A welding method for welding thick plates with hollow tungsten very high penetration TIG filler wire

A welding method and tungsten electrode technology, applied in the cooling of welding equipment, welding accessories, electrode clamps, etc., can solve the problems that the welding wire is too late to melt, is not suitable for thick plate welding, and the welding wire stays for a short time, etc., to achieve super penetrating ability , Realize the effect of fully automatic operation and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

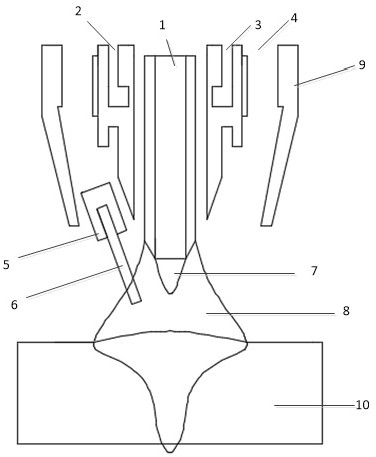

[0015] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

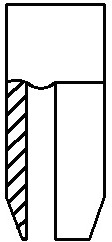

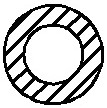

[0016] Such as Figure 1-3 As shown, the present invention is a welding method for hollow tungsten very high penetration TIG wire-filled thick plates, characterized in that: the welding method comprises the following steps:

[0017] Step 1: Before welding, grind or clean the surface of the workpiece to be welded, fix the polished or cleaned workpiece on the welding fixture, the thickness of the workpiece is 5-14mm, and the distance between the bottom of the tungsten electrode and the workpiece is 2- 3mm;

[0018] Step 2: Start the welding machine and set the welding parameters: the welding method is continuous welding or pulse welding, the welding current is 300-100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com