Optical cable splice box

A technology of optical cable joint box and box body, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of sealing effect influence, sealing ring instability, low precision requirements, etc., and achieve the effects of cost saving, good sealing performance and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

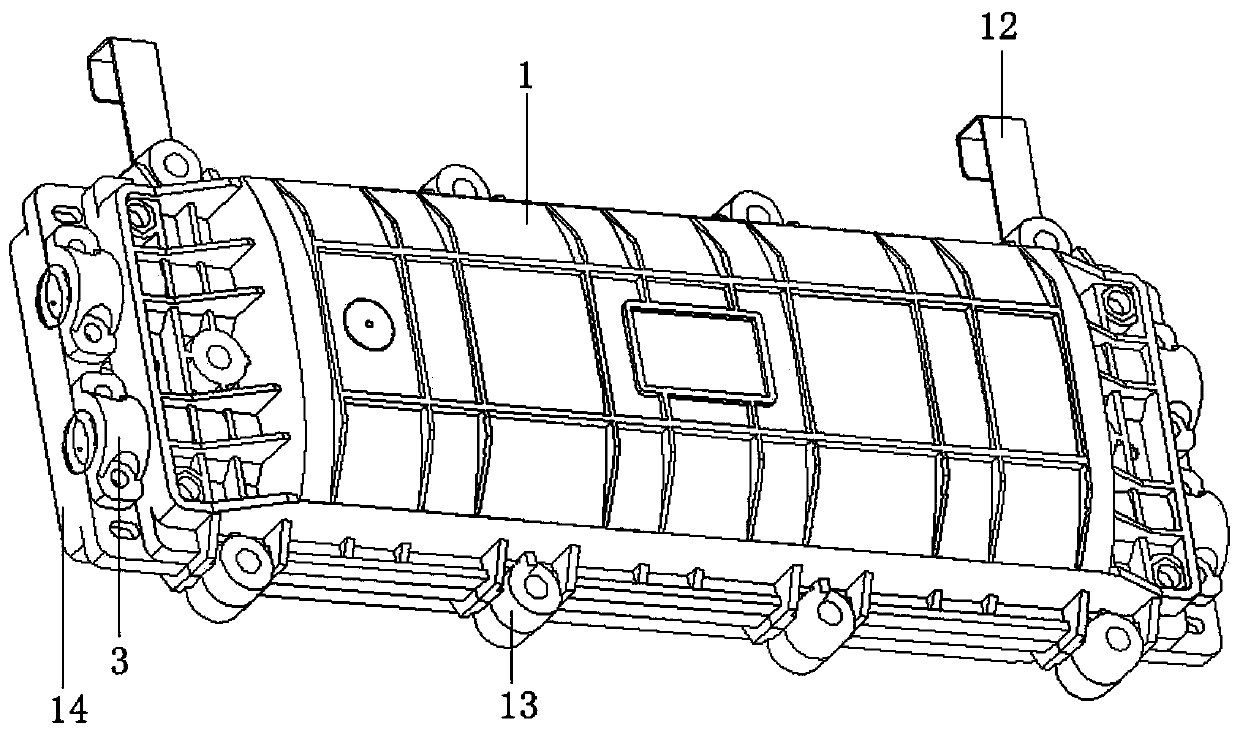

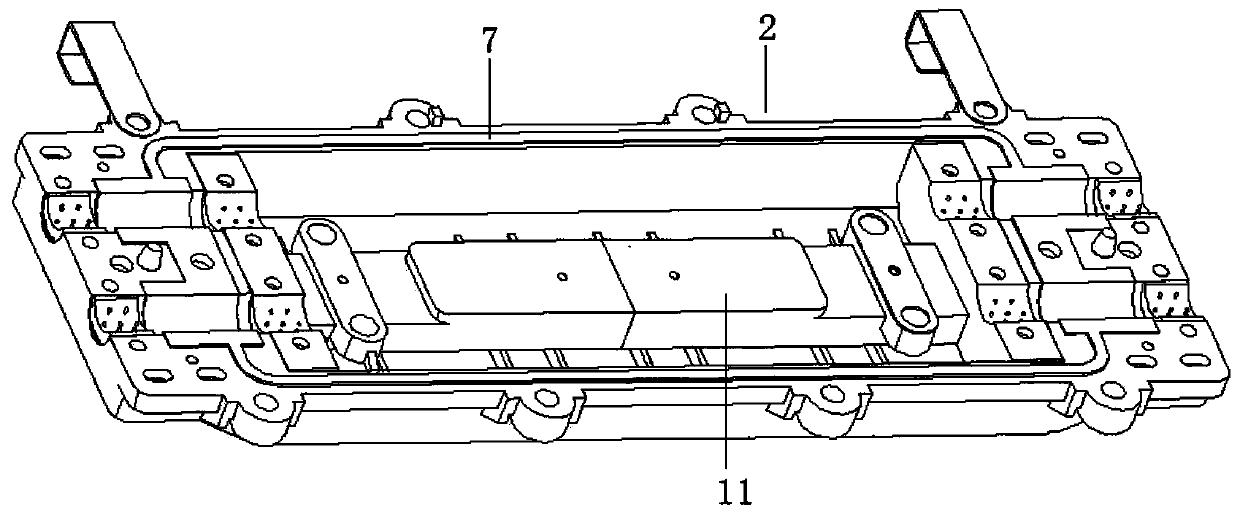

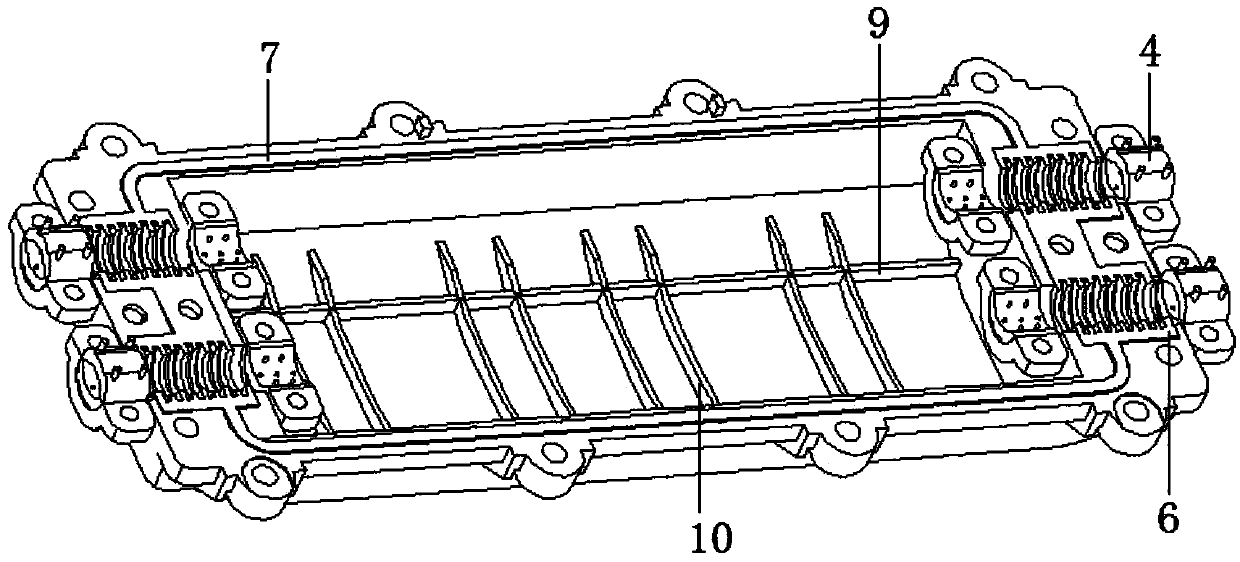

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7In the shown embodiment, an optical cable splice box includes an upper half box 1 and a lower half box 2, and the upper half box 1 and the lower half box 2 are connected by screws to form a box body, and the box body The two ends of the body are respectively provided with at least two optical fiber hole frames. The optical fiber hole frame includes an outer section and an inner section. The sealing part 3 is formed, the outer section is provided with an optical fiber inlet sleeve 4, and the optical fiber inlet sleeve 4 is provided with a number of raised position-limiting studs 5, and the inner section is formed by the lower half box 2. The half hole groove and the half hole groove on the upper half box 1 jointly constitute, and the elastic ferrule 6 corresponding to the half hole groove is provided in the described half hole groove, and the upper half box 1 and the lower half box 2 are all ...

Embodiment 2

[0027] In this embodiment, the basic structure and implementation mode are the same as in Embodiment 1, and the differences are as Figure 5 As shown in: the middle part of the big bottom edge of the sealing strip 7 is provided with a V-shaped groove 17, and the two inner sides of the V-shaped groove 17 are provided with tightening guide grooves 18, and the V-shaped groove 17, tightened The length and length direction of the guide groove 18 are consistent with the sealing strip 7 , and the two sides of the sealing strip 7 protrude outward to form an anti-overflow limiting portion 19 . In addition, since the two V-shaped grooves 17 jointly form a deformation space, a cylindrical support rod can be arranged in the deformation space, and the length direction of the support rod is the same as that of the V-shaped groove 17 .

[0028] When the two half-boxes are connected and compressed, the two sealing rings stick to each other and squeeze each other. If such a force is applied fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com