Concrete batching stirring control system

A control system and concrete technology, applied in control devices, batching and batching instruments, etc., can solve the problems of unstable quality of finished concrete, affecting weighing accuracy and stability, reducing feeding speed, etc., to improve scalability and use flexibility. , The programming is convenient, and the effect of improving the real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

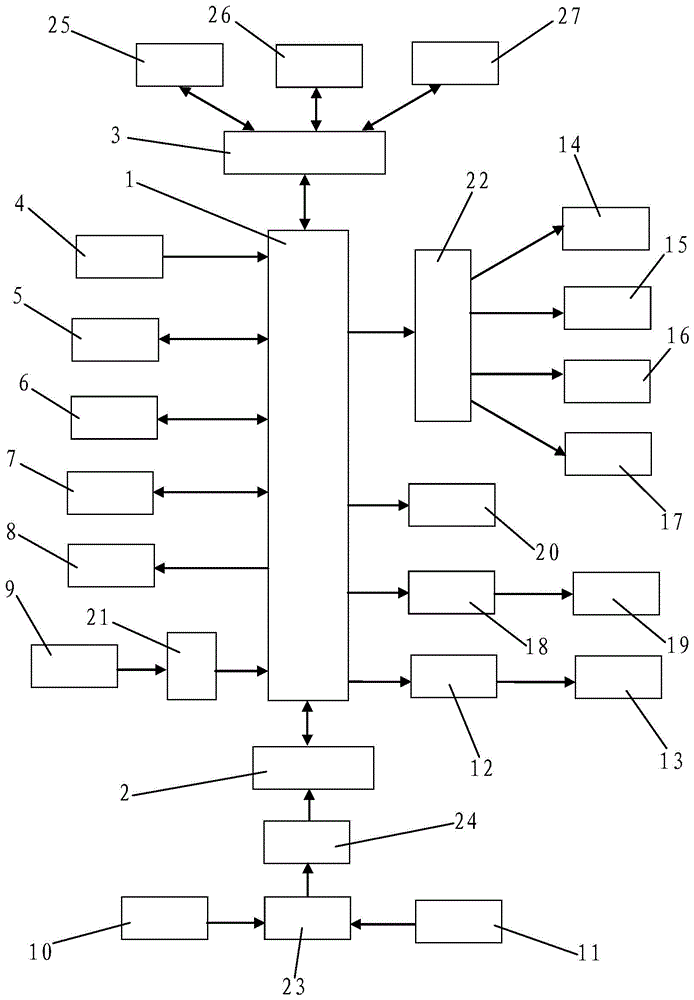

[0020] Such as figure 1 As shown, the present invention includes an input signal device, an output signal device, a main controller 1 that receives the material ratio information input from the HMI man-machine interface 4 and controls the entire concrete batching and mixing process, is used to collect field sensor signals and The sensor signal is transmitted to the main controller 1, the sub-controller 1 2, the sub-controller 2 used to expand the function of the concrete batching and mixing control system so that the system can communicate with the monitoring center host computer, and the sub-controller 2 used for A memory 5 for storing system operating parameters and the material ratio information, a watchdog circuit 6 for preventing the main controller 1 from crashing due to various disturbances, and a timer 7 and a sound system connected with the main controller 1 respectively. Light alarm 8; the input signal device includes a limit stroke switch 9, a load cell 10 for real-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com