Semiconductor production line optimized dispatching device

A technology for optimizing scheduling and production lines, applied in biological models, control/regulation systems, instruments, etc., can solve problems such as optimal scheduling schemes for semiconductor production lines that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

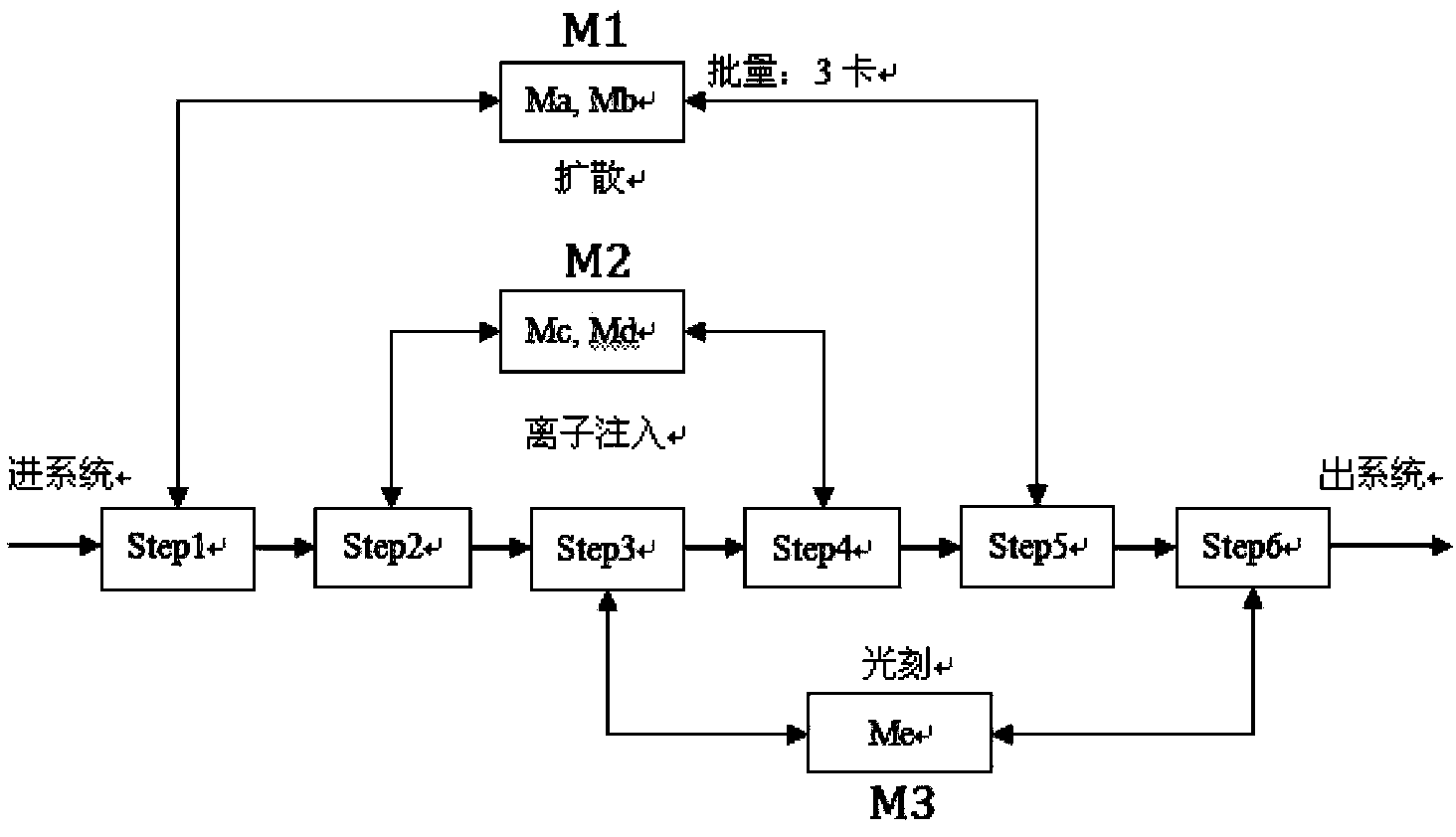

[0073] image 3 A simplified model Mini-Fab of a semiconductor production line is given. The model includes 3 equipment groups (M 1 , M 2 , M 3 ), where: M 1 There are two interchangeable devices (M a , M b ), which simulates the diffusion processing area of a semiconductor production line, and is a batch processing equipment; M 2 There are two interchangeable devices (M a , M b ), which simulates the ion implantation processing area of the semiconductor production line, which is a non-batch processing equipment; M 3 There is a device (M e ), which simulates the lithography processing area of a semiconductor production line, and is a non-batch processing equipment. The processing flow of the workpiece processed on this model is exactly the same, including 6 processing steps, respectively in M 1 , M 2 , M 3 The processing is completed on the above, and the specific processing flow can be found in the attached image 3 , the same process of different workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com