Building industrialization concrete horizontal structure prefabricated part application primary design method

A technology of prefabricated components and horizontal structures, applied in building components, building structures, buildings, etc., can solve the problems of small application, standardization, poor versatility, and increased design procedures, so as to reduce investment, enhance versatility, and reduce design. and production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

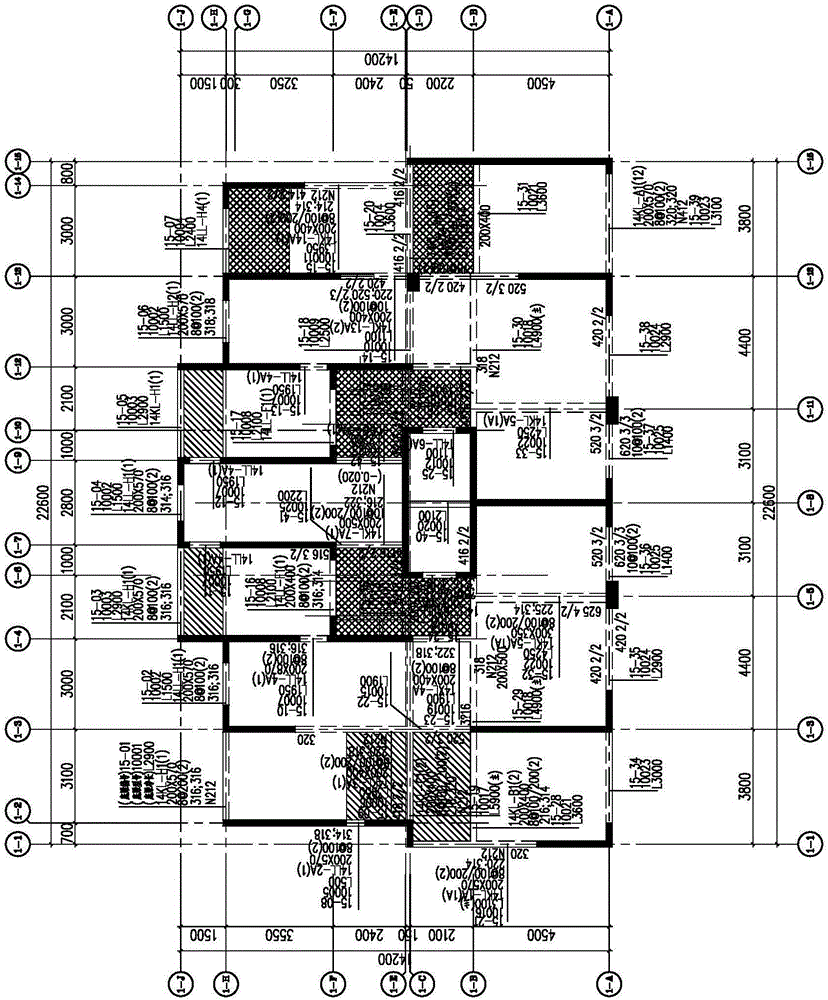

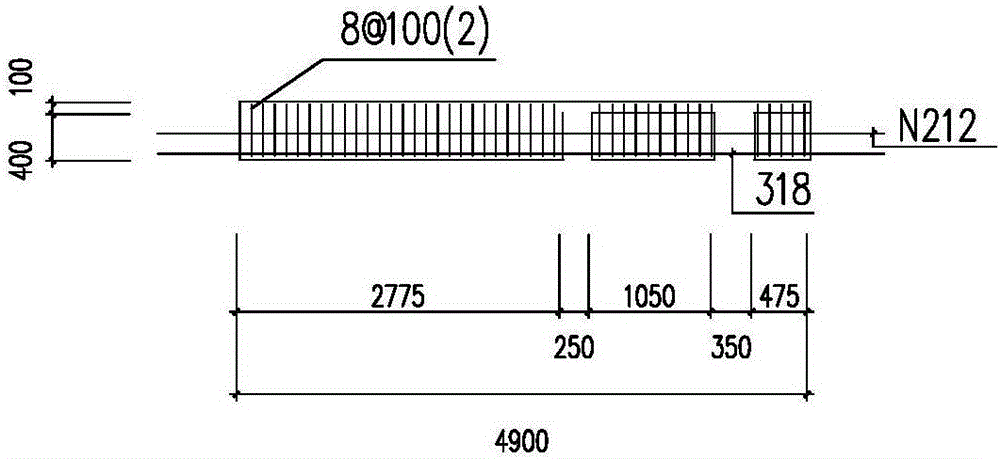

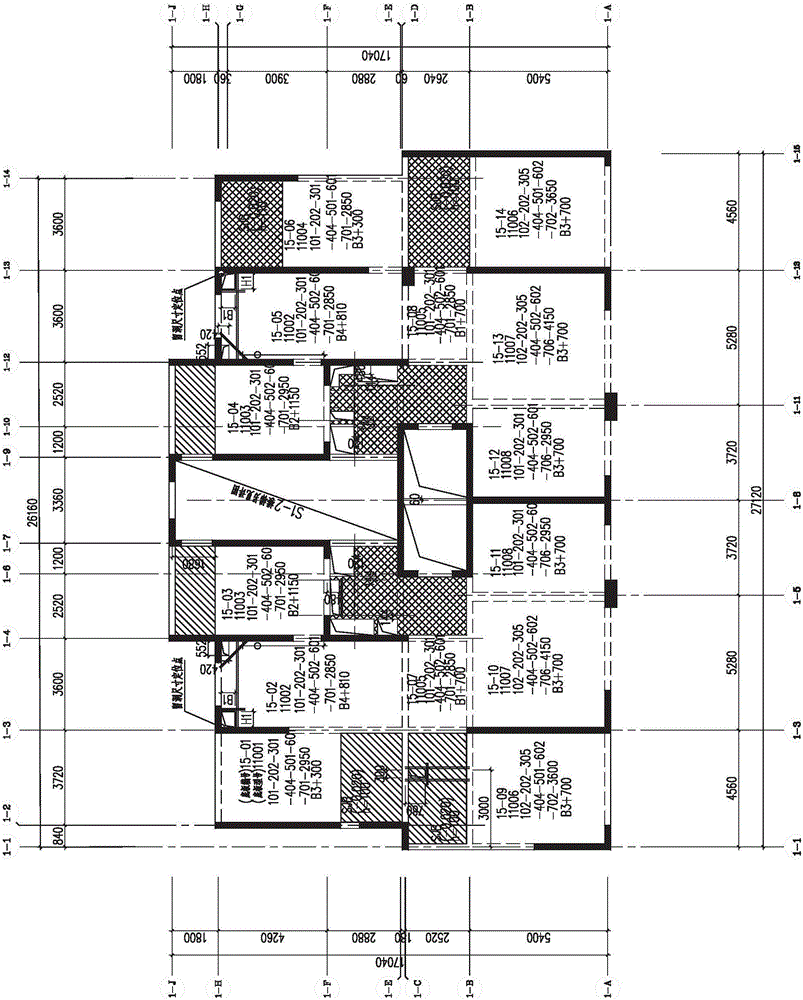

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0054] The industrialization of new buildings in my country has encountered a development bottleneck, and the engineering application of prefabricated concrete structures is very small. The standardization of prefabricated parts and components of concrete structures is low, and the corresponding design must adopt the method of secondary deepening special design, which increases the design cost, and there are few participating design units and few applied projects. The prefabricated components of the structure are poor in versatility, the utilization rate of the production formwork of the prefabricated components is low, and the production volume is also small, which makes the production costs of prefabricated components and components relatively high, which in turn restricts the enthusiasm of the owner to promote the application of industriali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com