NSGA-II-based automatic storage goods allocation optimization method

A technology of cargo location allocation and optimization method, which is applied in combustion engines, internal combustion piston engines, instruments, etc., can solve problems such as multi-objective optimization that is difficult to solve, and convergence cannot be guaranteed, and achieve high promotion and application value and social significance. Improve the efficiency of cargo access and evenly distribute the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

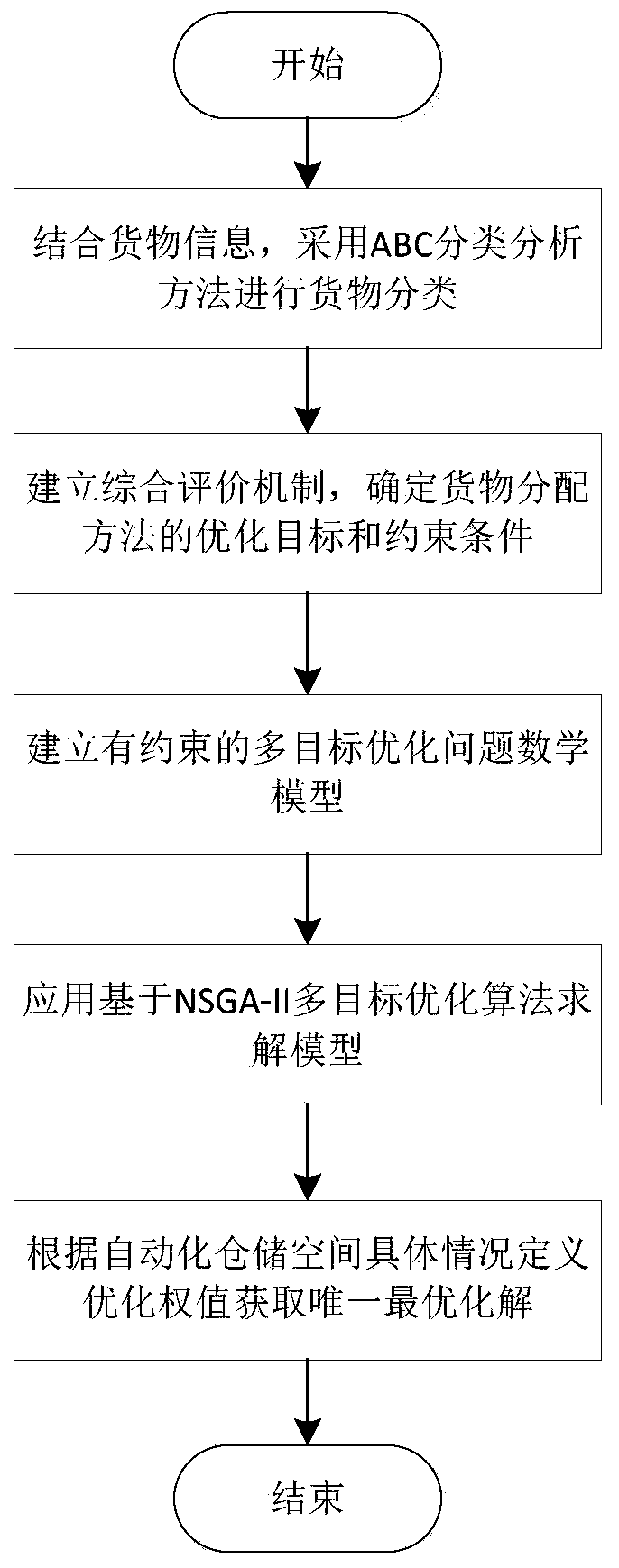

[0052] Such as figure 1 As shown, a NSGA-II-based automated storage location allocation optimization method, the specific implementation steps include:

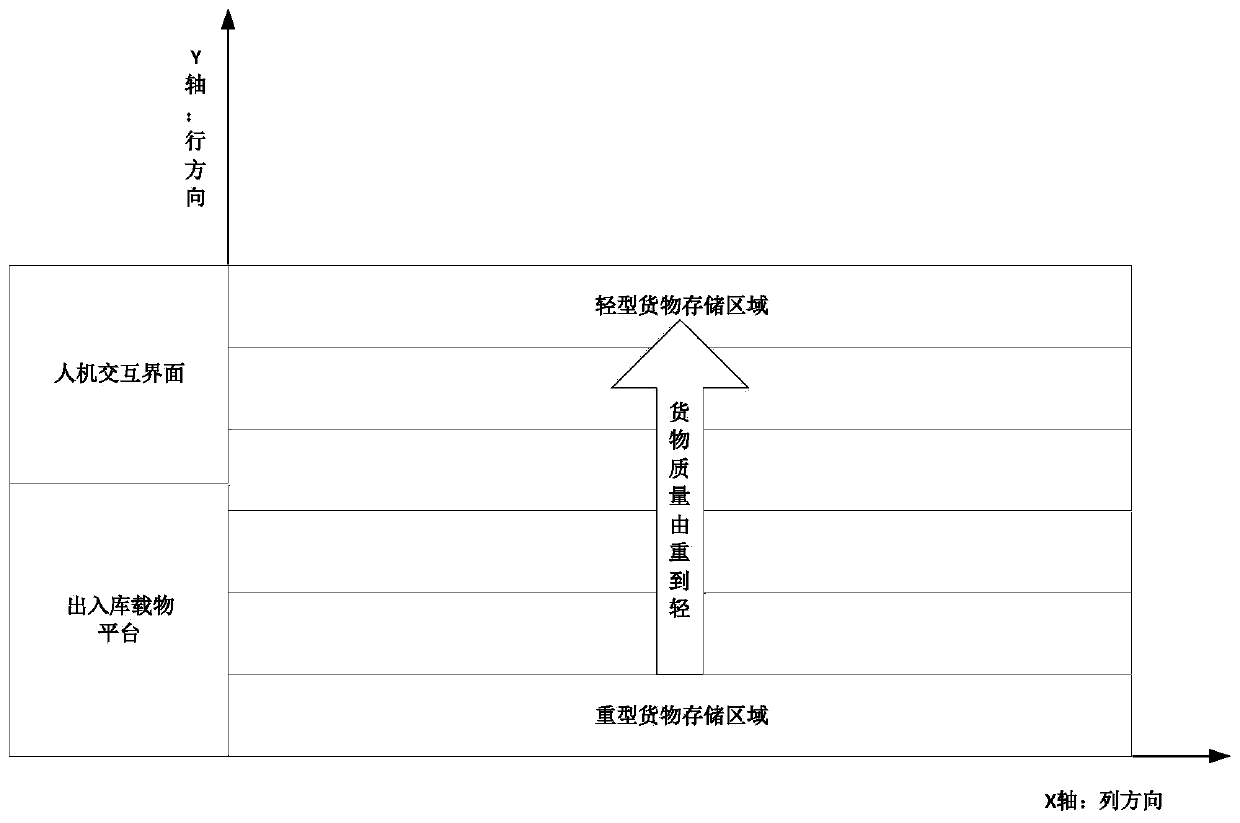

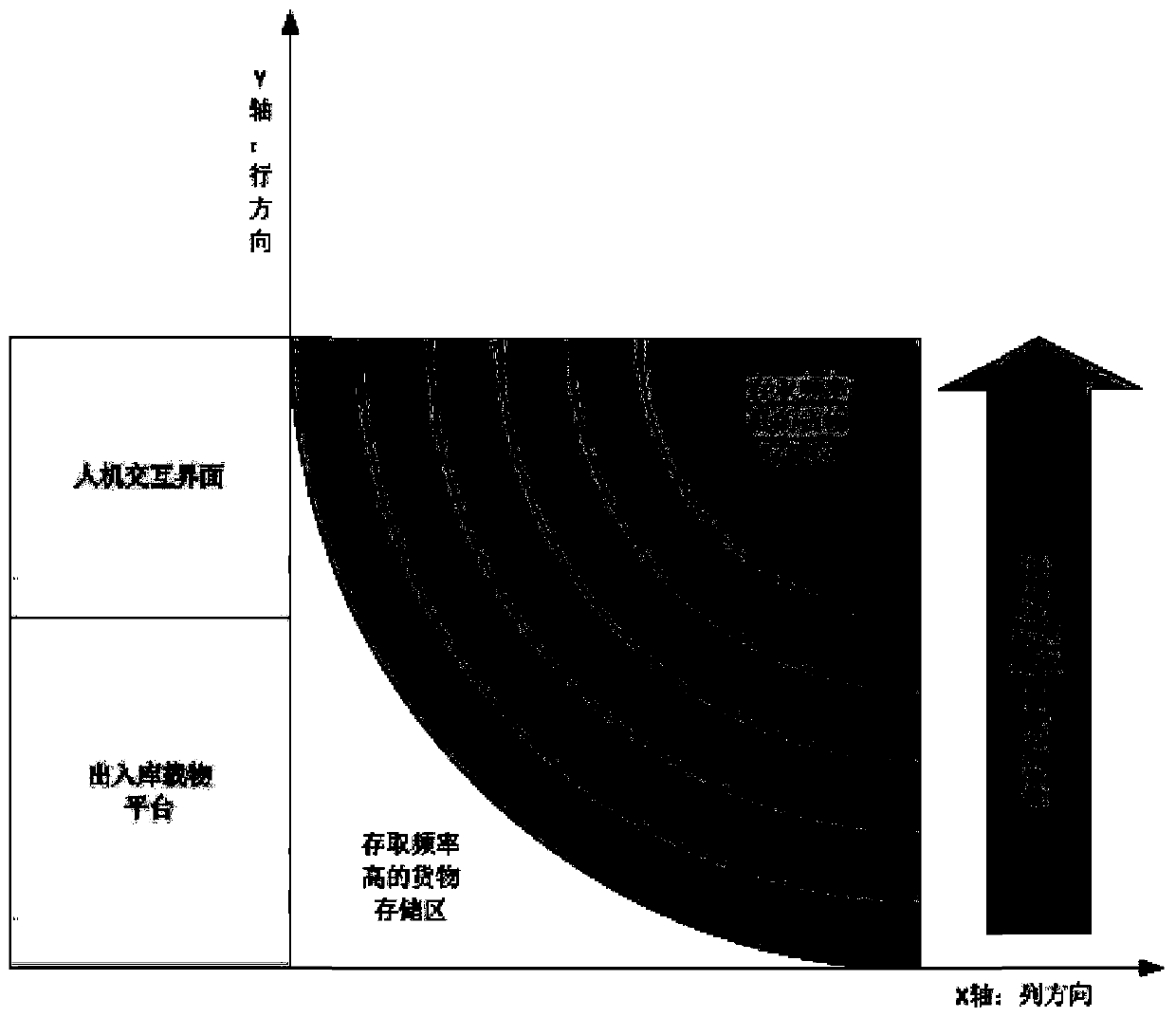

[0053] Step 1: The cabinet size setting requirements of the automated storage space are as follows: divide the automated storage space into two parts, one is the work operation area, and the other is the storage area. The working area includes the man-machine interface and the operation platform for entering and exiting the warehouse; the storage area can be designed according to the actual situation. Here, the application in the field of intelligent express cabinets is taken as an example. Since the stored goods are express packages, the setting of the container storage area includes i-layer and j-rows The shelf, in which the unit cabinet is composed of a size with a bottom length of L meters, a height of H meters, and a depth of D meters; and the three-axis moving device is used to move the pallet to achieve flexible adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com