Automatic backswing outer handle structure for car

A technology for outer handles and handles, which is applied in the field of automatic back-swing outer handle structures, which can solve the problems of high assembly precision, reduced production efficiency, and low reliability, and achieve comfortable hand feeling, improved production efficiency, and stable and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

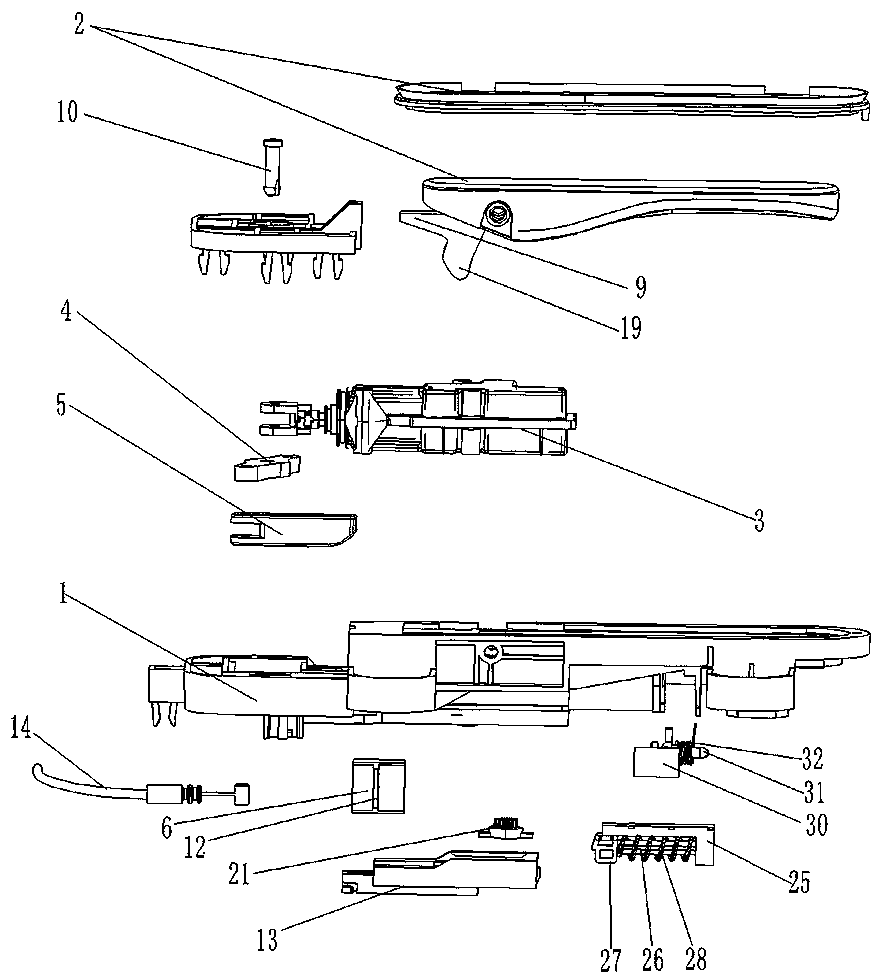

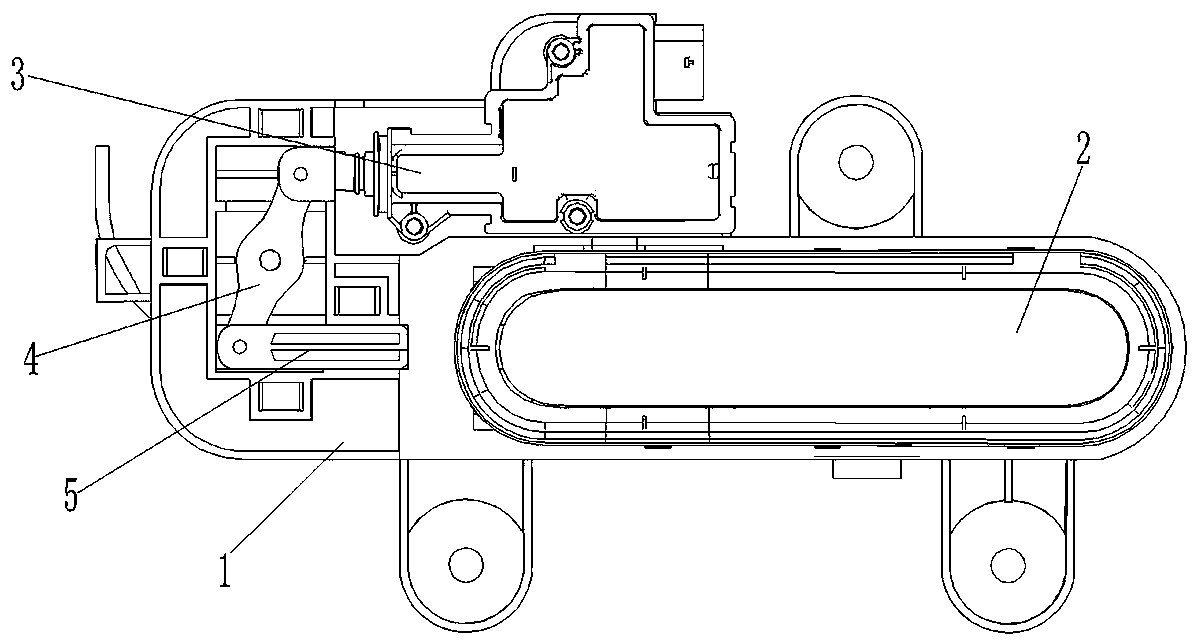

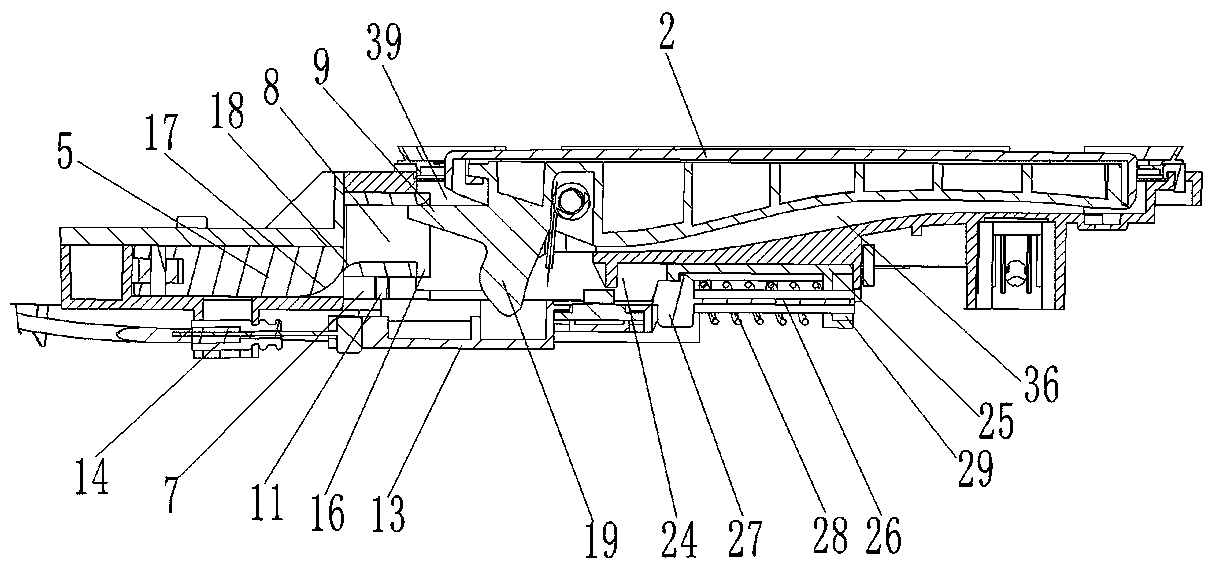

[0051] refer to Figure 1 to Figure 16 , an automatic swing-back outer handle structure for a vehicle, comprising:

[0052] handle base 1, the handle base 1 is fixed in the car body;

[0053] The handle main body 2, the handle main body 2 is hidden in the handle base 1 and flush with the vehicle body, and the handle main body 2 is rotationally connected with the handle base 1, the handle The main body 2 can move between the initial hidden state and the pre-deployed state, and the front end of the handle main body 2 is pressed when the vehicle is out of power to move the handle main body 2 from the initial hidden state to the pre-deployed state;

[0054] The handle main body 2 has at least a fully expanded state. When the handle main body 2 is in the pre-deployed state, the handle main body 2 continues to be pulled, so that the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com