A High Frequency-Arc Hybrid Welding Method

A hybrid welding and arc welding technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult general application, and achieve the effects of solving heat shortage, increasing welding capacity, and heating directly and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

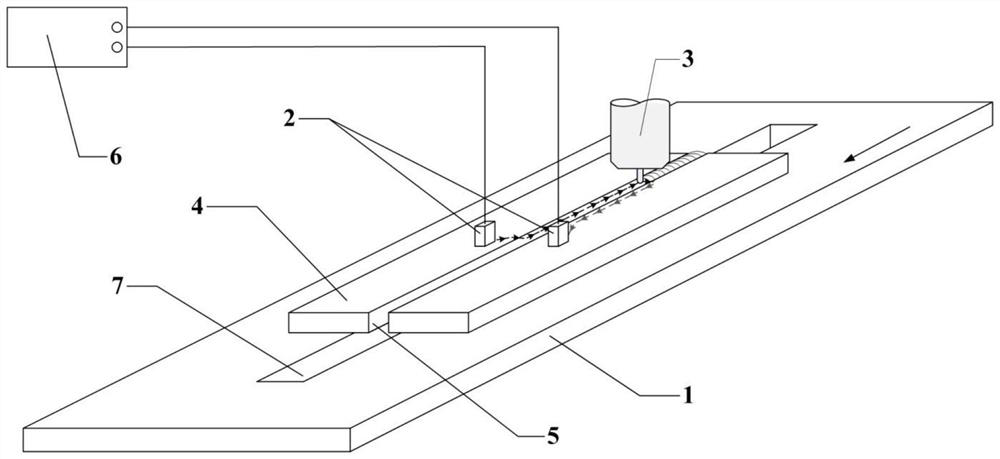

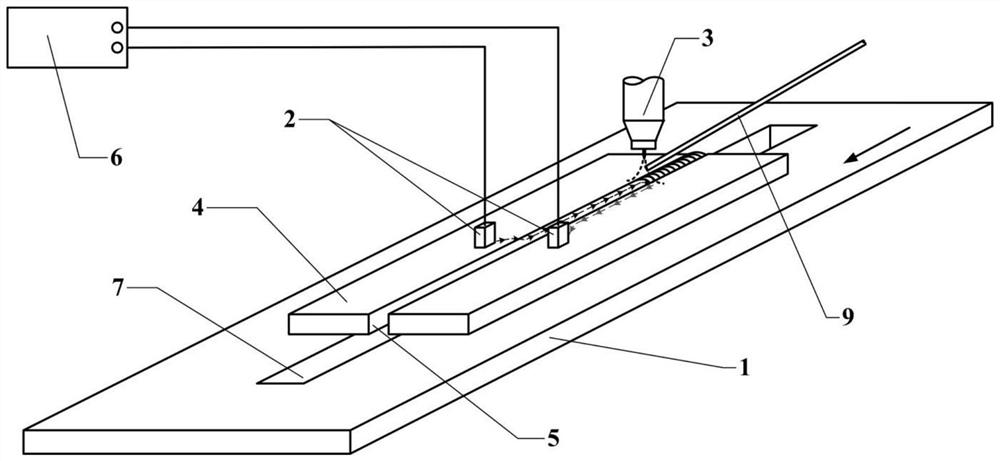

Method used

Image

Examples

Embodiment 1

[0041] 3.5mm thick carbon steel Q235-b butt welding. The parameters of high-frequency-melting electrode gas-shielded arc hybrid welding are: weld gap 5 controlled at 0.8mm, welding speed 25mm / s (1500mm / min), high-frequency power supply output current frequency 600kHz, anode voltage 5kV, anode current 2A, arc The welding voltage of the welding machine is 20V, the current is 170A, the wire feeding speed is 16m / min, the shielding gas is argon, the flow rate is 15L / min, and the welding wire is ER50-6 low carbon steel welding wire with a diameter of 1.0mm. The parameters of high frequency-non-melting electrode gas shielded arc hybrid welding are: weld gap 5 controlled at 0.8mm, welding speed 10mm / s (600mm / min), high frequency power supply output current frequency 600kHz, anode voltage 5kV, anode current 2A, The welding voltage of the arc welding machine is 10V, the current is 120A, the wire feeding speed is 8m / min, the shielding gas is argon, the flow rate is 15L / min, and the weldi...

Embodiment 2

[0043] 3.0mm thick carbon steel Q235-b and 3.0mm 1060 pure aluminum butt fusion brazing, high frequency-melting electrode gas shielded arc composite detailed parameters are as follows: weld gap 5 is controlled at 0.8mm, welding speed 20mm / s (1200mm / min ), high-frequency power supply output current frequency 600kHz, anode voltage 2kV, anode current 0.5A, arc welding machine welding voltage 13V, current 110A, wire feeding speed 11m / min, shielding gas is argon, flow rate 15L / min, welding wire diameter 0.8mm ER4043 Al-Si alloy welding wire. The detailed parameters of the high-frequency-non-melting electrode gas-shielded arc composite are as follows: the weld gap 5 is controlled at 0.8mm, the welding speed is 10mm / s (600mm / min), the output current frequency of the high-frequency power supply is 600kHz, the anode voltage is 2kV, and the anode current is 0.5A , The arc welding machine has a welding voltage of 10V, a current of 100A, a wire feeding speed of 6m / min, a shielding gas of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com