Off-line programming system and method of optical visual sensor with linear structure for welding robot

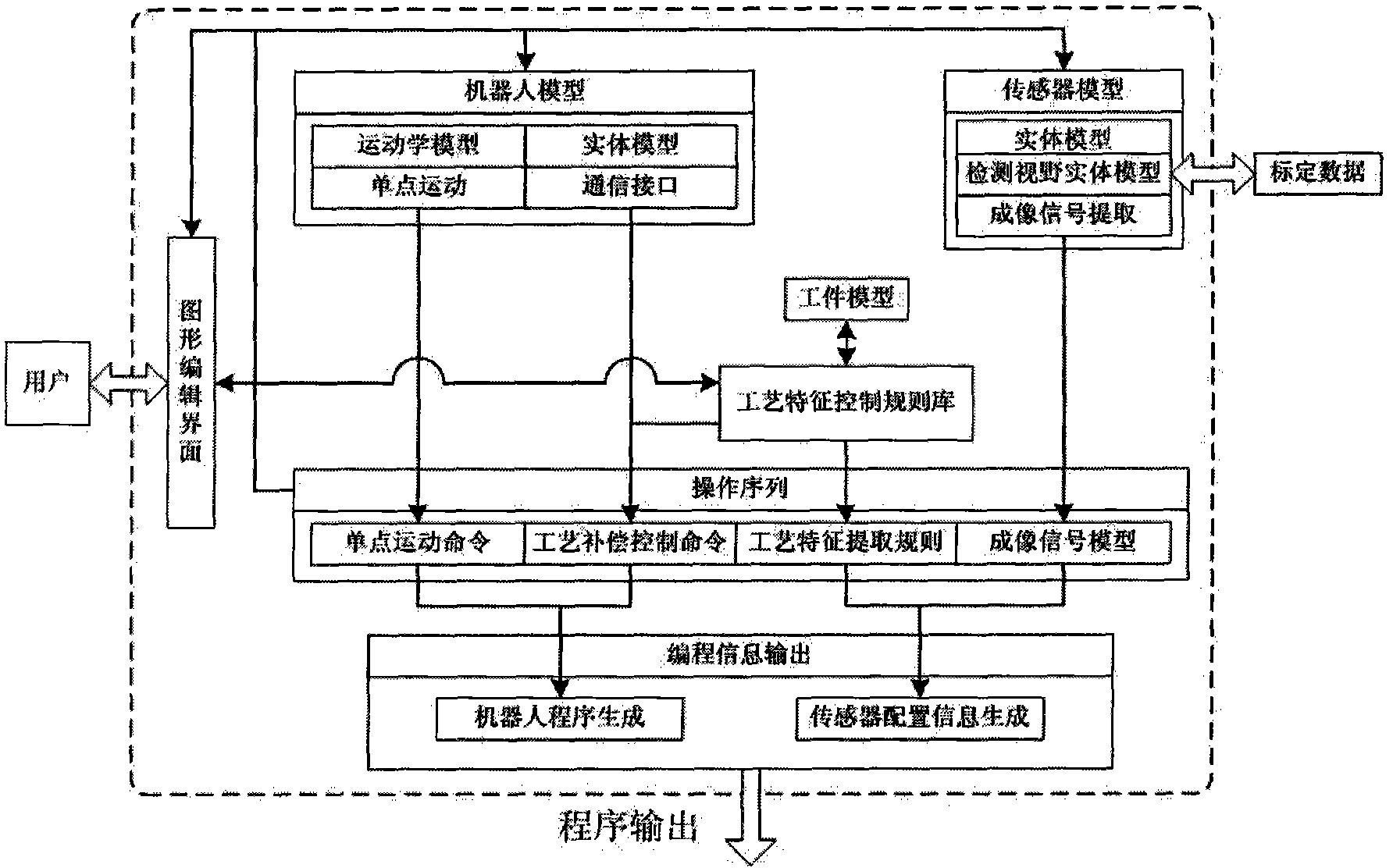

A vision sensor, robot line technology, applied in manipulators, manufacturing tools, etc., can solve the problems affecting the coordinated development and application of welding robot intelligent technology, and the difficulty of robot offline programming technology to exert its advantages, and achieve the effect of expanding the scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

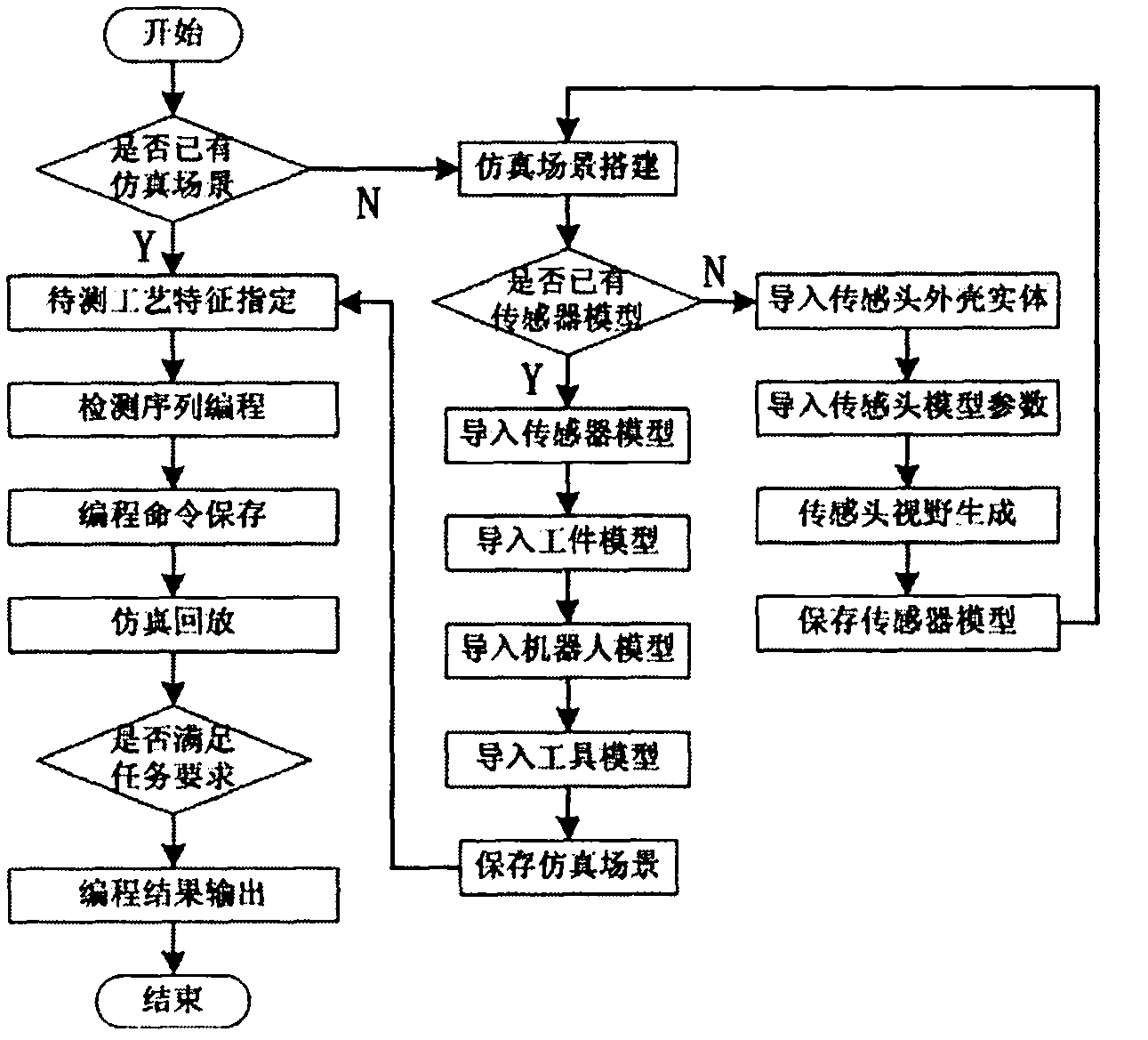

[0043]This example adopts solidworks running on the operating system based on PC and Windows as the software development platform, in which the simulation scene is established in the solidworks assembly space (corresponding to *.sldasm file), and each solid model is also a 3D entity in solidworks (corresponding to *.sldprt).

[0044] 1. Simulation scene construction

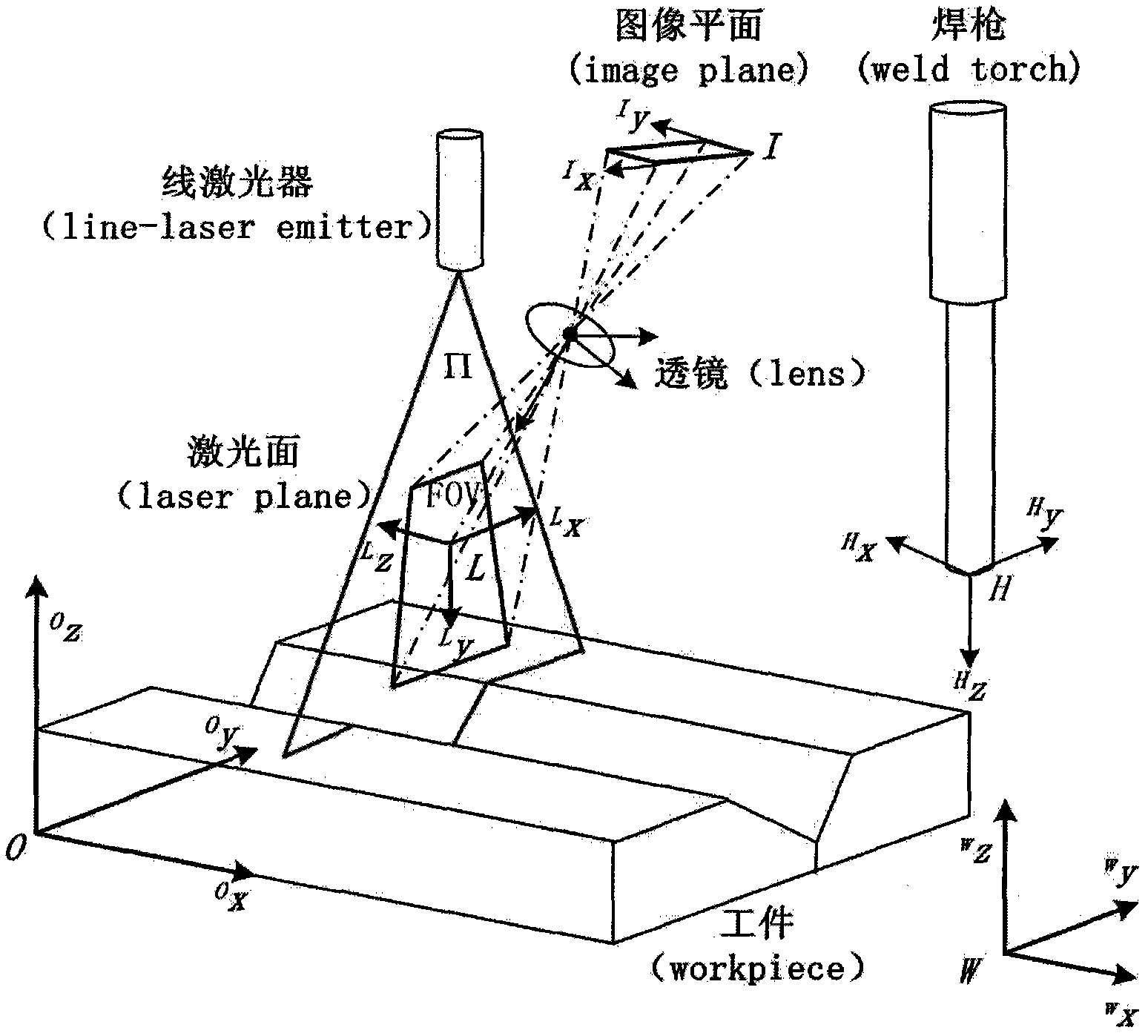

[0045] Open the scene file of the air simulation environment, import the sensor head model, the workpiece to be tested, the three-dimensional solid model of the robot and its tools, and complete the necessary assembly. Among them, the relative posture relationship between the camera coordinate system and the tool hand coordinate system, and the relative posture relationship between the workpiece to be measured and the robot base coordinate system should have been determined in the early des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com