Air guiding non-consumable gas shielded arc welding method

A technology of gas shielded welding and non-melting electrodes, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing welding workload, reducing production efficiency, and wide heat-affected zone, so as to increase penetration ability, Efficient and high-speed welding, the effect of increasing welding penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

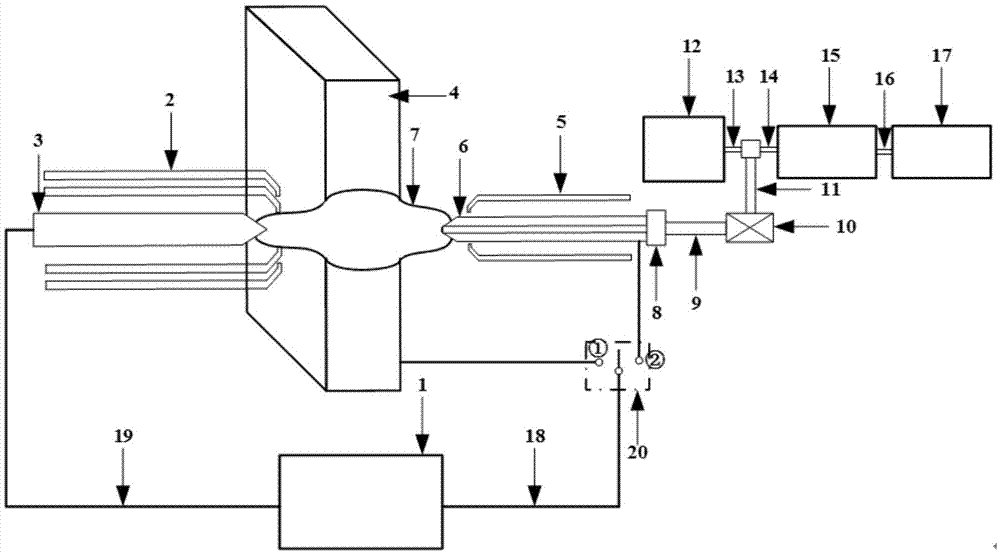

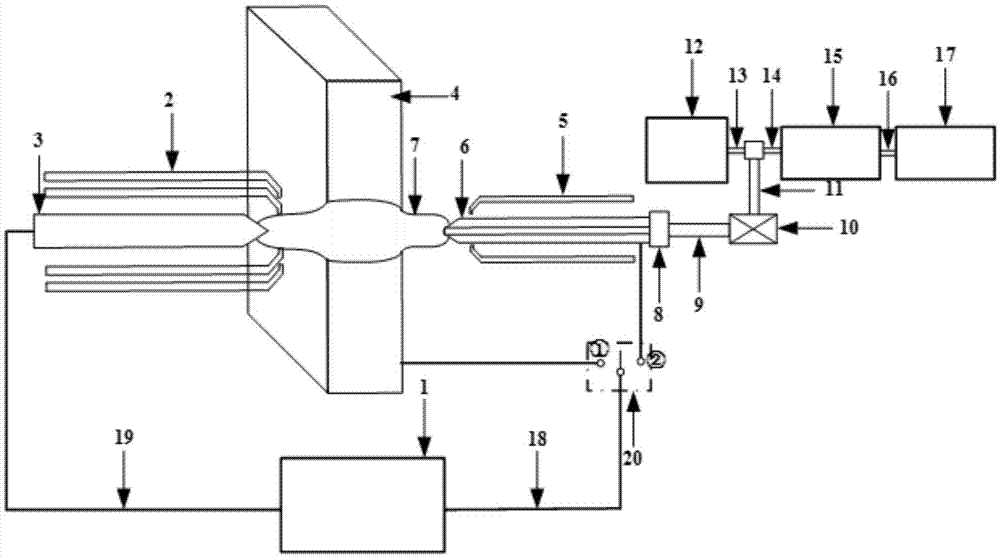

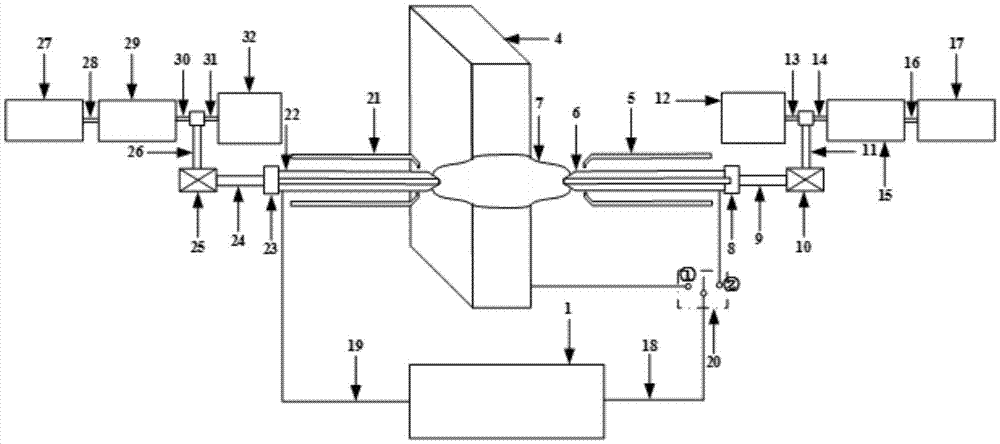

[0050] A gas-guided non-melting electrode gas-shielded welding method in this embodiment takes the PAW-GTAW mode and selects a DC power supply as an example, and the specific operations are as follows:

[0051] Step 1. Before welding, after grinding and cleaning the 8mm thick aluminum alloy plate of the workpiece to be welded, fix it on the welding fixture; according to figure 1 As shown, connect the gas circuit, water circuit and circuit. The plasma welding torch and the TIG welding torch are respectively located on both sides of the workpiece. The axes of the two welding torches are perpendicular to the workpiece and are connected to the same welding power supply at the same time; The air path established by the valve, the connecting joint, the hollow tubular electrode and the auxiliary air-guiding pipeline is correctly connected; when the valve is in the closed state, start the air pumping device, perform pumping and depressurization treatment on the pressure release device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com