Method for achieving industrial robot off-line programming based on three-dimensional modeling software

An industrial robot, software-implemented technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of long time, inability to select the best attitude data, manually set teaching points, etc. Effects of offline programming work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

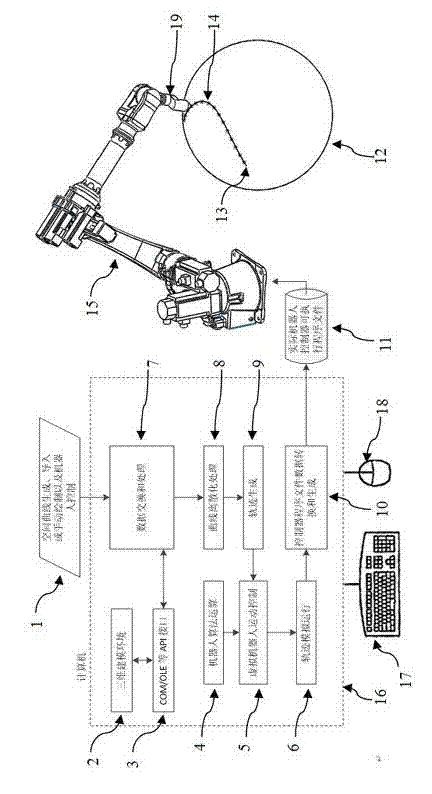

[0041] figure 1 Among them, the computer device for realizing the method includes a computer main body and a display 16, a keyboard 17 for data input, and a mouse 18 for pointing.

[0042]The computer main body 16 is a personal computer, which has a three-dimensional modeling environment 2. The CPU used as the main control and calculation reads and executes the three-dimensional modeling environment, and generates curve starting point and feature point data, calculates trajectory point data and processes and generates The actual robot controller can execute the program file 11, which is transmitted to the actual robot system 15 through TCP / IP or USB, and the data in the file is used for the operation of the actual robot system 15.

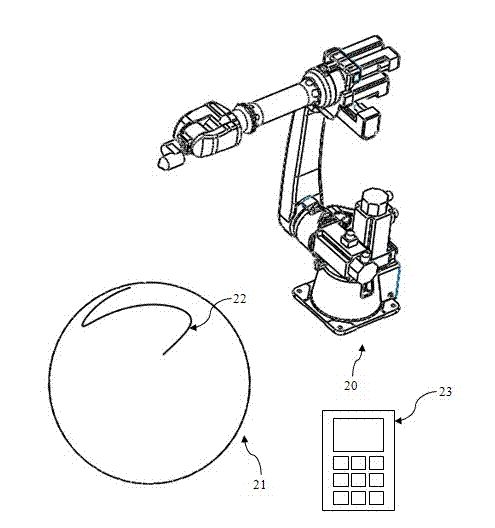

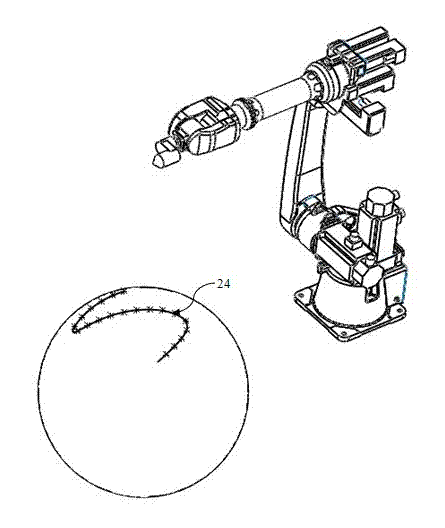

[0043] Suppose to figure 2 The general-purpose six-degree-of-freedom serial robot 20 is an offline progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com