Efficient combined automatic TIG welding technology of butt joint of thick plates

A welding process and combined technology, used in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the complicated root cleaning and root sealing welding procedures, high requirements for workpiece assembly accuracy, and unstable welding seam forming quality. and other problems, to achieve the effect of improving welding efficiency, low assembly accuracy requirements, and stable welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1. This embodiment provides a high-efficiency combined automatic TIG welding process for butt jointing of 100 mm thick S30408 stainless steel plates, including the following steps:

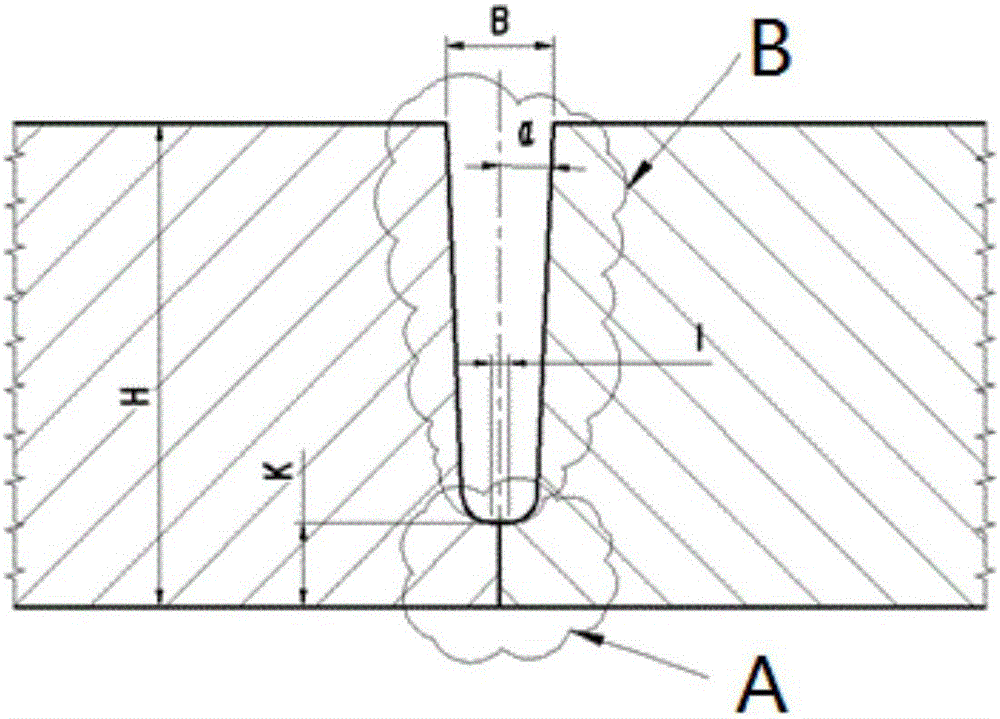

[0045] (1) The groove adopts figure 1 The single-sided U-shaped narrow gap groove with a blunt edge shown in the figure has a bevel angle of 2°, a root blunt edge of 12mm, an assembly clearance of 0-1mm, and an offset of 1mm. The groove is made by mechanical processing. processing.

[0046] (2) Before welding, use a clean white cloth dipped in acetone solution to wipe the inner and outer surfaces of the groove within 50mm from the edge of the groove to remove oil and other impurities that affect the welding quality.

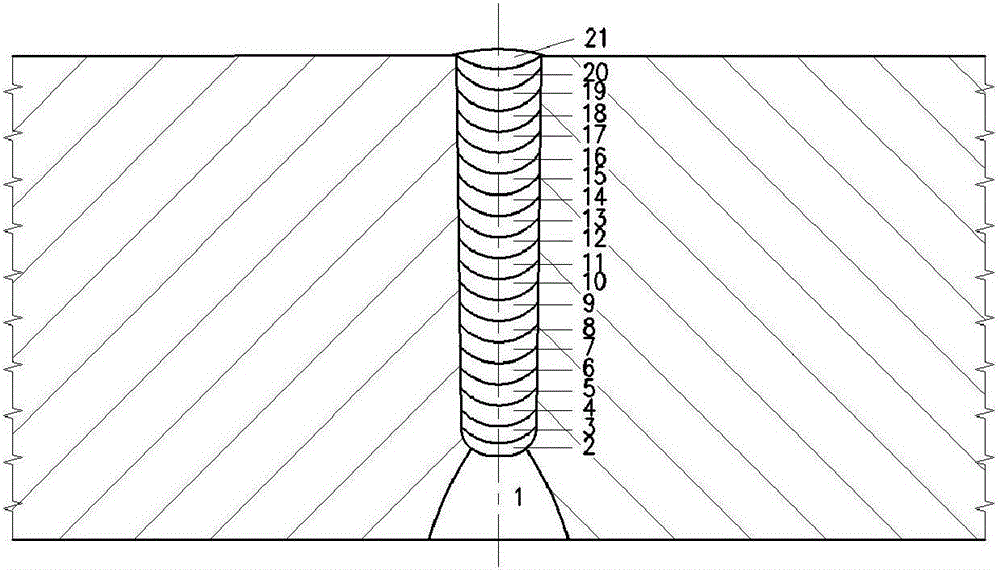

[0047] (3) Automatic deep-hole TIG root sealing welding is used for root sealing and self-fluxing welding. The diameter of the selected tungsten electrode is 6.3mm. The process specification is: welding current 480A~500A, arc voltage 18V~20V, welding speed 200mm / ...

Embodiment 2

[0051] Embodiment 2. This embodiment provides a high-efficiency combined automatic TIG welding process for the butt joint of 120mm thick SA508-3 steel plates for nuclear power, including the following steps:

[0052] (1) The groove adopts figure 1 The single-sided U-shaped narrow-gap bevel with a blunt edge is shown, the bevel angle is 2.1°, the root blunt edge is 10mm, the assembly clearance is 0-1mm, and the misalignment is 1mm. The groove is processed by mechanical processing. .

[0053] (2) Before welding, use a clean white cloth dipped in acetone solution to wipe the inner and outer surfaces of the groove within 50mm from the edge of the groove to remove oil, rust and other impurities that affect the welding quality.

[0054] (3) Automatic deep-hole TIG root sealing welding is used for root sealing and self-fluxing welding. The diameter of the selected tungsten electrode is 6.3mm. The process specification is: welding current 450A~470A, arc voltage 18V~20V, welding speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com