Automated welding machining system for non-standard components based on structural light vision

An automatic welding and processing system technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of unstable welding teaching accuracy and low welding efficiency, improve labor intensity and working environment, save money Processing time, the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

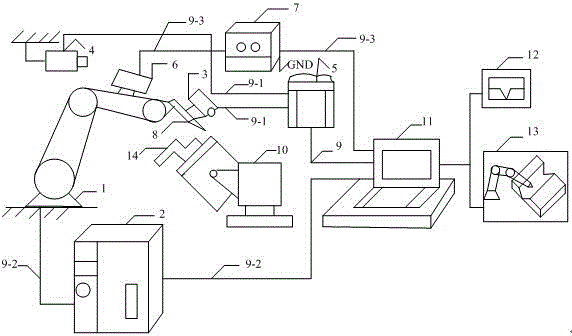

[0039] The present invention is an automatic welding processing system for non-standard parts based on structured light vision, which includes a welding seam vision detection system, a welding execution system, and a communication and control system.

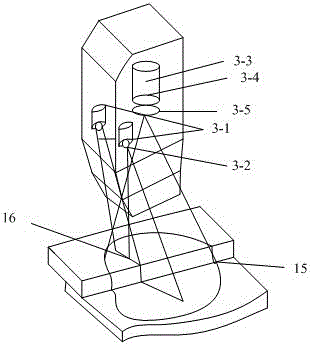

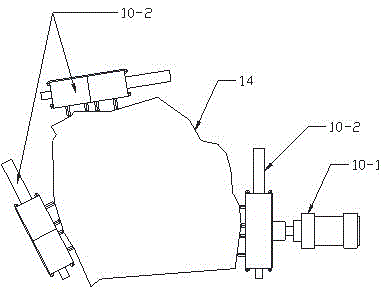

[0040] The welding seam vision inspection system is used for seam identification, position detection, process monitoring and image transmission to the communication and control system; such as figure 1 As shown, it includes a line structured light sensor 3, a monitoring CCD camera 4 and an image acquisition card 5, wherein the line structured light sensor 3 is fixedly installed on the end effector of the industrial robot 1 and maintains a relatively fixed position with the welding torch 8, forming a The robot hand and eye are used for seam recognition and position detection; the monitoring CCD cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com