Automatic storage device for U-shaped pipes for nuclear power evaporator and control method of automatic storage device

A nuclear power evaporator, automatic control system technology, applied in conveyors, storage devices, transportation and packaging, etc., can solve the problems of wasting manpower and occupying space, and achieve speeding up cargo access, improving production management level, and improving utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

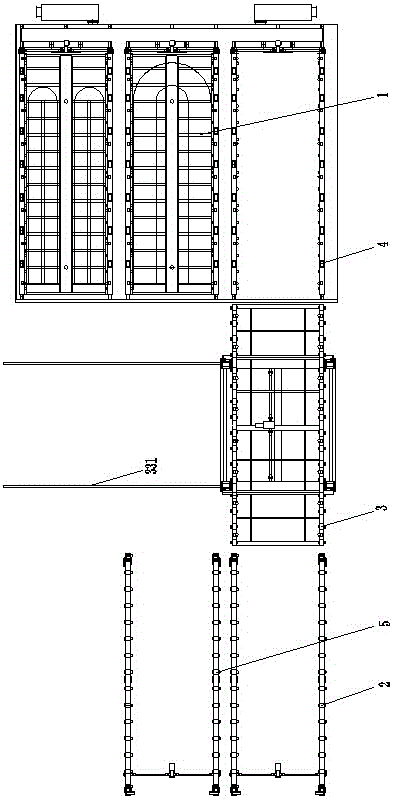

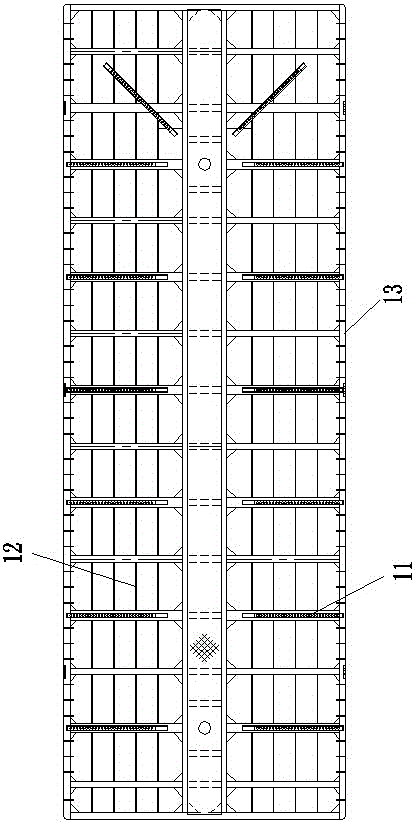

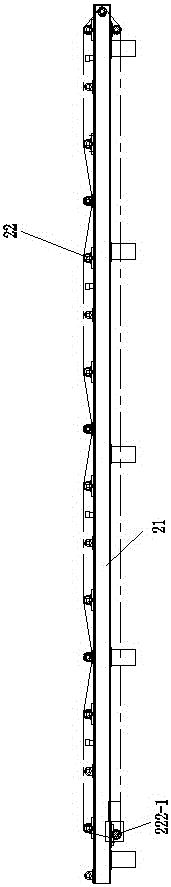

[0039] see Figure 1 to Figure 9 , the present embodiment includes twenty-four trays 1, a set of warehousing and waiting mechanism 2, a set of translation lifting mechanism 3, three sets of warehousing 4, a set of outbound and waiting mechanism 5 and an automatic control system. The tray 1 is used to place the finished U-shaped tube; the warehousing and waiting mechanism 2 is used for parking and moving the tray 1; the translation lifting mechanism 3 is used for translation and lifting of the tray 1, and is connected to the warehouse The mechanism of the material waiting mechanism 2 and the material warehouse 4; the material warehouse 4 is used to store the material tray 1; the described outbound material waiting mechanism 5 is used for parking and moving the material tray 1, and the material tray on the translation lifting mechanism 3 1. Move to the warehouse-waiting mechanism 5. The automatic control system is used to control the mutual coordination of various institutions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com