An assembled construction method of electromechanical pipelines based on the BIM technology

A construction method and prefabricated technology, applied in cable installation, cable installation devices, electrical components, etc., can solve the problems of reducing model accuracy, scanning, model errors, etc., to improve accuracy and quality efficiency, refinement and Visually manage, reduce type and number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

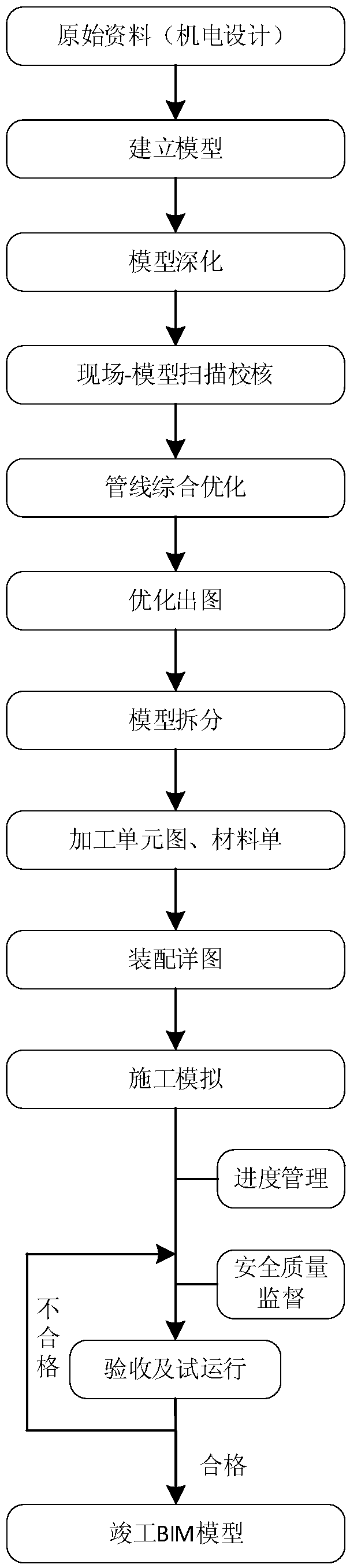

[0040] Such as figure 1 As shown, a BIM-based mechanical and electrical pipeline assembly construction method includes the following steps:

[0041] S1: Division of prefabricated processing models

[0042] According to the pipeline system, the location of the installation section, the difficulty of construction, the degree of integration, the construction schedule and the prefabrication processing capacity of the factory, it is divided into batches;

[0043] S2: Creation of the model

[0044] Create 3D model drawings according to different CAD construction drawings, and integrate each 3D model drawing into a BIM model;

[0045] S3: Processing of the model

[0046] (1) BIM model deepening

[0047] According to the mechanical and electrical pipeline system and the installation location of the interval, the BIM models of different disciplines are collaborat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com