Patents

Literature

33 results about "Inductive programming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inductive programming (IP) is a special area of automatic programming, covering research from artificial intelligence and programming, which addresses learning of typically declarative (logic or functional) and often recursive programs from incomplete specifications, such as input/output examples or constraints.

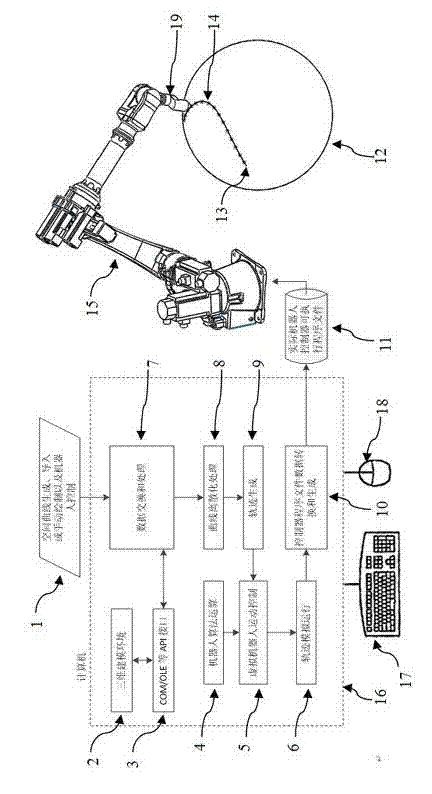

Method for achieving industrial robot off-line programming based on three-dimensional modeling software

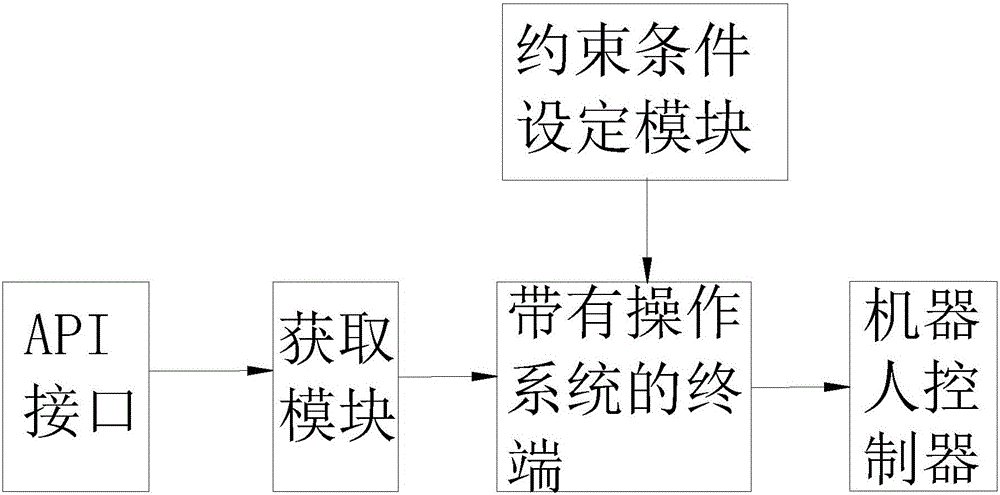

ActiveCN103085072AShorten the timeEasy accessProgramme-controlled manipulatorGoal programmingMathematical model

The invention discloses a method for achieving industrial robot off-line programming based on three-dimensional modeling software. The principle of the method is that a three-dimensional modeling software application programming interface (API) which is suitable for COM or object linking and embedding (OLE) and the like is used in the three-dimensional modeling software environment, model and space matrix data in the three-dimensional modeling software are obtained, a robot virtual body model and a mathematical model are built, and a virtual robot motion control system is realized; discretization from a curve to a point is conducted through obtained space line data, and therefore a motion trail of a robot is generated, actual robot operation is simulated; and an industrial robot controller operational procedure generating module is built, an actual controller executable file is generated and lead out so as to be operated in an actual robot controller, and industrial robot off-line programming can be achieved. The method can achieve off-line programming operation rapidly and generate optimal gesture of corresponding points automatically, time for generating training data is short, and a space curve trail can be achieved conveniently and rapidly, wherein a basis of the space curve trail is difficult to find in reality to conduct teaching.

Owner:NANJING ESTUN ROBOTICS CO LTD

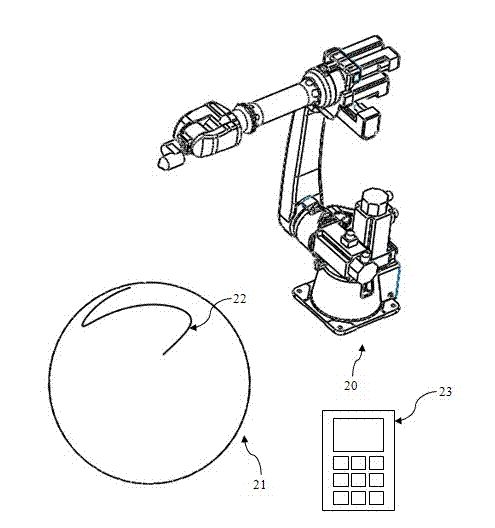

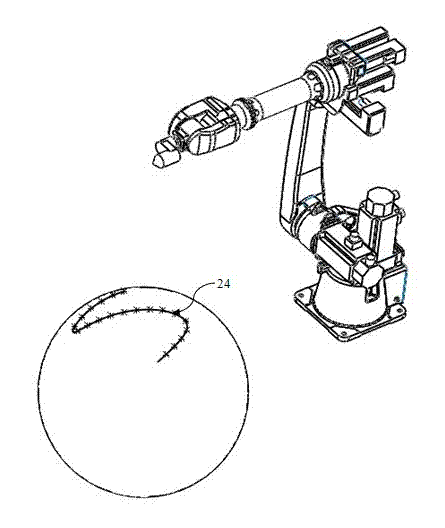

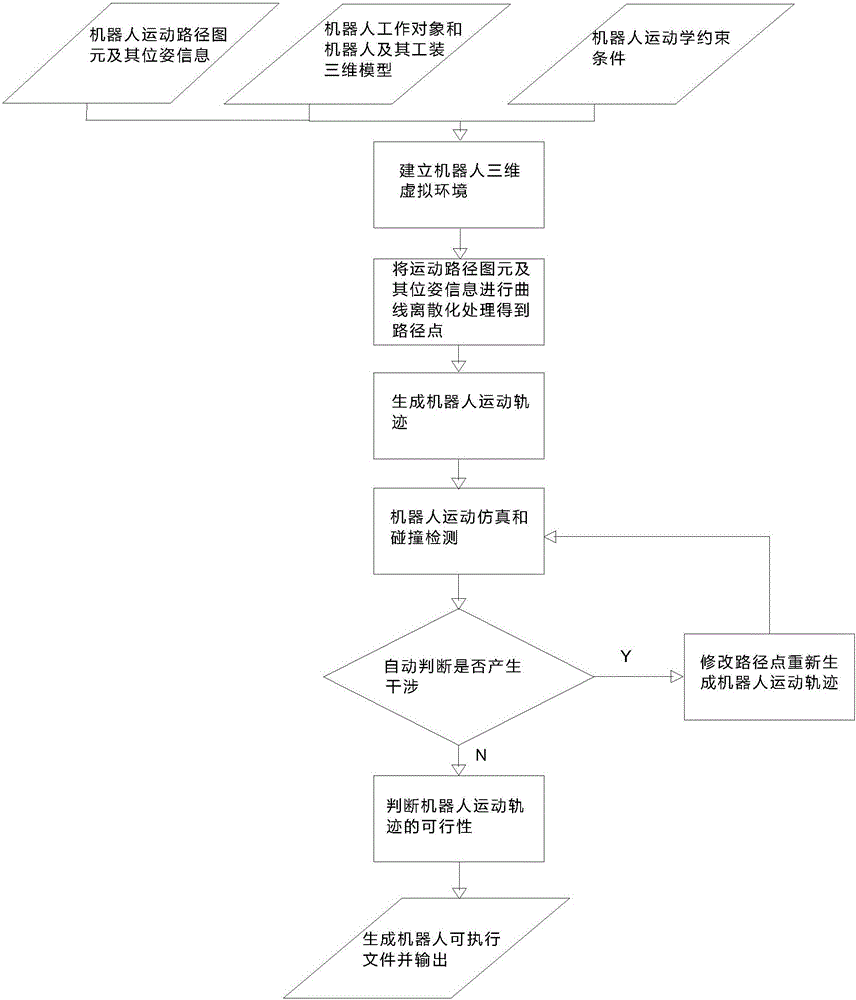

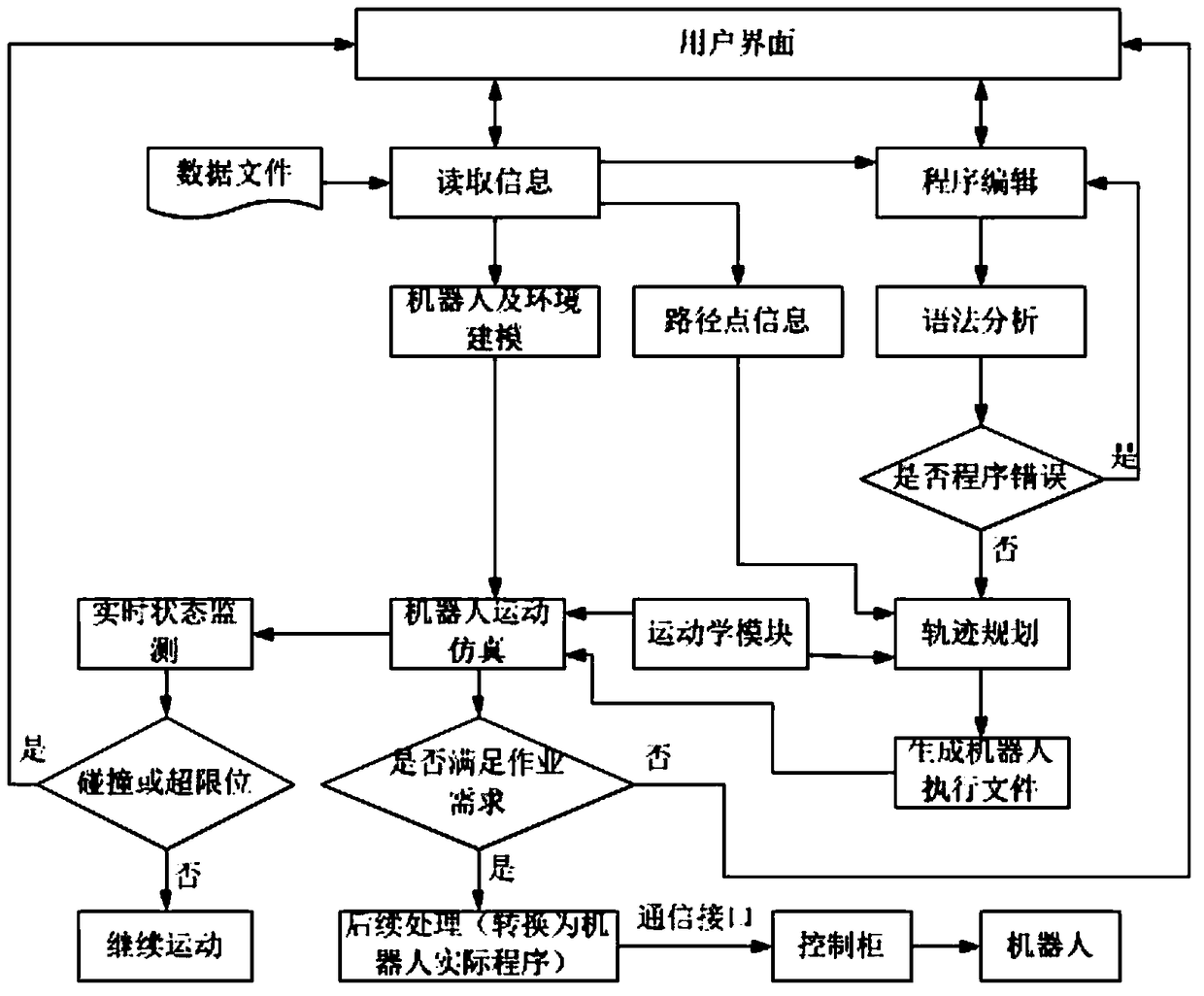

Robot off line programming system and method

InactiveCN105945942ARealize motion controlRealize automatic programmingProgramme-controlled manipulatorSpecial data processing applicationsOperational systemCollision detection

The invention discloses a robot off line programming system and method. The robot off line programming method includes: importing a robot kinematic constraint condition, a three-dimensional model of a working object of a robot, three-dimensional models of the robot and a tooling thereof into a robot three-dimensional virtual environment; performing curve discretization on extracted robot motion path graph primitives and pose information thereof, extracting path points, and generating a robot motion path; performing robot motion simulation and collision detection; modifying the path points according to a given definition on basis of the result of robot motion simulation and collision detection, generating a new robot motion path and pose, and displaying the new robot motion path and pose in an operation system; acquiring a feasibility result and generating a robot executable file; and communicating with the robot, importing the robot executable file into a robot controller, and realizing robot motion control. The robot off line programming system and method can effectively simplify operations, and improve the efficiency of robot programming work.

Owner:GUANGDONG UNIV OF TECH +1

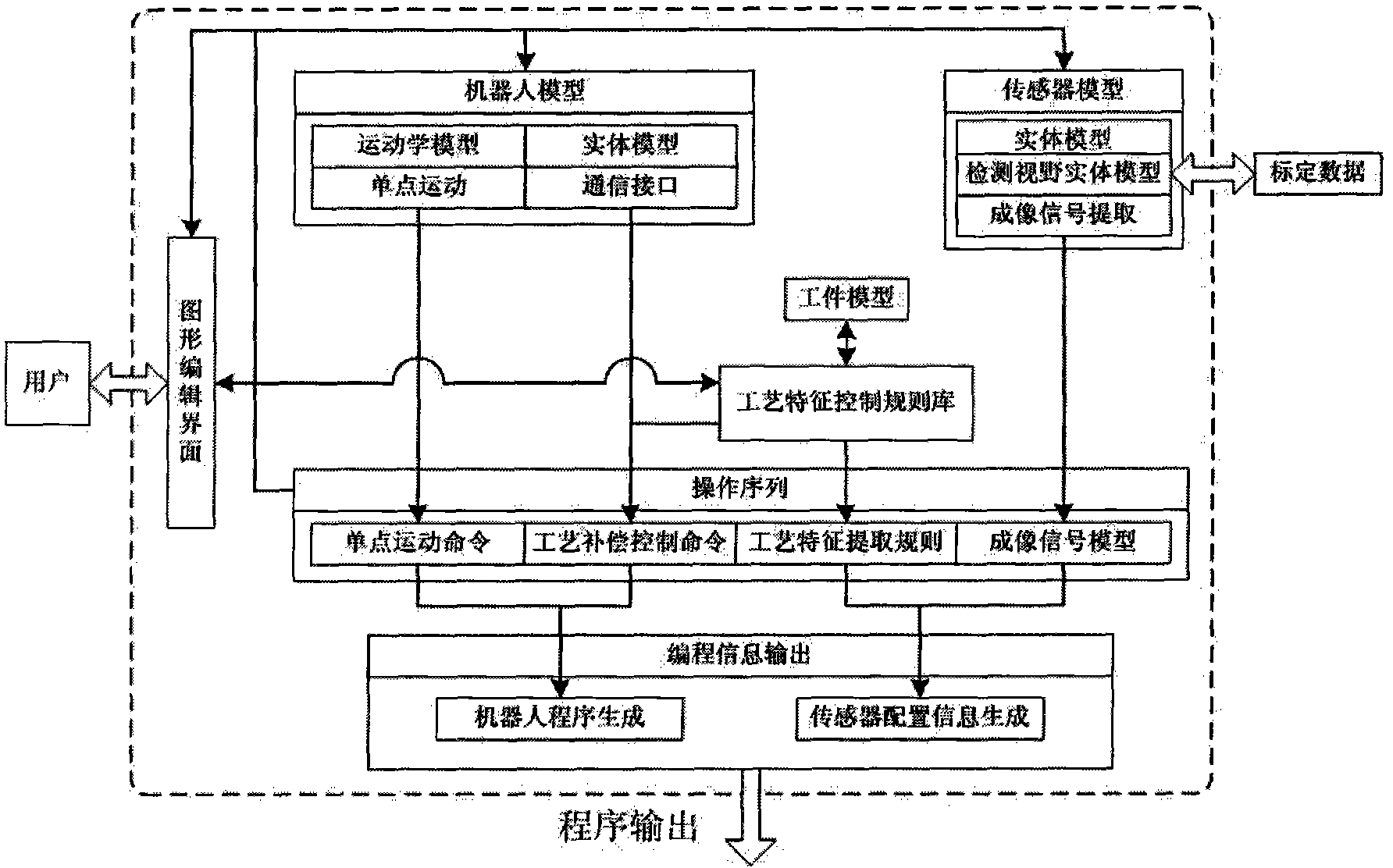

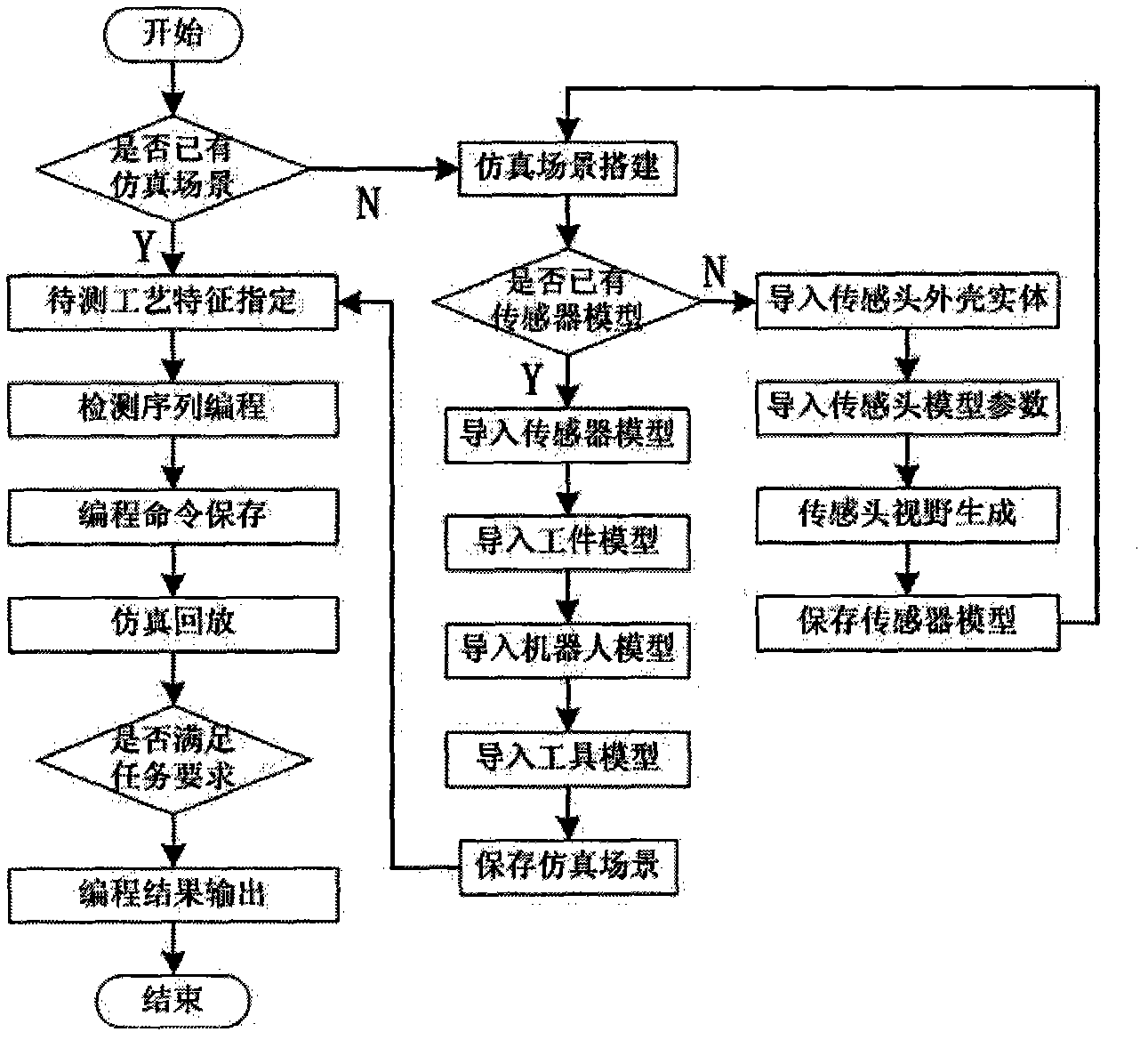

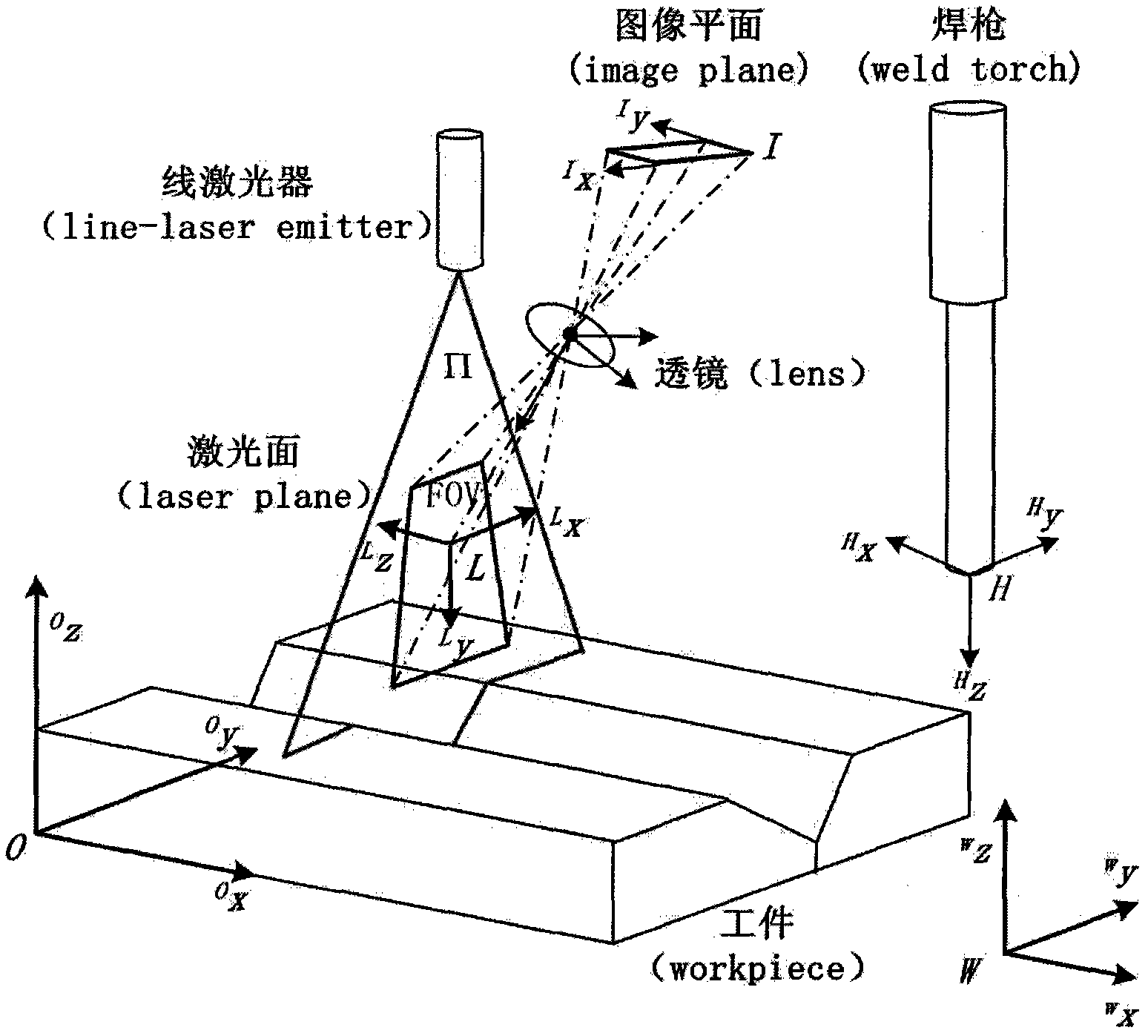

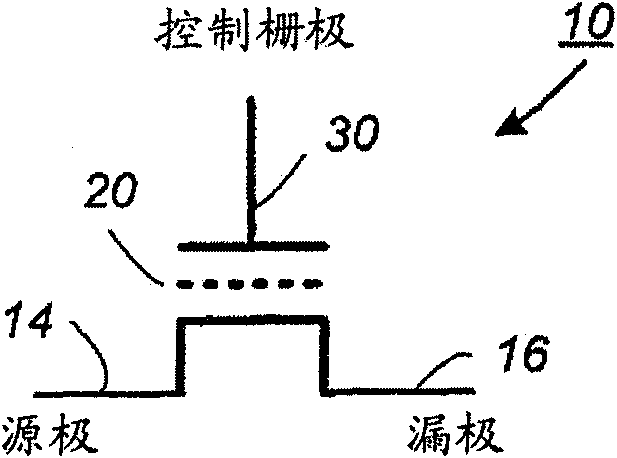

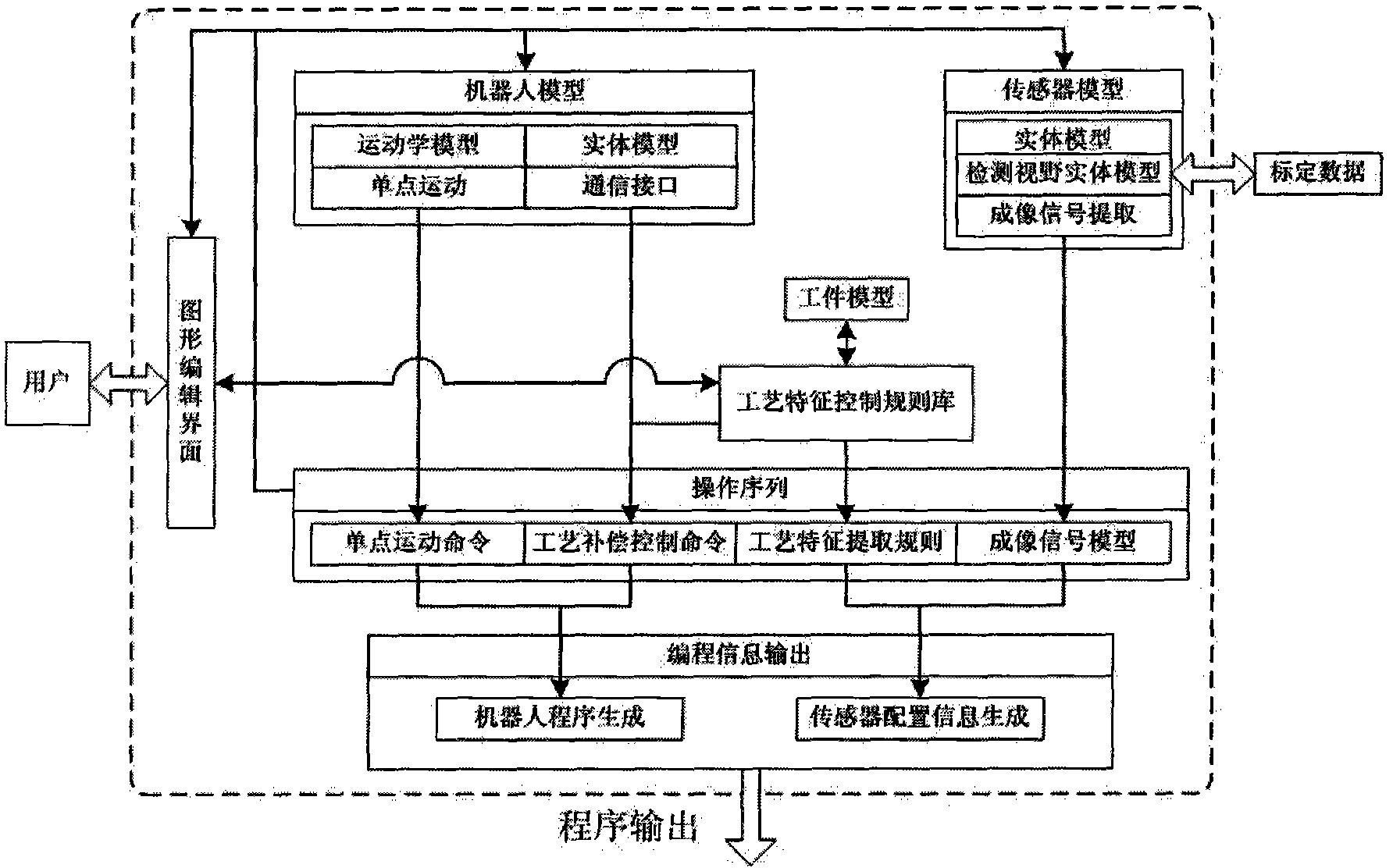

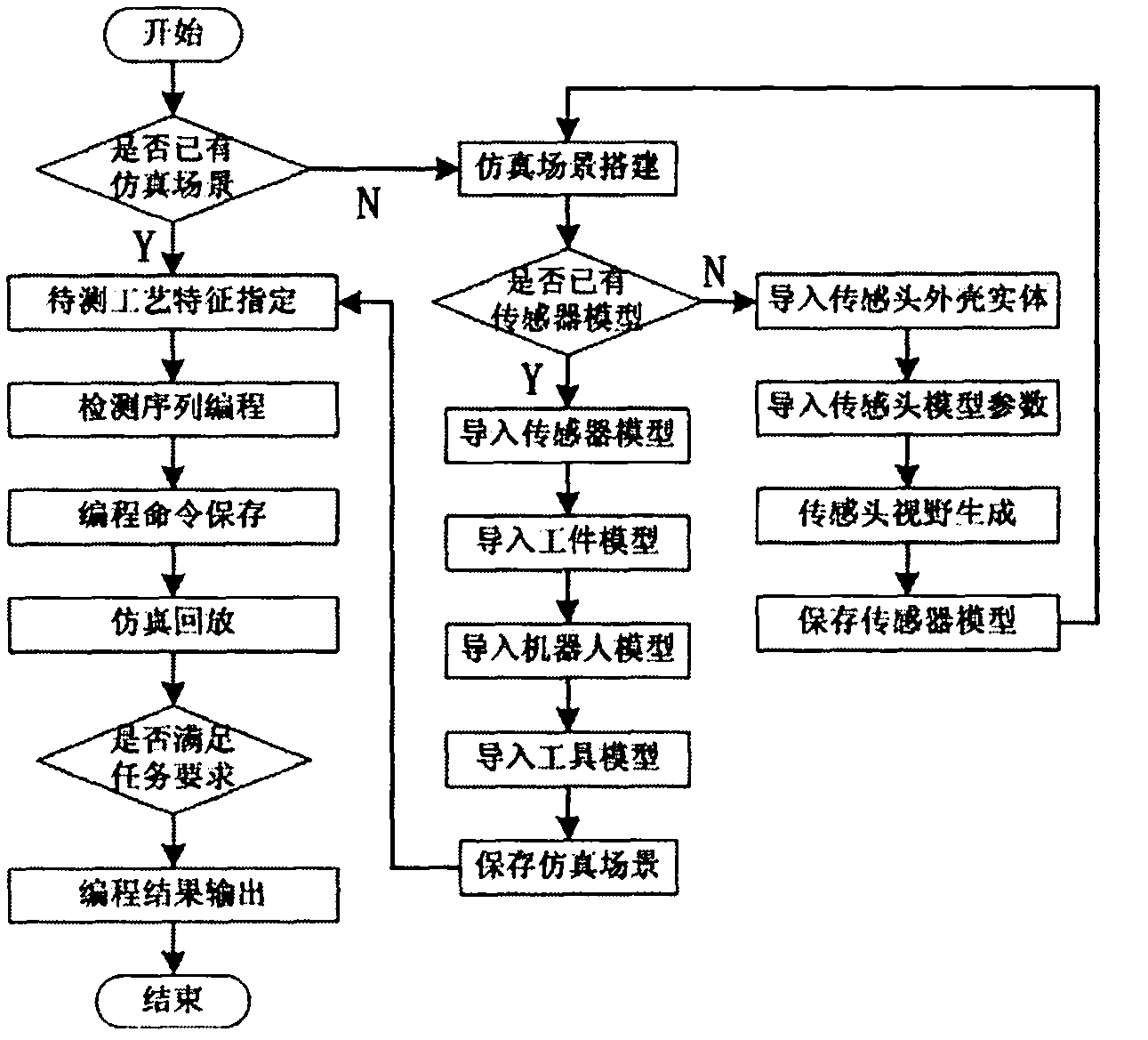

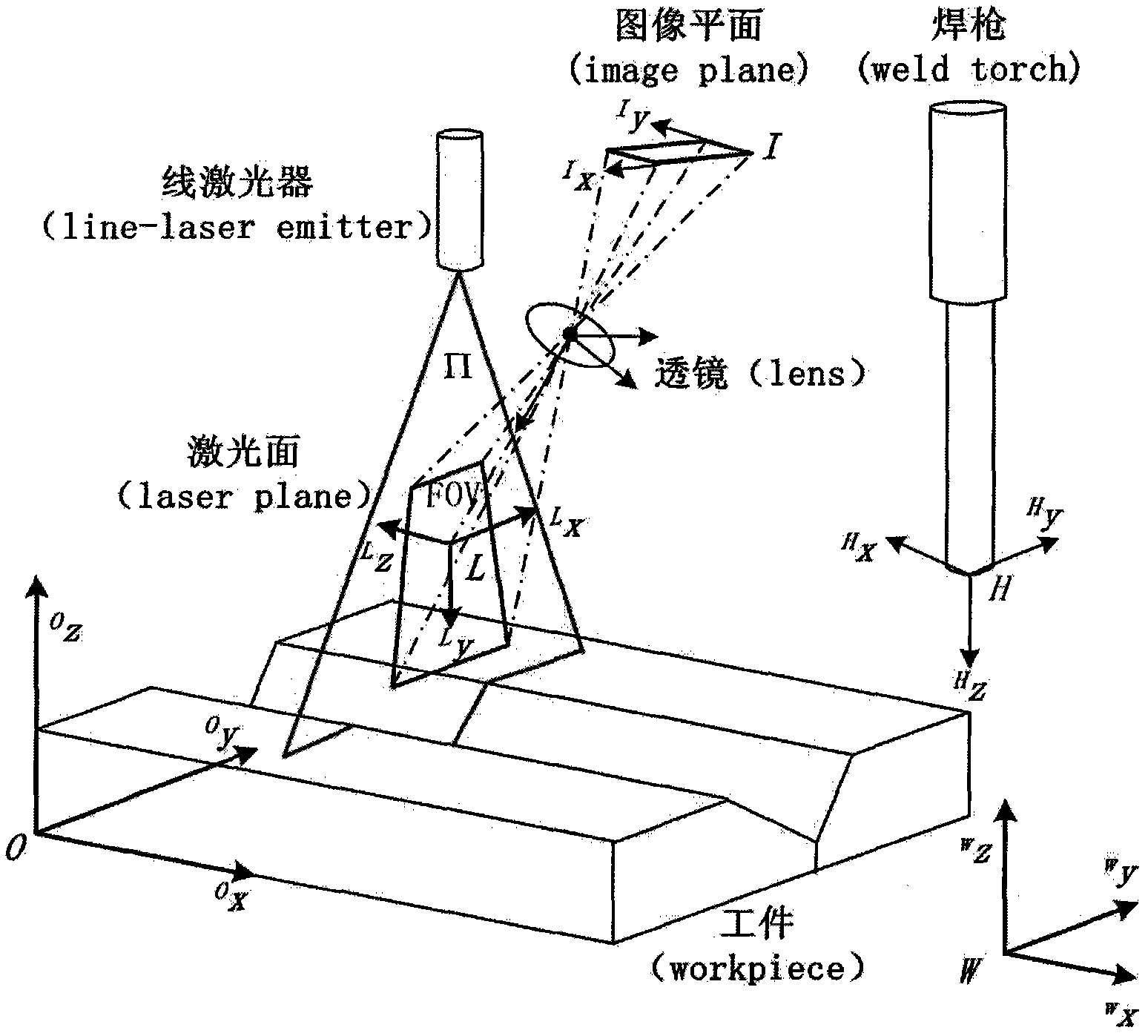

Off-line programming system and method of optical visual sensor with linear structure for welding robot

InactiveCN101973032AIntuitive detection statusIntuitive display of detection statusManipulatorInteractive graphicsSimulation

The invention relates to an off-line programming system and method of an optical visual sensor with a linear structure for a welding robot. The system comprises a sensor model, a robot model, a process control rule base, a graphic editing interface, an operation sequence module and a programming information output, wherein the sensor model is used for simulating a sensor imaging process to acquire a view model and simultaneously completing detection view substantiation to be convenient for user graphic programming; the robot model is used for simulating the single-point motion of the robot and providing communication interface information of connecting sensor input signals; the process control rule base is used for providing process feature extraction rules for different welding tasks andcontrol command related information of processes; the graphic editing interface is used for interactive graphic programming between a user and a system; the operation sequence module is used for saving the information of a series of detection points, wherein the information comprises single-point motion commands, process compensation control commands, process feature extraction rules and imaging signal model information; and the programming information output is used for outputting the program text of the robot and the configuration information text of the sensor system.

Owner:SOUTHEAST UNIV

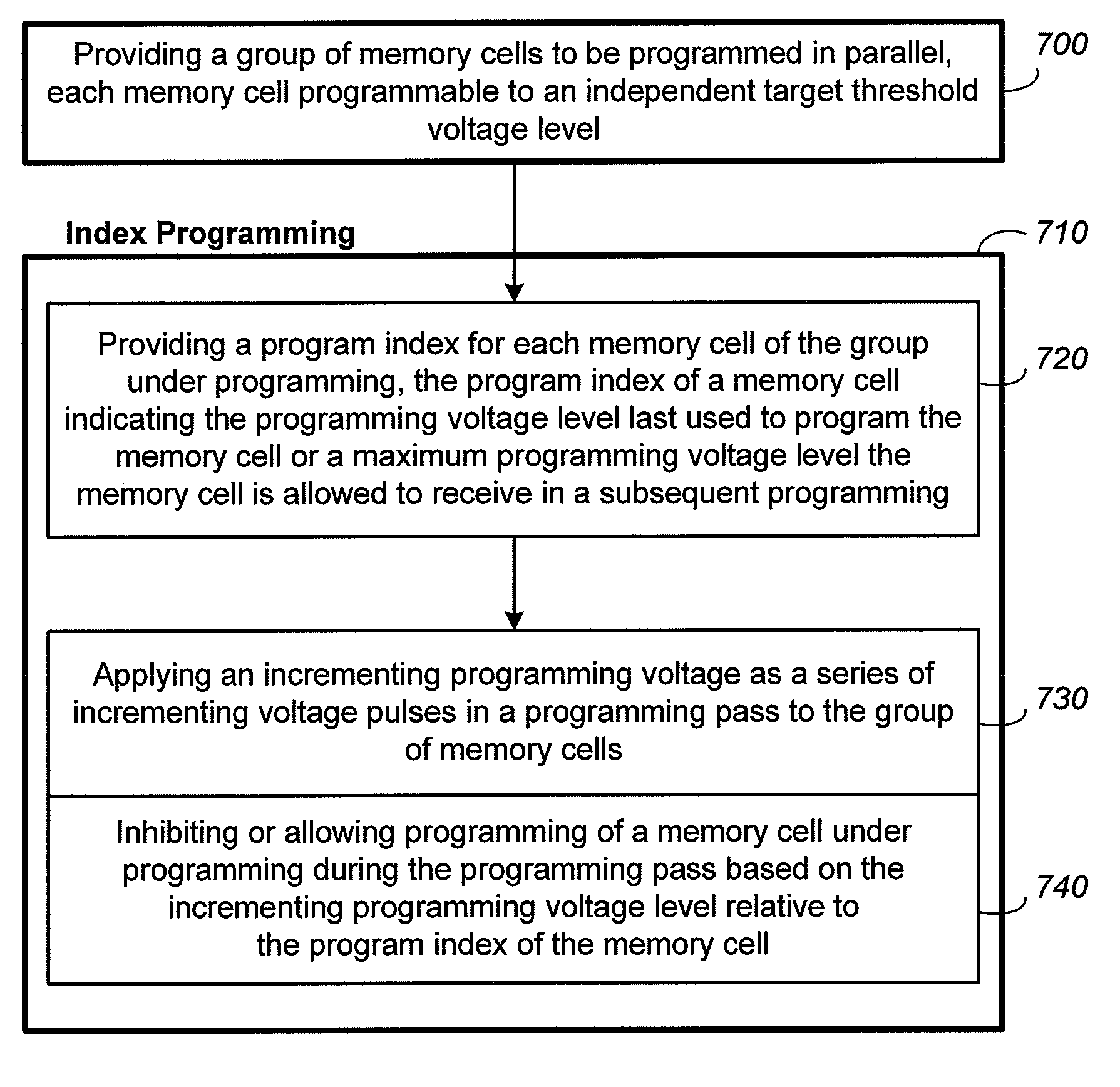

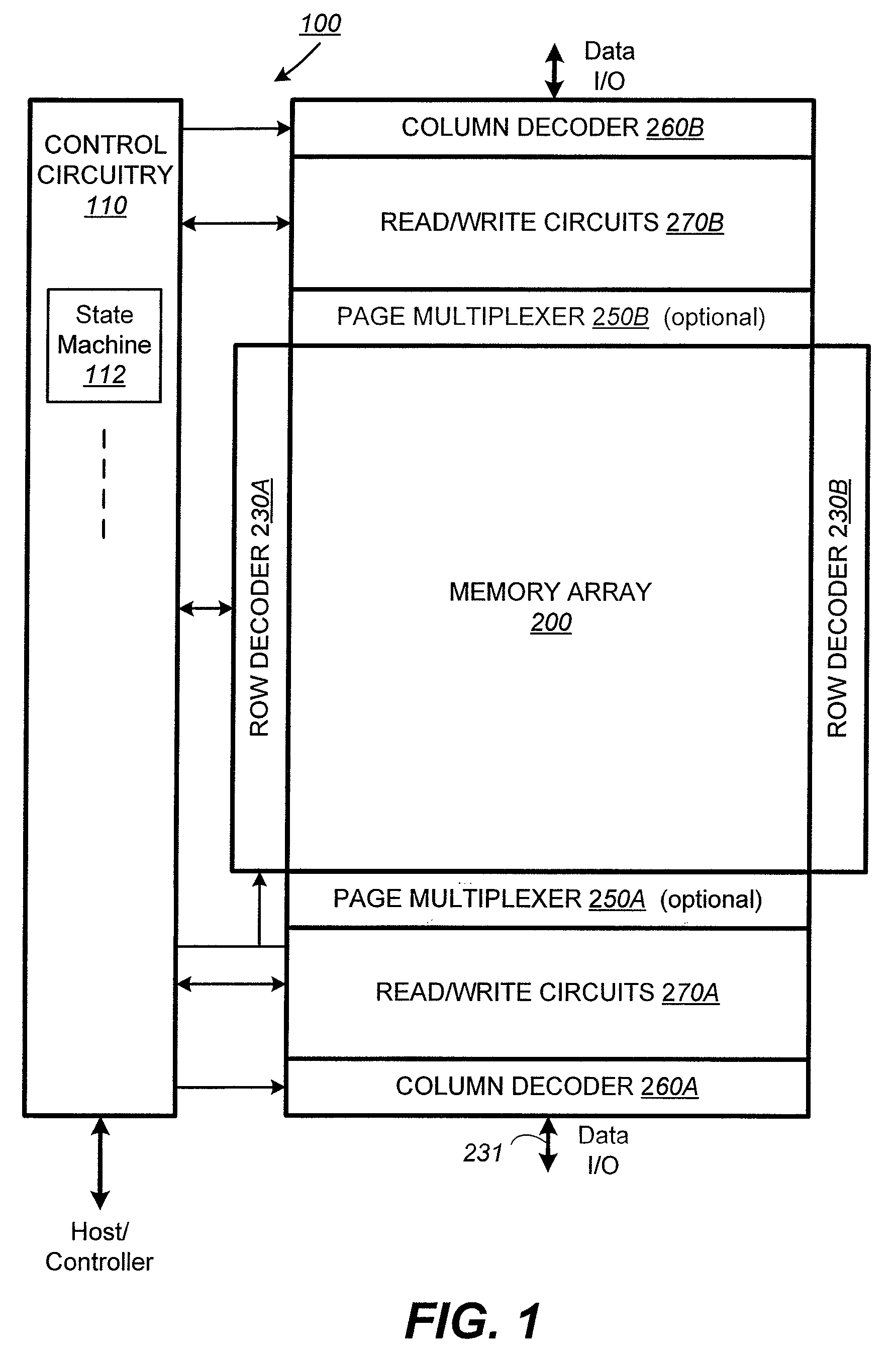

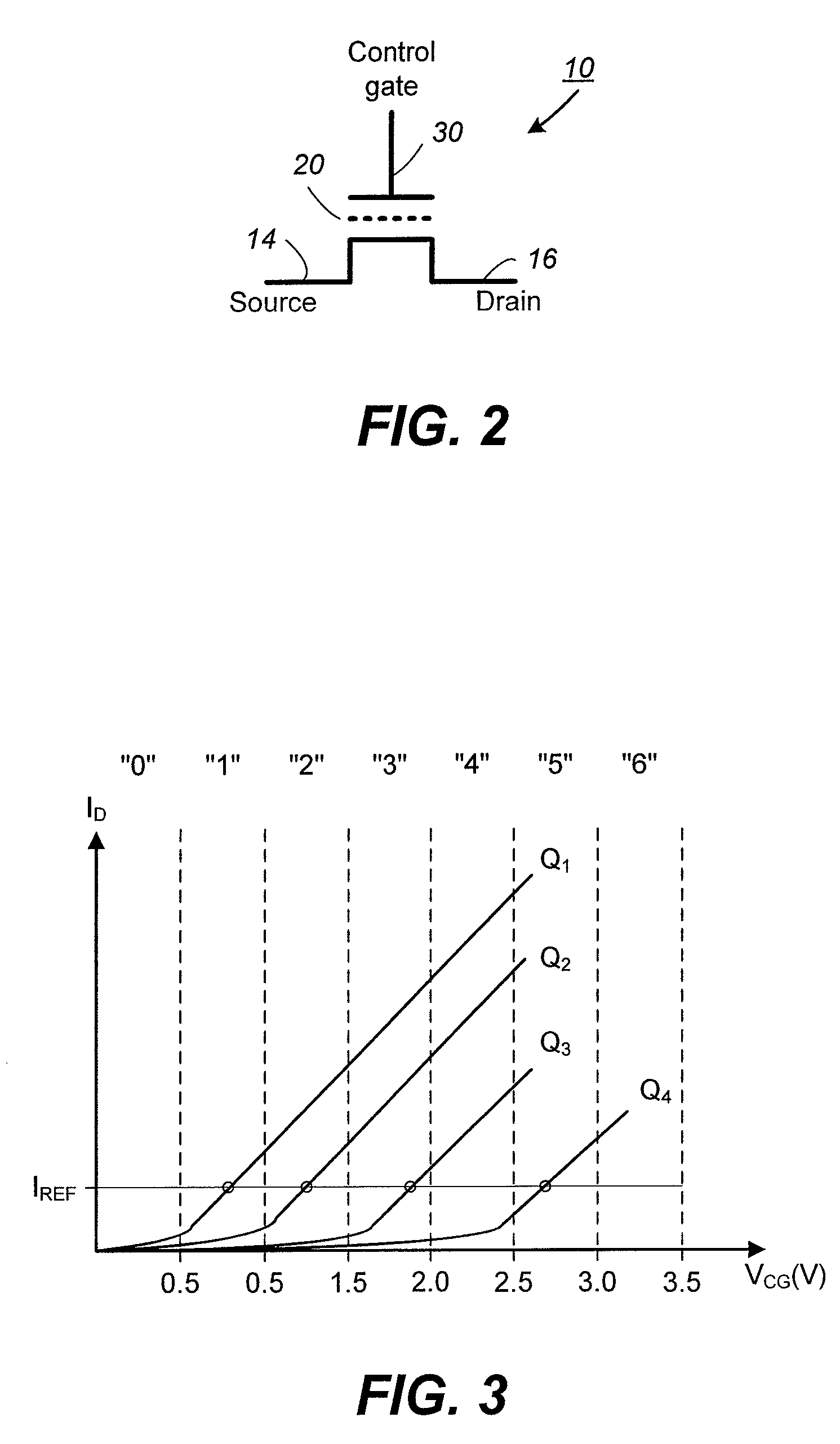

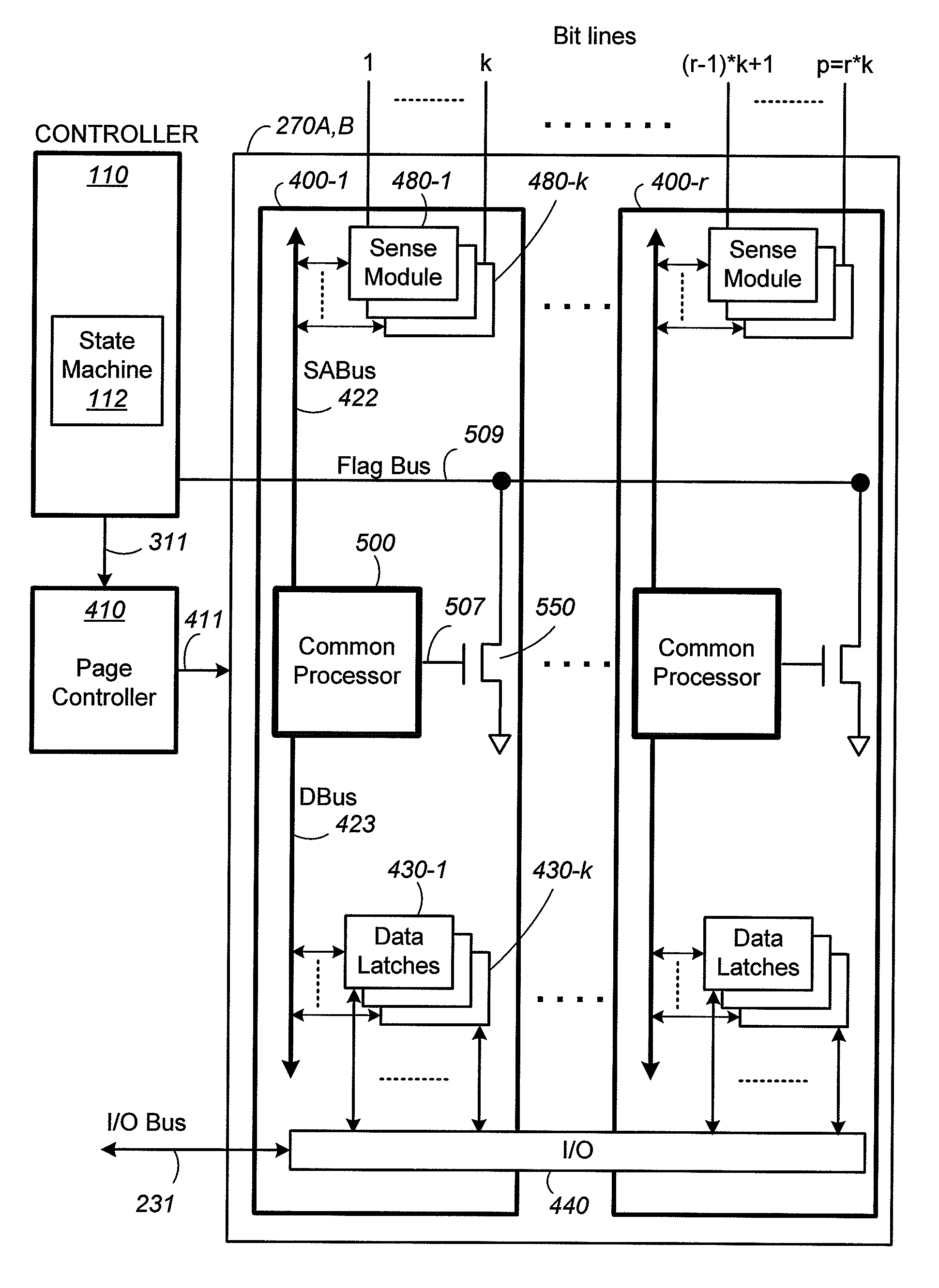

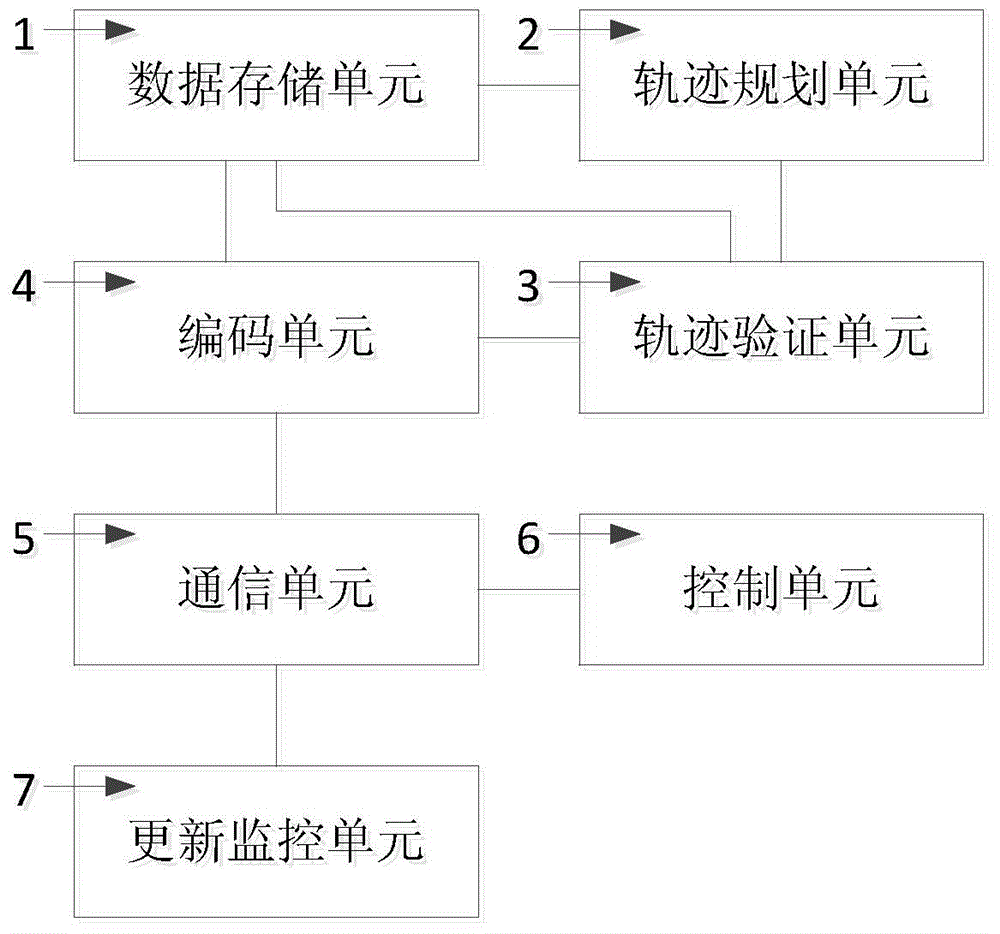

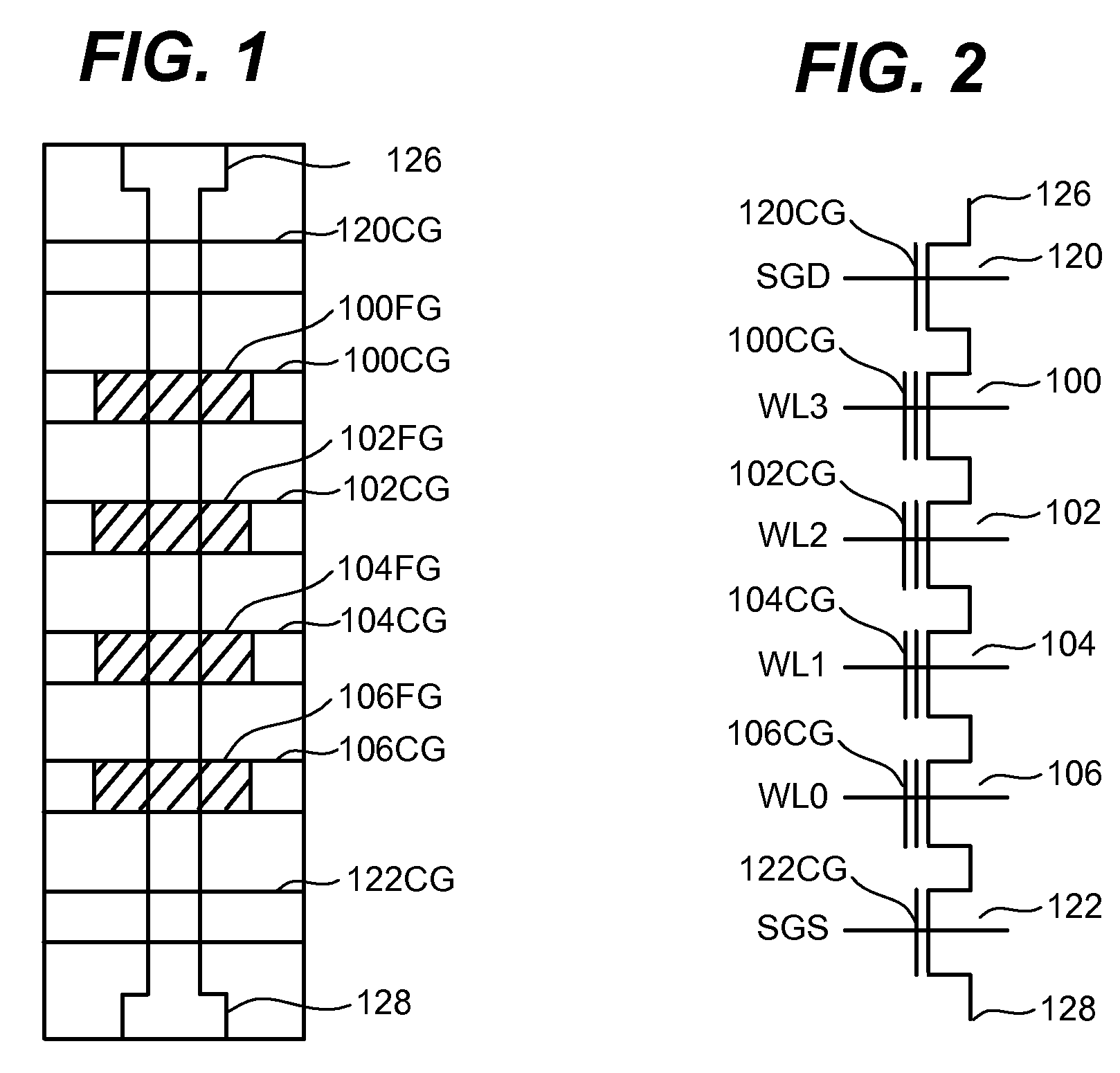

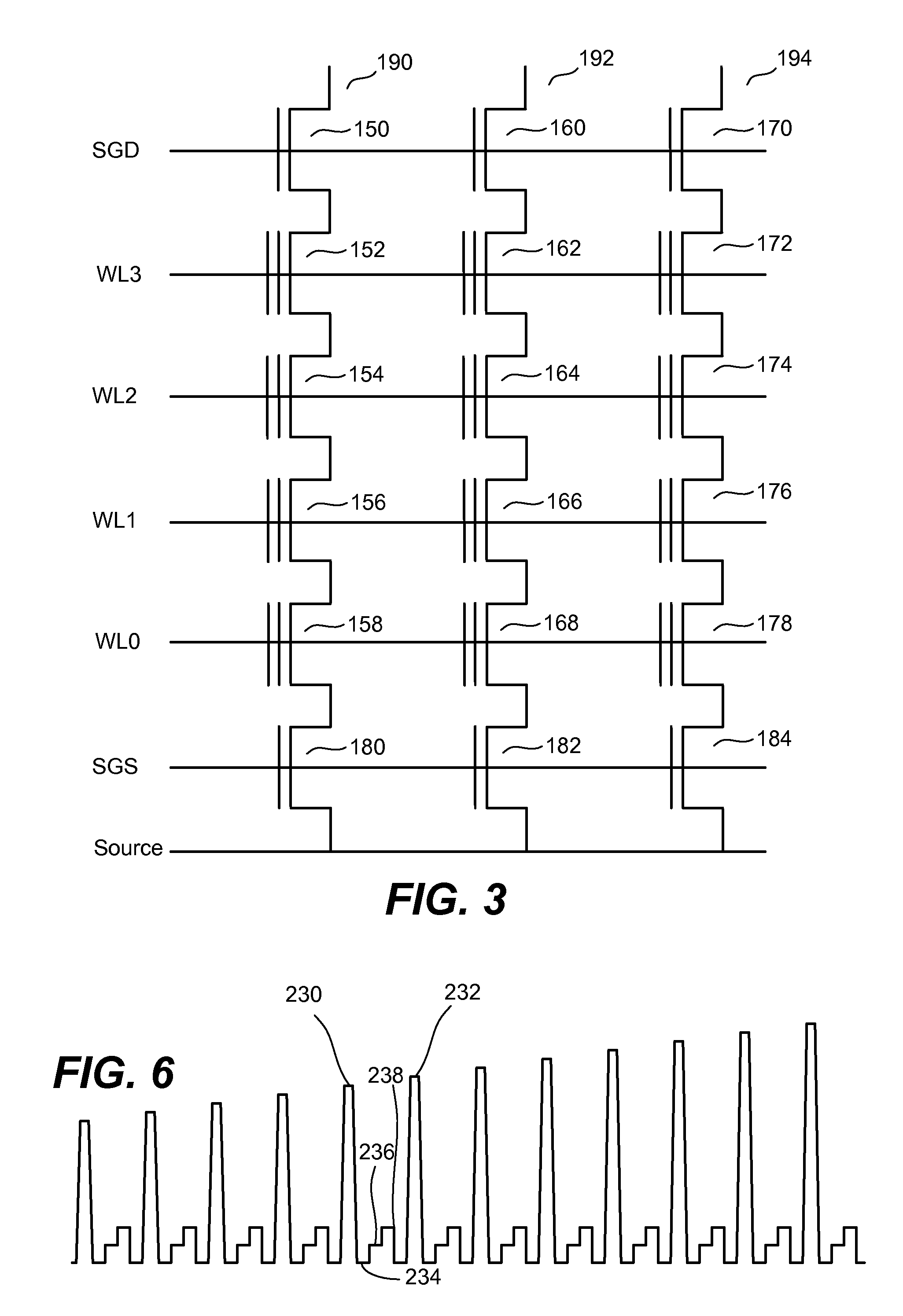

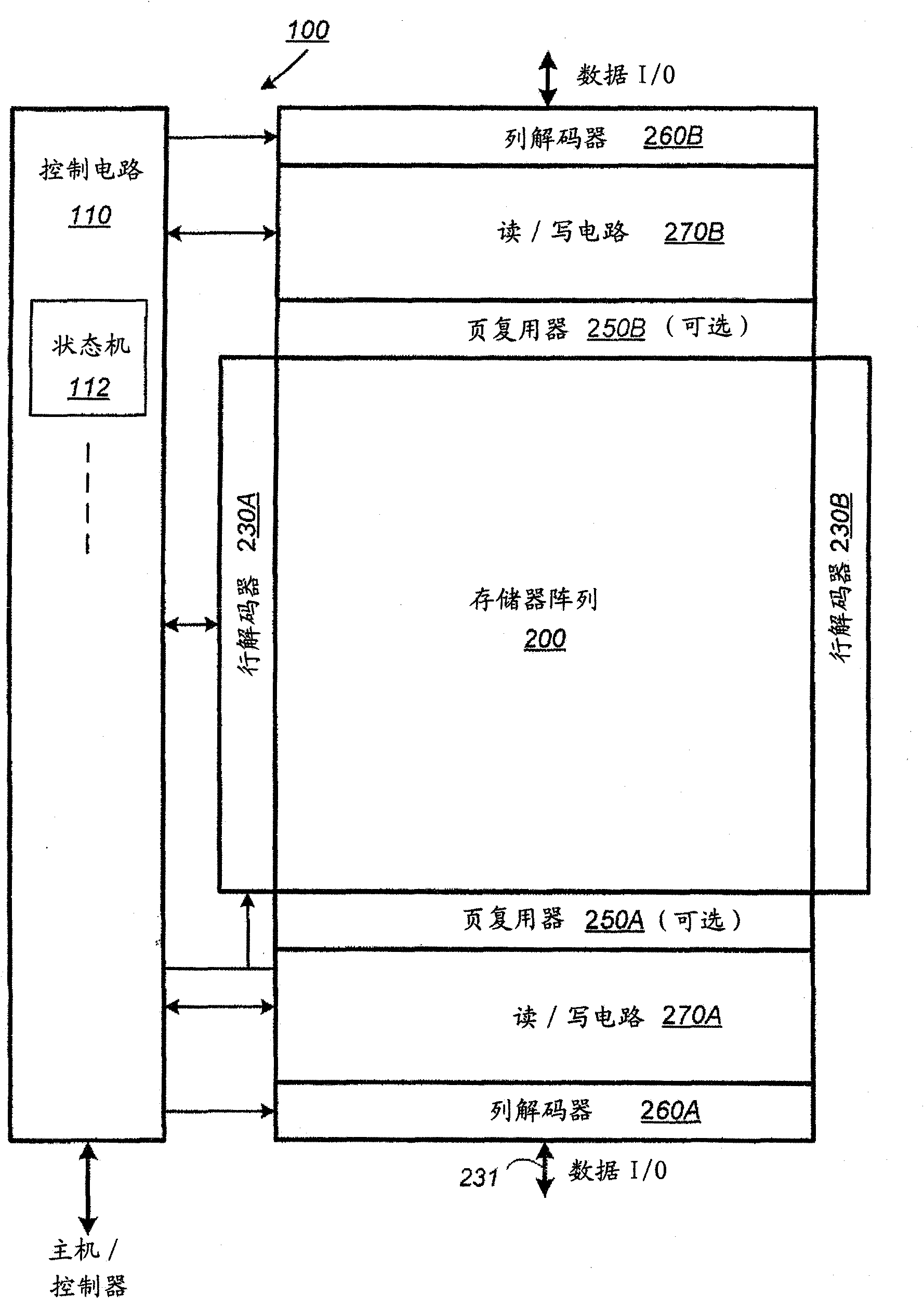

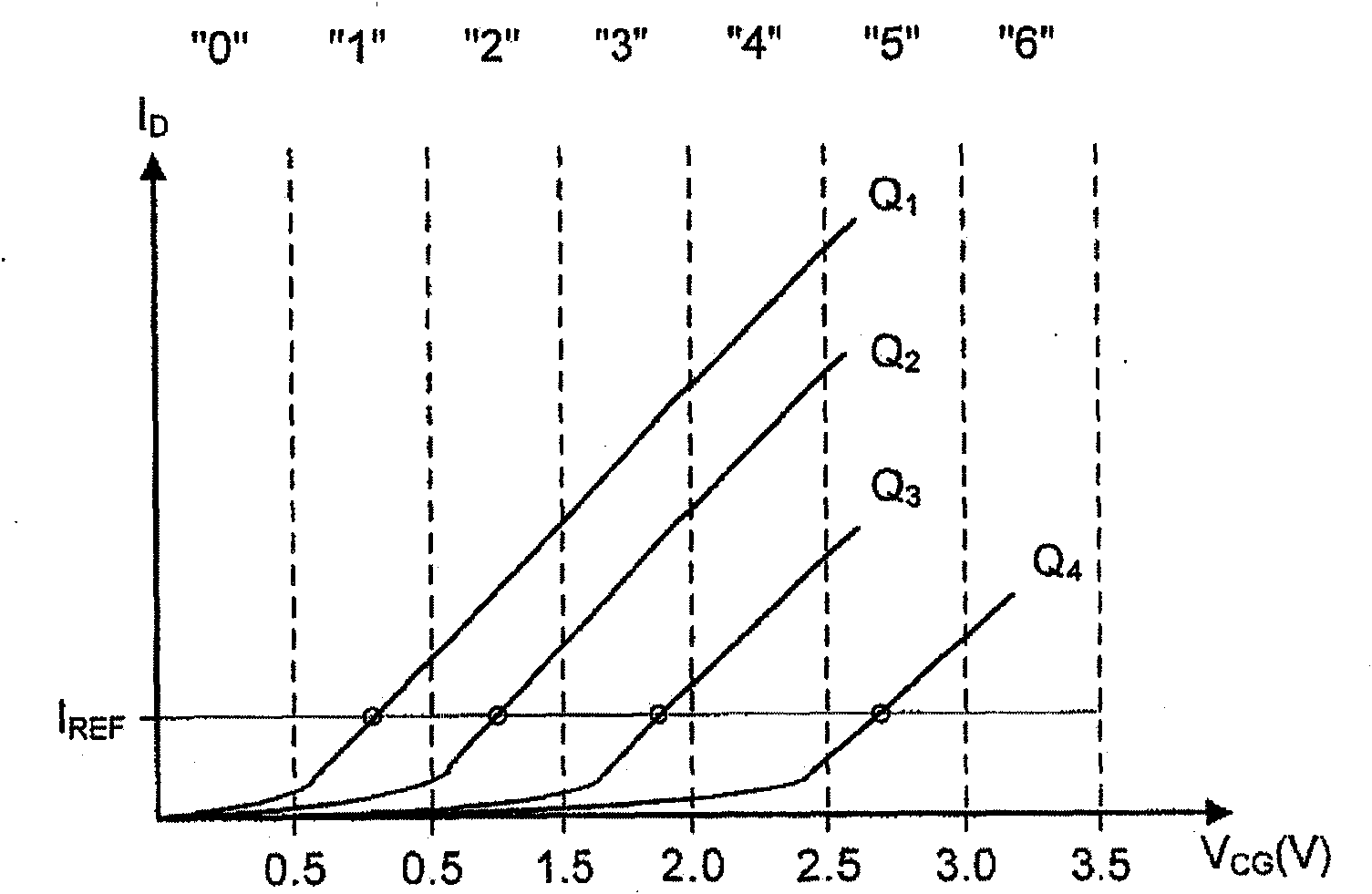

Method for index programming and reduced verify in nonvolatile memory

ActiveUS7800945B2Save stepsTighten distributionRead-only memoriesDigital storageInductive programmingMultiple pass

Owner:SANDISK TECH LLC

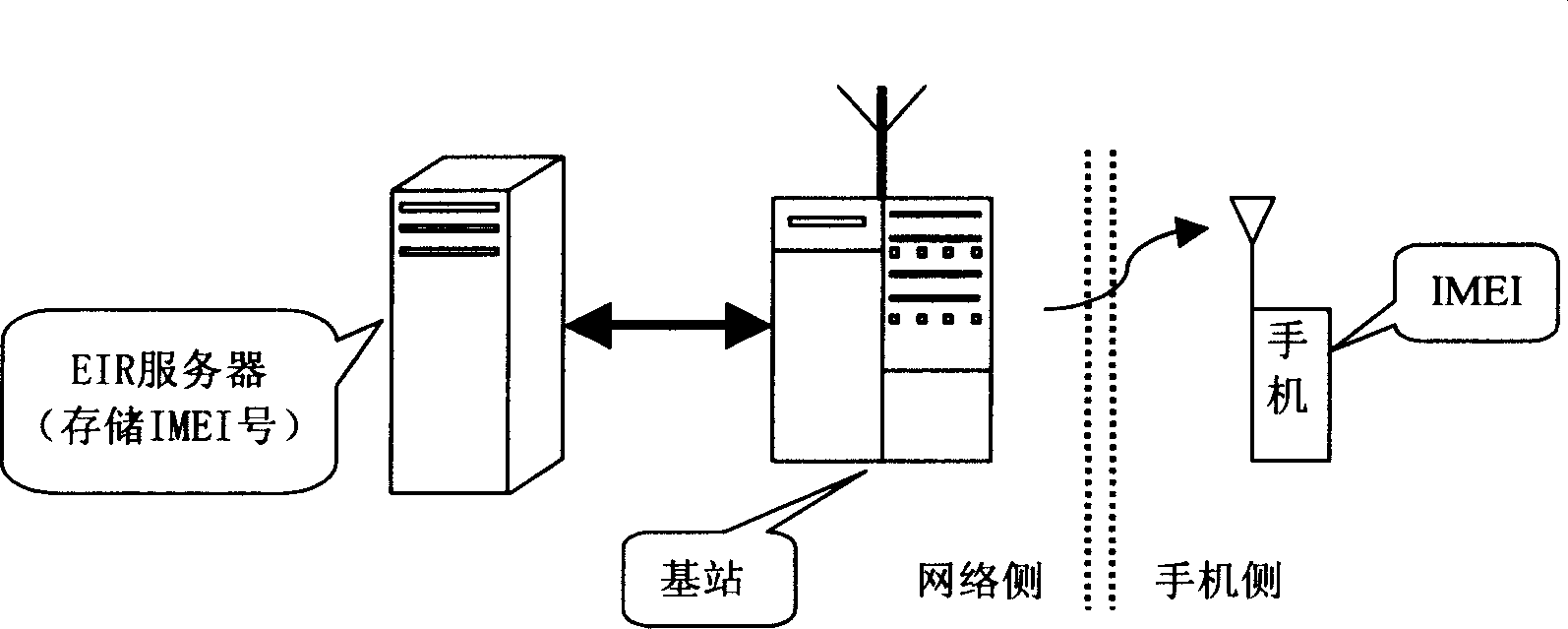

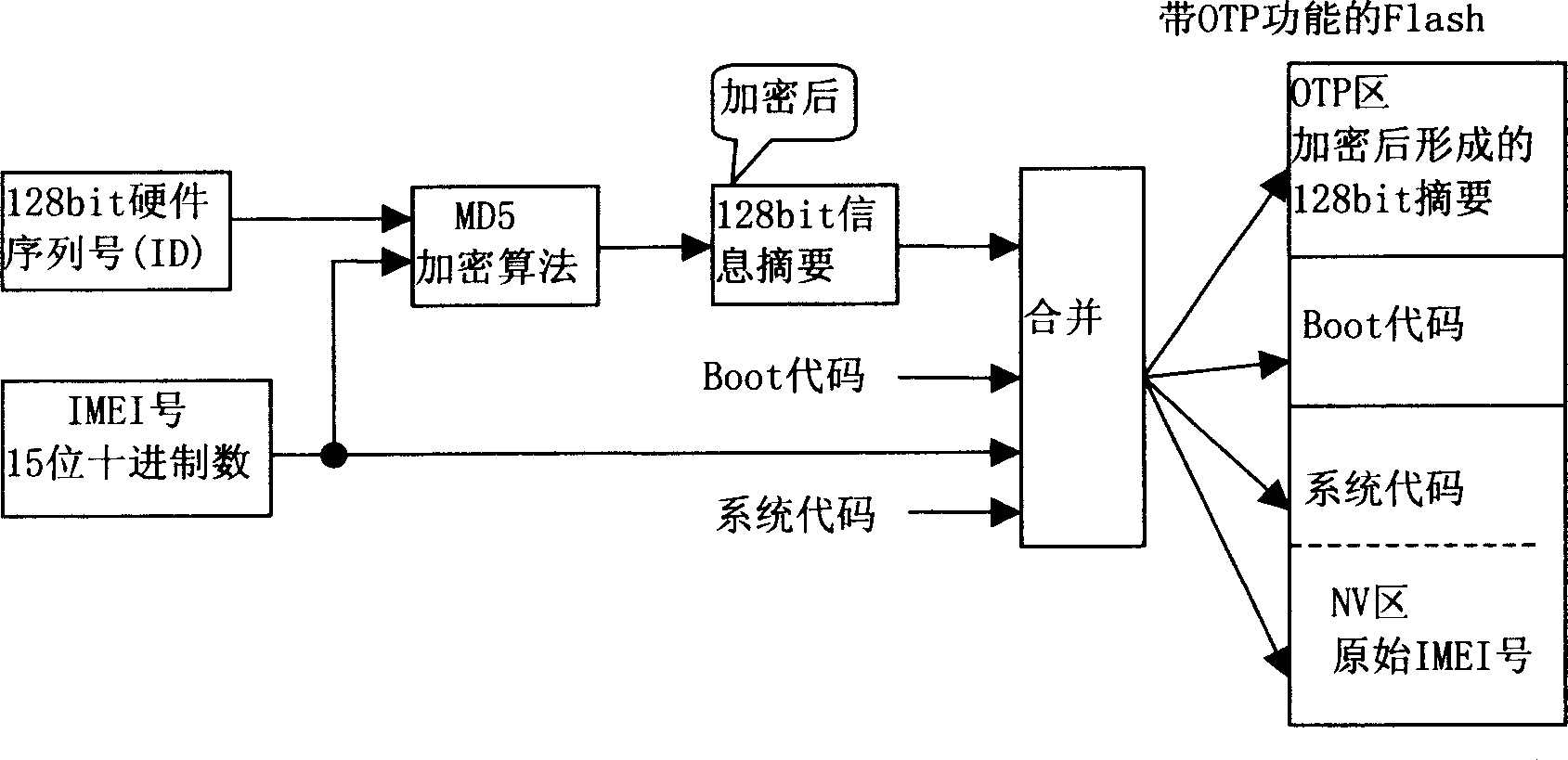

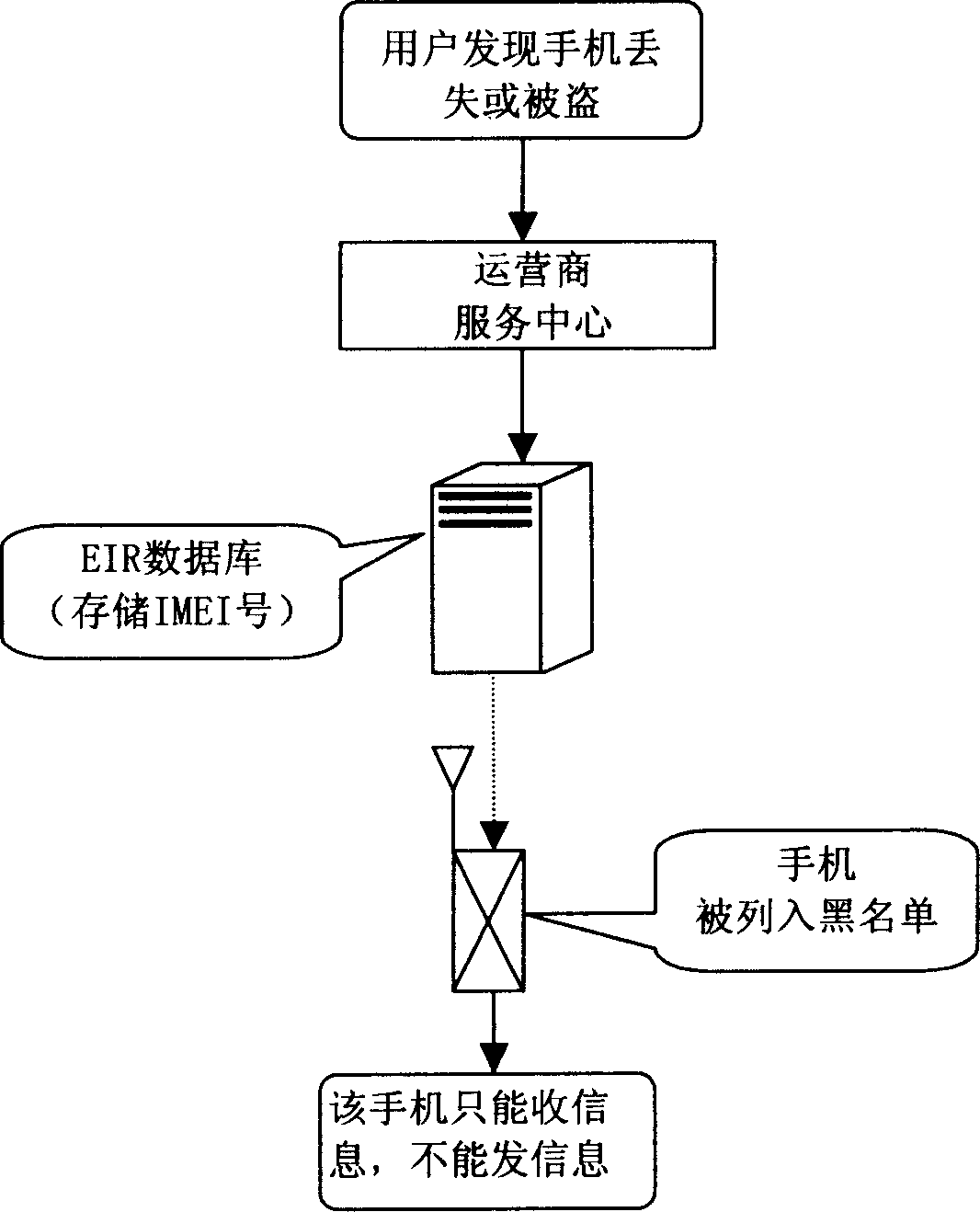

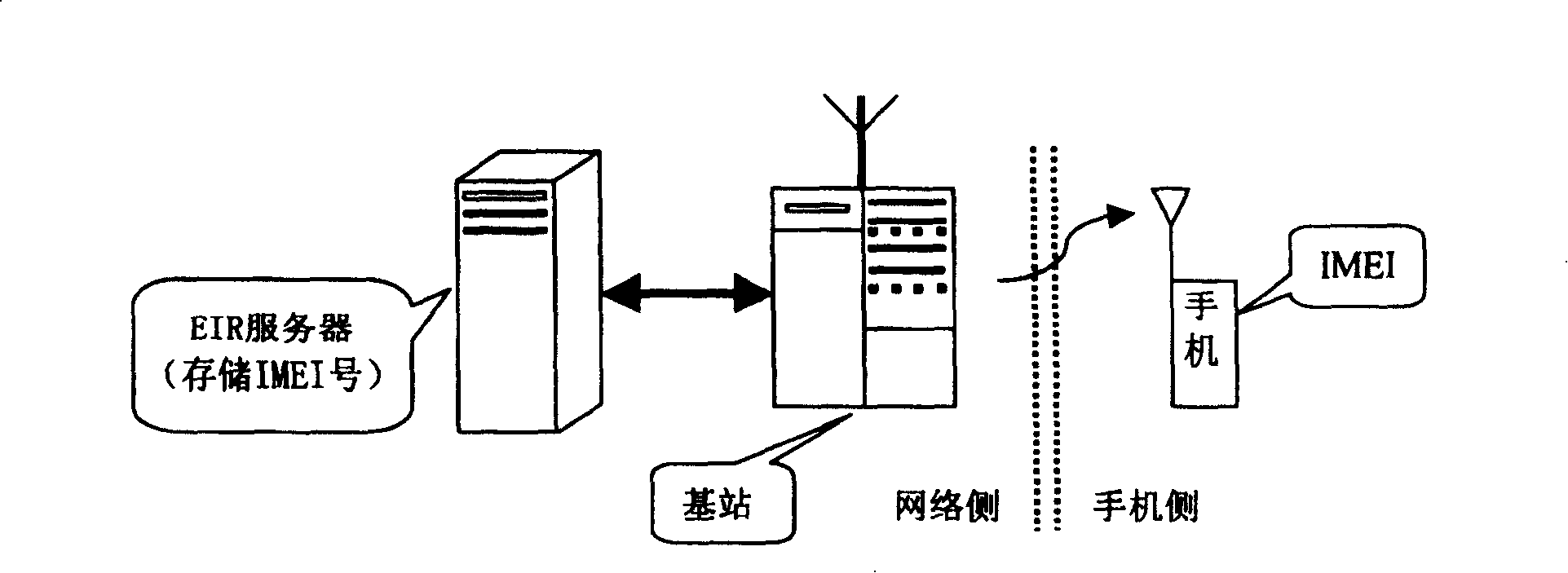

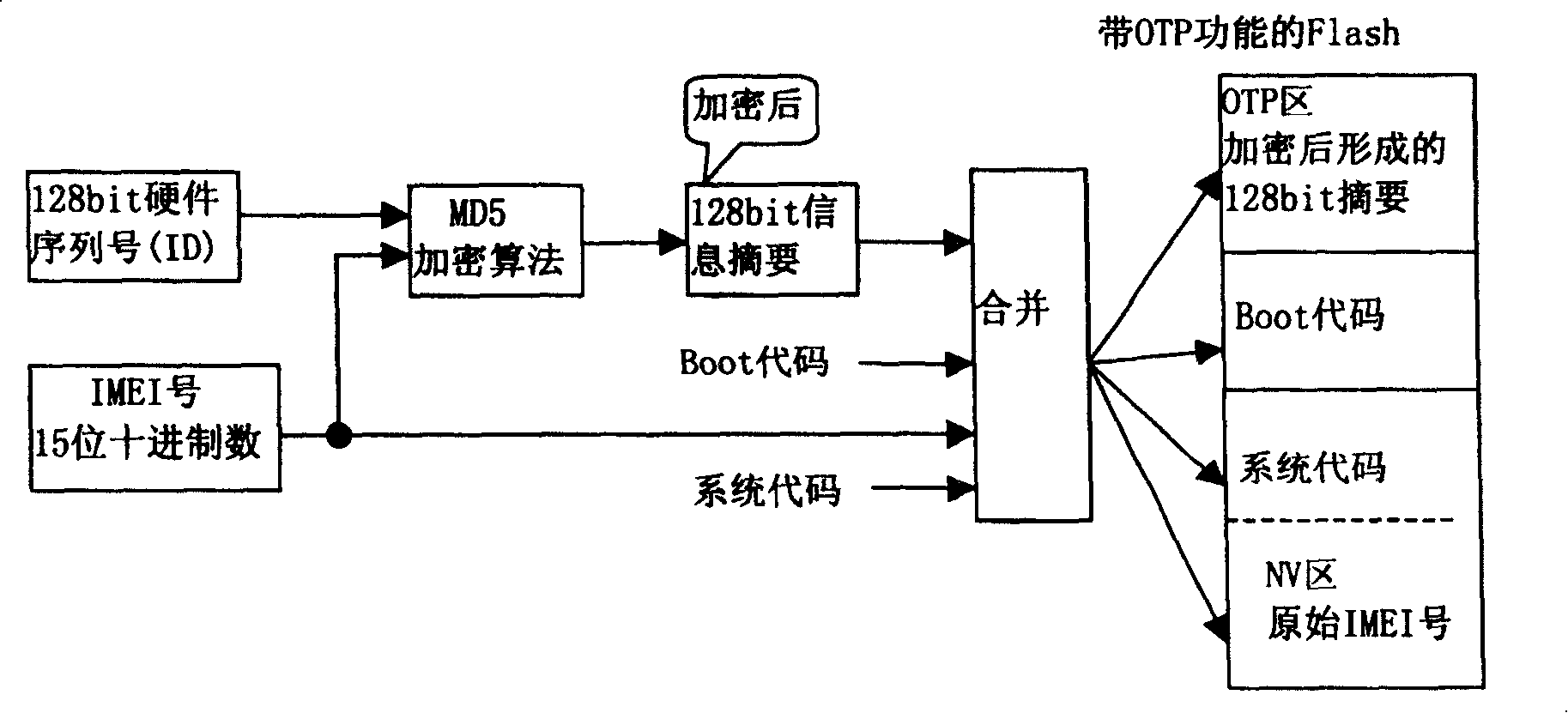

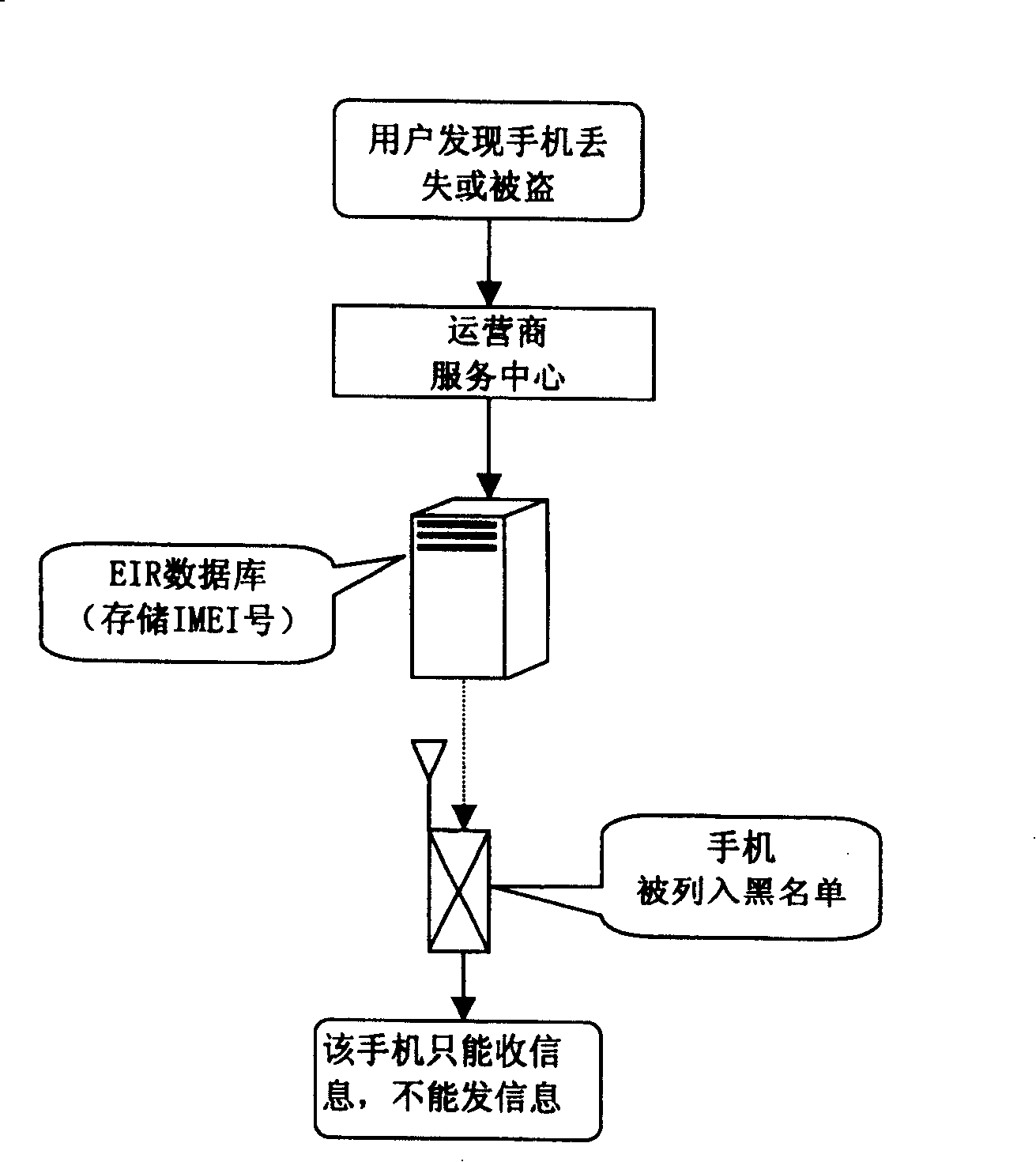

Protection method and system for preventing fraudulent use of mobile terminal

ActiveCN1913679APrevent number changeUser identity/authority verificationRadio/inductive link selection arrangementsInductive programmingSerial code

The security protection method and system described in this invention pre-save a serial number of identification in the mobile terminals. The network equipment checks the serial number of identification. If the identification is not passed, the mobile terminals are defined as illegal users, to prohibit the use of network through the mobile phones or lock them by the service provider's network when they are lost of stolen. The serial number of identification (such as 128bit summary information) is stored in the flash memory with a OTP function of one-time programming through the MD5 encryption on IMEI, which can only be written one time and has finished when the mobile phone leaves the factory. The content read out from the second time of writing is not the same one of the writing.

Owner:HUAWEI TECH CO LTD

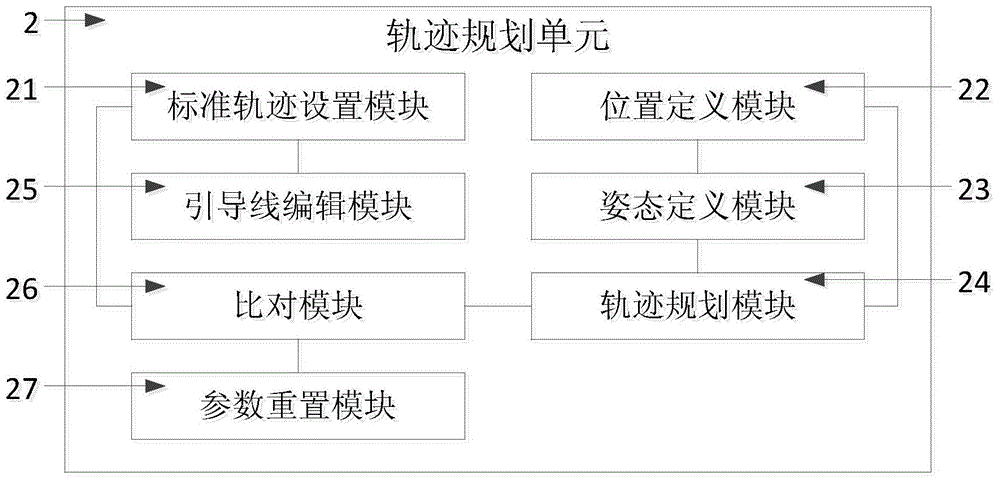

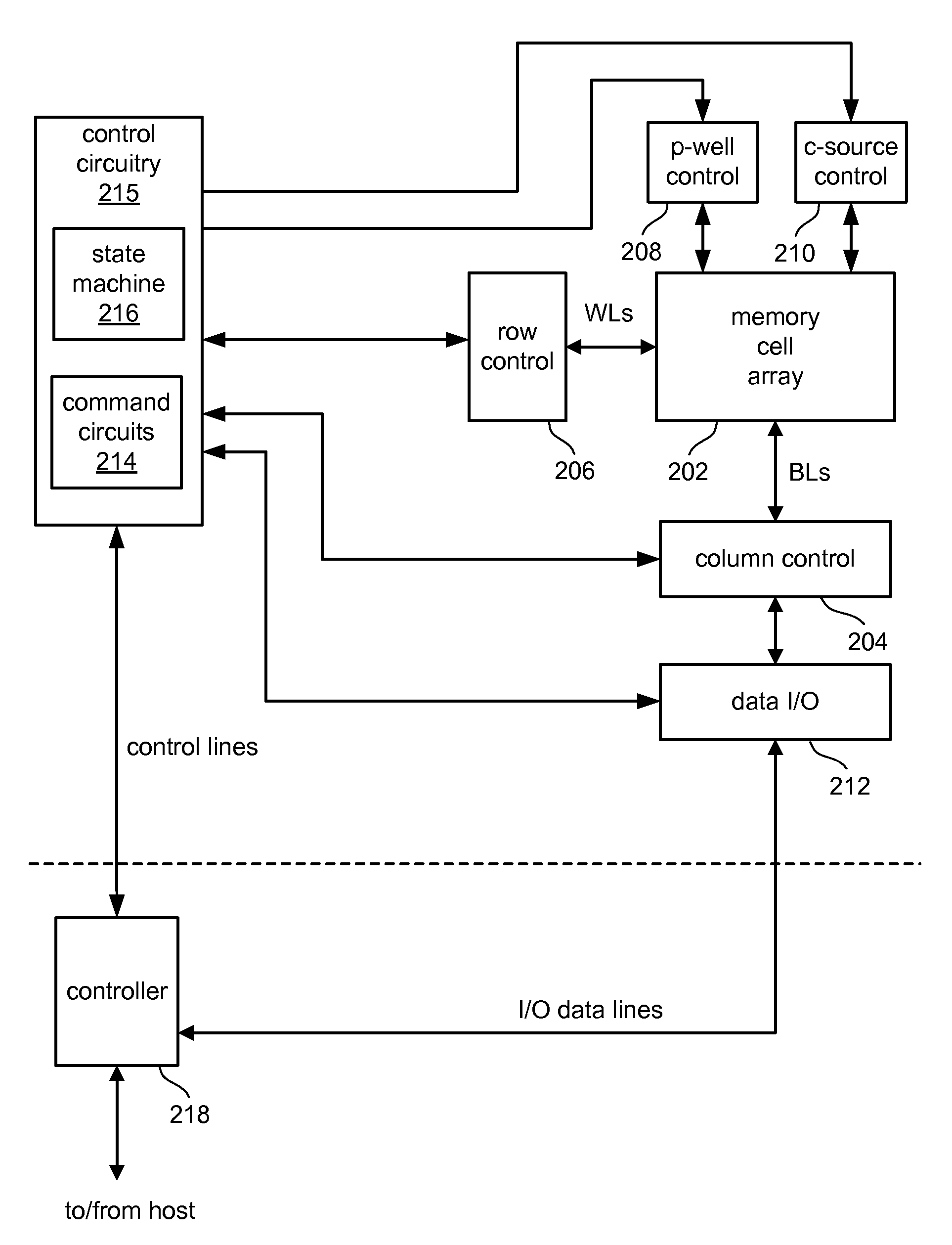

Nonvolatile memory with index programming and reduced verify

ActiveUS7826271B2Save stepsTighten distributionRead-only memoriesDigital storageTheoretical computer scienceInductive programming

In a non-volatile memory a group of memory cells is programmed respectively to their target states in parallel using a multiple-pass index programming method which reduces the number of verify steps. For each cell a program index is maintained storing the last programming voltage applied to the cell. Each cell is indexed during a first programming pass with the application of a series of incrementing programming pulses. The first programming pass is followed by verification and one or more subsequent programming passes to trim any short-falls to the respective target states. If a cell fails to verify to its target state, its program index is incremented and allows the cell to be programmed by the next pulse from the last received pulse. The verify and programming pass are repeated until all the cells in the group are verified to their respective target states. No verify operations between pulses are necessary.

Owner:SANDISK TECH LLC

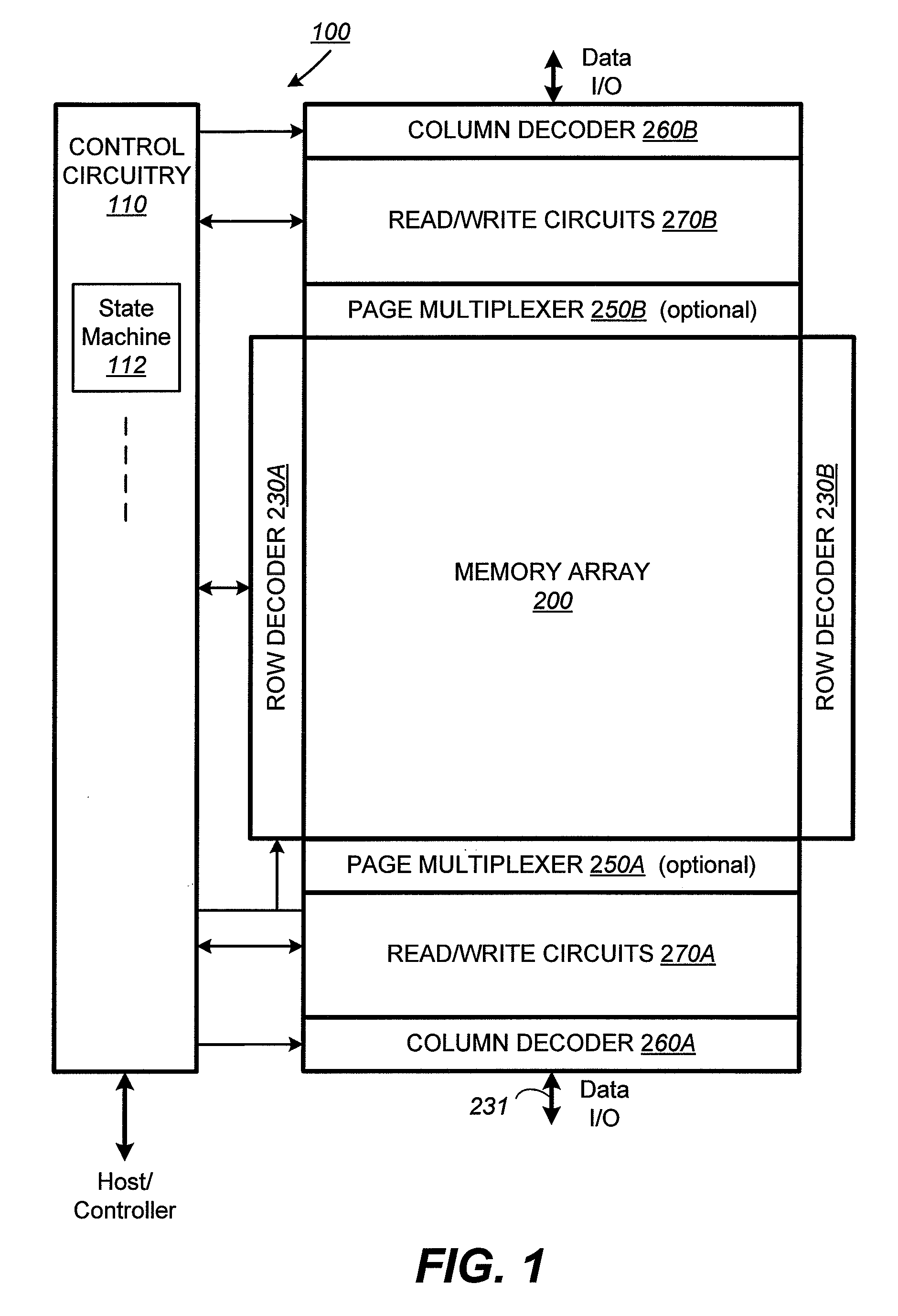

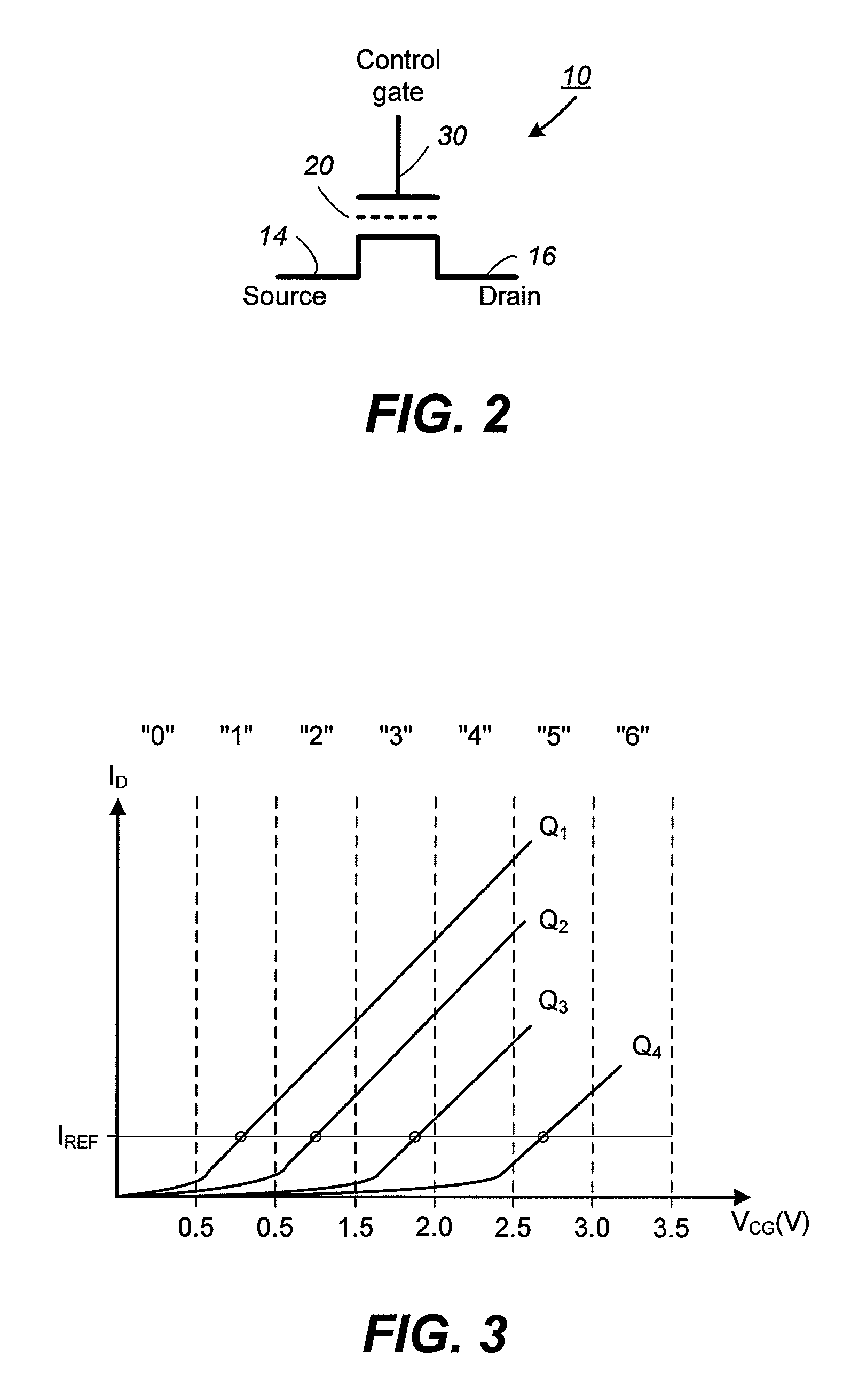

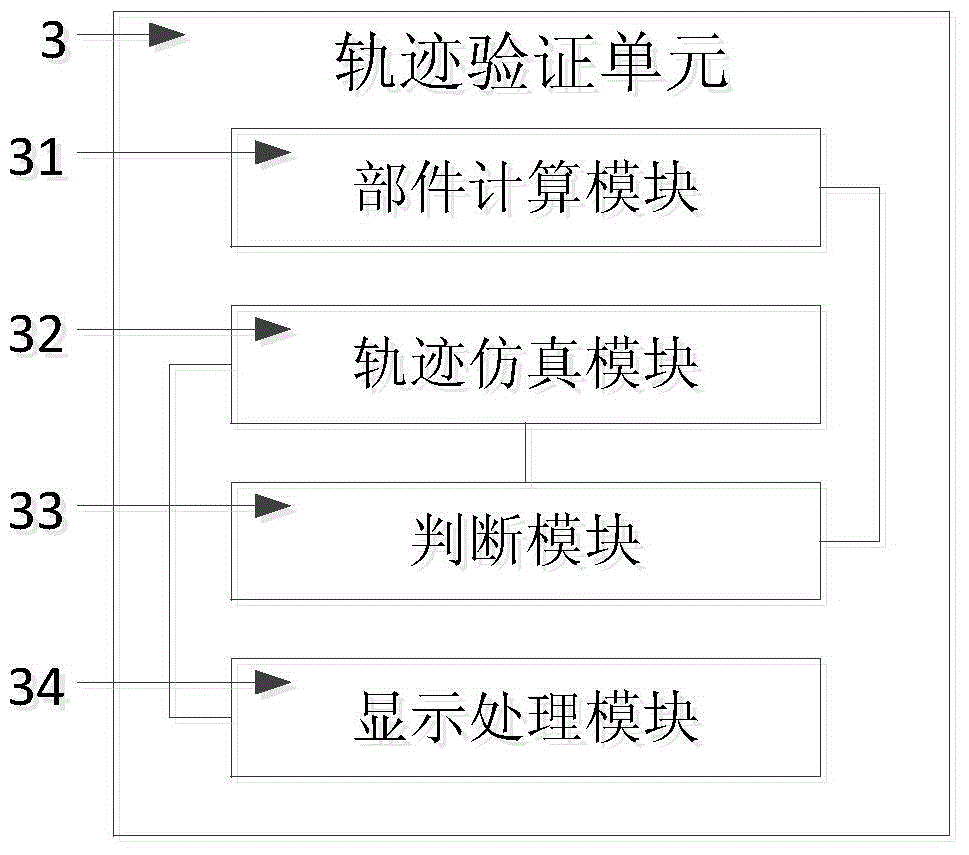

Robot off-line programming system

ActiveCN105171745AEasy and fast programmingProgramming Precise and StableProgramme-controlled manipulatorGoal programmingInductive programming

The invention discloses a robot off-line programming system, and belongs to the technical field of robots. The robot off-line programming system comprises a data storage unit, a track planning unit, a track verifying unit and a coding unit, wherein the data storage unit is used for storing programming data; the track planning unit is used for processing a preset first three-dimensional model associated with a workpiece to be processed and programming data to obtain pose information of a second three-dimensional model associated with a robot, and then processing the pose information so as to obtain first track information of a practical processing track of the robot; the track verifying unit is used for verifying the first track information according to the programming data; the coding unit is used for performing coding with the programming information according to the verified first track information so as to form an updating program which can be recognized by the corresponding robot and transmitting the updating program to the corresponding robot to perform program updating. The technical scheme adopted by the robot off-line programming system has the benefits that the programming is simple, convenient and rapid, the programming is also accurate and stable, can guarantee the normal operation of robot equipment, and is free from the influence of an off-line programming process, and the whole off-line programming process is low in cost and easy to realize.

Owner:SHANGHAI FANUC ROBOTICS +1

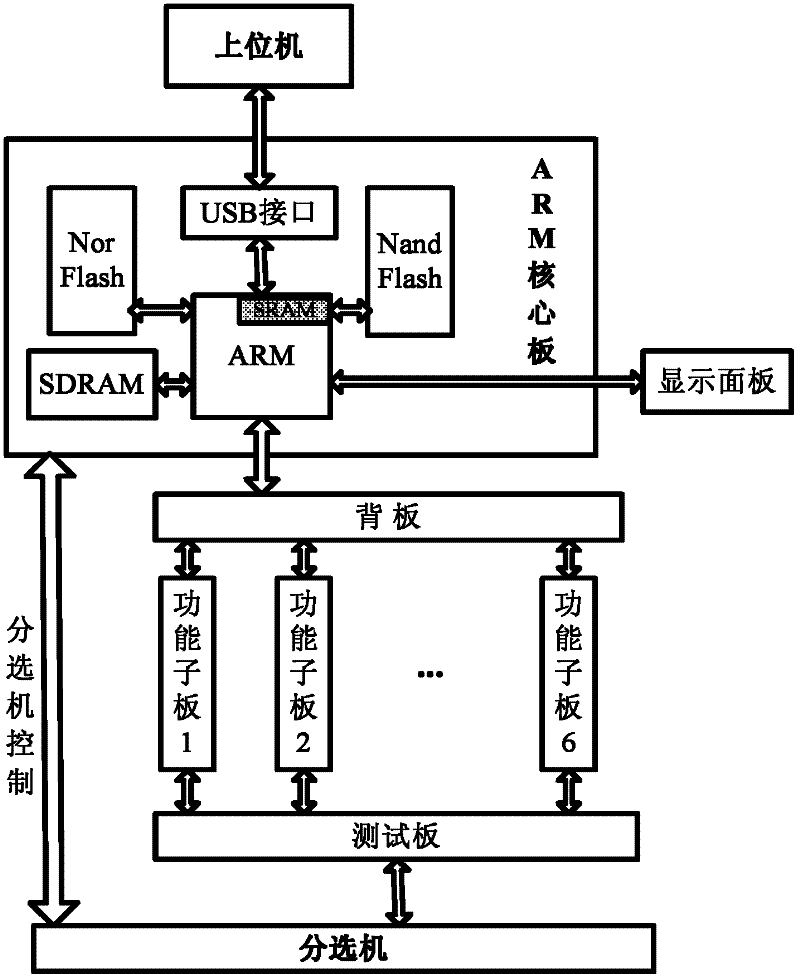

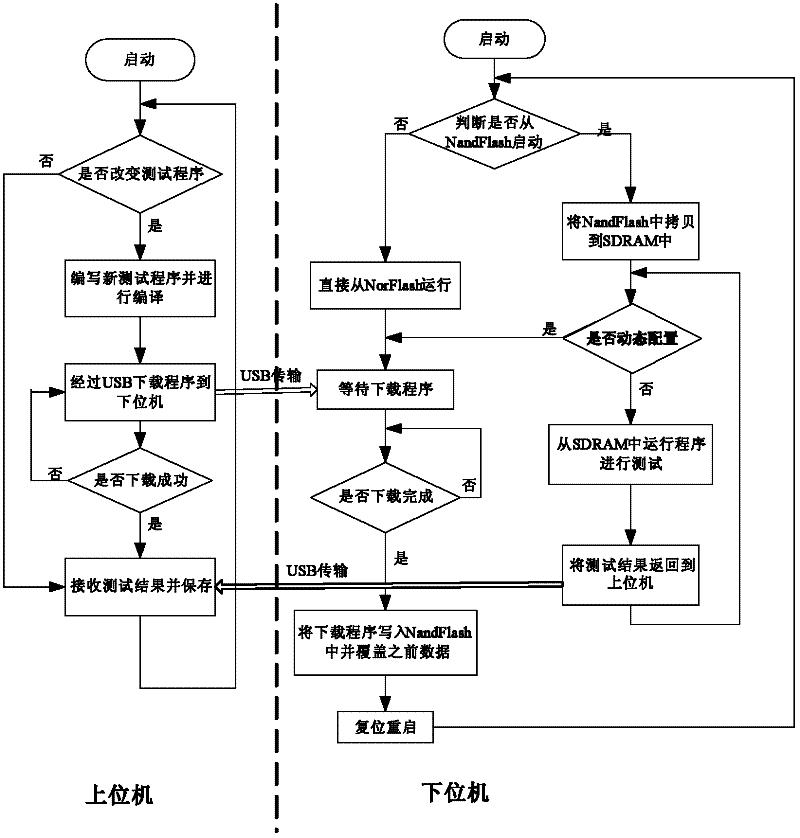

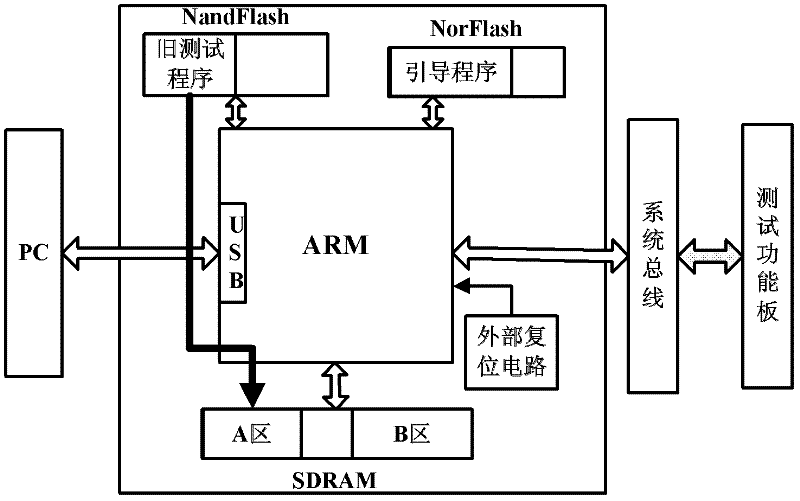

Dynamic allocation method for on-line programming of integrated circuit tester

InactiveCN102565671AQuick testFast dynamic configurationElectronic circuit testingProgram loading/initiatingIntegrated circuit layoutInductive programming

The invention discloses a dynamic allocation method for on-line programming of an integrated circuit tester. A microprocessor directly acquires a command from a NorFlash and executes the command by setting a boot flash selection pin in a lower computer when a testing program error occurs, so as to wait for downloading of the testing program for integrated circuit testing. Under the normal conditions, the testing task can be conducted by directly copying data in a NandFlash to an external SDRAM (Synchronous Dynamic random access memory) and operating the data; and in the testing process, the microprocessor automatically stores the downloaded testing program into the NandFlash to overwrite the existing testing program if receiving the testing program transmitted from an upper computer, and then automatically reboots the testing program to conduct testing according to the new testing program. Therefore, dynamic testing environment allocation can be achieved rapidly according to the requirements of users without switching memories. Meanwhile, the lower computer of the integrated circuit tester can be operated independently from the upper computer so as to achieve rapid testing and dynamic allocation.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Seamless connection method for off-line programming and on-site debugging of robot

InactiveCN101434067AEasy to useReduce environmental problemsProgramme-controlled manipulatorGoal programmingEngineering

The invention discloses a method for seamless connection of off-line programming and field debugging of a robot, which comprises the following steps: three-dimensional models of a tooling fixture and a robot tool are designed, and the three-dimensional models and a robot model are conducted into off-line programming software; the technological feasibility of the tool fixture, the robot tool and the robot is checked; real objects are arranged at proper positions according to the installation positions of the tool fixture, the robot and the robot tool; the installation situation of the robot tool in the installation situation is guaranteed to be consistent with the actual installation situation; the relative position of a coordinate system of the tooling fixture actually arranged at the proper position in a robot based coordinate system is measured; the installation position of the tooling fixture relative to the robot in the off-line programming software is calibrated according to a measurement result to ensure that the installation situation is consistent with the actual installation situation; and a robot program is generated after the measurement and calibration and is conducted into the robot, and the robot directly utilizes the program to finish the practical production. The program generated by the method can be directly used for practical production, and truly achieves the seamless connection of off-line programming and field debugging.

Owner:四川成焊宝玛焊接装备工程有限公司

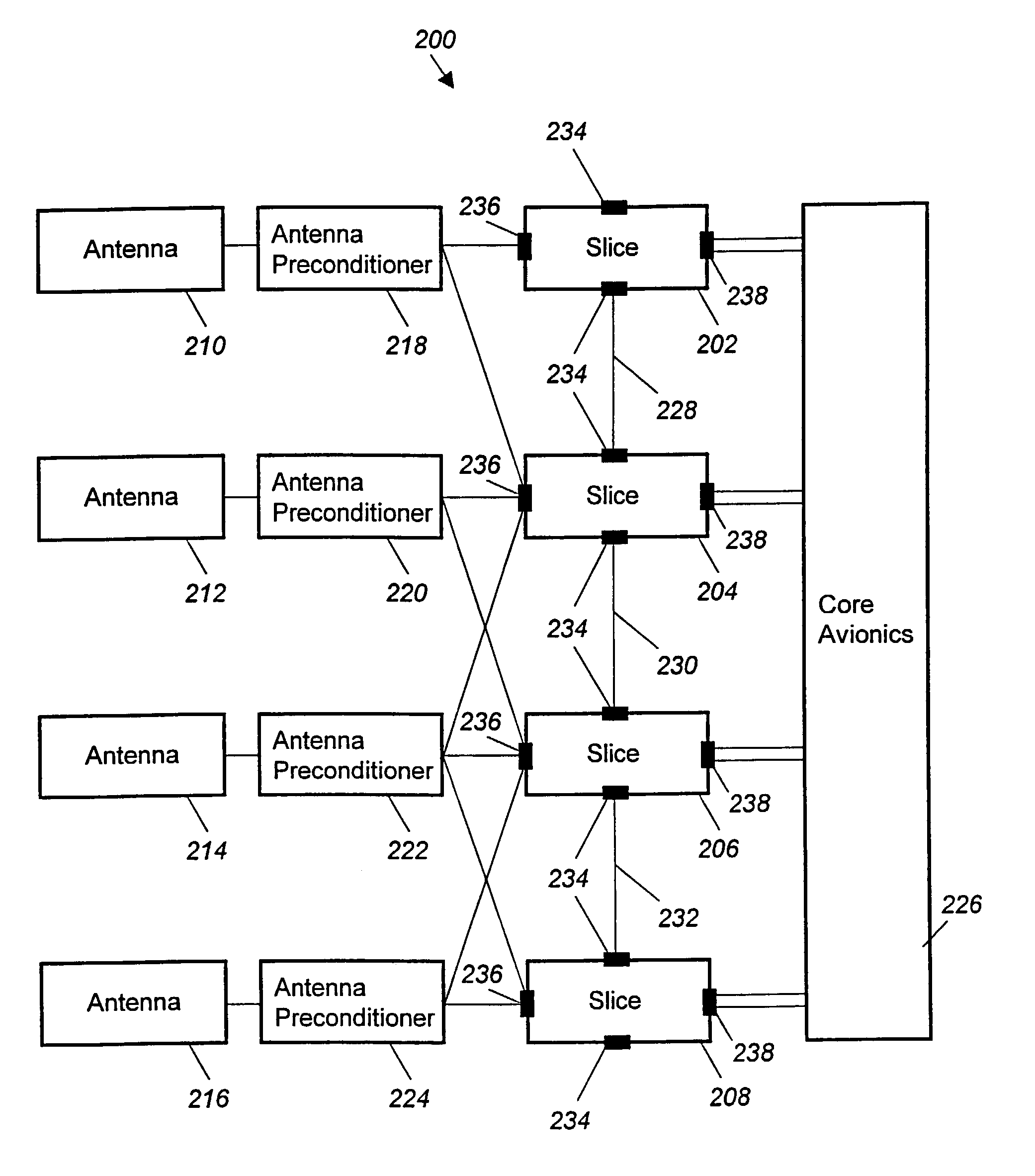

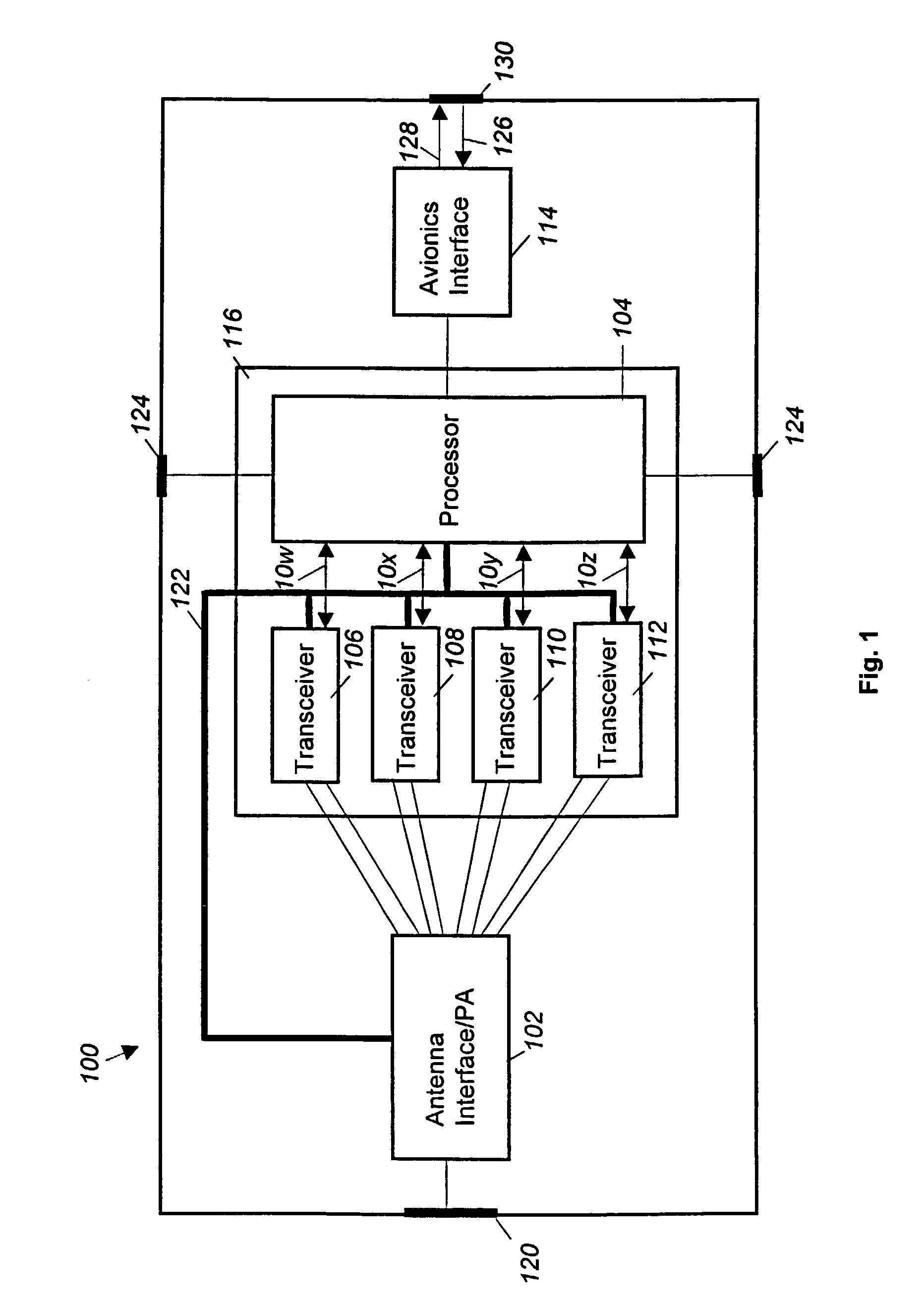

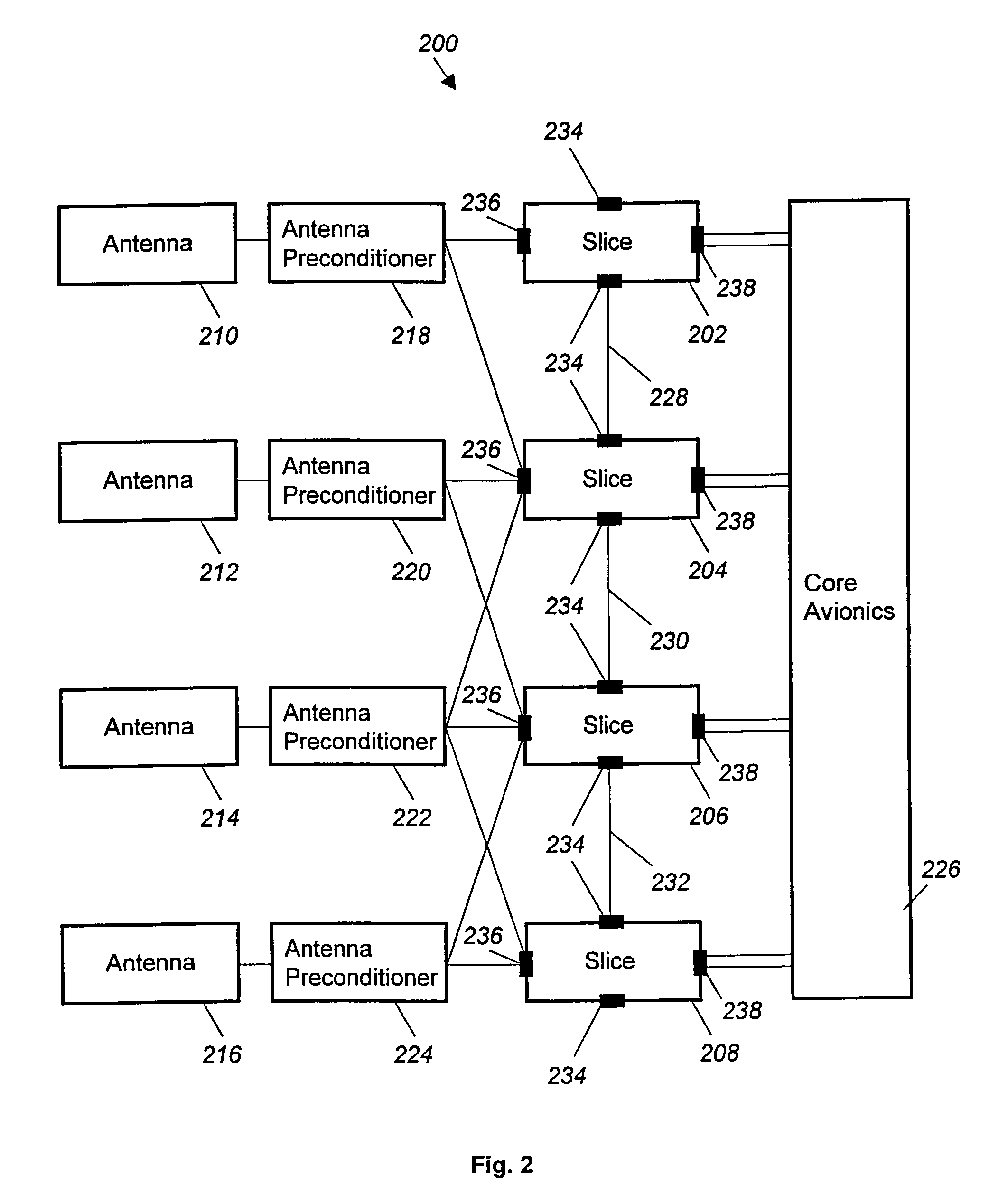

Real-time programming of electronic radio system resource assets

InactiveUS7136643B2Reduced reconfigurableReducing architectural complexity and SWAP requirementAircraft componentsModulated-carrier systemsControl signalInductive programming

A method to efficiently implement a reconfigurable electronic radio system (400) including resource assets (402–408, 410–416, 418, 420–426, 428) and a processor (428). The processor (428) generates RF control and switching control signals during each mission segment of an aircraft to create radio function threads through the resource assets (402–408, 410–416, 418, 420–426, 428) to realize the radio functions for that mission segment. The processor (428) may also be coupled to a master processor (440) that sends the processor (428) a radio function set selection signal. The radio function set selection signal identifies the radio function set that the processor (428) will implement through the resource assets (402–408, 410–416, 418, 420–426, 428). The processor (428) performs all signal, data, message, cryptographic and control processing required for the radio function threads being implemented by the resource assets.

Owner:NORTHROP GRUMMAN SYST CORP

High voltage generation and control in source-side injection programming of non-volatile memory

Non-volatile memory is programmed using source side hot electron injection. To generate a high voltage bit line for programming, the bit line corresponding to a selected memory cell is charged to a first level using a first low voltage. A second low voltage is applied to unselected bit lines adjacent to the selected bit line after charging. Because of capacitive coupling between the adjacent bit lines and the selected bit line, the selected bit line is boosted above the first voltage level by application of the second low voltage to the unselected bit lines. The column control circuitry for such a memory array does not directly apply the high voltage and thus, can be designed to withstand lower operating voltages, permitting low operating voltage circuitry to be used.

Owner:SANDISK TECH LLC

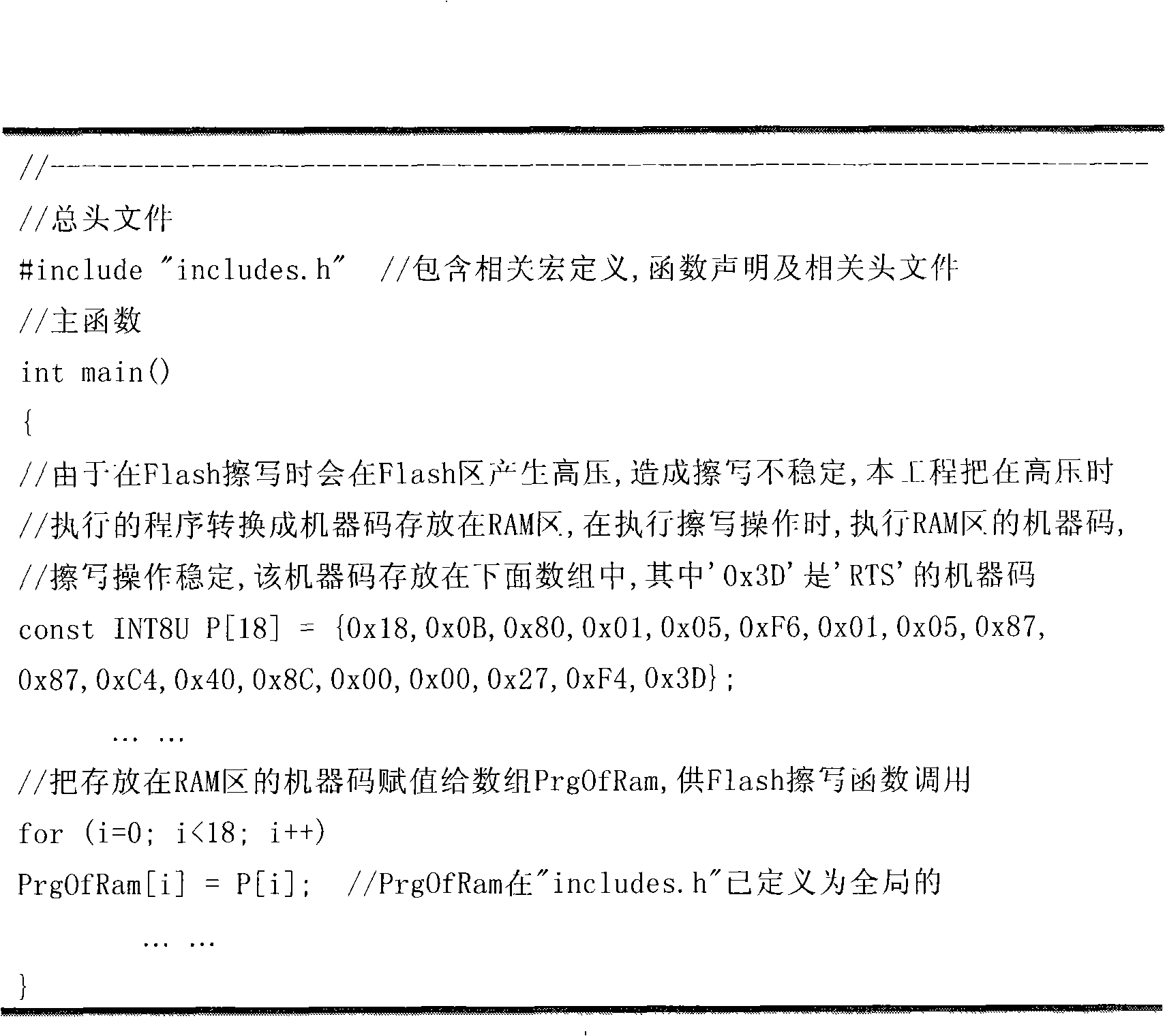

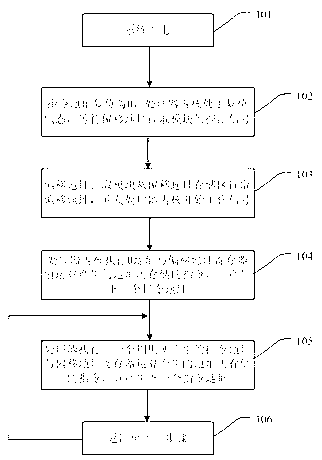

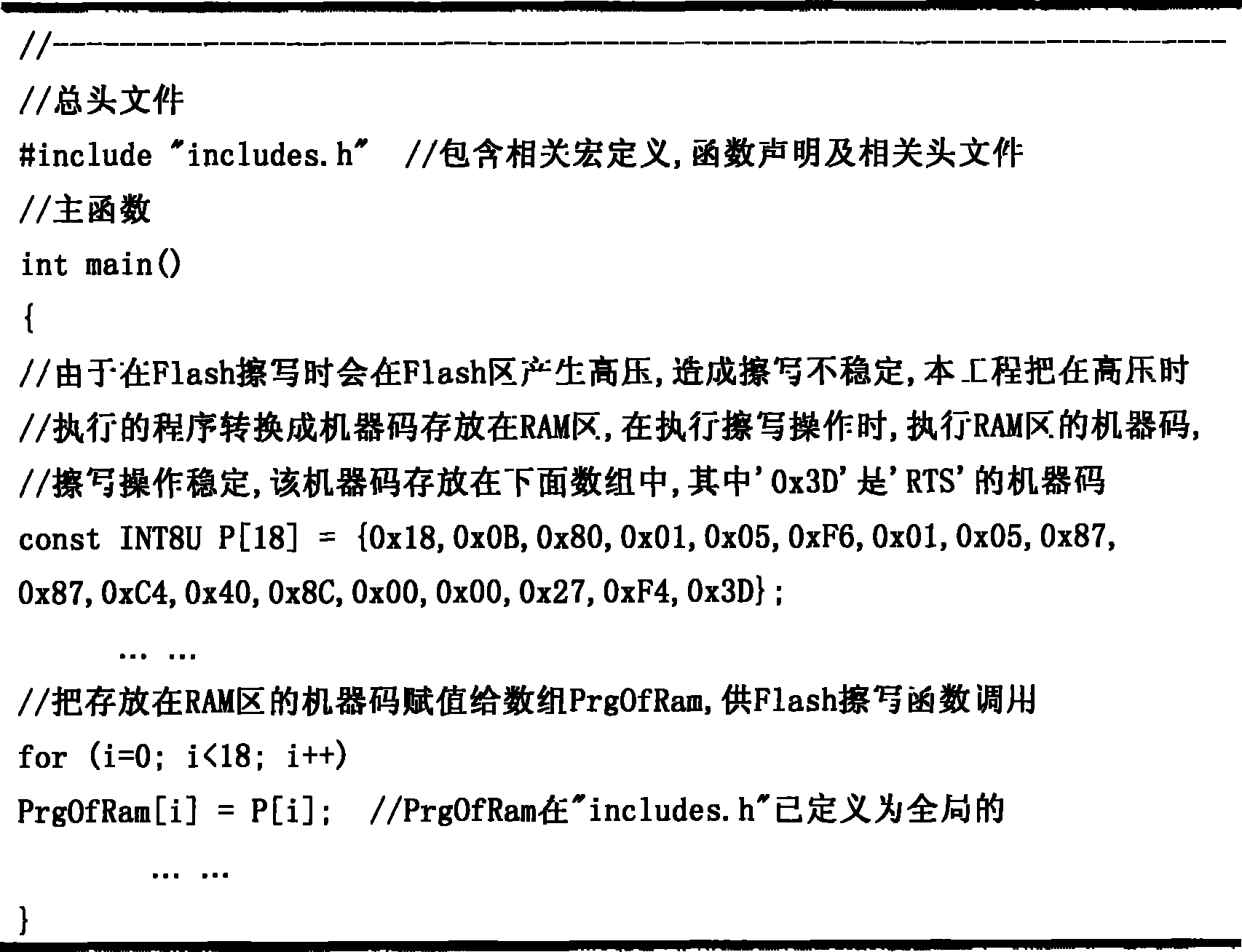

Control method for Flash memory on-line programming

InactiveCN101409106AGuaranteed stabilityOnline programming convenienceRead-only memoriesReturn statementGeneric programming

The invention discloses an on-line programming control method of a Flash memory, comprising erasing operation and read-in operation. The method is characterized in that machine codes of operation statements and return statements of the Flash memory in the period of adding high pressure are preset in an RAM. The operation statements include the statement for writing interrupt identification in a status register so as to start a corresponding command, as well as the statement for judging the completion of a wait command; and in the processes of erasing operation and writing operation, program operation is carried out when the period of adding high pressure turns to the RAM. The invention separates the instable factors caused in the period of adding high pressure from the erasing and writing operations of the Flash memory, and the control method has universality and convenient programming and ensures the on-line programming stability of the Flash memory.

Owner:SUZHOU UNIV

Construction method for off-line programming of robot

The invention relates to a construction method, based on the three-dimensional design software environment, for off-line programming of a robot. The construction method is characterized in that an industrial robot off-line programming system operating under the Solldwork8 environment is developed by mainly applying a SolldworKs API secondary development function and the Vc++ programming language, and the pose coordination calculation function, the robot inverse operation function and the job program automatic generation function of the FANUC M-9001A / 2000 type industrial robot are achieved. It is proved through comparison with the RoboSulde simulation result that the off-line programming system is stable and reliable and has good production and utilization value.

Owner:刘程秀

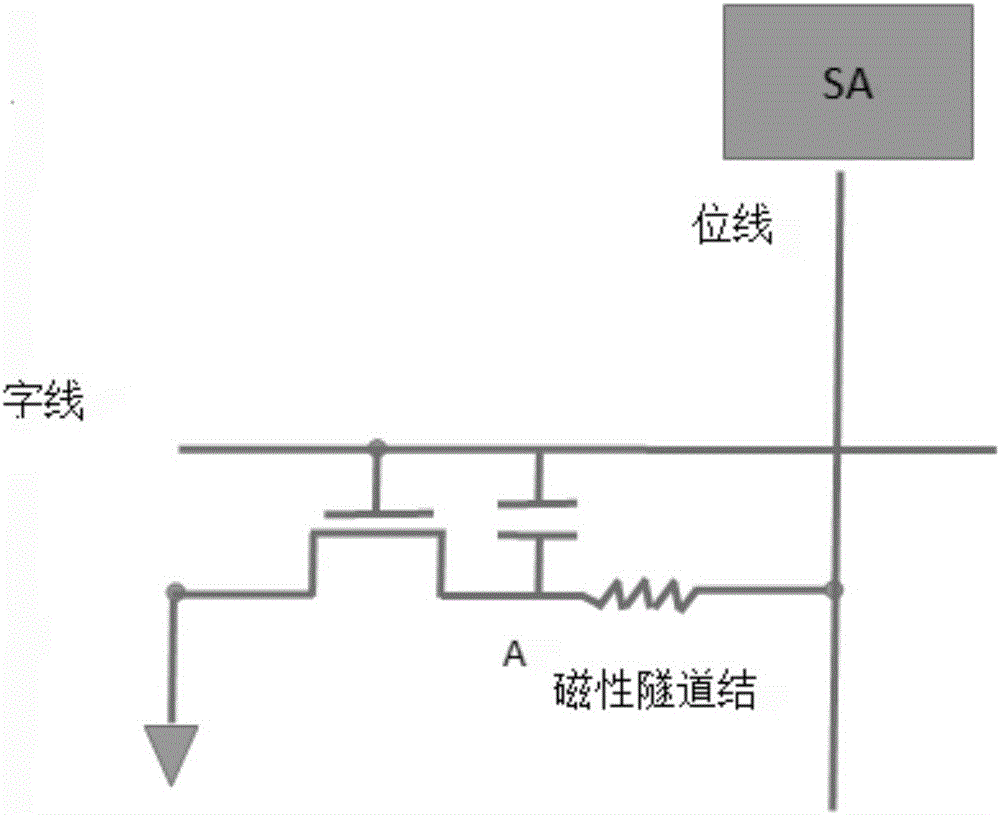

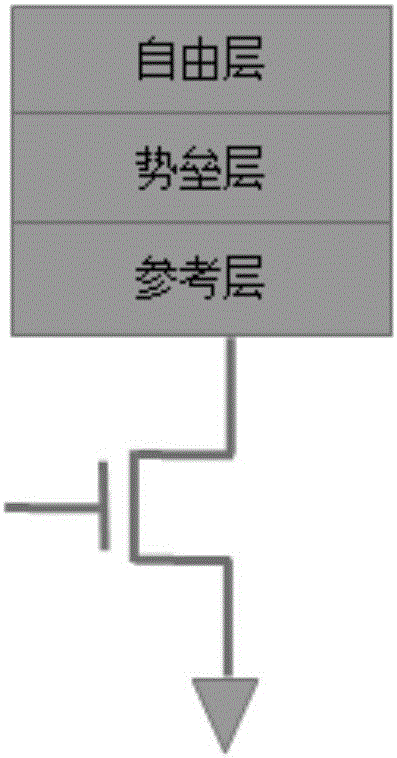

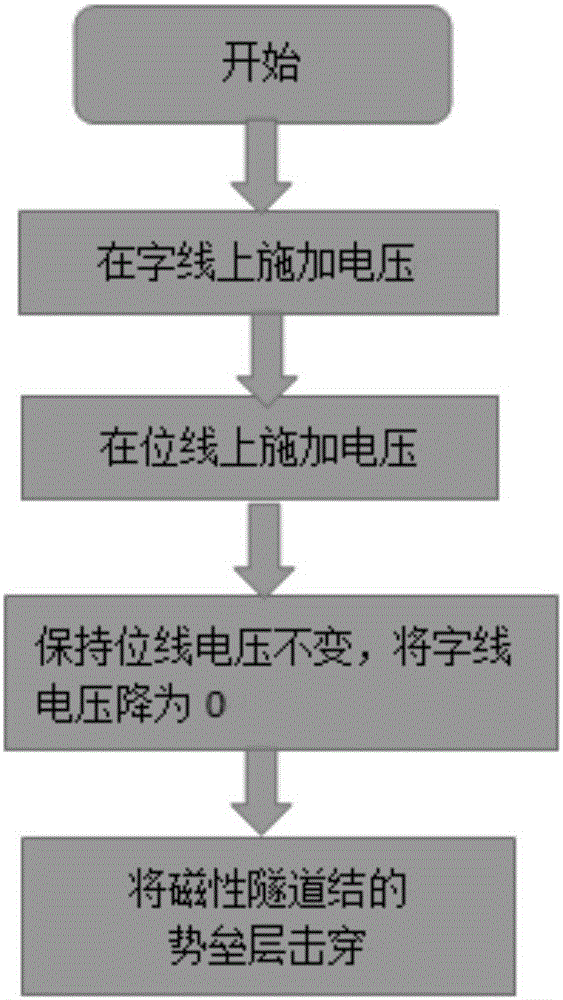

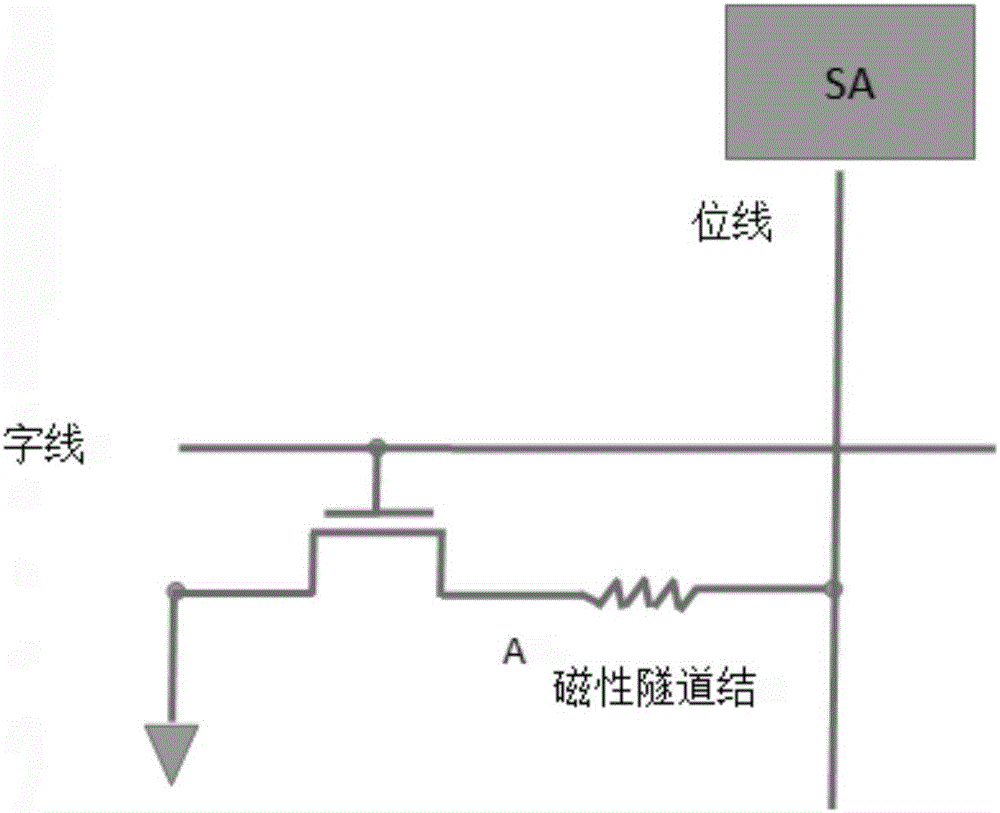

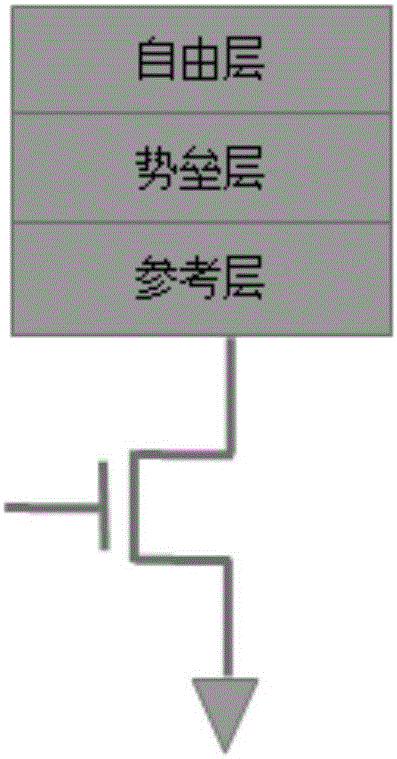

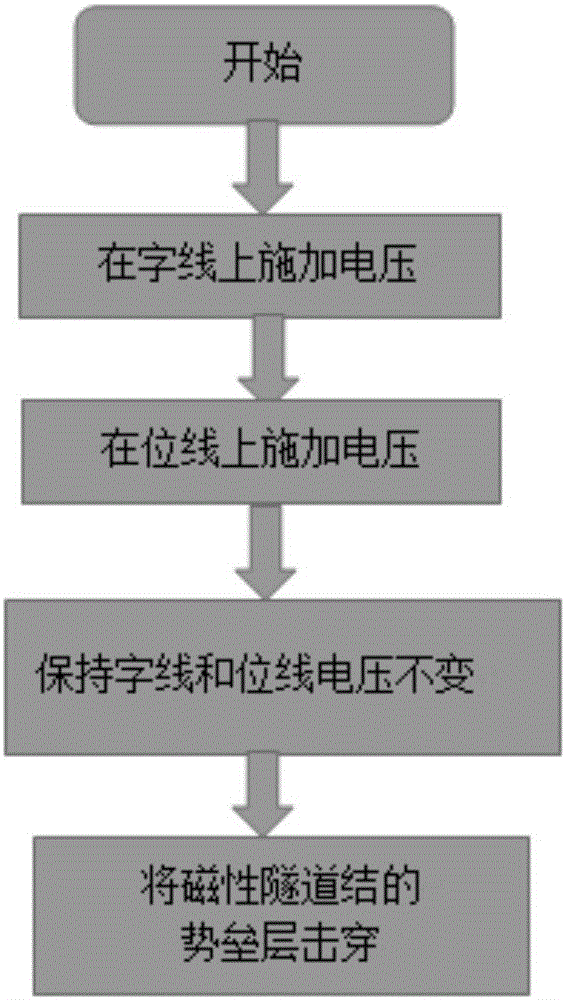

Capacitor mechanism-based one-time programmable device and programming realization method

InactiveCN106128496ASmall footprintReduce power consumptionRead-only memoriesDigital storageCapacitanceInductive programming

The invention relates to a capacitor mechanism-based one-time programmable device and a programming realization method. The capacitance mechanism-based one-time programmable device comprises a switch MOS tube, an MTJ (magnetic tunnel junction) and a capacitor. Through the capacitor which is rechargeable, when the voltage is relatively low, a manner of charging the capacitor to generate a voltage higher than a normal programming voltage of the MTJ is used to carry out one-time writing on an OTP device, and a barrier layer in the MTJ is punched through, so that the effect of one-time programming is achieved. According to the method, a manner of supercharging through internal capacitor charging is utilized to reduce the externally required programming voltage, so that compared with the traditional OTP structure, the capacitor mechanism-based one-time programmable device is small in floor space, easy to realize and simple to operate, and can be used for reducing the power consumption of one-time programming and saving the manufacturing cost.

Owner:CETHIK GRP

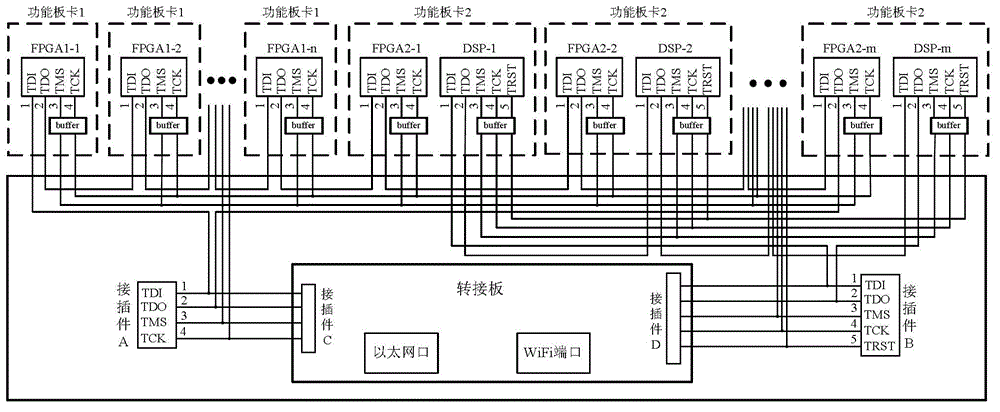

Program on-line programming system for multimedia card (MMC) flexible direct-current power transmission valve base controller

ActiveCN103064701AEasy to upgrade onlineProgram burning methods are flexible and diverseProgram loading/initiatingComputer hardwareInductive programming

The invention provides a program on-line programming system for a multimedia card (MMC) flexible direct-current power transmission valve base controller. The program on-line programming system comprises function board cards 1, function board cards 2 and a connecting board, wherein the function board cards 1 and the function board cards 2 are arranged in parallel, and the connecting board is respectively connected with the function board cards 1 and the function board cards 2. The program on-line programming system for the valve base controller for a high-capacity MMC flexible direct-current power transmission converter has the advantages that program programming modes are flexible and diverse and do not interfere with each other.

Owner:CHINA EPRI ELECTRIC POWER ENG CO LTD +2

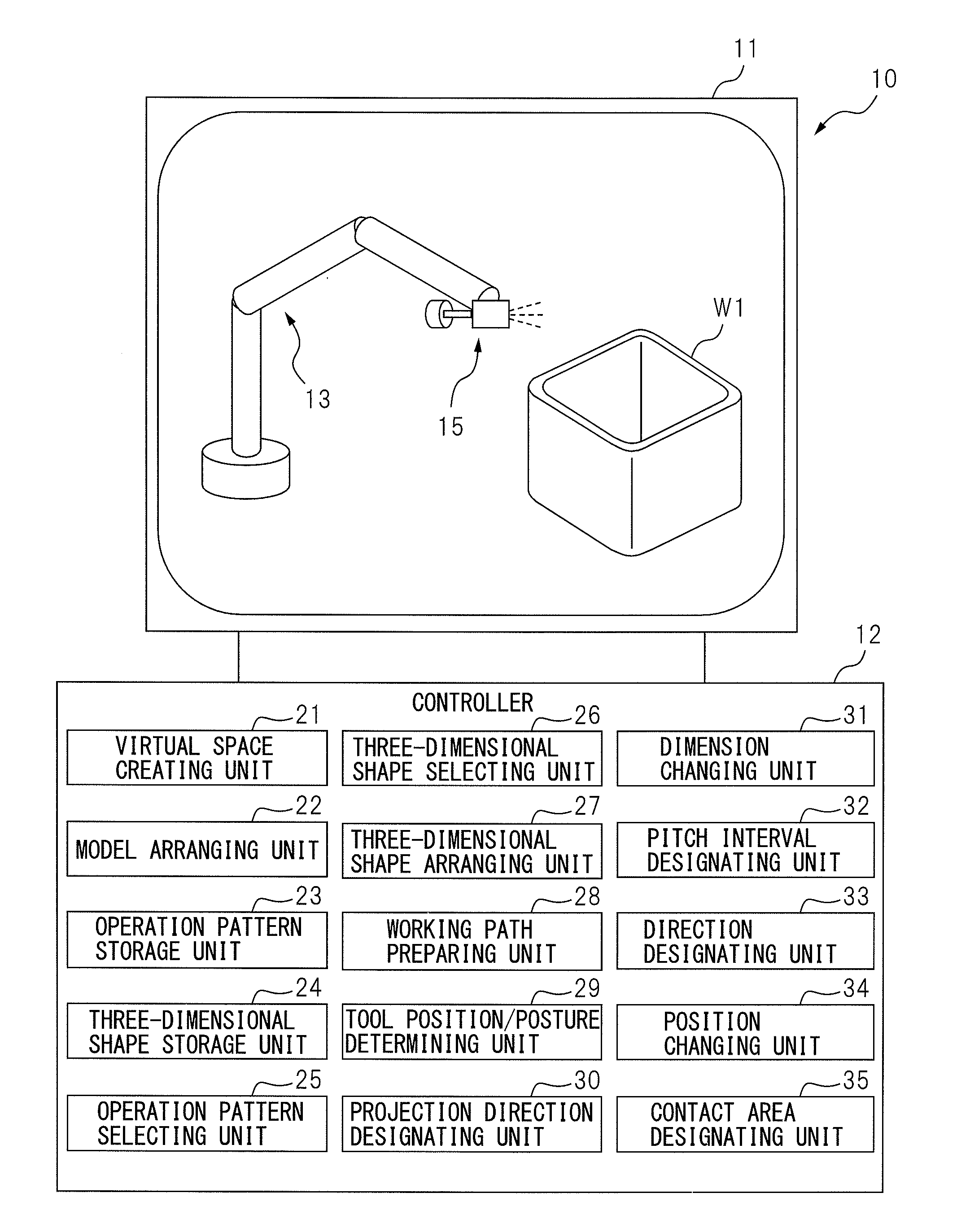

Off-line programming system

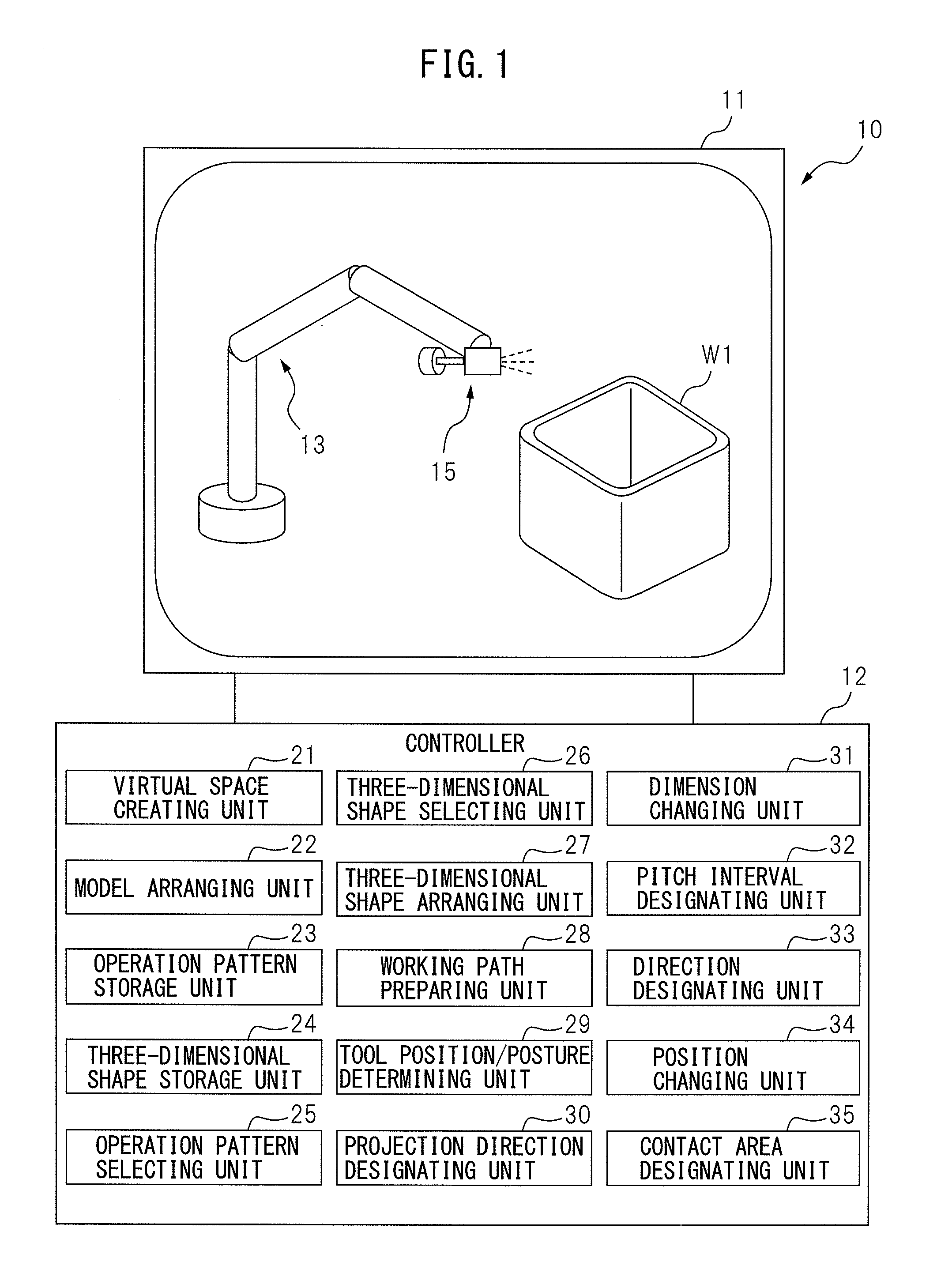

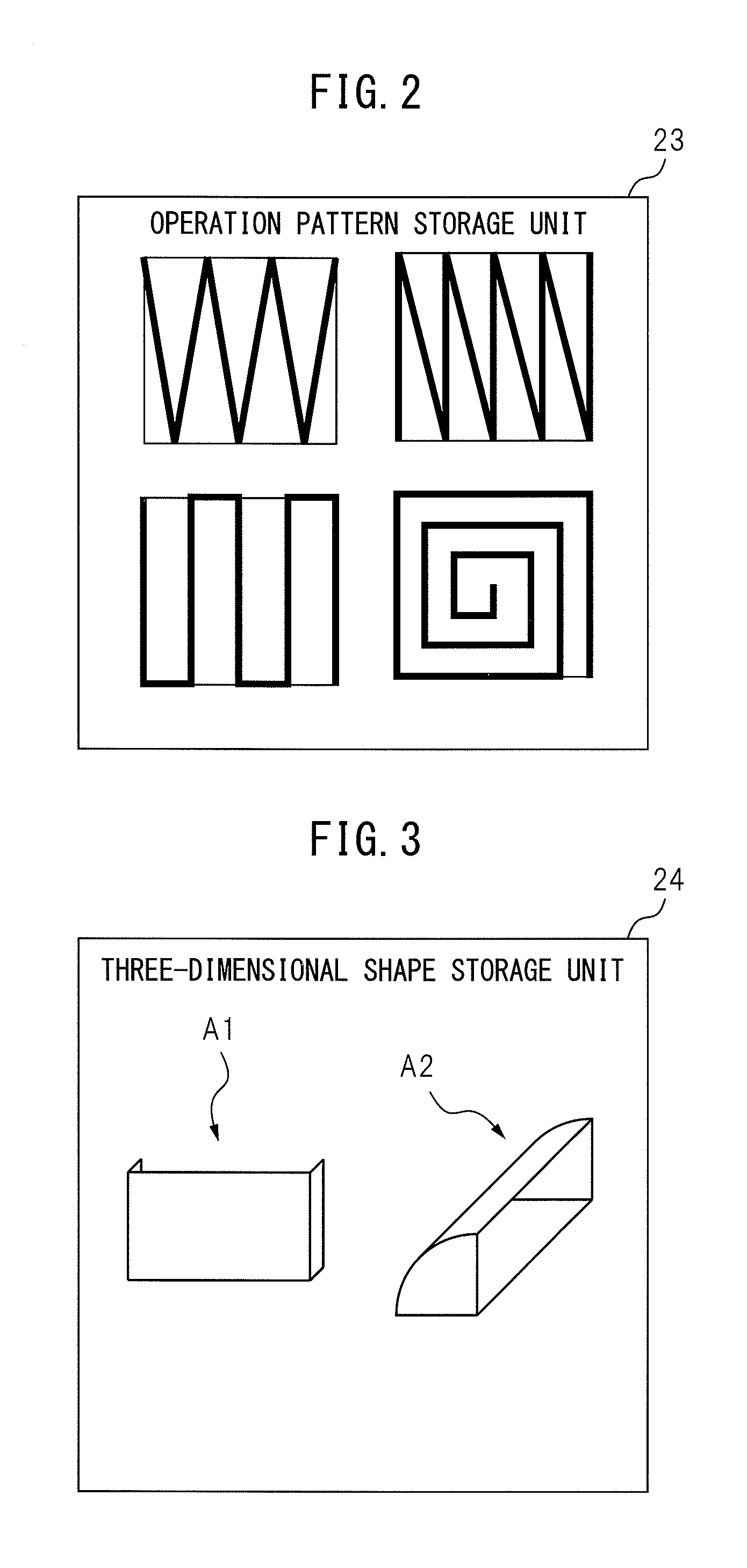

ActiveUS20130325177A1Workpiece to be greatly reducedReduce in quantityProgramme controlProgramme-controlled manipulatorVirtual spaceThree dimensional shape

An off-line programming system (10) which includes a three-dimensional shape arranging unit (27) which fills in a curved surface or consecutive plurality of flat surfaces of a selected three-dimensional shape by selected operation patterns and arranges a three-dimensional shape in a virtual space so that the operation patterns will be projected on surfaces of the workpiece model, a working path preparing unit (28) which projects operation patterns on the surfaces of the workpiece model so as to prepare a working path of the tool, and a tool position / posture determining unit (29) which uses the prepared working path and normal direction of the surface of the workpiece model as the basis to automatically determined the position or position / posture of the tool model.

Owner:FANUC LTD

Protection method and system for preventing fraudulent use of mobile terminal

ActiveCN100401822CPrevent number changeUser identity/authority verificationRadio/inductive link selection arrangementsInductive programmingSerial code

Owner:HUAWEI TECH CO LTD

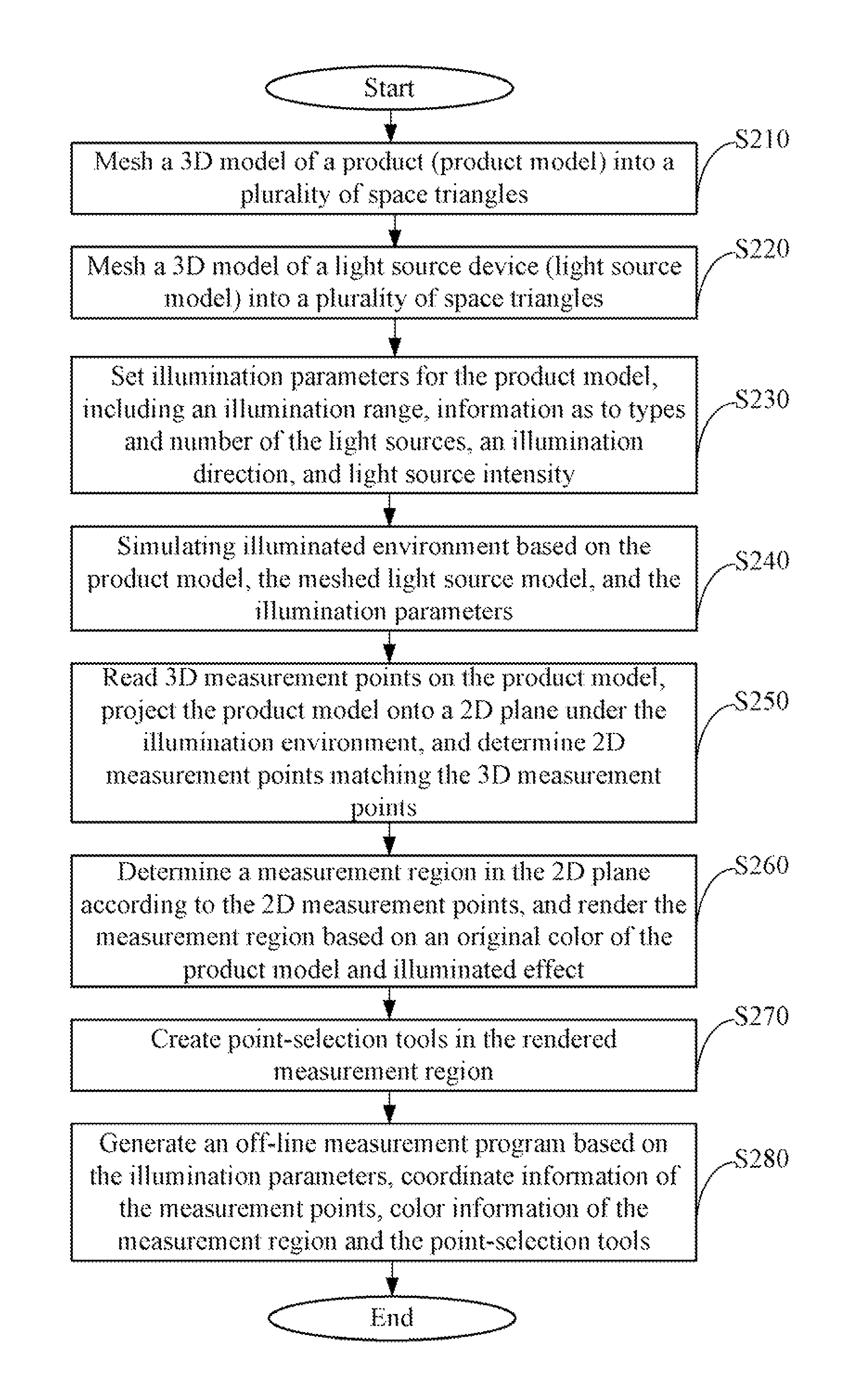

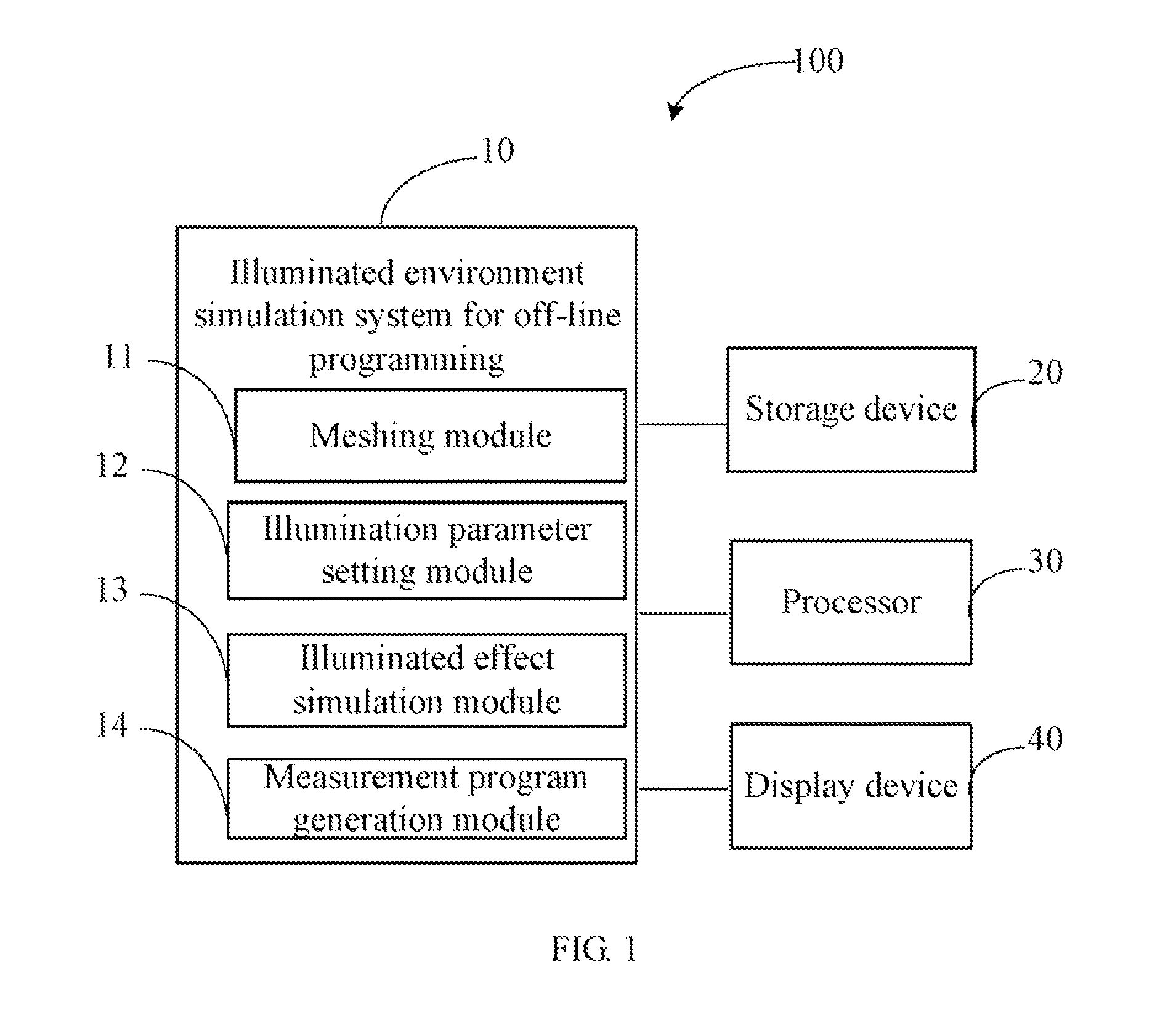

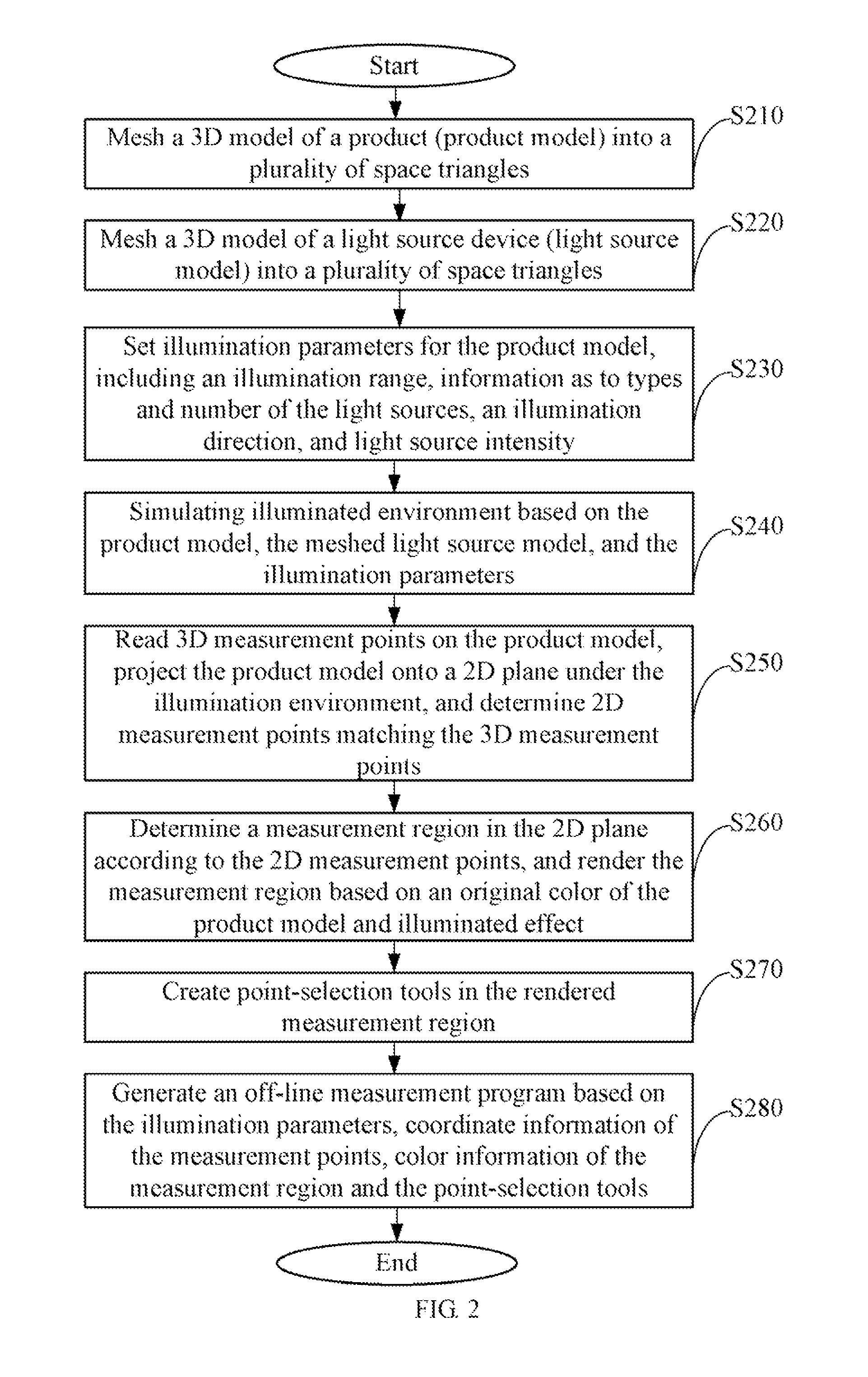

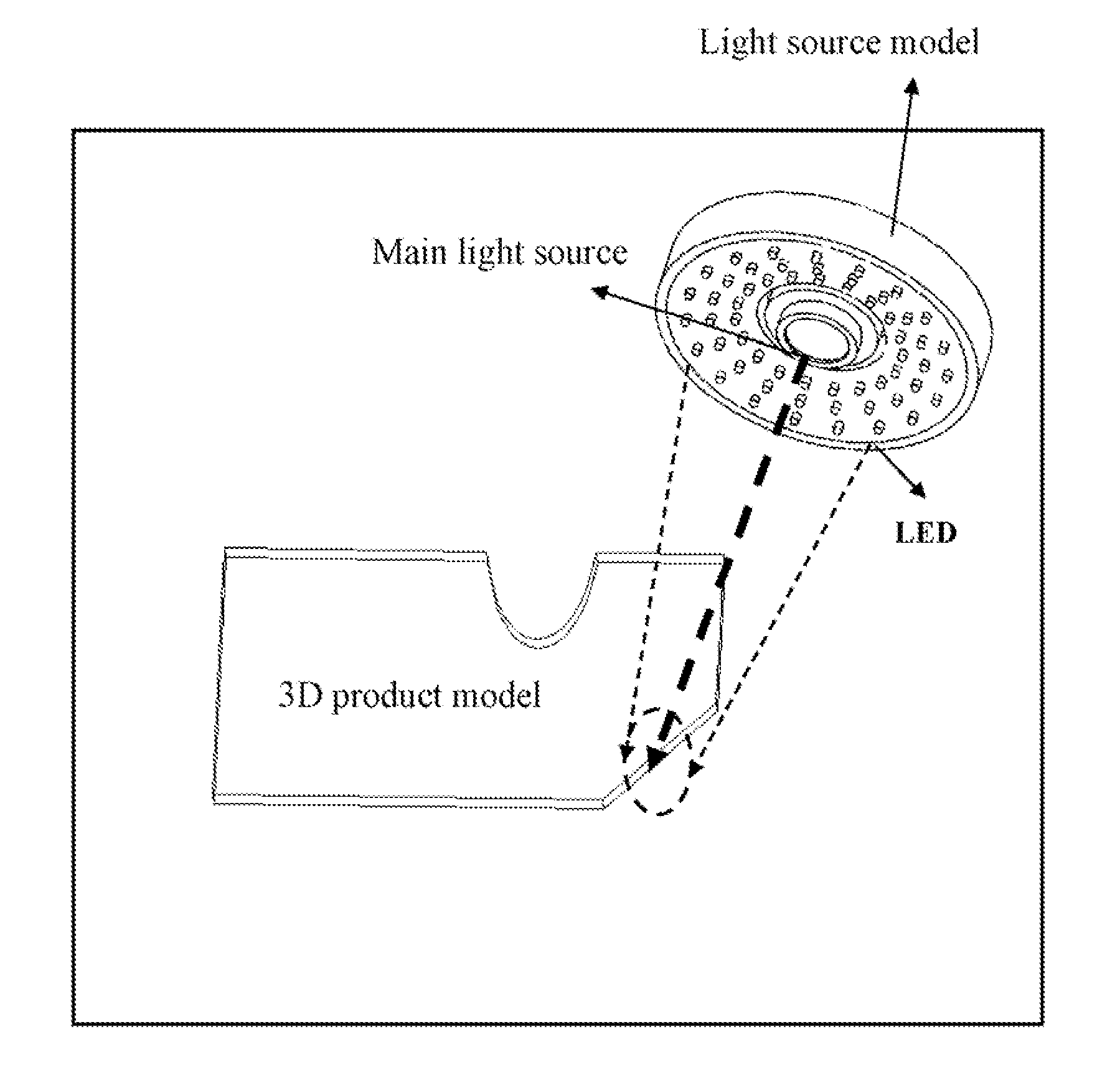

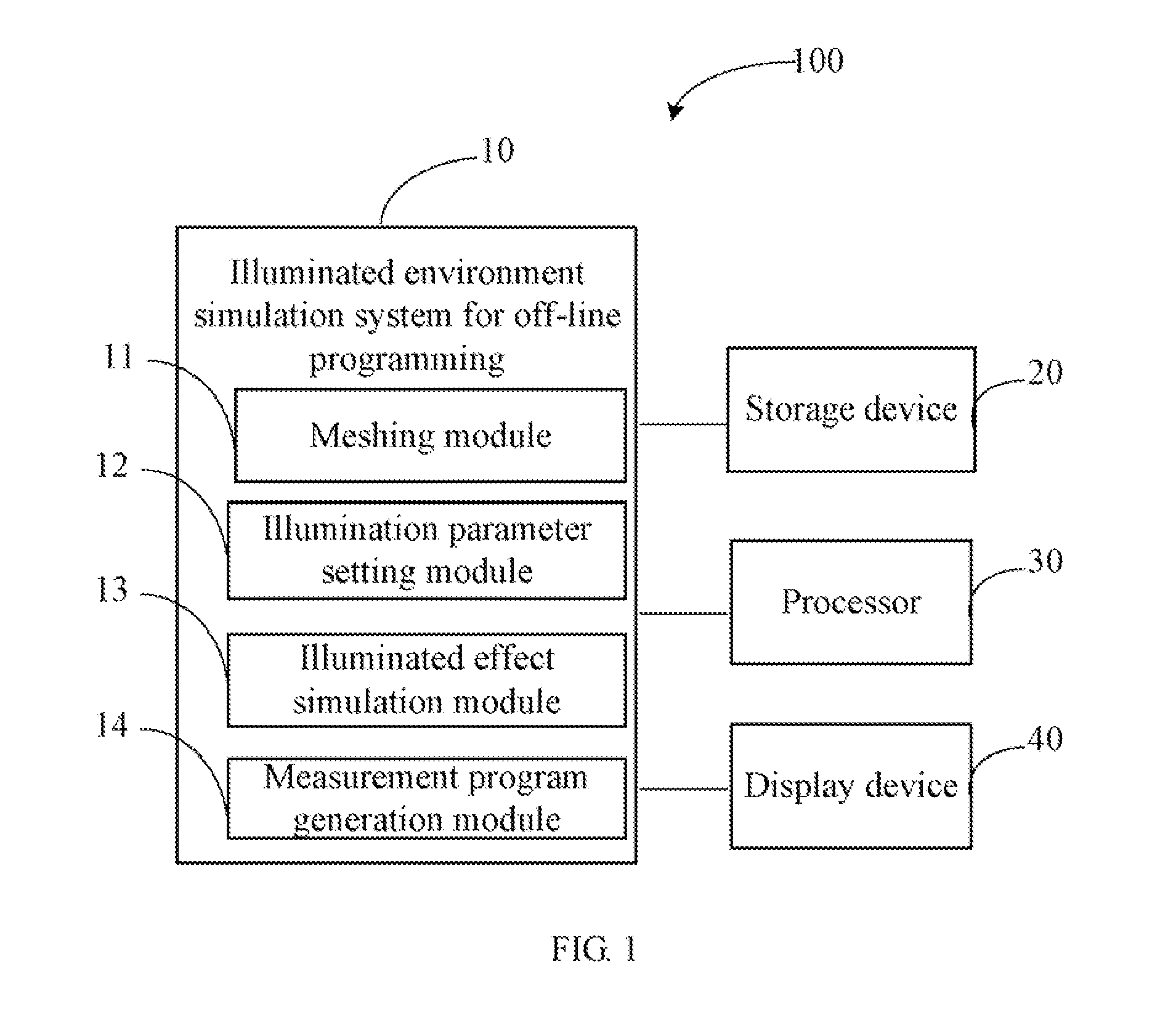

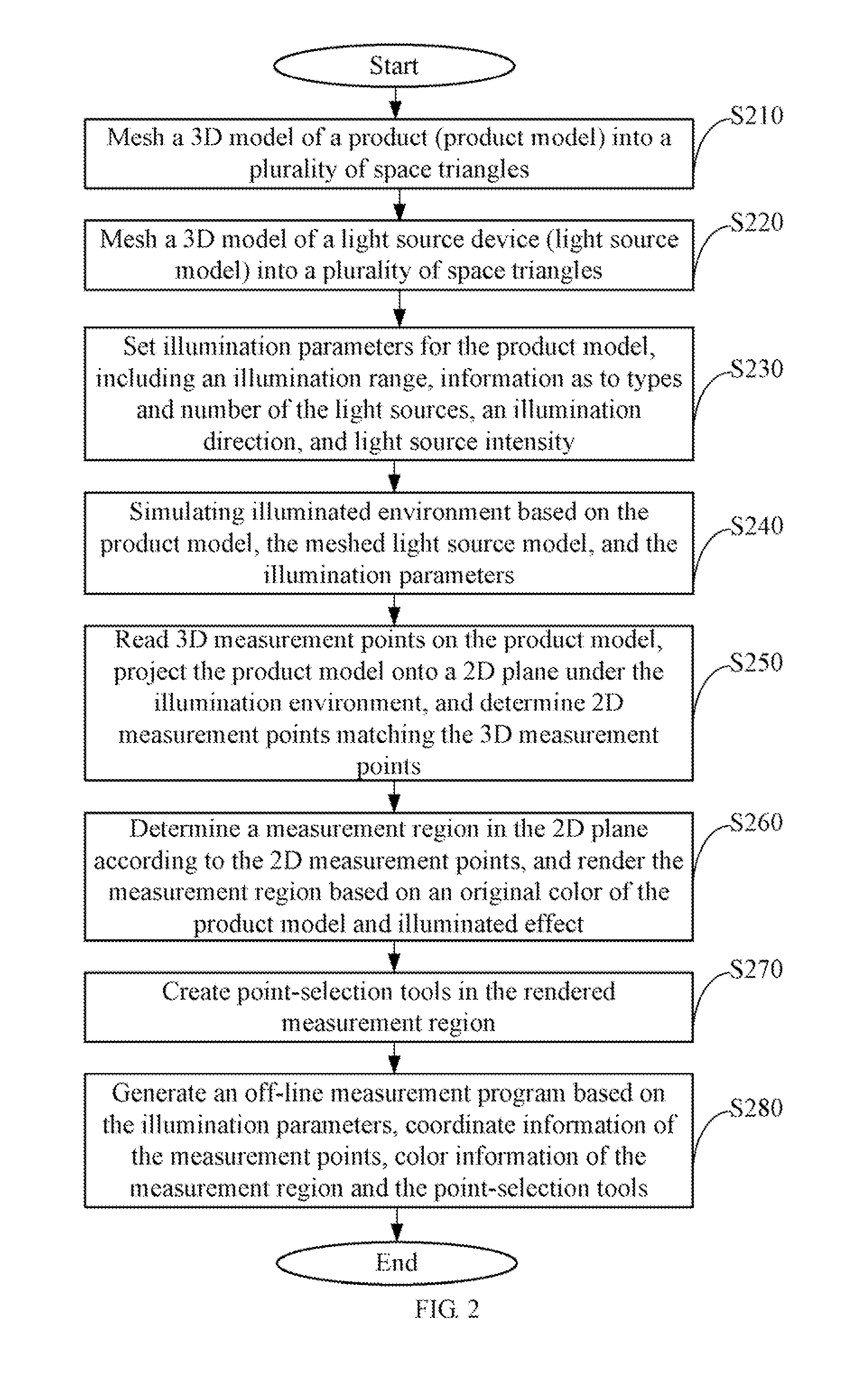

Method of simulating illuminated environment for off-line programming

InactiveUS8606549B2Computer aided designSpecial data processing applicationsComputer graphics (images)Measurement point

A method reads information of a three-dimensional (3D) product model and a light source model, and meshes the product model by multiple space triangles. The method further sets illumination parameters based on the information of product model and the light source model, simulates illuminated environment based on the illumination parameters, and projects the product model to a two-dimensional (2D) plane under the illuminated environment. 2D triangles matching the space triangles and 2D measurement points matching the 3D measurement points are determined in the 2D plane, and a measurement region is determined based on the 2D measurement points. Then, the 2D triangles in the measurement region are given colors based on illuminated effect produced by the illuminated environment, and point-selection tools are created for the 2D measurement points. At last, an off-line program is generated according to information of the measurement region and the point-selection tools.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

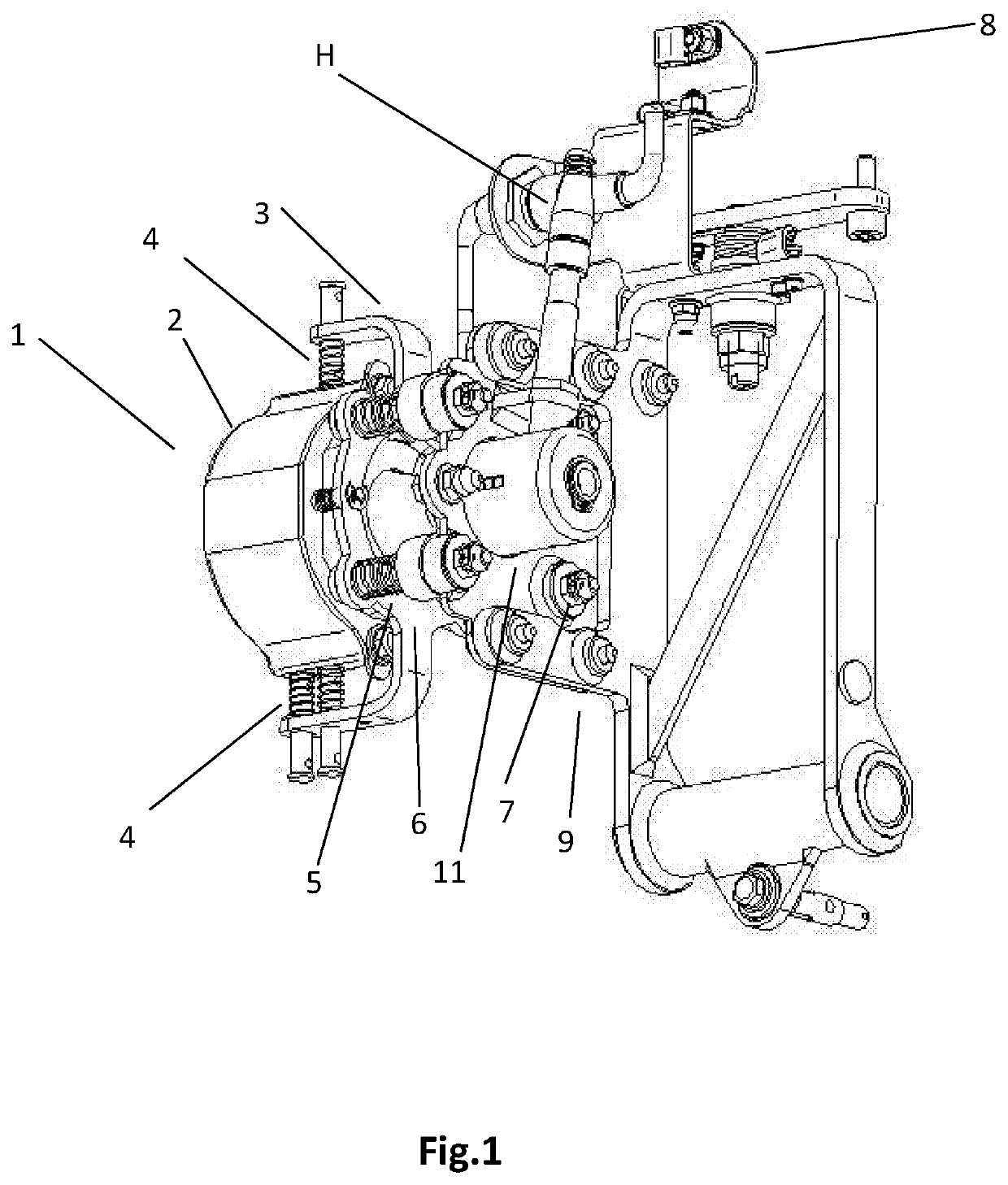

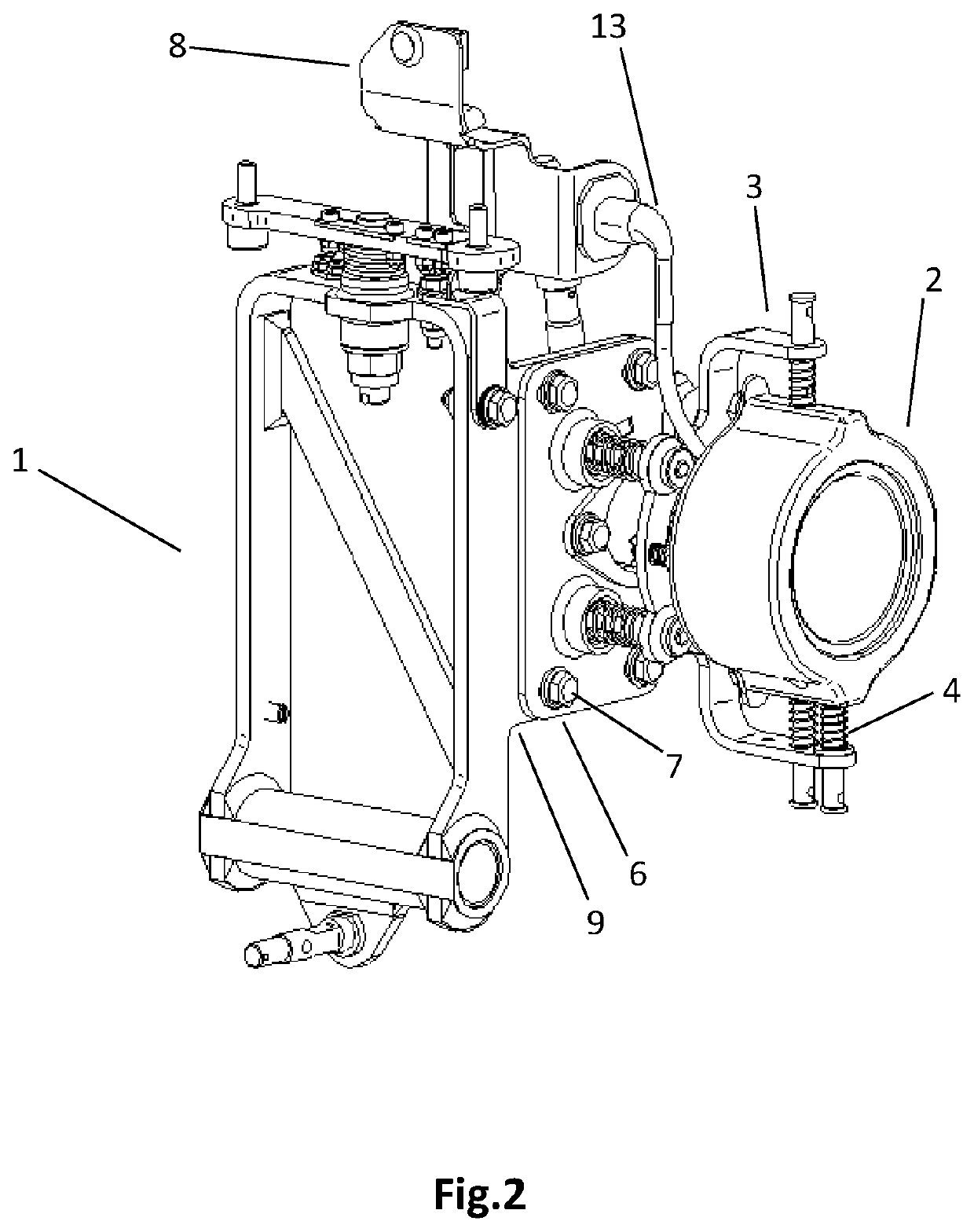

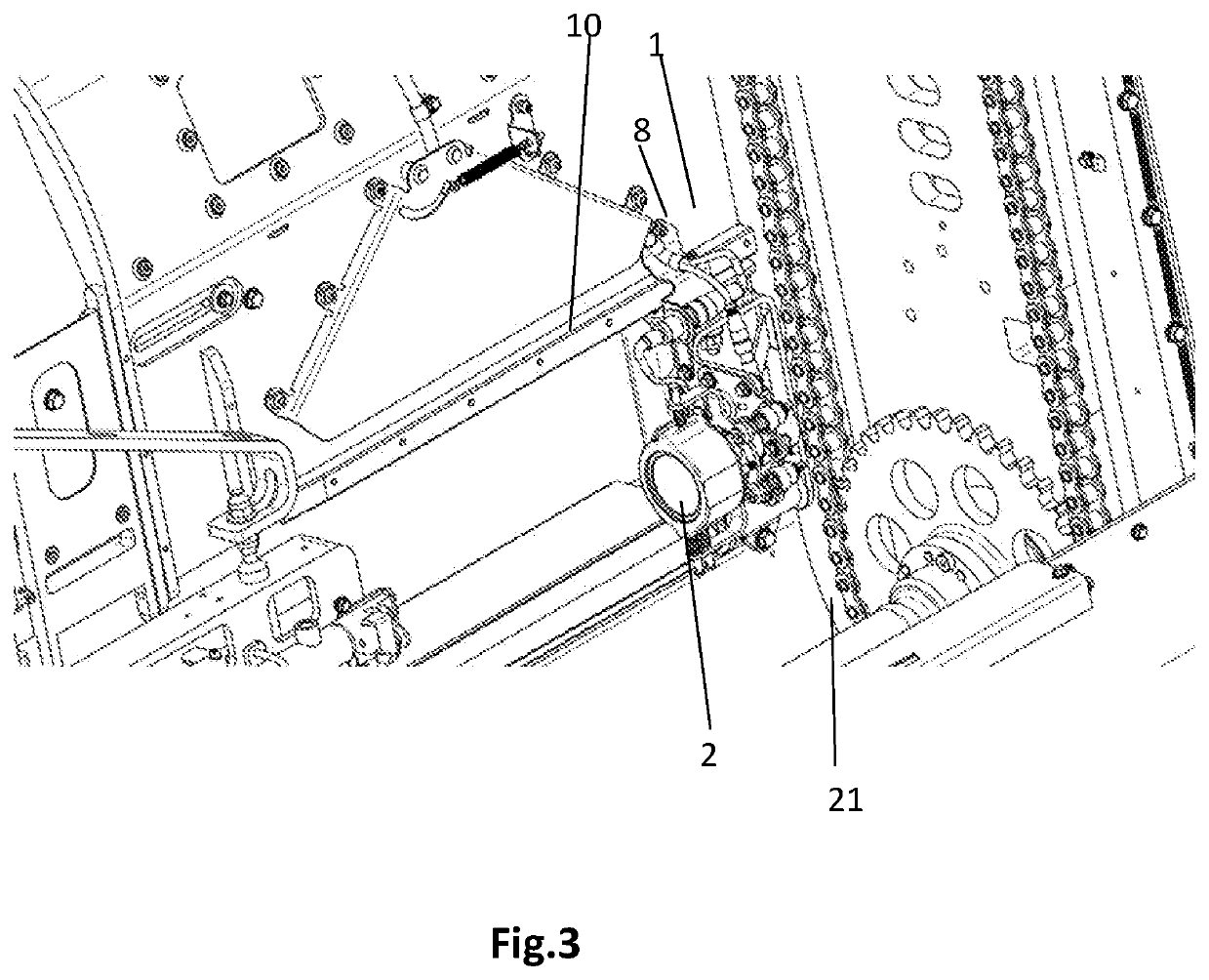

Method and system for inductive programming of a fuze

ActiveUS11060830B2Accurate couplingNot to damageAmmunition loadingElectric fuzesSoftware engineeringInductive programming

A method and a system for inductively programming a fuze including at least one target coil arranged in a projectile by a fuze setter including at least one setter coil, the method includingi) conveying at least one of a projectile or a fuze setter by an actuator to bring the at least one target coil and the at least one setter coil in an inductive coupling position,ii) programming the fuze by transferring predetermined fuzing data from the at least one setter coil to the at least one target coil,iii) optionally transferring fuzing data from the at least one target coil to the at least one setter coil to confirm correct programming of the fuze has been performed, andiv) retracting at least one of the fuze setter or projectile from the inductive coupling position when the transfer of fuzing data has been completed.

Owner:BAE SYST BOFORS

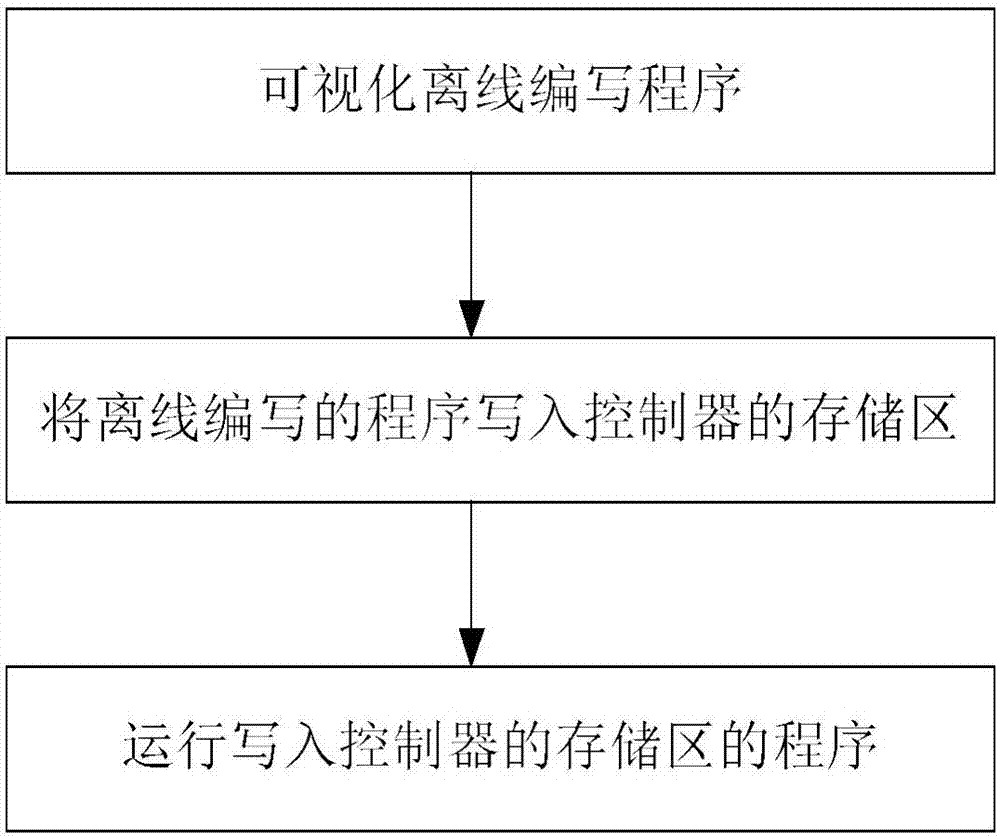

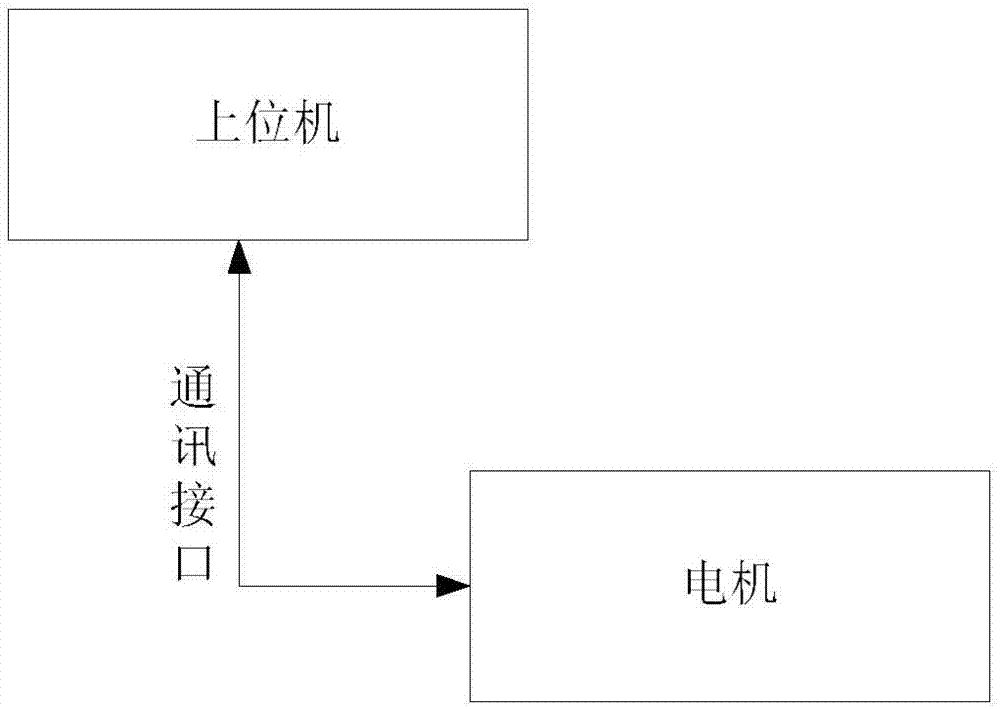

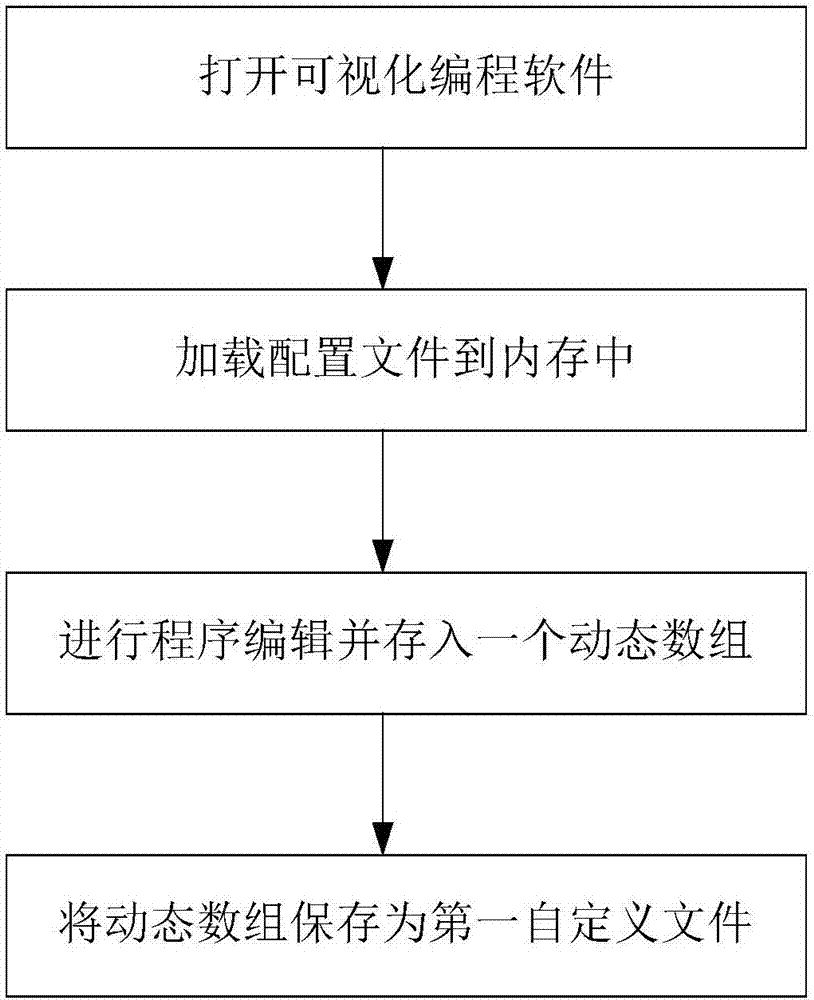

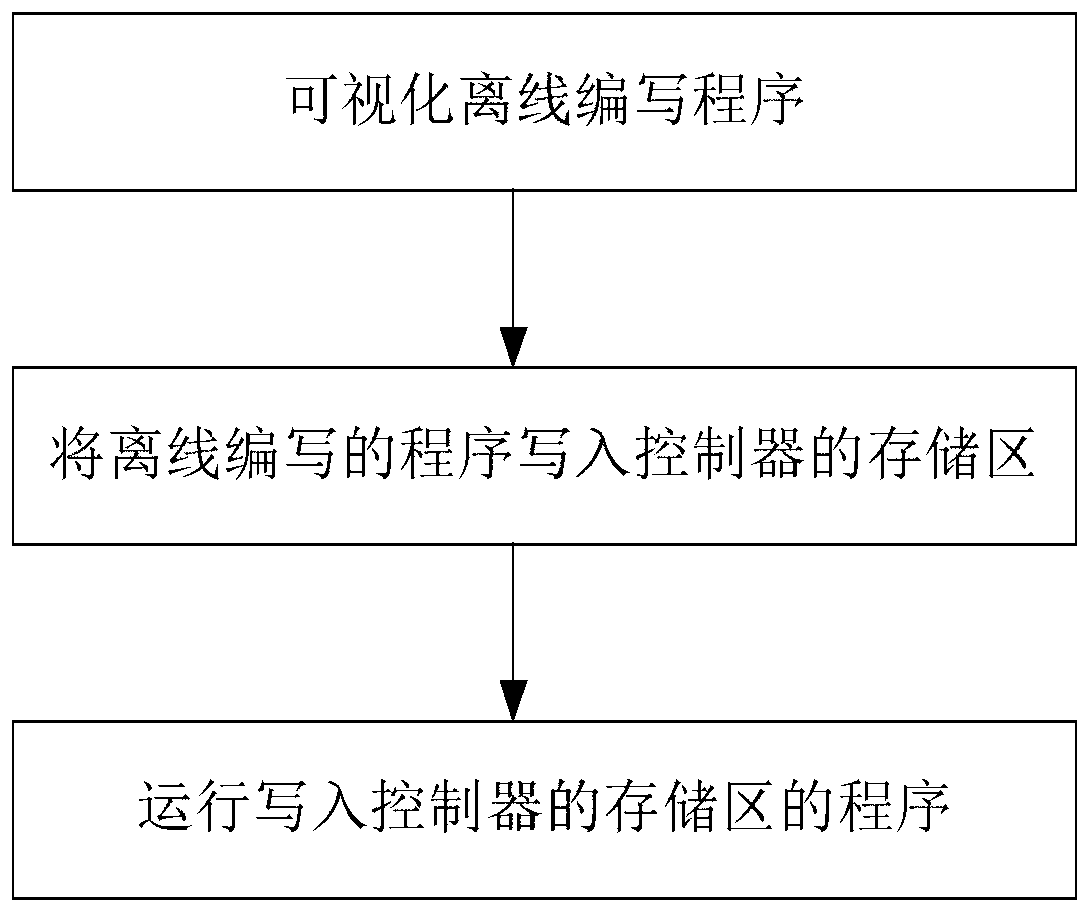

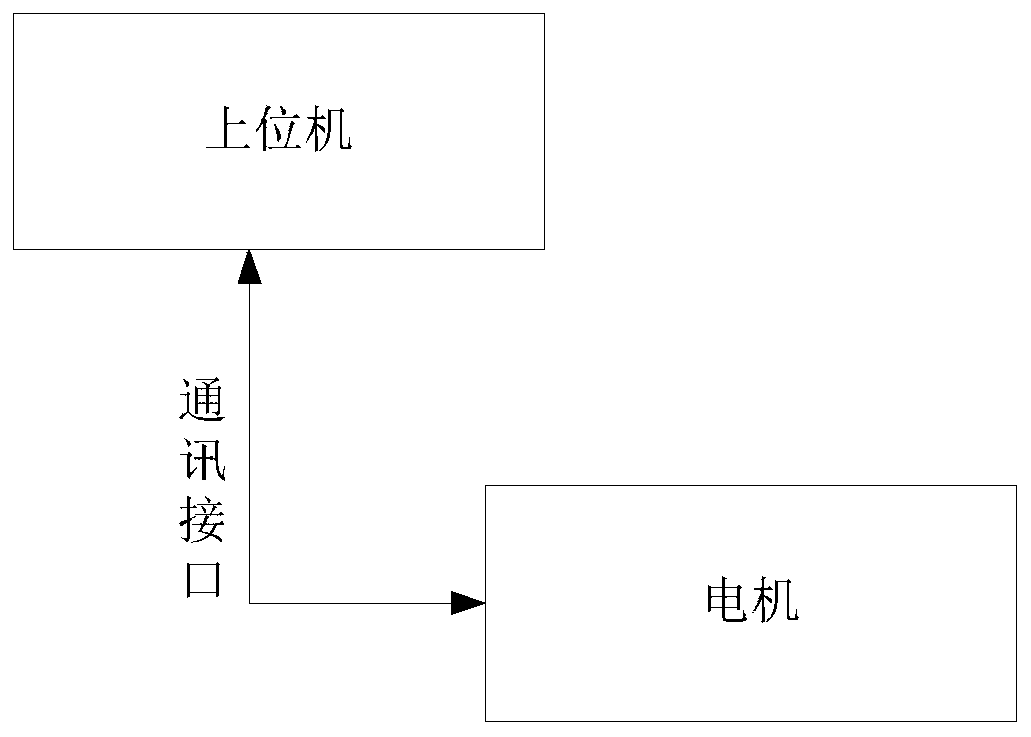

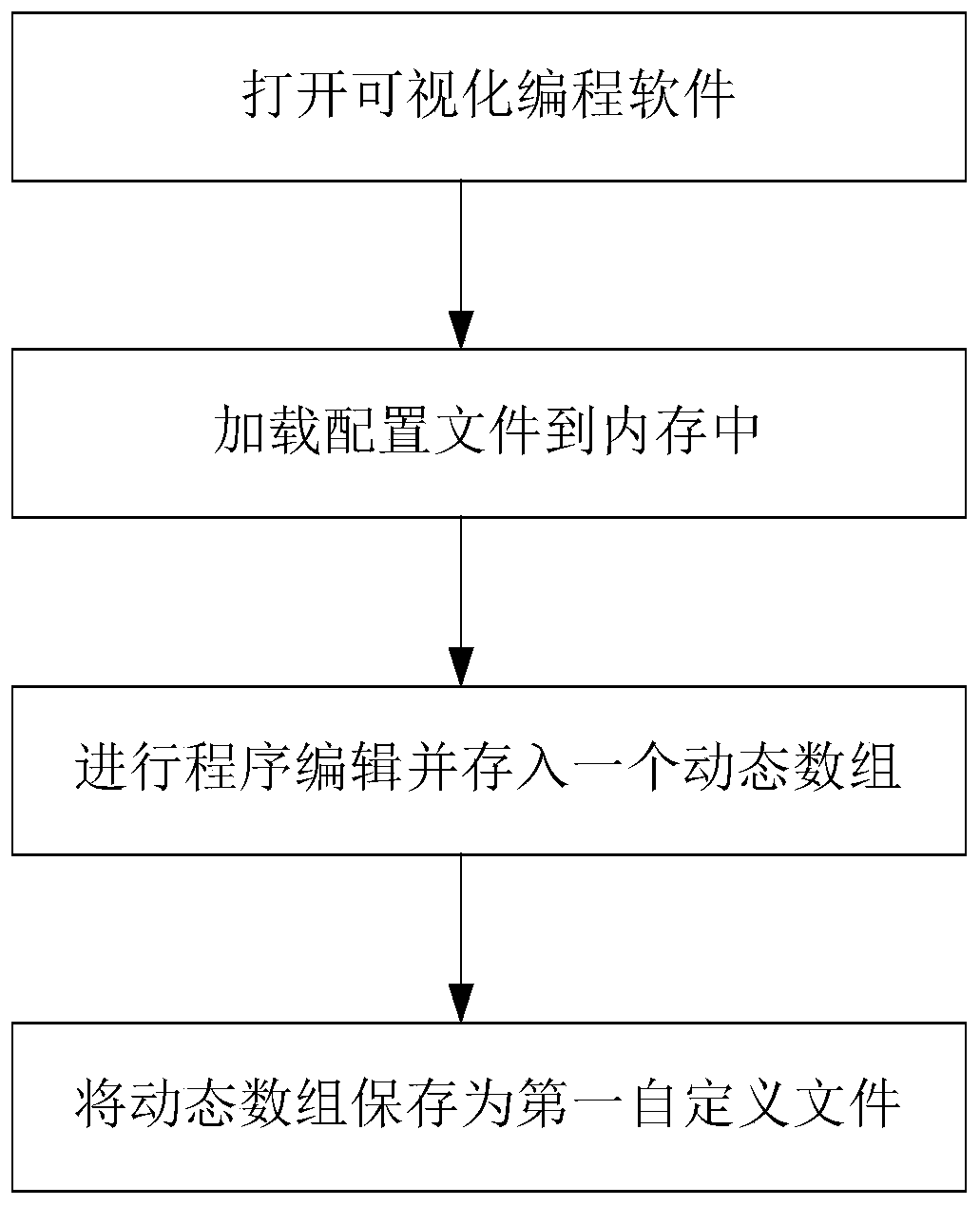

Visual programming method and system for motor controller

ActiveCN107168133AEasy programmingProgramming is clear and intuitiveProgramme control in sequence/logic controllersState variationArray data structure

The invention relates to the technical field of electric and electronic, and specifically relates to a visual programming method and system for a motor controller. The visual programming method for a motor controller includes the steps: visually compiling a program off-line, writing the off-line compiled program into a memory region of a controller, and operating the program written into the memory region of the controller, wherein visually compiling the program off-line includes the steps: opening the visual programming software, loading a configuration file into the memory, performing program editing, saving the program into a dynamic array, and saving the dynamic array as the first customize file. The visual programming method and system for a motor controller can realize on-line programming, debugging and single command execution, thus being convenient for program designing and debugging for the staff, and can also realize the off-line operation function, so that the staff can write the logical program flow of the application scene into the controller and disconnects communication with a host computer after saving and through power up execution or state change of I / O to trigger and stop the program so as to be suitable for some simple or fixed logical application scenes conveniently.

Owner:CHONGQING PUSI ROBOT CONTROL SYST

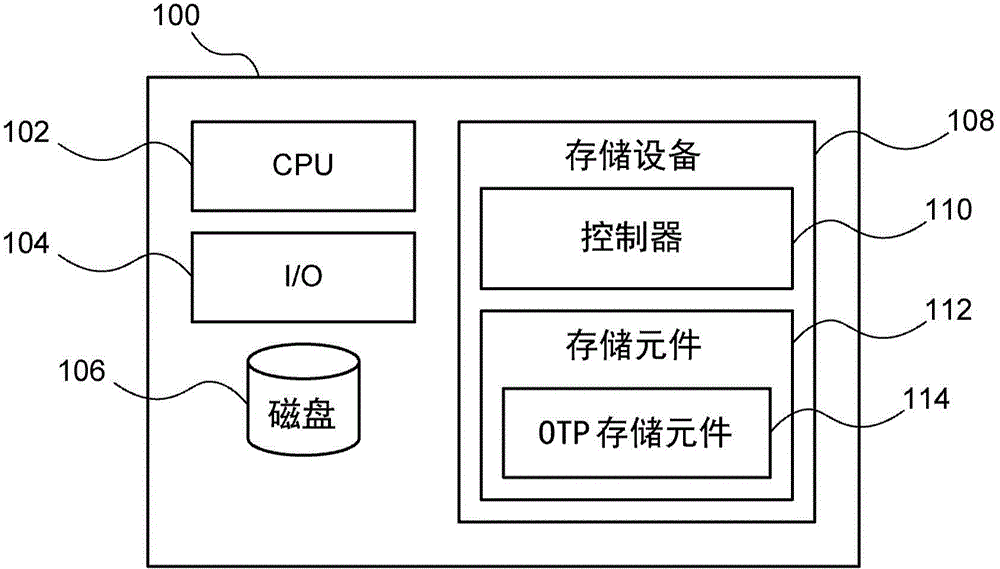

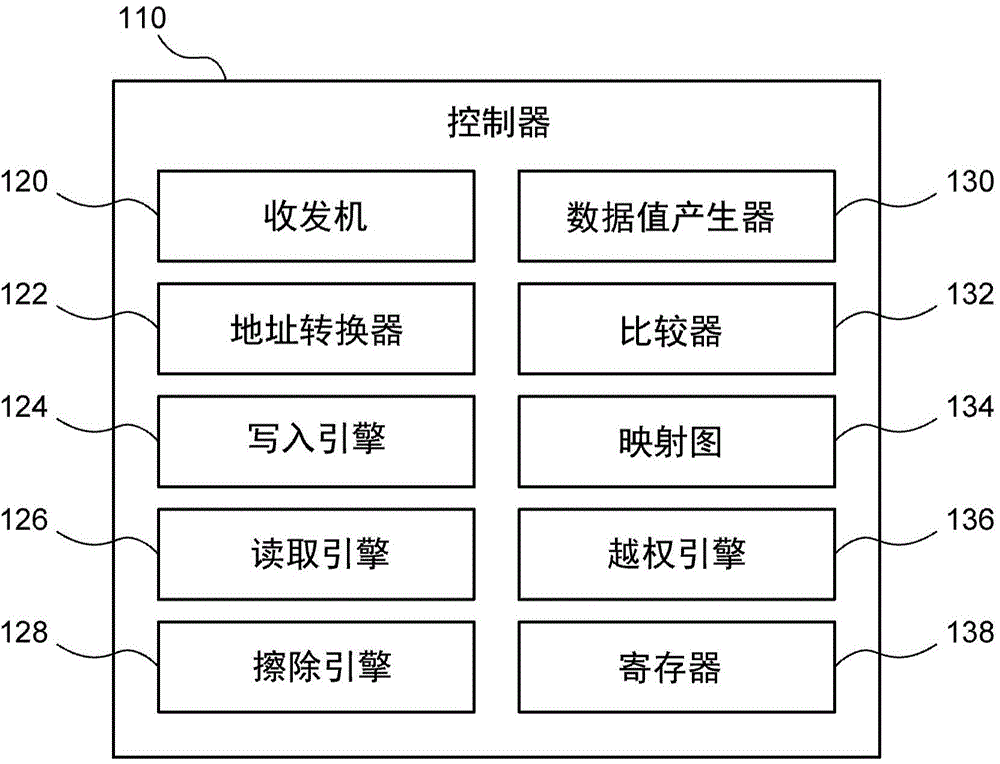

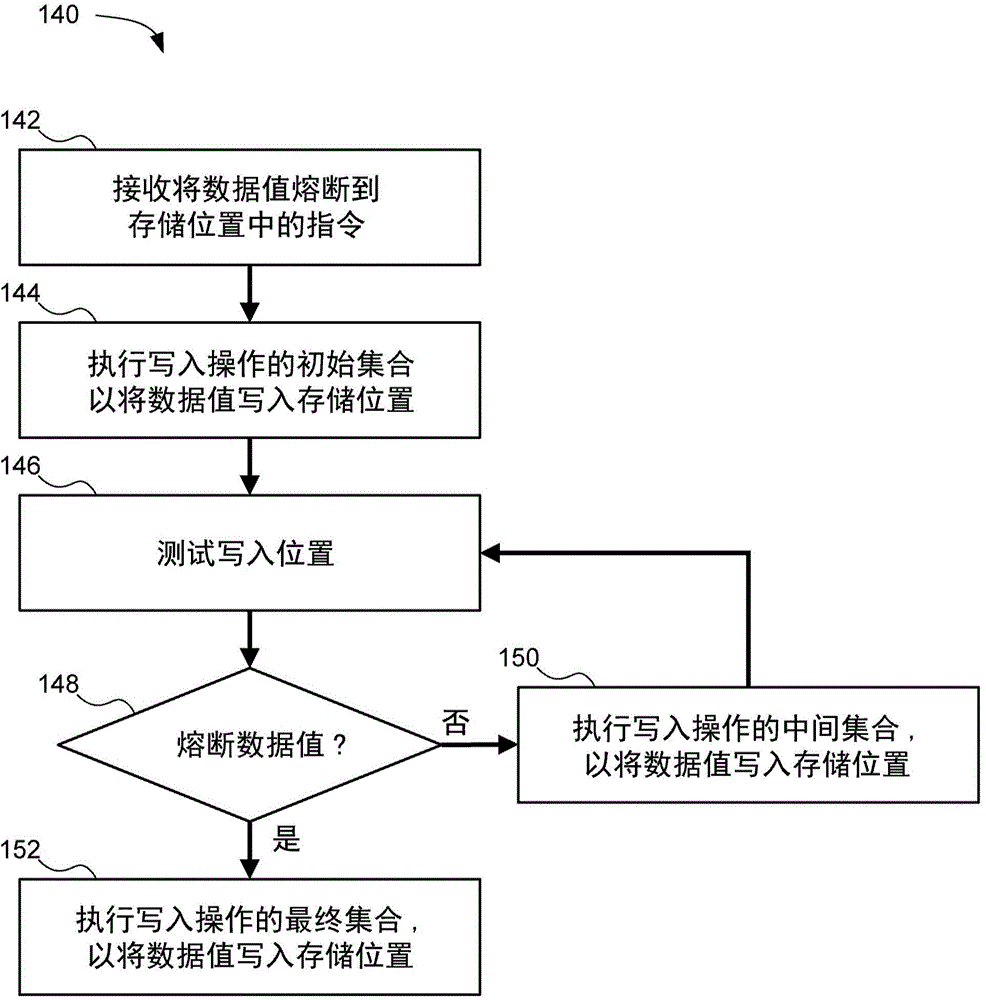

One-time programming in reprogrammable memory

A portion of a reprogrammable storage device is used to implement permanent data storage. The storage device includes a plurality of electrically erasable memory elements and a controller. The plurality of electrically erasable memory elements are configured to store data. Each memory element is programmable a number of write cycles before reaching a write failure state. The controller is coupled to the plurality of memory elements. The controller includes a receiver and a write engine. The receiver receives an instruction to drive a selected memory element to the write failure state. The write engine repeatedly writes a data value, in a plurality of write operations, to the selected memory element until the write failure state of the selected memory element is established.

Owner:NXP BV

One time programmable device and programming realization method

InactiveCN106128495ALower breakdown voltageSmall footprintRead-only memoriesDigital storagePunchingEngineering

The invention relates to a one time programmable device and a programming realization method. The one time programmable device comprises a switching MOS (Metal Oxide Semiconductor) tube, a magnetic tunneling junction and a constant potential. A traditional OTP (One Time Programmable) structure is optimized, the source electrode of a switching tube is directly grounded, and an effect that the voltage of two ends of the magnetic tunneling junction is increased so as to realize the one time punching of a barrier layer and one time programming under a situation of normal working voltage can be achieved. By use of the method, breakdown voltage required by a traditional circuit structure is lowered. Compared with a traditional OTP structure, the one time programmable device has the characteristics of being simple in structure, small in area occupation and convenient in design, production and operation, the power consumption of one time programming can be lowered, and manufacture cost is saved.

Owner:CETHIK GRP

Method of simulating illuminated environment for off-line programming

InactiveUS20120173206A1Computer aided designSpecial data processing applicationsComputer graphics (images)Measurement point

A method reads information of a three-dimensional (3D) product model and a light source model, and meshes the product model by multiple space triangles. The method further sets illumination parameters based on the information of product model and the light source model, simulates illuminated environment based on the illumination parameters, and projects the product model to a two-dimensional (2D) plane under the illuminated environment. 2D triangles matching the space triangles and 2D measurement points matching the 3D measurement points are determined in the 2D plane, and a measurement region is determined based on the 2D measurement points. Then, the 2D triangles in the measurement region are given colors based on illuminated effect produced by the illuminated environment, and point-selection tools are created for the 2D measurement points. At last, an off-line program is generated according to information of the measurement region and the point-selection tools.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Off-line programming system and off-line programming method of welding robot based on tablet computer

ActiveCN105786483BEasy to optimize movementEasy to acceptProgramme controlProgramme-controlled manipulatorTablet computerOperational system

The invention discloses a welding robot offline programming system based on a tablet computer, which comprises a system modeling module, a kinematics simulation module, a track planning module, an automatic programming module, a status detection module, and a communication module. The invention further discloses an offline programming method of the offline programming system. The offline programming system provided by the invention has the advantages that compared with the traditional online teaching programming system, the system adopts a human operating interface based on the Linux operating system; highly controllable edit capabilities achieve easy optimization of motions of all axes; an actual working environment is simulated, and arc welding, spot welding and other welding functions of a robot are achieved; special offline and simulation technologies facilitate program optimization, and a completed program can be directly read and adopted by the robot through a wireless network, so that the onsite verification waiting time is shortened, and errors and unnecessary risks are reduced; the cost is low, so that the system is highly acceptable by a vast number of users; the operation is simple and convenient, and the teaching effects are good.

Owner:NANJING PANDA ELECTRONICS +2

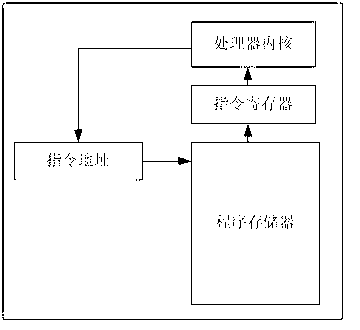

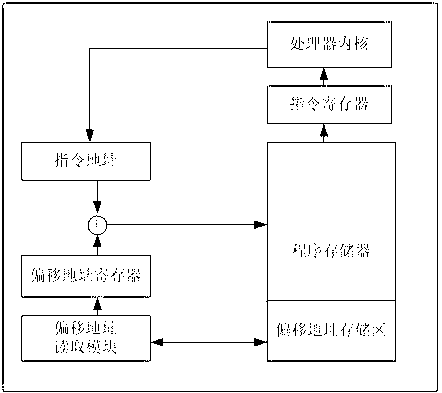

OTP (one time programmable) single chip microcomputer framework and method for realizing multi-time programming

ActiveCN103235534ADoes not affect normal workImprove efficiencyProgramme controlComputer controlMicrocomputerMicrocontroller

The invention discloses an OTP (one time programmable) single chip microcomputer framework and a method for realizing multi-time programming. An offset address storage area is reserved in a program storage in the OTP single chip microcomputer. Every time the single chip microcomputer is programmed, an end address of programming of this time is written in the storage area after being added 1. When the single chip microcomputer is reset, an offset address reading module reads data from the area. By the single chip microcomputer framework and the method for realizing multi-time programming, the program storage of the single chip microcomputer can be used for many times without influencing normal operation of the single chip microcomputer, multi-time programming can be realized, and using efficiency of the single chip microcomputer can be improved.

Owner:CHIPSEA TECH SHENZHEN CO LTD

Control method for Flash memory on-line programming

InactiveCN101409106BGuaranteed stabilityOnline programming convenienceRead-only memoriesReturn statementHigh pressure

The invention discloses an on-line programming control method of a Flash memory, comprising erasing operation and read-in operation. The method is characterized in that machine codes of operation statements and return statements of the Flash memory in the period of adding high pressure are preset in an RAM. The operation statements include the statement for writing interrupt identification in a status register so as to start a corresponding command, as well as the statement for judging the completion of a wait command; and in the processes of erasing operation and writing operation, program operation is carried out when the period of adding high pressure turns to the RAM. The invention separates the instable factors caused in the period of adding high pressure from the erasing and writingoperations of the Flash memory, and the control method has universality and convenient programming and ensures the on-line programming stability of the Flash memory.

Owner:SUZHOU UNIV

Visual programming method and system for motor controller

ActiveCN107168133BEasy programmingProgramming is clear and intuitiveProgramme control in sequence/logic controllersArray data structureGoal programming

The invention relates to the technical field of electric and electronic, and specifically relates to a visual programming method and system for a motor controller. The visual programming method for a motor controller includes the steps: visually compiling a program off-line, writing the off-line compiled program into a memory region of a controller, and operating the program written into the memory region of the controller, wherein visually compiling the program off-line includes the steps: opening the visual programming software, loading a configuration file into the memory, performing program editing, saving the program into a dynamic array, and saving the dynamic array as the first customize file. The visual programming method and system for a motor controller can realize on-line programming, debugging and single command execution, thus being convenient for program designing and debugging for the staff, and can also realize the off-line operation function, so that the staff can write the logical program flow of the application scene into the controller and disconnects communication with a host computer after saving and through power up execution or state change of I / O to trigger and stop the program so as to be suitable for some simple or fixed logical application scenes conveniently.

Owner:CHONGQING PUSI ROBOT CONTROL SYST

Nonvolatile memory and method with index programming and reduced verify

ActiveCN102067233BTighten the distributionImprove programming accuracyRead-only memoriesDigital storageInductive programmingMultiple pass

In non-volatile memory, a set of memory cells are individually programmed in parallel to their target states using a multi-pass index programming approach that reduces the number of verification steps. For each cell, a programming index is maintained to store the last programming voltage applied to that cell. Each cell is indexed during the first programming pass where a series of increasing programming pulses are applied. The first programming pass is followed by verification and one or more subsequent programming passes to trim any deviations to the respective target states. If the cell has not verified to its target state, its programming index is incremented and the cell is allowed to be programmed with the next pulse starting from the last pulse received. The verification and programming passes are repeated until all cells in the group are verified to their respective target states. No verification operations are required between pulses.

Owner:SANDISK TECH LLC

Off-line programming system and method of optical visual sensor with linear structure for welding robot

InactiveCN101973032BIntuitive detection statusIntuitive display of detection statusManipulatorInteractive graphicsSimulation

Owner:SOUTHEAST UNIV

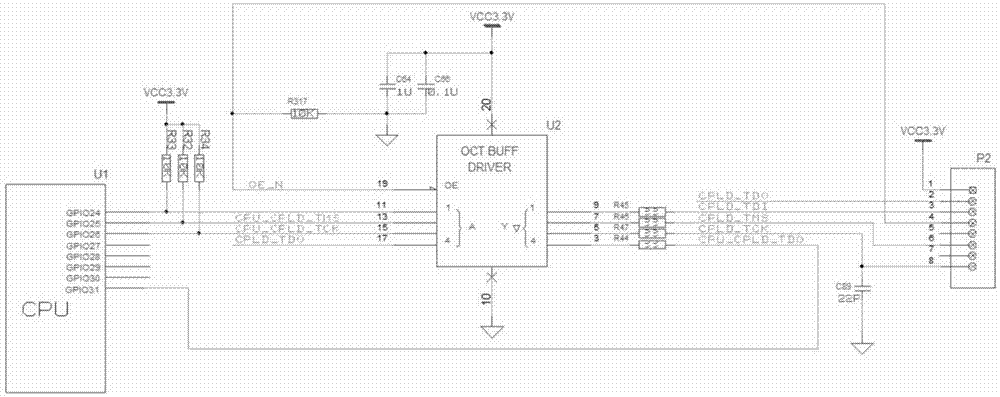

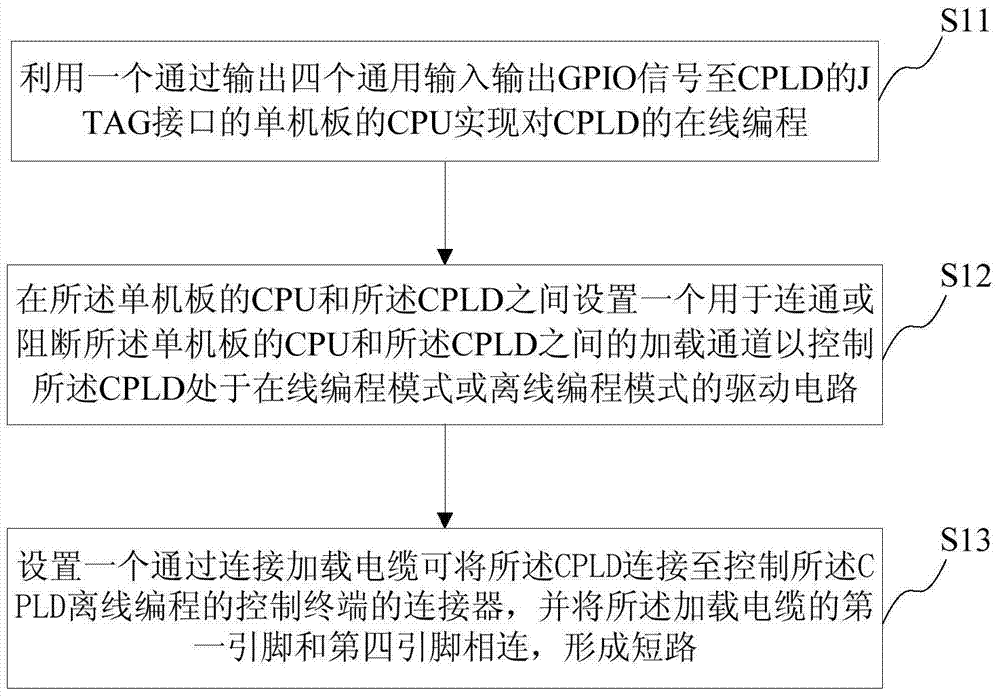

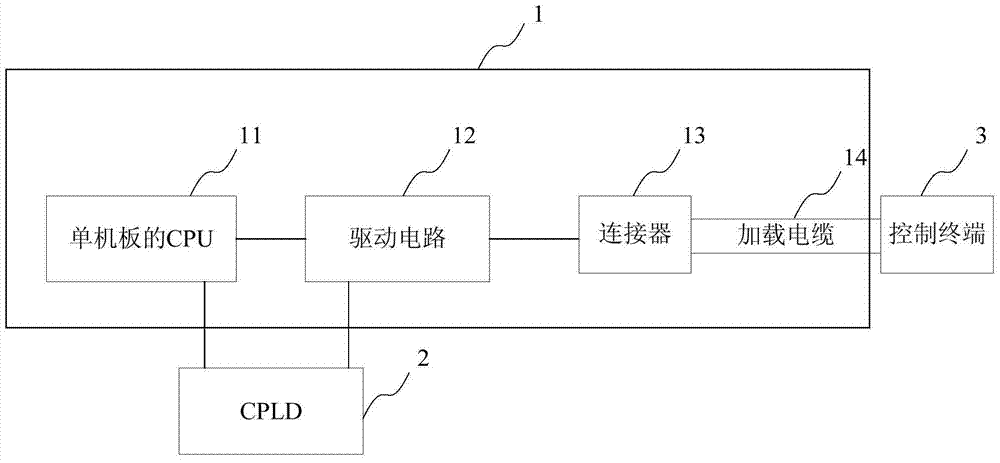

Control method and control circuit for realizing cpld on-line programming and off-line programming

ActiveCN105068482BEasy to debugReduce maintenance costsProgramme controlComputer controlComputer terminalJoint Test Action Group

The invention provides a control method and control circuit for realizing CPLD online programming and off-line programming. The control method and the control circuit are applied to the control of programming of a CPLD arranged on a single board computer. The control circuit comprises a CPU of the single board computer, wherein the CPU realizes online programming of the CPLD by outputting four general-purpose input / output GPIO signals to JTAG interfaces of the CPLD; a driving circuit which is connected between the CPU of the single board computer and the CPLD, and is used for communicating or blocking a loading channel between the CPU of the single board computer and the CPLD so as to control the CPLD to be in an online programming mode or an off-line programming mode; and a connector which can enable the CPLD to be connected to a control terminal for controlling the off-line programming of the CPLD by connecting with a loading cable, wherein a first pin and a fourth pin of the loading cable are connected to form a short circuit. The two working modes of online programming and off-line programming of the CPLD are supported simultaneously under the condition of not needing man-made or software extra configuration.

Owner:湖州丰源农业装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com