Realization method for general type production and manufacturing unit and control system thereof

A technology for producing manufacturing units and control systems, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of lack of versatility, high cost, lack of independent change and addition of product process, etc., to achieve Effects of reduced application and development costs, simplified program development, and reduced frequency of revisions and updates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

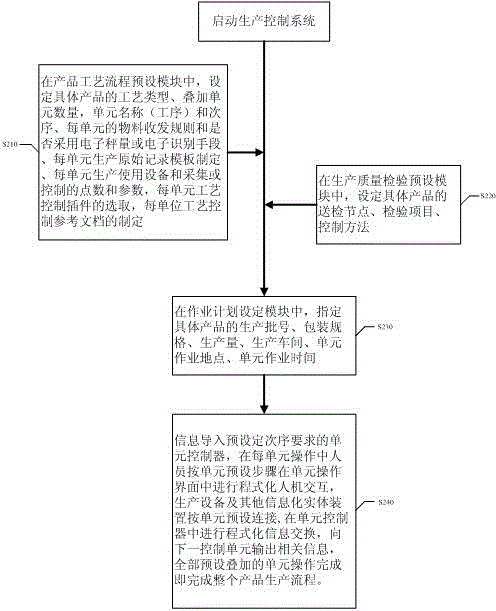

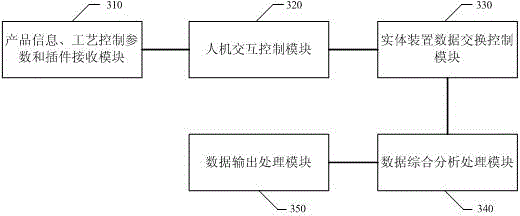

[0036] Below we will further elaborate on the method and system for realizing the production and manufacturing control software control of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand the method principle and structural composition of the present invention more clearly, but it cannot be used to explain Limit the protection scope of the present invention.

[0037] The invention belongs to a new method for developing and compiling a manufacturing process control system. The purpose of the method is to establish a set of simple and fixed modes in the source program compiling process and improve the working efficiency of the source program compiling. Enhance the versatility and openness in the process of using the target program, and adapt to the application of the whole product manufacturing process.

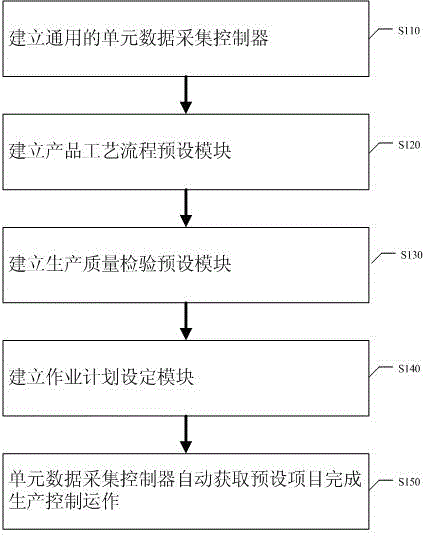

[0038] figure 1 It is a schematic flow chart of a general-purpose manufacturing unit control system and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com