A high-strength and toughness flux-cored wire material for fcb method automatic welding

A flux-cored wire and flux-cored technology, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of reduced weld metal toughness, grain growth, and low-temperature impact toughness values that cannot meet the requirements. , to achieve the effect of improving strength and toughness, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] 1). The drug core powder is mixed with alloy powder, and various alloy powders are sieved to ensure that the particle size of the alloy powder is 80-100 mesh. Weigh according to the formula ratio, stir and homogenize repeatedly.

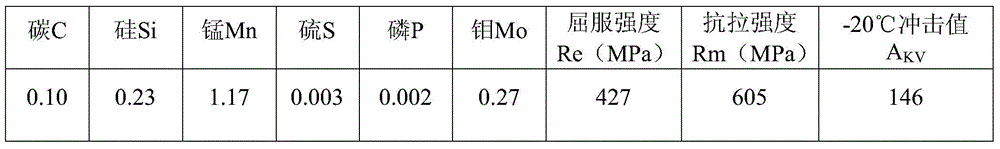

[0038] The formula ratio of each alloy powder is: silicon-calcium alloy (Ca28Si60) 1.0-3.0%, electrolytic manganese 2.0-4.0%, 50% ferrovanadium 0.5-1.0%, 25% ferro-titanium 0.5-1.0%, 62% CrN 0.3-0.8% , 55% ferromolybdenum 2.0-4.0%, 99 oxide rare earth Ce1.0-2.5%, atomized iron powder 83-93%.

[0039] 2). Dry the stirred and homogenized alloy powder at 80°C and keep it warm for 1 to 2 hours to remove the moisture and moisture in the alloy powder.

[0040] 3). On the flux-cored wire production line, add the baked alloy powder into a U-shaped groove made of a commercially available SPCC cold-rolled steel coil with a thickness of 1.0 mm and a width of 18.5 mm.

[0041] 4). The flux core rate coefficient of the flux cored wire is 25%, and the err...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com