Capacitor mechanism-based one-time programmable device and programming realization method

A one-time, capacitive technology, applied in the field of integrated circuit manufacturing, can solve the problems of increasing power consumption and complex circuit structure, and achieve the effect of reducing power consumption, reducing programming voltage, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

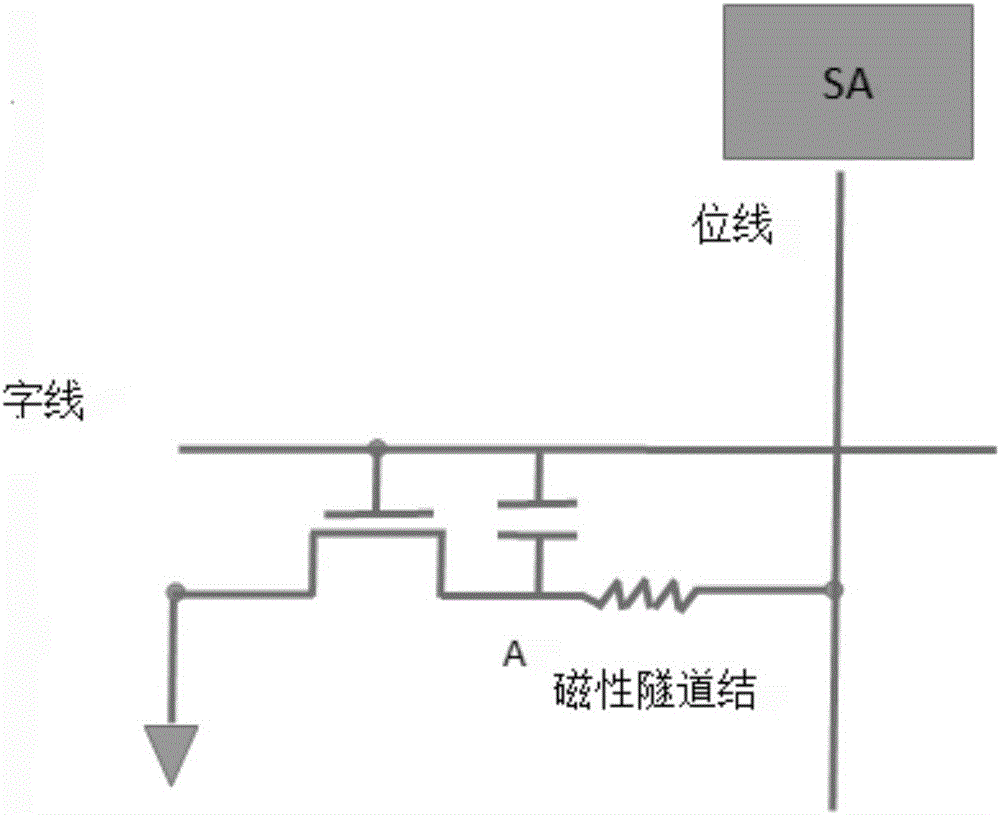

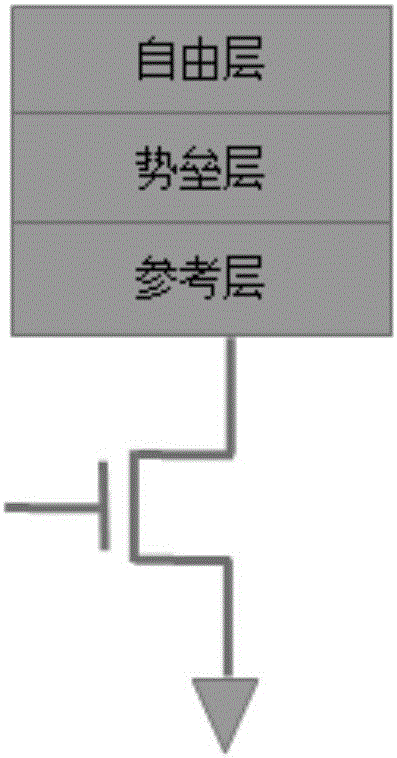

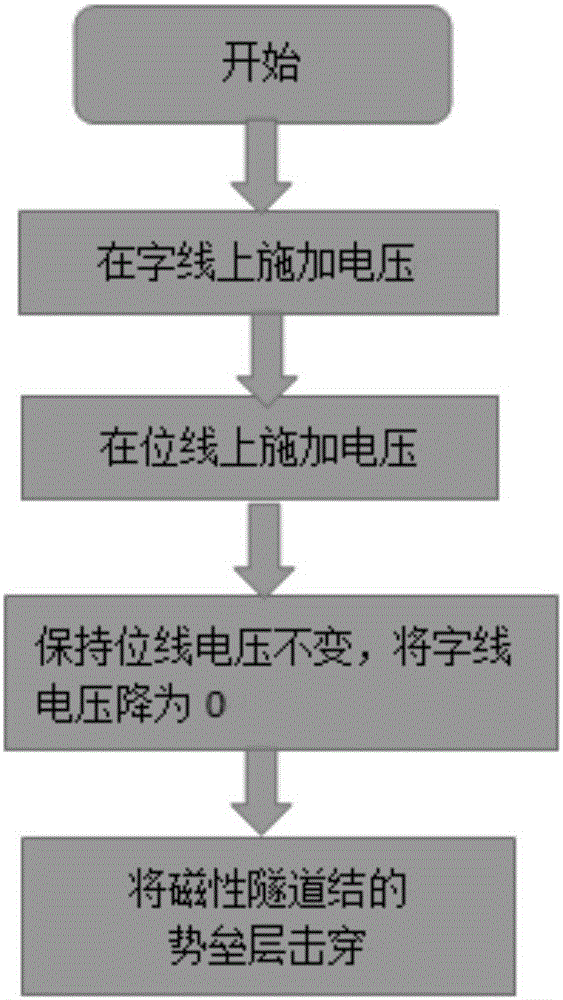

[0021] Example: such as figure 1 As shown, a one-time programmable device based on a capacitor mechanism is composed of a MOS switch tube, a magnetic tunnel junction, a capacitor, a word line, a bit line, a sense amplifier circuit, and a potential generating device. The magnetic tunnel junction includes a free layer, a barrier layer, and a reference layer; the barrier layer is sandwiched between the free layer and the reference layer, such as figure 2 shown. figure 1 Point A in the figure is the drain of the MOS switch; the free layer of the magnetic tunnel junction is connected to the drain of the MOS switch; the reference layer of the magnetic tunnel junction is connected to the bit line. The gate of the MOS switch tube is connected to the word line; the source of the MOS switch tube is connected to the potential generating device. The potential generated by the potential generating device is a fixed ground potential. One end of the capacitor is connected to the word lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com