socket assembly machine

A socket group and assembly mechanism technology, applied in the assembly/disassembly of contacts, can solve problems such as low efficiency and cumbersome sockets, and achieve the effect of accurate insertion action and improved socket assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

[0056] The terms "first" and "second" used herein do not specifically refer to a sequence or order, nor are they used to limit the present application, but are only used to distinguish components or operations described with the same technical terms. .

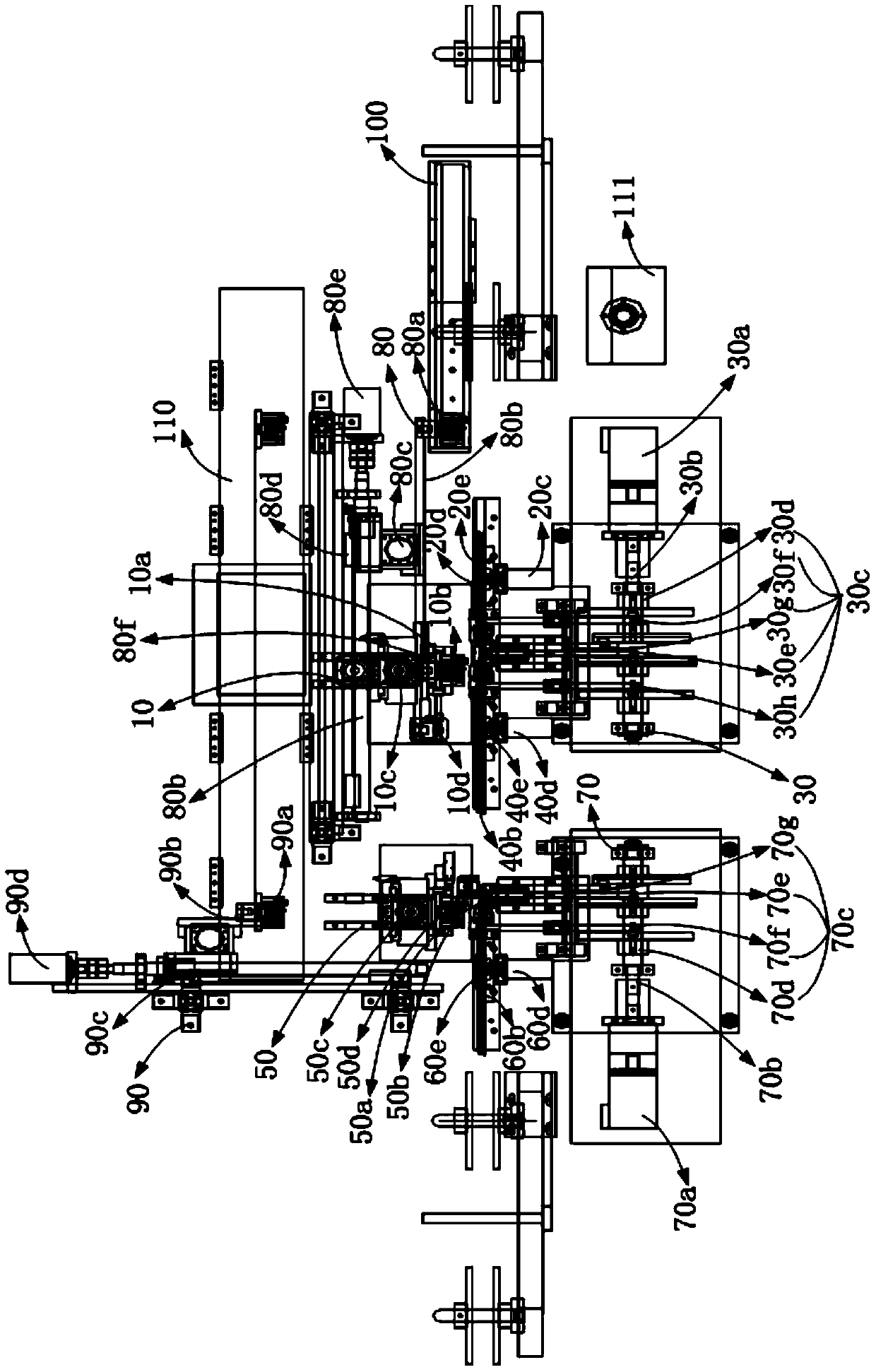

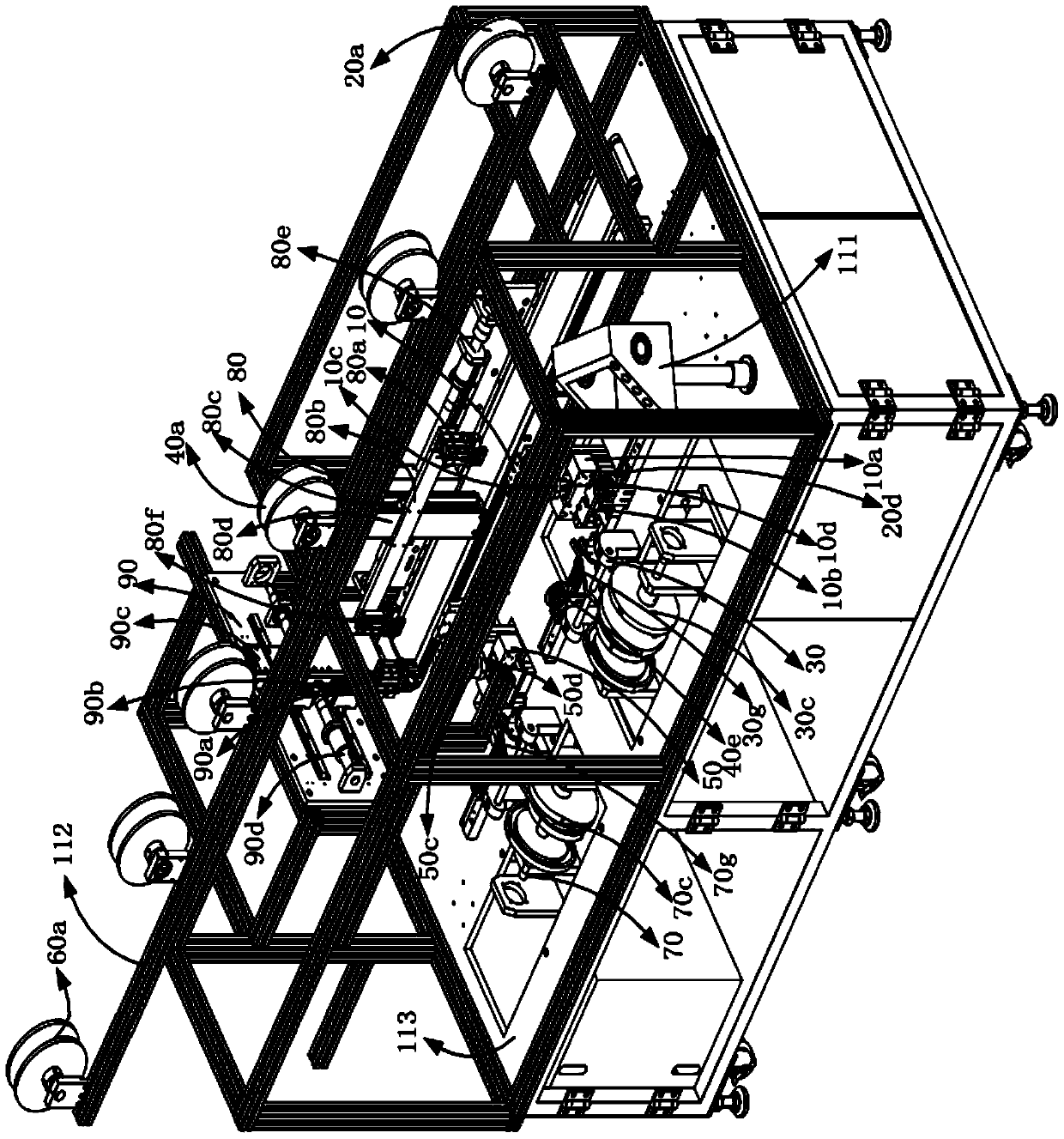

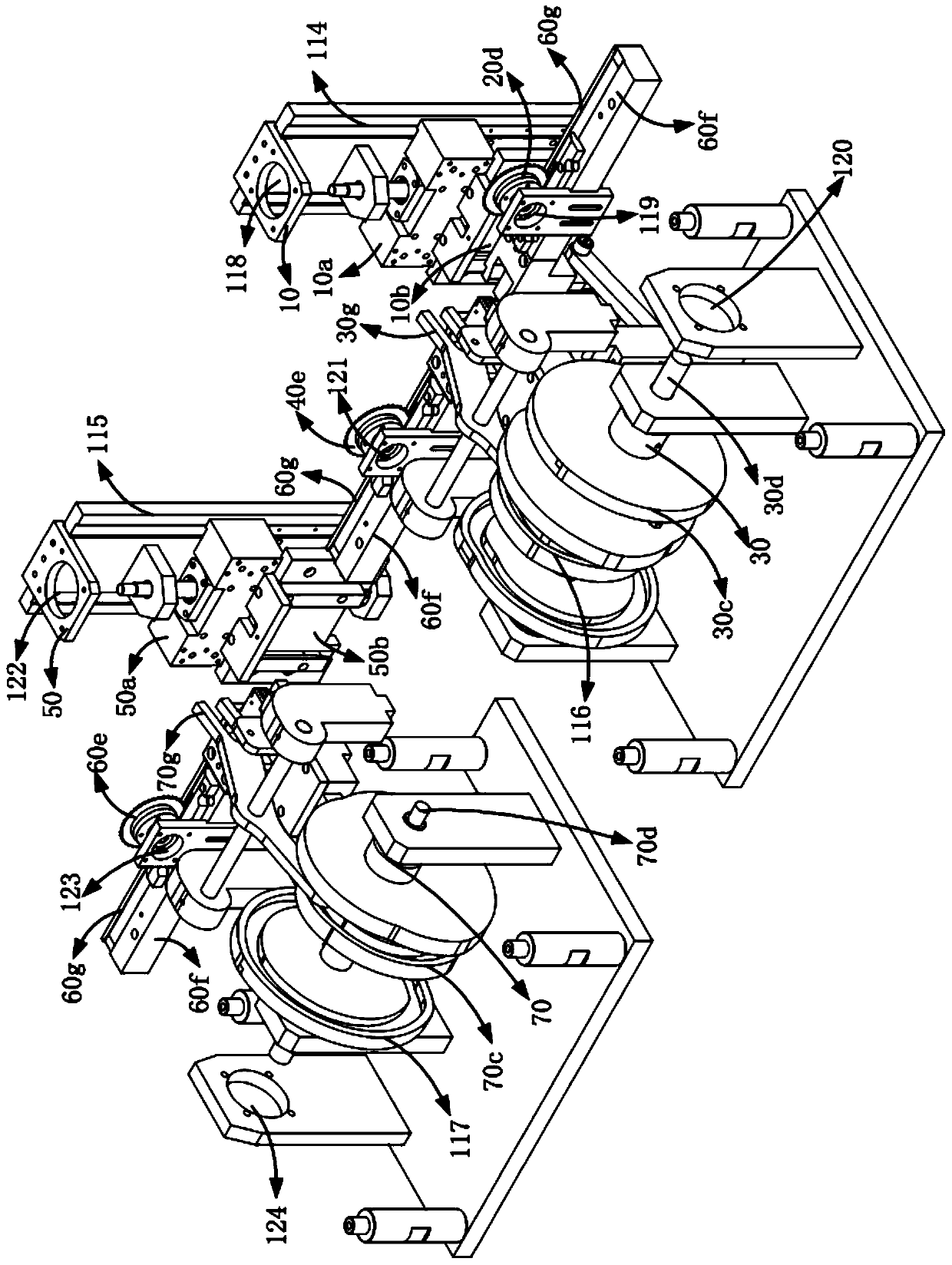

[0057] Please refer to figure 1 with 2 , is a schematic diagram of the whole machine of the socket assembly machine in this embodiment, the socket assembly machine includes an external machine platform, and the external machine platform includes an assembly platform 113 and a plurality of vertical stands 112 installed on the assembly platform 113, and a man-machine is also installed on the assembly platform 113 The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com