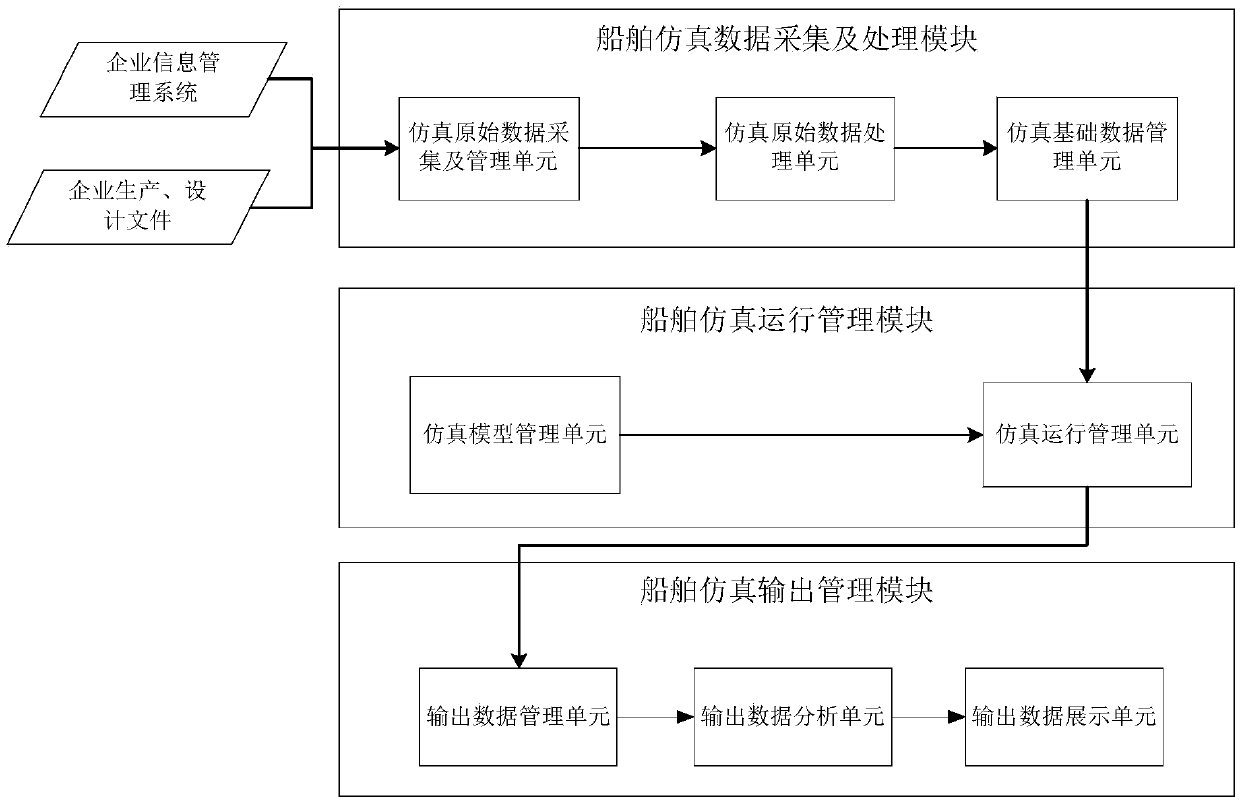

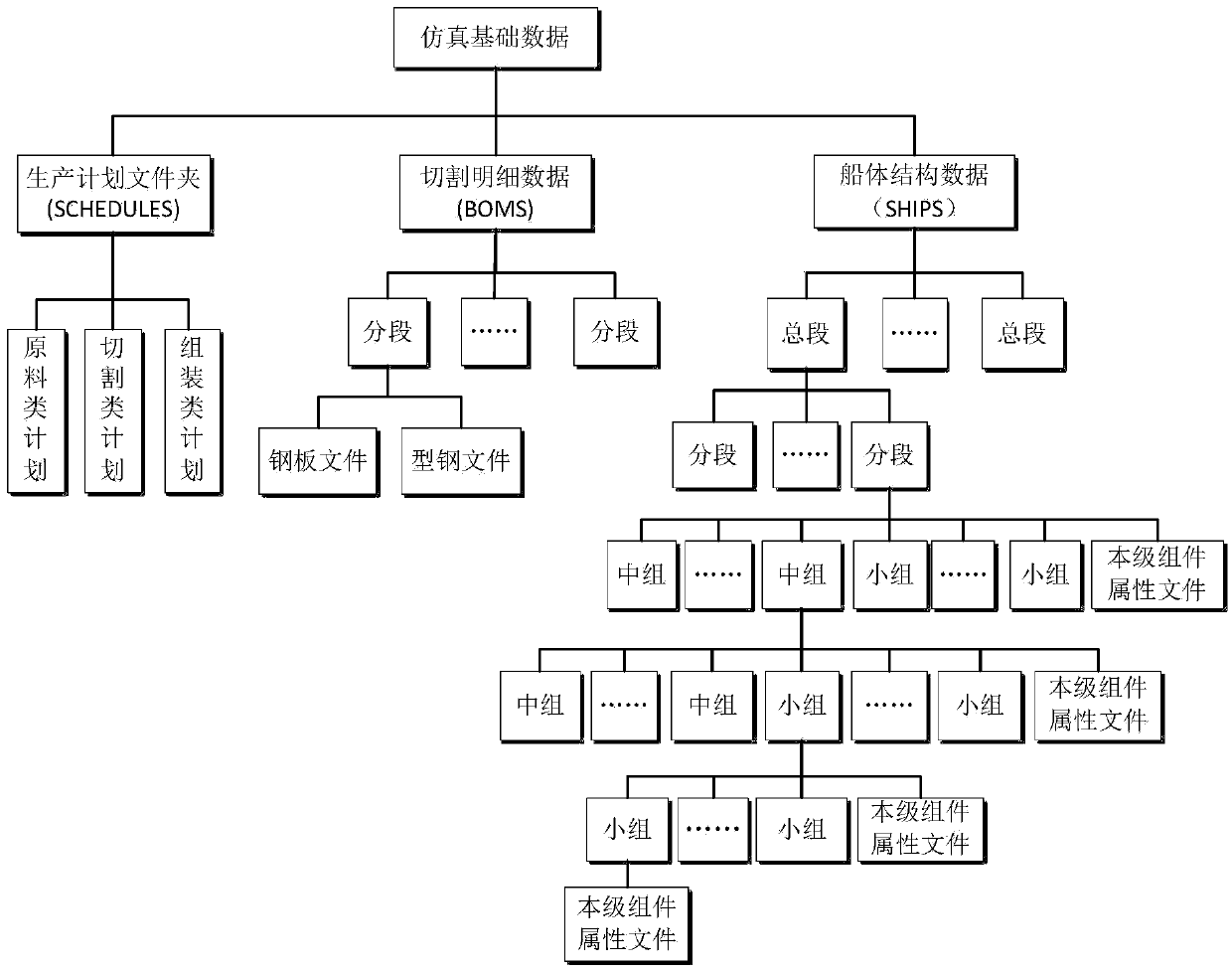

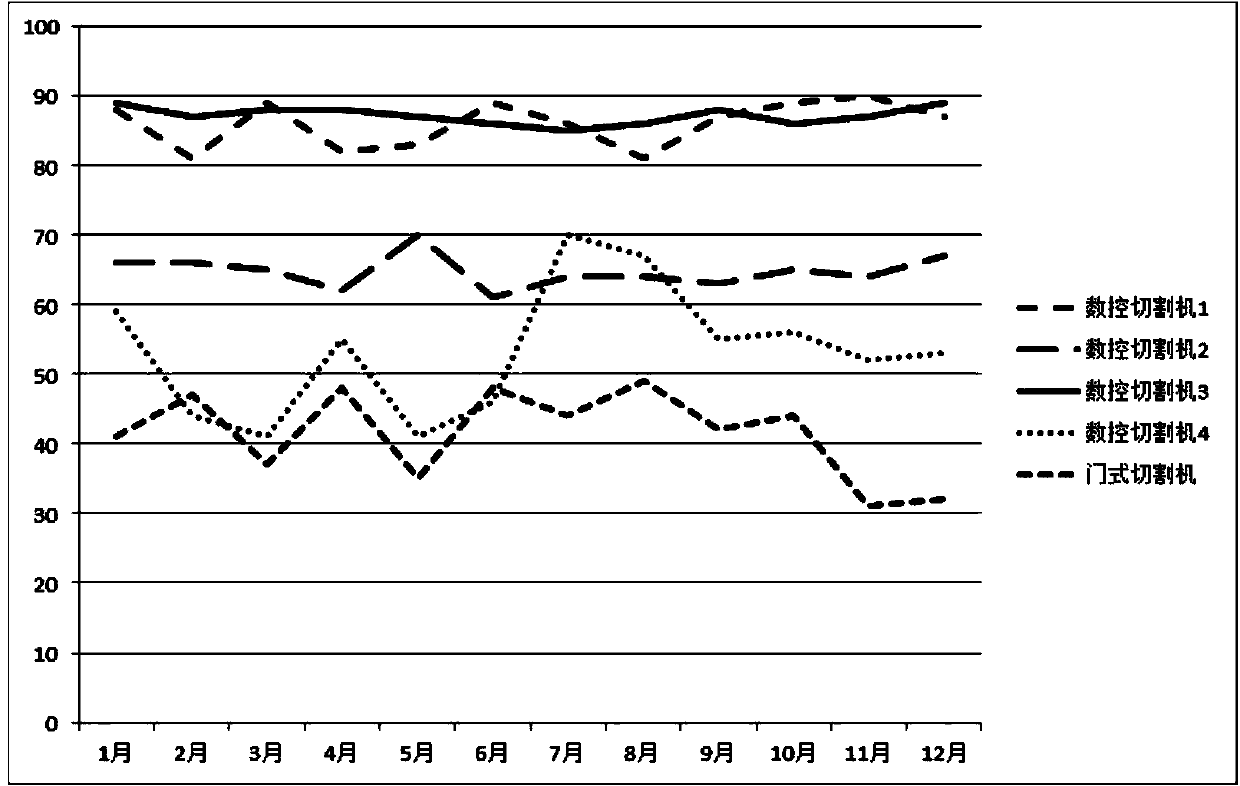

Directory tree structured data and simulation system for supporting simulation of ship construction process

ActiveCN103440384AImprove accuracyImprove production management levelSpecial data processing applicationsData processingSimulation system

The invention relates to a directory tree structured data and simulation system for supporting the simulation of a ship construction process, belonging to the technical field of ship manufacturing. The system comprises a ship simulation data acquisition and analysis module, a ship simulation running management module and a ship simulation output data processing module, wherein the ship simulation data acquisition and analysis module is used for acquiring original simulation data and outputting basic simulation data to the ship simulation running management module after processing and analyzing the original simulation data according to simulation requirements; the ship simulation running management module is used for selecting a corresponding simulation model from a built-in simulation model library according to the basic simulation data and establishing a simulation running task to perform simulation running; and the ship simulation running management module is also used for reading various basic simulation data from the ship simulation data acquisition and analysis module according to the requirements of the simulation model during a simulation model running process and outputting the simulation output data to the ship simulation output data processing module to perform a charting show after the simulation running.

Owner:上海东方申信科技发展有限公司 +1

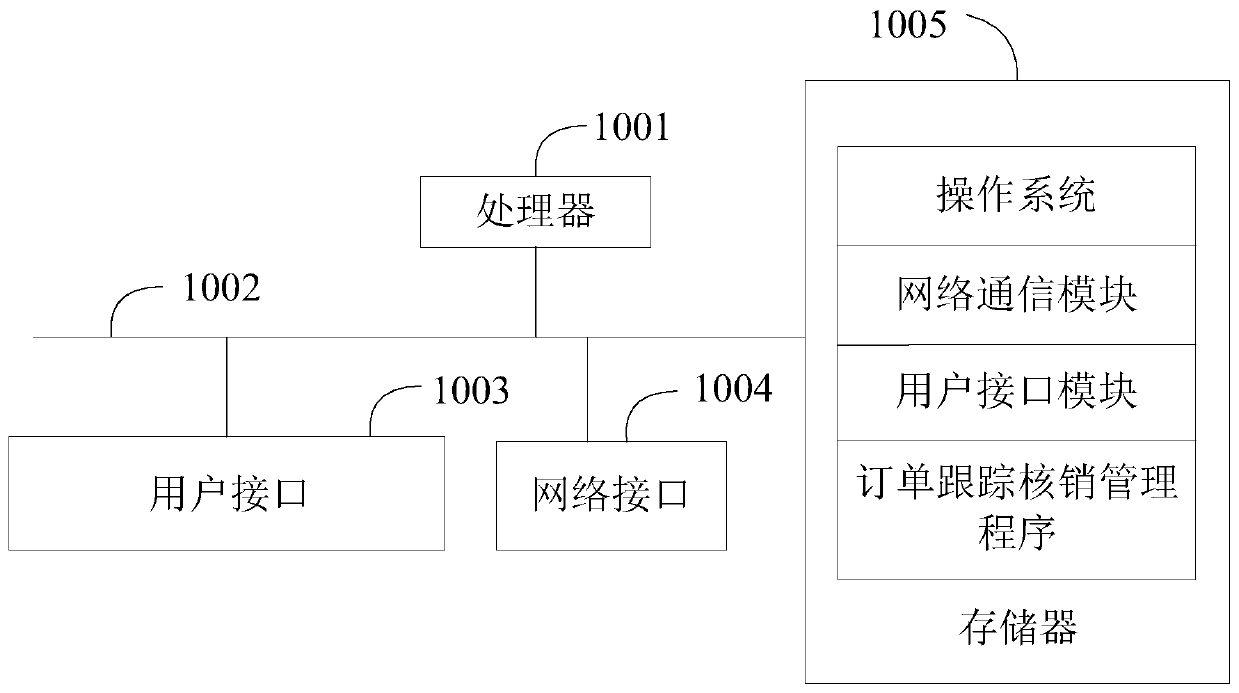

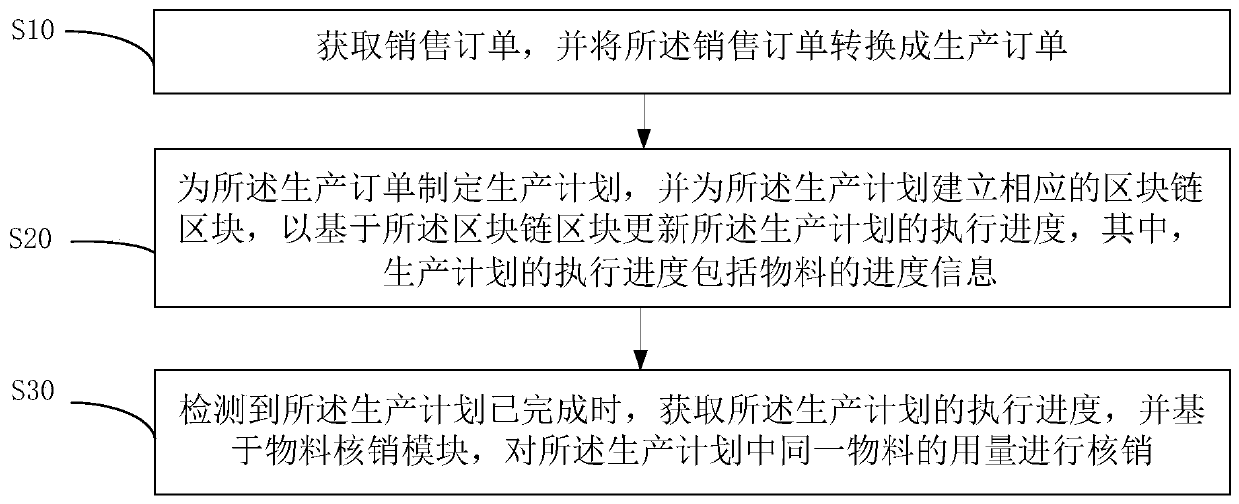

Order tracking cancel-after-verification management method and system and storage medium

InactiveCN111461914AAvoid risk of lossImprove management efficiencyDatabase distribution/replicationResourcesManagement efficiencyIndustrial engineering

The invention discloses an order tracking cancel-after-verification management method and system, and a storage medium. The method comprises the steps: obtaining a sales order, and converting the sales order into a production order; a production plan is made for the production order, a corresponding block chain block is established for the production plan, the execution progress of the productionplan is updated based on the block chain block, and the execution progress of the production plan comprises progress information of materials; when it is detected that the production plan is completed; obtaining an execution progress of the production plan, the system is based on a material cancel-after-verification module. Performing cancel-after-verification on the use amount of the same material in the production plan; according to the material cancel-after-verification equation, the cancel-after-verification of each material is automatically completed, users and clients can master the progress of the order more quickly, analyze the execution condition of each plan, improve the management efficiency and prevent the risk of material loss, and a consensus mechanism is formed based on theblockchain, so that tamper-proof traceability is realized.

Owner:SHENZHEN DIANLIAN TECH CO LTD

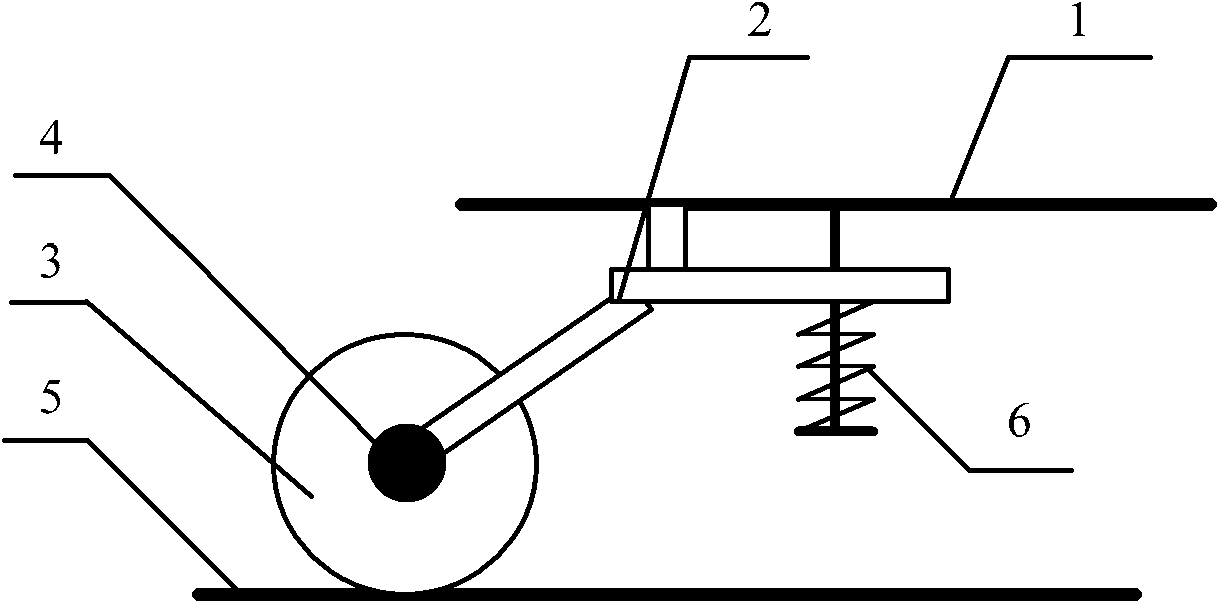

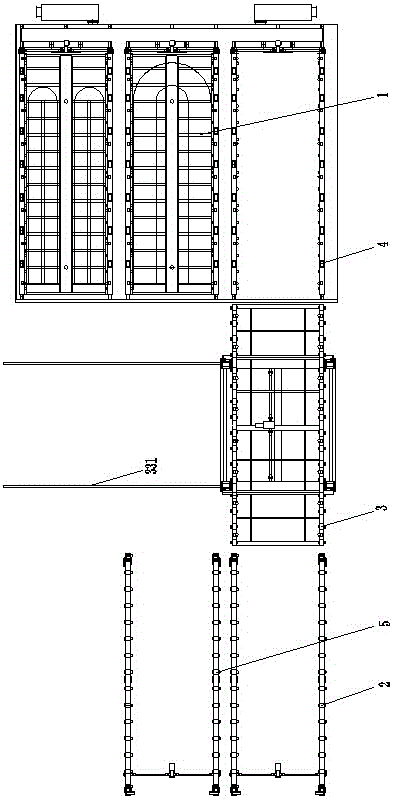

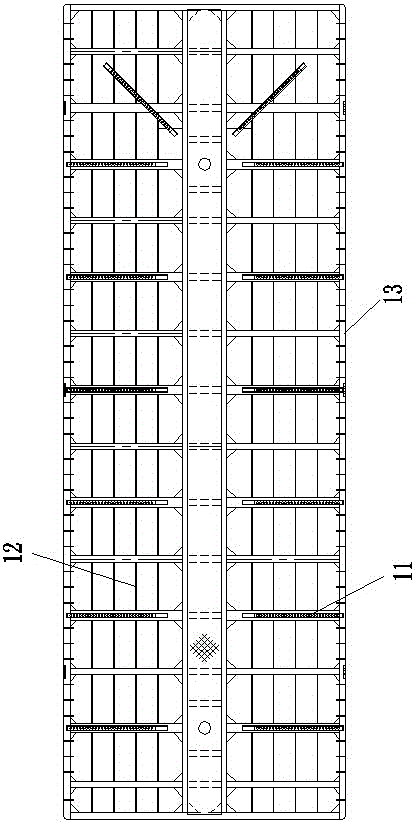

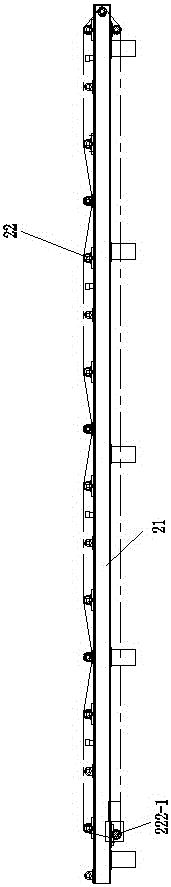

Automatic storage device for U-shaped pipes for nuclear power evaporator and control method of automatic storage device

ActiveCN106185154AFill in the blanksIncrease profitConveyorsStorage devicesAutomatic controlNuclear power

The invention relates to an automatic storage device for U-shaped pipes for a nuclear power evaporator and a control method of the automatic storage device. The automatic storage device for the U-shaped pipes for the nuclear power evaporator comprises material discs and an automatic control system and further comprises a material staying mechanism, a horizontal movement lifting mechanism and material storerooms. The material discs are used for placing of the U-shaped pipes. The material staying mechanism is composed of a storage material staying mechanism and a delivery material staying mechanism which are both used for parking and moving of the material discs. The horizontal movement lifting mechanism is used for moving the material discs between the material staying mechanism and the material storerooms. The material storerooms are used for storing the material discs. The automatic control system is connected with the material staying mechanism, the horizontal movement lifting mechanism and the material storerooms and controls the operation of the material staying mechanism, the horizontal movement lifting mechanism and the material storerooms. The invention further discloses the control method of the automatic storage device. According to the automatic storage device and the control method, the structure is simple, high efficiency and practicability are achieved, the space utilization rate is increased, the automation degree is improved, and labor intensity is relieved.

Owner:CHINA UNITED ENG

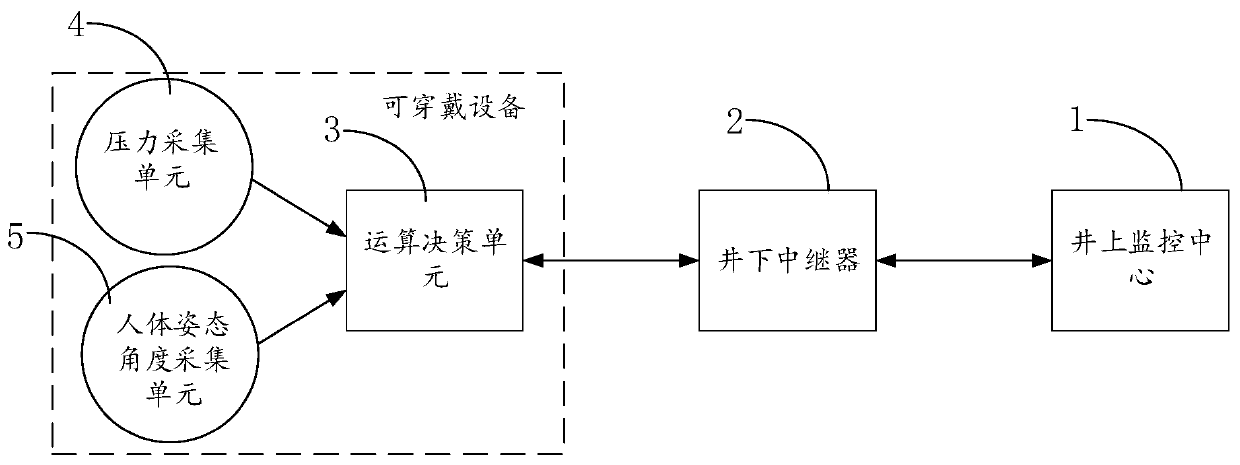

Underground coal mine human posture monitoring system

InactiveCN110123334AAccurate collectionAccurate monitoringInertial sensorsDiagnostic recording/measuringMonitoring systemEngineering

The invention discloses an underground coal mine human posture monitoring system which comprises an overground monitoring center, underground repeaters and a wearable device. Pressure sensors of pressure acquisition units of the wearable device are arranged on silicone insoles in two working boots of an underground worker, a human posture angle acquisition unit is fixed onto the outer side of working pants of the underground worker by a telescopic belt, an operation decision making unit comprises an inertial measurement sensor for acquiring waist posture data and a processing module, the processing module is used for acquiring current posture data of the underground worker and judging whether a current posture is safe or not according to a preset algorithm, and the overground monitoring center acquires the current posture data of the underground worker and / or judgment results of the current posture of the underground worker through the wirelessly connected underground repeaters. According to the system, some possible hazardous operations or hazardous states of a current worker wearing the device are forecasted and early warned by judging change of human postures, so that working hazardous conditions of the underground worker are avoided as far as possible.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

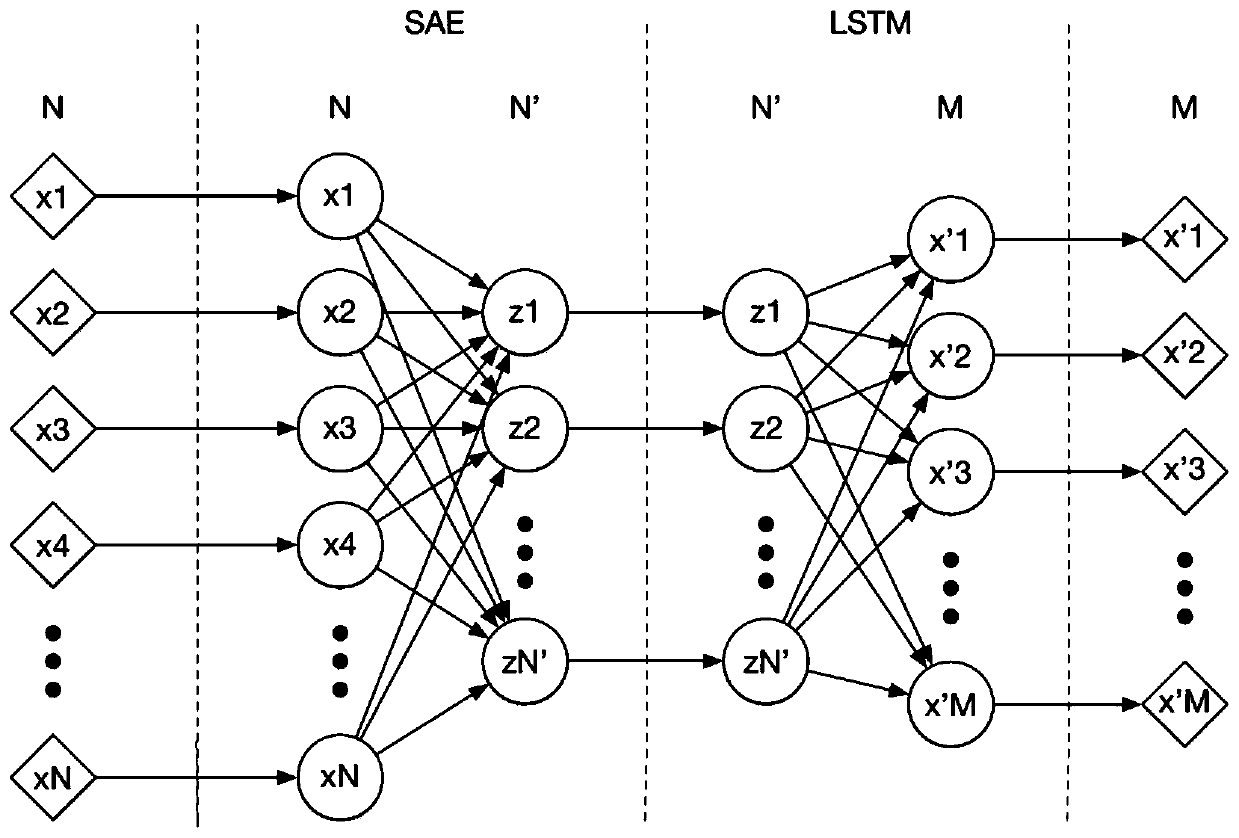

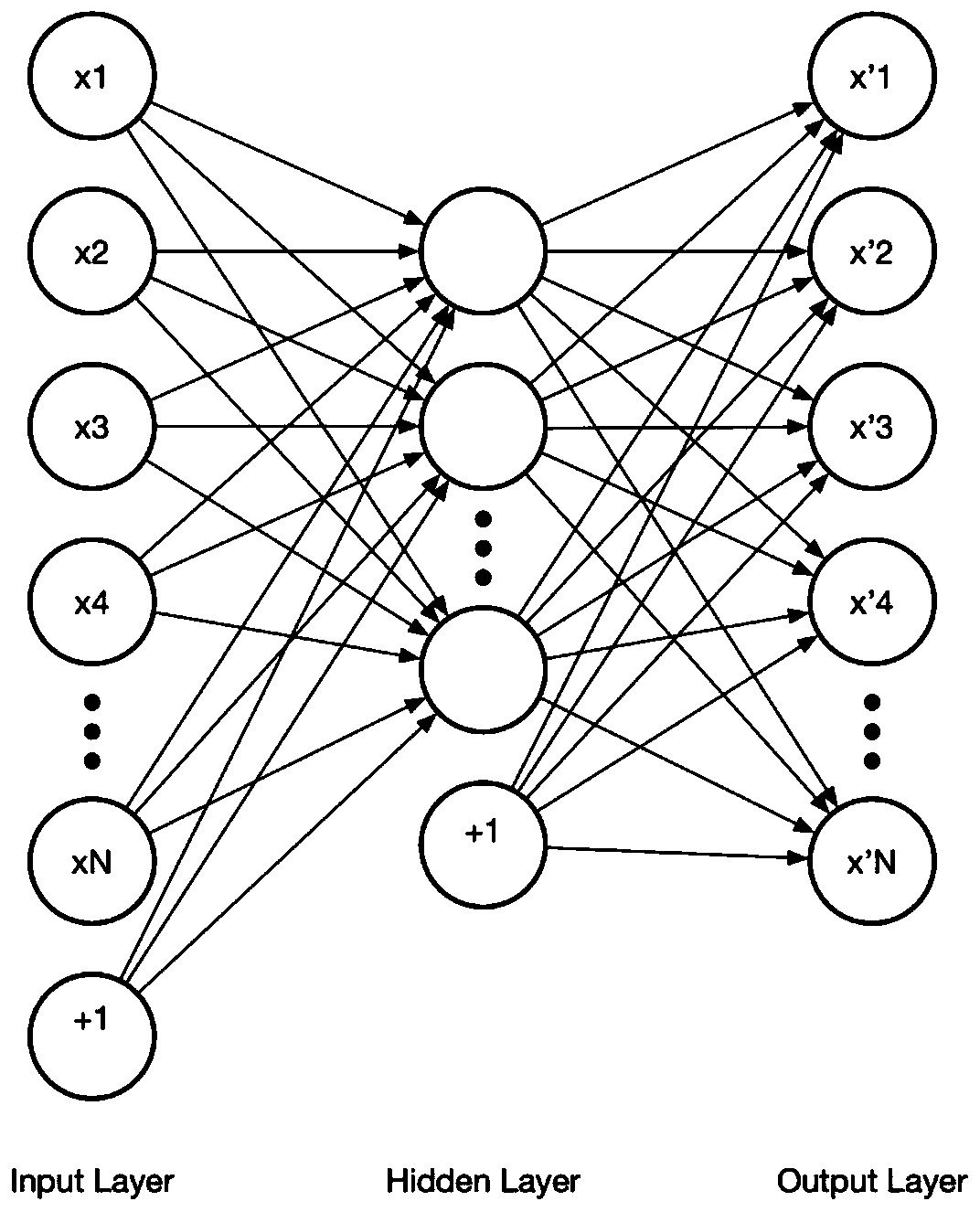

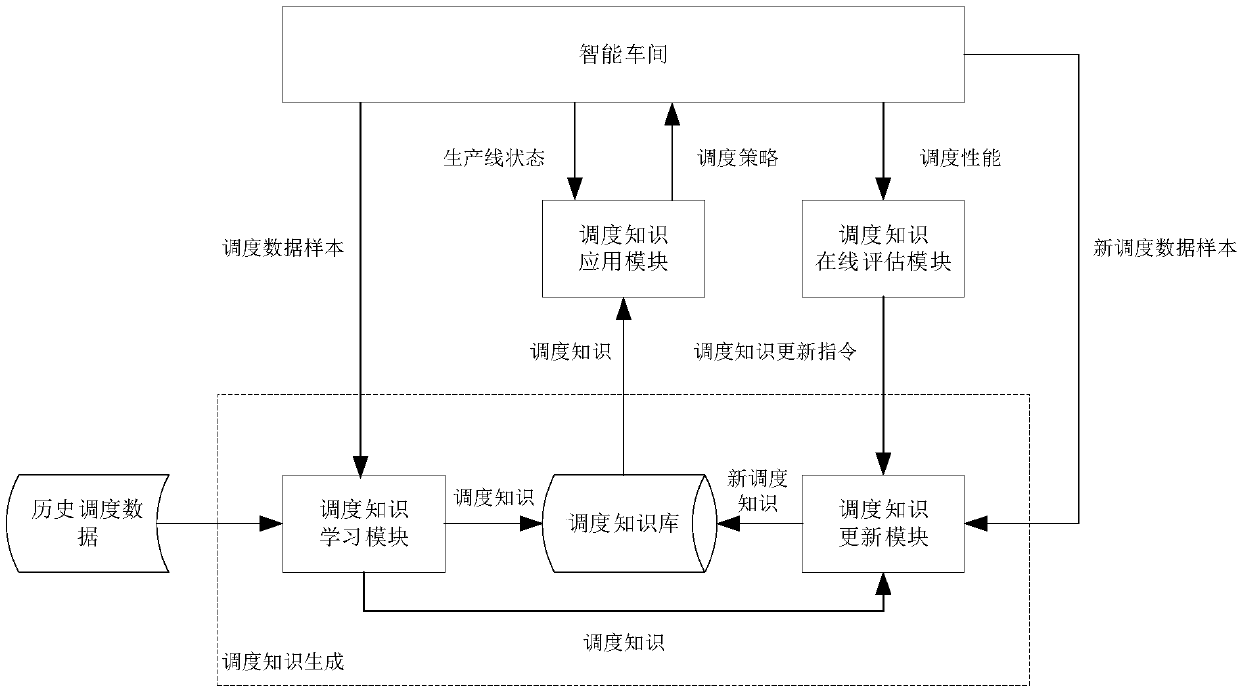

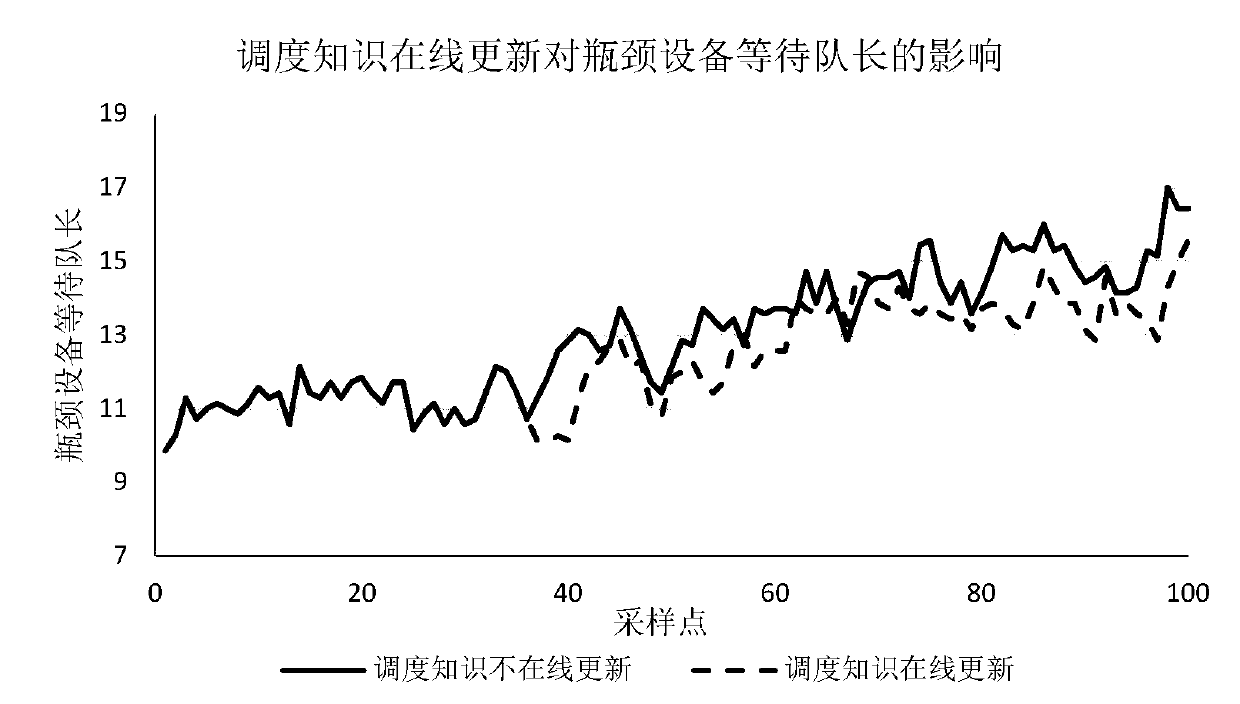

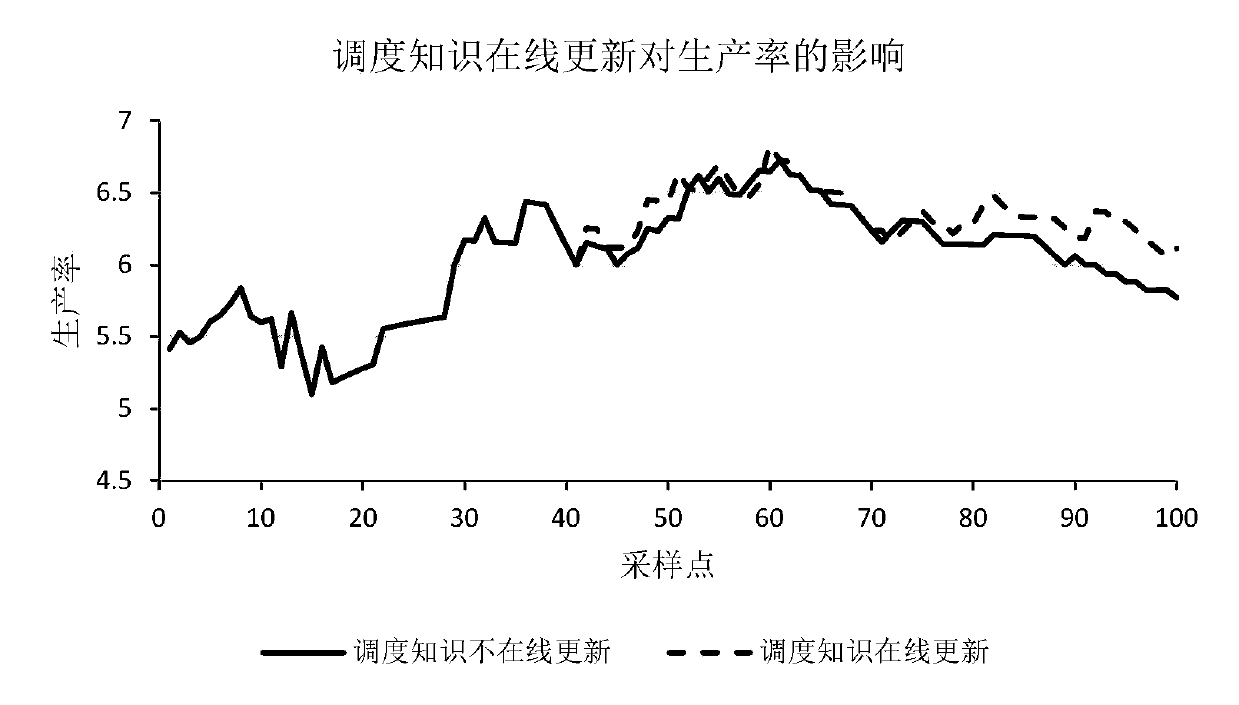

A scheduling knowledge management system for intelligent manufacturing

InactiveCN109523136AImprove adaptabilityImprove performanceResourcesManufacturing computing systemsKnowledge applicationOnline learning

The invention relates to a scheduling knowledge management system for intelligent manufacturing. The system comprises a scheduling knowledge learning module driven by data, which is used for knowledgemining of scheduling data samples to obtain scheduling knowledge. A scheduling knowledge application module, responsive to receiving a scheduling request, for calling the scheduling knowledge to generate a scheduling policy matching with an intelligent workshop production state and obtaining a scheduling result; An on-line scheduling knowledge evaluation module, responding after obtaining a scheduling result, for judging the validity of the scheduling knowledge according to the scheduling result; The scheduling knowledge updating module responds when the scheduling knowledge is judged to be invalid, and is used for applying an online learning method to adjust the scheduling knowledge on the basis of adding updated samples. Compared with the prior art, the invention can better improve theadaptability of the scheduling knowledge, ensure the scheduling effectiveness, and has the advantages of continuously optimizing the overall performance of the intelligent workshop.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com