Pre-gluing method for pipeline joint

A pre-coating and pipeline technology, applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, threaded connections, etc., can solve the problems of low production efficiency, pollution of downstream parts, etc., to prevent pollution or bumping, Easy to save, convenient and fast operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0015] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

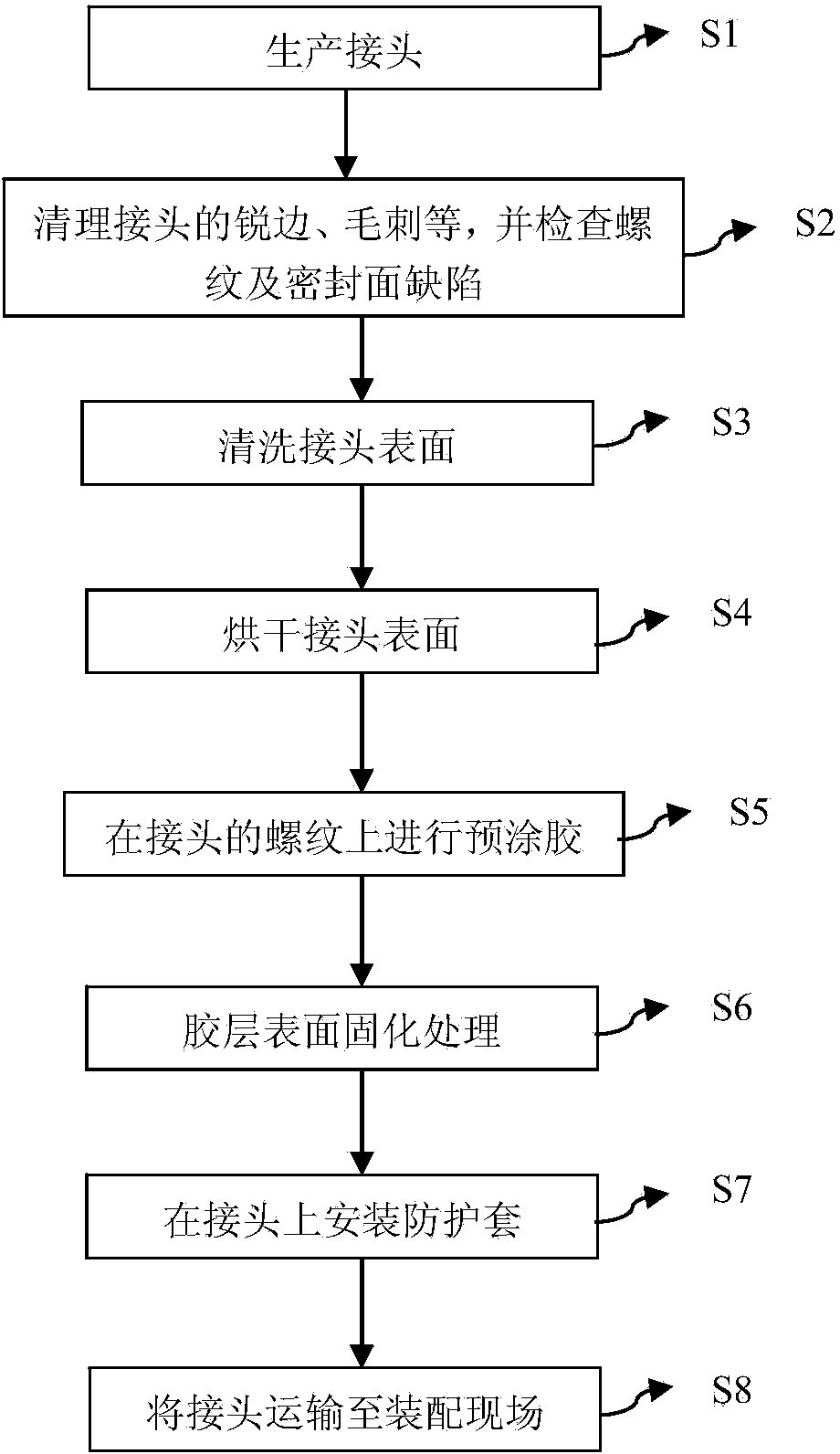

[0016] Such as figure 1 As shown, according to the pre-glue method of the joint of the pipeline according to the specific embodiment of the present invention, glue is applied on the thread of the joint at the processing site after the joint of the pipeline is processed, and then the joint is transported to the assembly site for assembly .

[0017] Gluing method of the present invention comprises the steps:

[0018] S1: R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com