Automatic assembling machine for substrate equipping electric components

A technology for assembly machines and parts, applied in the field of automatic assembly machines, can solve the problems of long cooling air transmission line, complex structure of linear motors, flow loss, etc., and achieve the effects of avoiding thermal fluctuations, improving cooling effect, and reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

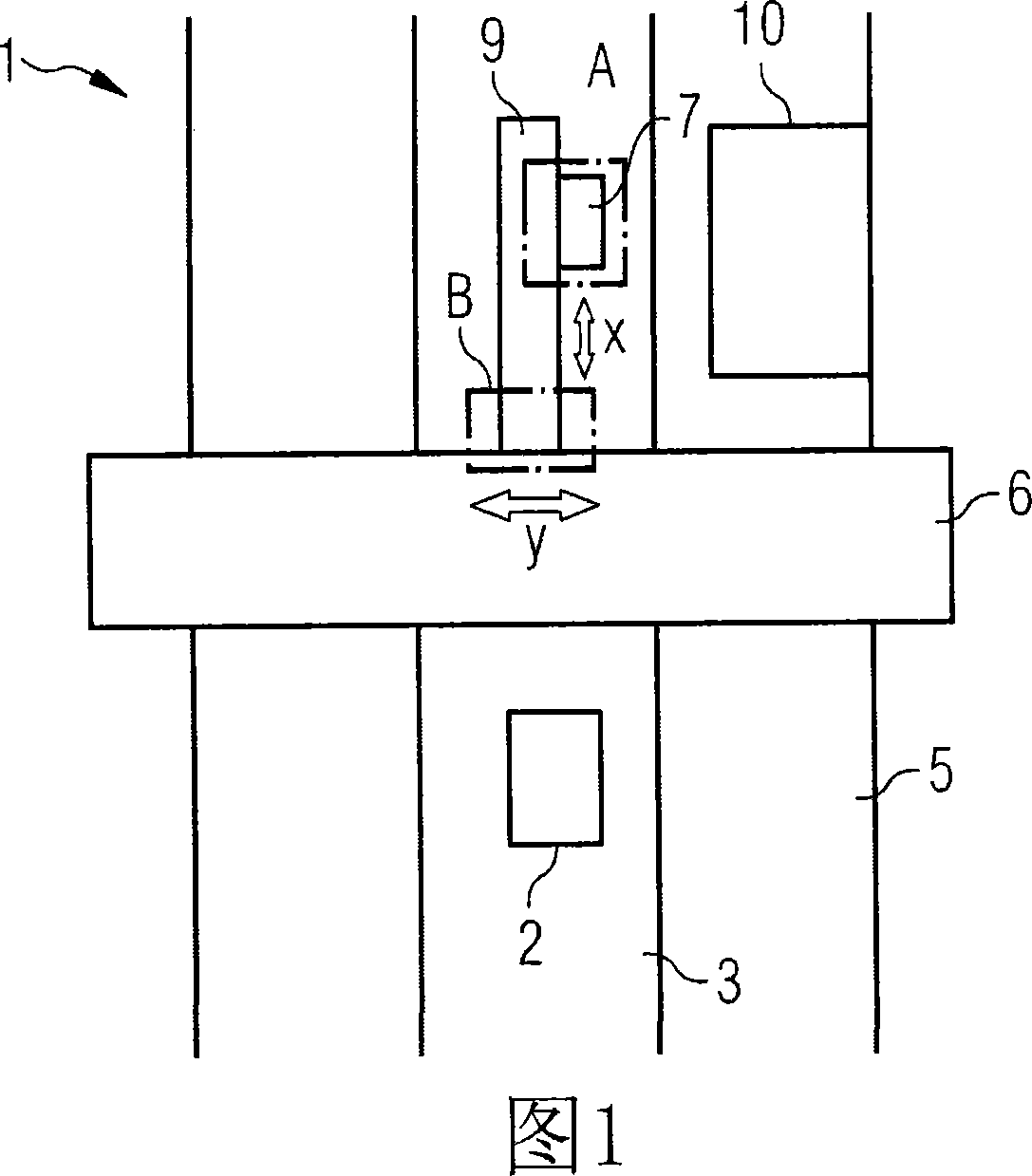

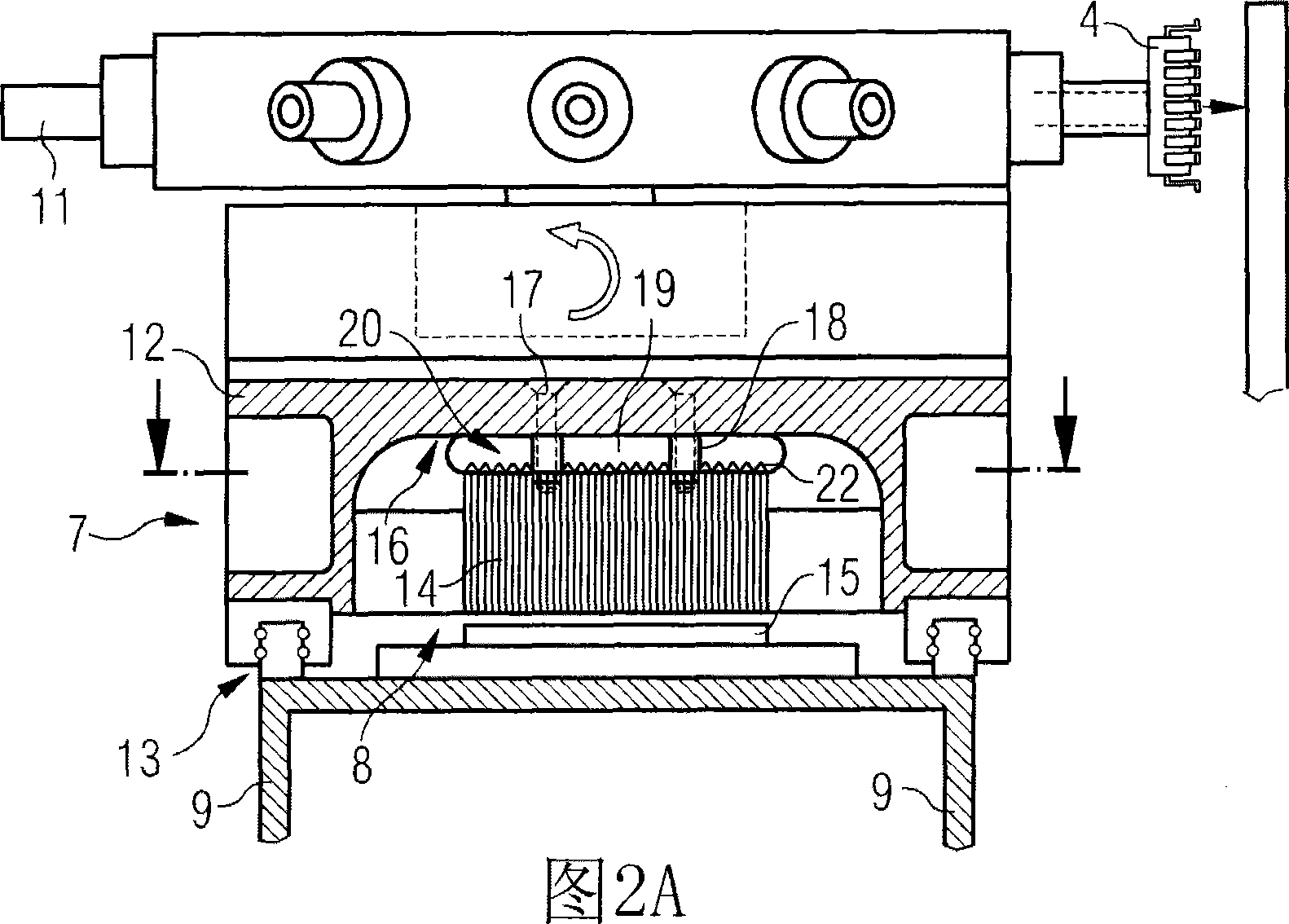

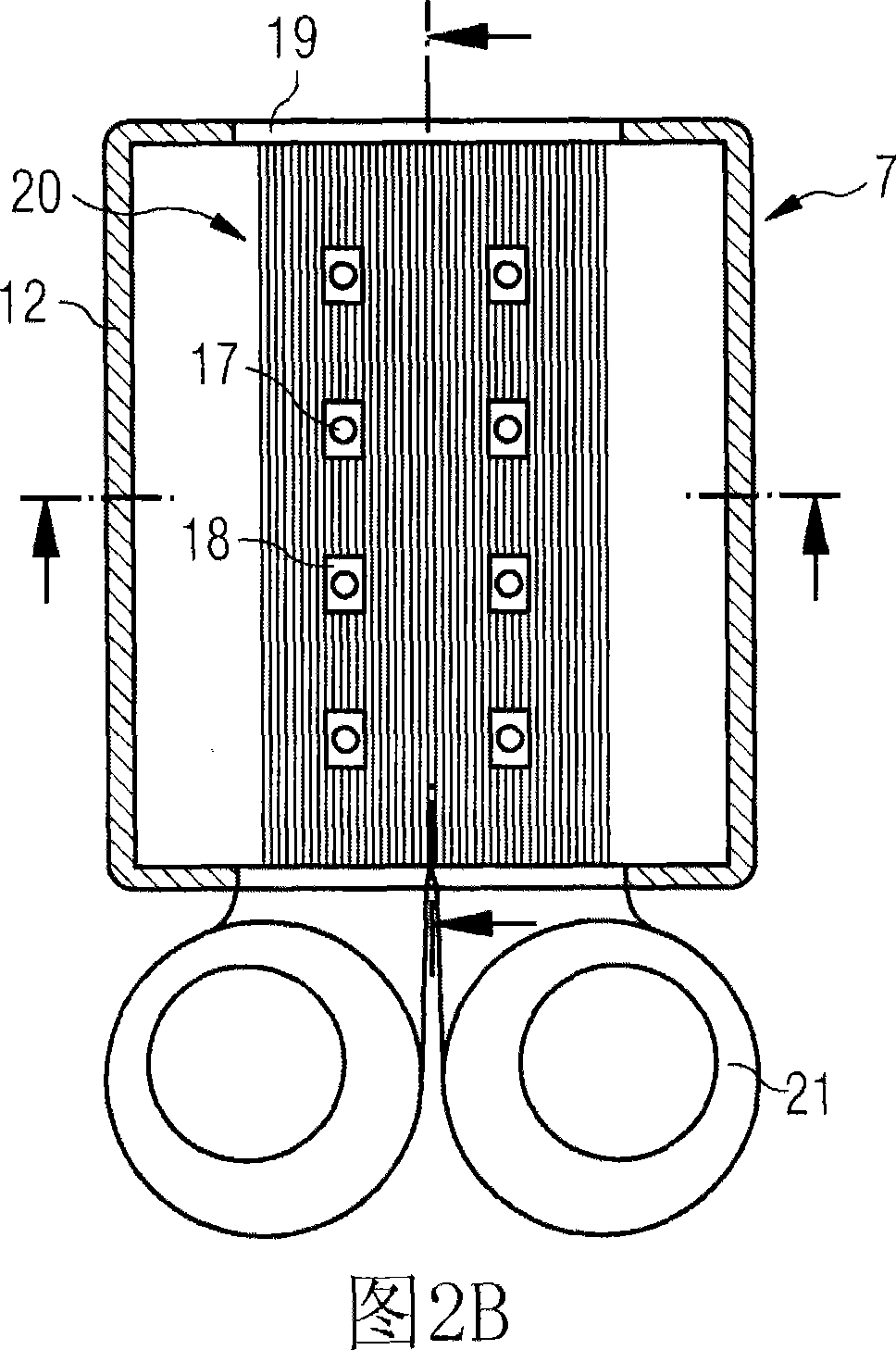

[0014] FIG. 1 shows an embodiment of an automatic assembly machine 1 in a schematic top view. The substrates 2 to be assembled are transported by means of a conveyor belt 3 to an assembly station, where they are equipped with electrical components 4 (see FIG. 2A ), and then taken away from said assembly station. The conveyor belt 3 is arranged on a chassis 5 of the automatic assembly machine 1 . The chassis 5 includes a frame 6 spanning the conveyor belt 3 like a bridge.

[0015] The assembly process is carried out by an assembly head 7 which is movable in a movement direction X along a positioning arm 9 driven by a linear motor 8 (not shown in FIG. 1 ). The positioning arm 9 itself is mounted on the bridge support 6 and can also move in a moving direction Y driven by a linear motor (not shown in FIG. 1 ). In this case, both the assembly head 7 and the positioning arm 9 can be regarded as movable parts that can move relative to the chassis 5 driven by the linear motor.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com