Hydraulic oil cylinder barrel and piston rod assembling device

A technology of hydraulic cylinder and assembly device, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient assembly accuracy, time-consuming and labor-intensive, and low concentration efficiency, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

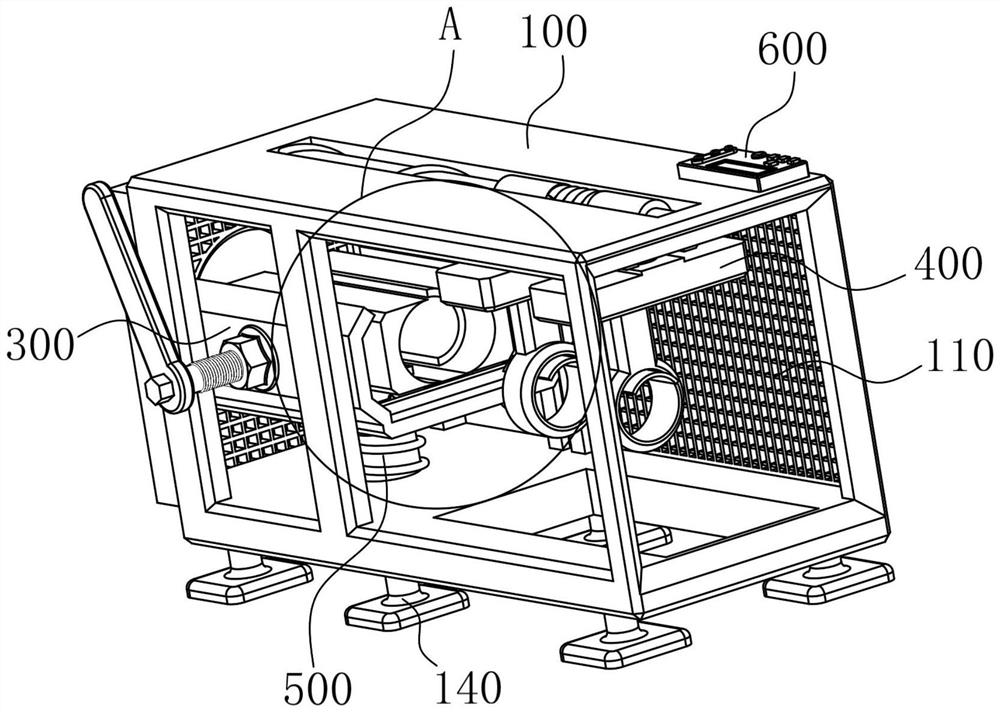

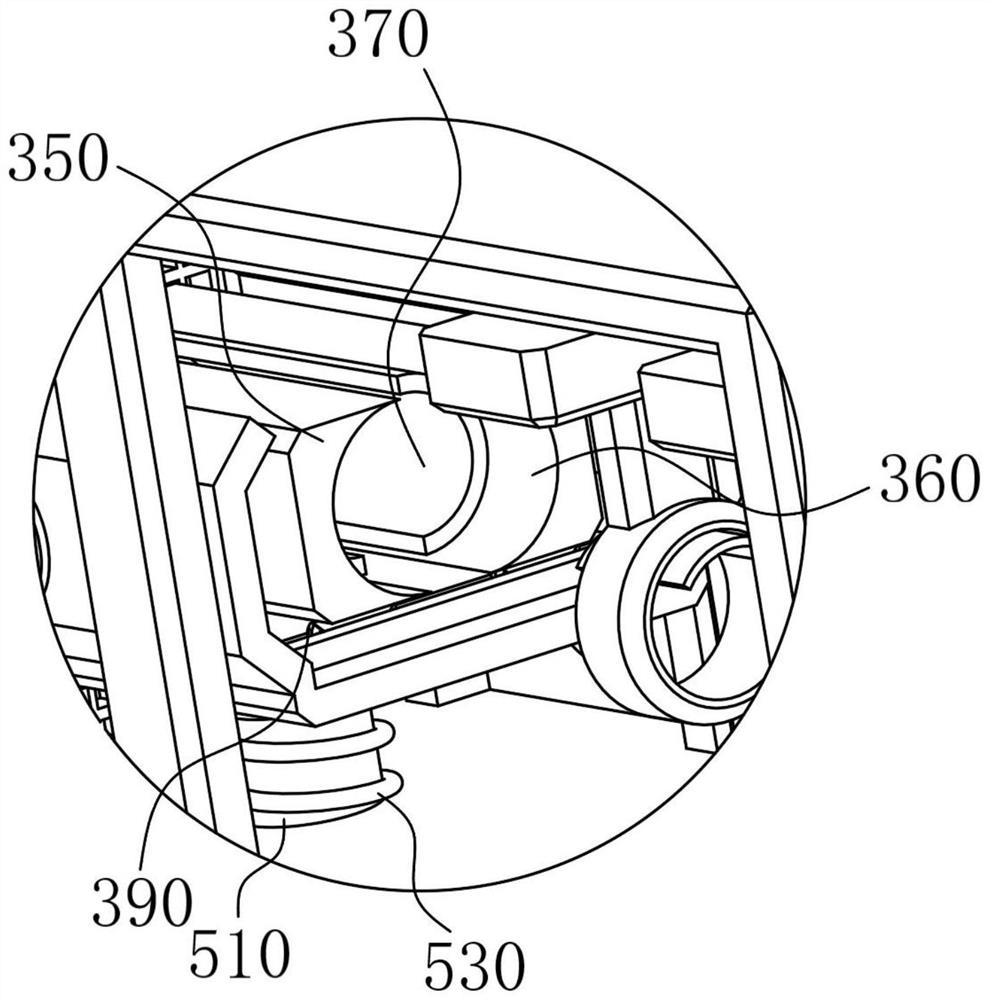

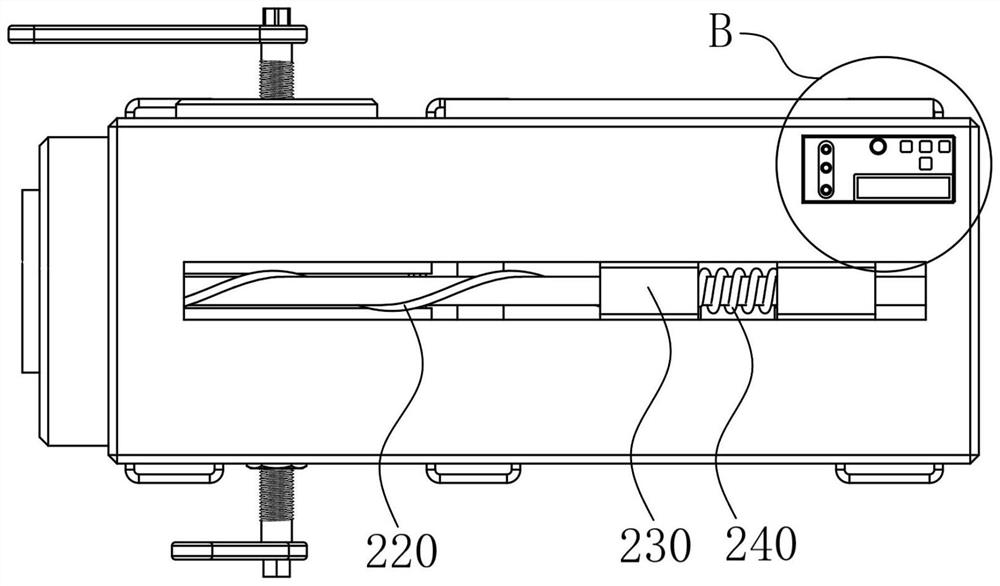

[0034] refer to figure 1 —8. The present invention is an assembly device for a hydraulic cylinder and a piston rod, including a main frame 100, a transmission device 200, a fastening device 300, a guiding and positioning device 400, a lifting device 500, and a console 600. The main frame 100 includes a main frame Skeleton body, grid plate 110, oil cylinder fixing plate 120 and fastening shaft partition 130, one end of grid plate 110 is connected with one surface of main frame body, one end of oil cylinder fixing plate 120 is connected with one surface of main frame body, fastening shaft spacer One end of the plate 130 is connected to one surface of the main frame body. The transmission device 200 includes a drive shaft 210, a transmission line 220, a first drive 230 and a second drive 250. The upper surface of the main frame body is provided with a rectangular through hole, and the drive shaft 210 is connected to the rectangular through hole. through-hole connection, the first...

Embodiment 2

[0043] When the personnel is in use, place the cylinder on the placement plate 540, and tighten the first fastening frame 350 and the The second fastening frame 360, the piston rod is placed in the guide 410, the guide rod 430 and the connecting column 460 are matched together to adjust the position of the piston rod, and by observing the display screen 630, press the button 620 to adjust the position of the rod body, and the main switch 640 The transmission process is adjusted under control, and finally the piston rod is inserted into the cylinder body through the transmission shaft 210 and the transmission line 220 to complete the assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com